1. Introduction

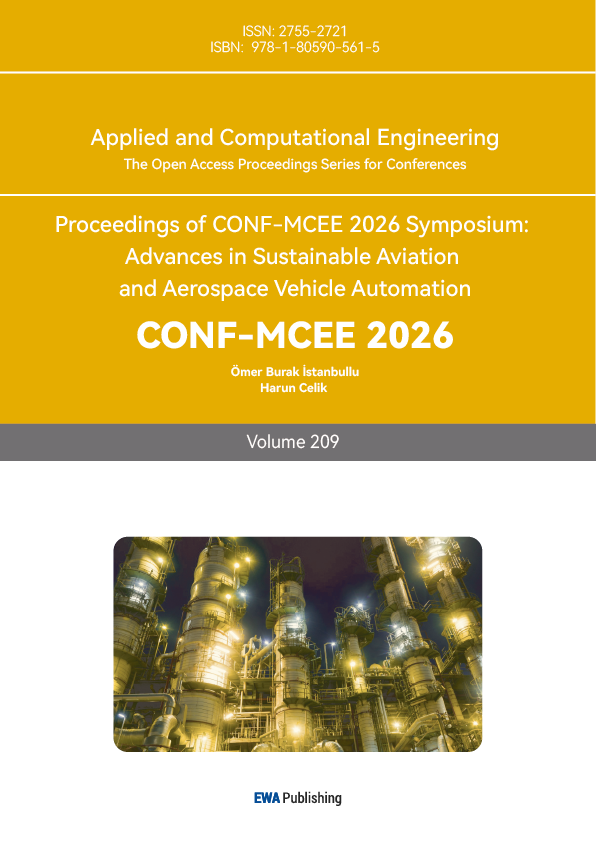

All-polymer solar cells (all-PSCs) are a subset of organic photovoltaic devices where the active layer consists entirely of polymeric materials: a polymer donor and a polymer acceptor. This distinguishes them from conventional organic solar cells, which often pair a polymer donor with a small-molecule acceptor (e.g., fullerene derivatives like PCBM). The core structure of all-PSCs typically includes a glass substrate, indium tin oxide (ITO) as the transparent electrode, a PEDOT:PSS hole-transporting layer, the active polymer blend layer, and an aluminum electrode (Figure 1).

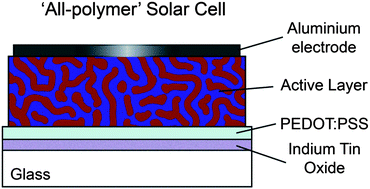

Functionally, all-PSCs operate on the bulk heterojunction principle. In this architecture, the polymer donor and acceptor form an interpenetrating network, maximizing the donor-acceptor interface area. When photons irradiate the device, they excite electrons in the polymer donor, creating excitons (bound electron-hole pairs). These excitons migrate toward the donor–acceptor interface, where they dissociate into free charge carriers—holes and electrons. The electrons then travel through the acceptor phase to reach the cathode, while the holes move through the donor material toward the anode, resulting in the generation of an electric current. (Figure 2).

Figure 2 illustrates the configurations and typical photoactive components of (a) a single heterojunction device, (b) a bulk heterojunction composed of a polymer donor and a molecular acceptor, and (c) an all-polymer bulk heterojunction solar cell. (d) Depicts the energy level alignment of the materials, highlighting the processes of light absorption, exciton dissociation, and charge collection [1].

2. Motivation

2.1. Excellent mechanical resilience

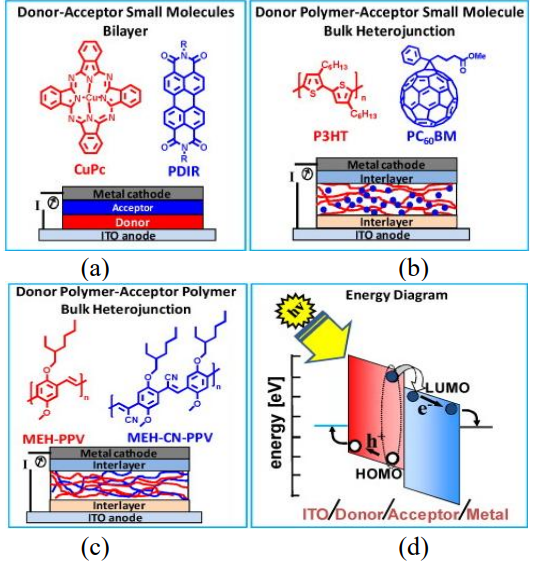

One of the most striking advantages of all-PSCs is their superior mechanical flexibility compared to both silicon-based solar cells and organic cells with small-molecule acceptors. This resilience stems from the polymer acceptors’ intrinsic flexibility and the entanglement of polymer chains, which strengthen the donor-acceptor interface.

For example, studies comparing PBDTTTPD blends with either the polymer acceptor P (NDI2HD-T) or the small-molecule acceptor PCBM demonstrated remarkable differences in mechanical performance. The PBDTTTPD:P (NDI2HD-T) blend film exhibited an elongation at break of 7.16%, 60 times higher than that of PBDTTTPD:PCBM (0.12%) [2]. Additionally, the modulus of the all-polymer blend (0.43 GPa) allowed for ductile crack growth under strain, whereas PCBM-based blends showed brittle behavior with minimal elongation [2]. This flexibility enables applications in wearable electronics, flexible displays, and curved surfaces, where rigid silicon cells are impractical (Figure 3).

2.2. High cost-efficiency

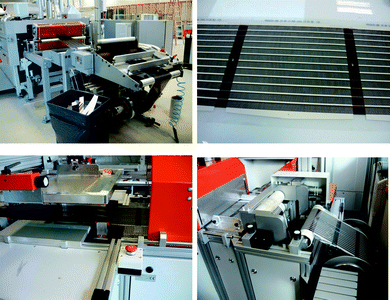

All-PSCs offer significant cost advantages over traditional silicon-based solar cells, primarily due to simplified manufacturing processes. Silicon cells require high-temperature, energy-intensive fabrication in cleanroom environments, driving up production costs. In contrast, all-PSCs can be processed using roll-to-roll printing, a low-cost technique compatible with large-area deposition on flexible substrates (Figure 4).

This approach reduces equipment investment and energy consumption, leading to substantially lower manufacturing costs. Estimates suggest that polymer solar cells could achieve electricity costs below 0.5 € Wp⁻¹ [3], making them competitive with conventional energy sources and accelerating the adoption of solar power.

3. Technical challenges

Despite the promising advantages of all-PSCs, several technical challenges must be overcome to enable their commercialization. The most significant hurdles are the performance gap with other photovoltaic technologies and the long-term operational stability of the devices.

3.1. Power Conversion Efficiency (PCE) gaps

All-PSCs currently lag behind silicon-based solar cells in PCE. Commercial crystalline silicon cells typically achieve PCEs exceeding 20%, with laboratory prototypes approaching 27%. In contrast, the highest reported PCEs for all-PSCs under standard test conditions remain around 17%–18% [4].

This gap originates from fundamental and materials-related limitations: (1) Limited Charge Carrier Mobility: The disordered nature of polymer chains often leads to lower and more unbalanced charge carrier mobility compared to highly crystalline inorganic semiconductors. This results in higher series resistance and greater charge recombination losses. (2) Energy Loss: All-PSCs typically exhibit higher energy losses, often exceeding 0.5 eV, which limits the open-circuit voltage. These losses stem from non-radiative recombination at the donor-acceptor interfaces and within the bulk, driven by energetic disorder and imperfect morphologies. (3) Photocurrent Limitations: While the absorption spectra of polymers can be tuned, achieving a broad, strong, and balanced absorption profile that covers the solar spectrum from visible to near-infrared (NIR) remains challenging. Inefficient photon harvesting and exciton dissociation further cap the generated photocurrent.

3.2. Operational and long-term stability

For any solar technology to be commercially viable, it must not only be efficient but also stable over decades of operation. All-PSCs face several degradation pathways:

Photo-oxidation: Exposure to light and oxygen can cause the photoactive layer to oxidize, breaking conjugated double bonds and degrading optoelectronic properties.

Morphological Instability: The nanoscale blend morphology of the bulk heterojunction is meta-stable. Over time and under thermal stress, the polymer phases can undergo demixing or excessive crystallization, destroying the optimal interpenetrating network and leading to severe performance decay.

Electrode Degradation: The low-work-function cathodes (e.g., aluminum) are susceptible to oxidation, while the acidic and hygroscopic nature of commonly used hole-transport layers like PEDOT:PSS can corrode the transparent ITO electrode.

Addressing these stability issues requires a multi-faceted approach, including the development of more stable electrode materials, the synthesis of polymers with higher inherent stability, and the implementation of robust encapsulation strategies to shield the devices from environmental stressors.

4. Technical approach

4.1. Morphology optimization

The morphology of the layer—specifically the phase separation and crystallinity of the polymer blend—strongly influences charge transport and device efficiency. Techniques such as thermal annealing and solvent annealing are widely used to control these properties.

Thermal annealing: Heating the blend film promotes crystallization and diffusion of polymer chains, refining the nanoscale structure of the BHJ. This improves charge transport pathways and reduces recombination losses [5].

4.2. Material innovation

Developing new polymer materials with improved optical and electronic properties is a key strategy. This includes designing polymers with higher absorption coefficients, better energy level alignment, and enhanced charge mobility.

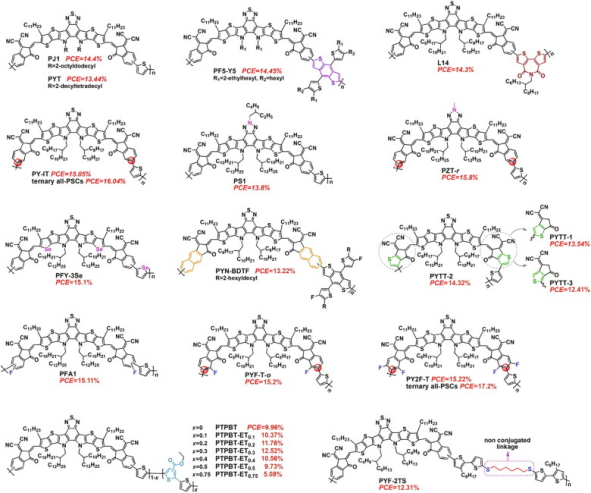

Notable progress has been made with Y6-derivative polymer acceptors (Figure 5). For example, ternary all-PSCs using PY2F-T:PYT as acceptors achieved a PCE of 17.2%, while PZT-r-based devices reached 15.8% (Table 1) [6]. These materials exhibit improved absorption, better energy alignment, and higher charge mobility compared to earlier generations.

Beyond Y6 derivatives, recent research has explored double-cable polymer acceptors, where electron-accepting units are covalently linked to the conjugated backbone. This architecture promotes intramolecular charge transfer and suppresses large-scale phase separation, leading to improved morphological stability. For example, a double-cable polymer incorporating perylene diimide (PDI) units achieved a PCE of over 12% while demonstrating exceptional thermal stability [7].

Furthermore, the development of new polymer donors with complementary absorption and higher hole mobility is equally critical. Materials like PM6 and D18 have become benchmark donors due to their well-matched energy levels with various polymer acceptors and good processability. The continuous innovation in both polymer donors and acceptors is creating a rich library of materials, enabling researchers to fine-tune the active layer properties for maximum performance and stability.

4.3. Examples of application

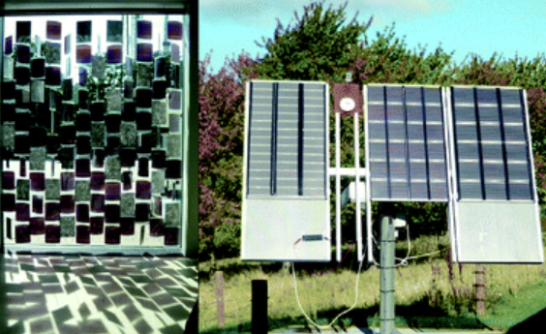

Applied in a movable curtain integrated with phase change materials, this semi-transparent solar shade consisted of 91 modules capable of generating electricity for lighting and device charging. (Figure 6).

A screen-printed solar cell module was utilized to supply power for charging a battery that operated a small FM radio. (Figure 7).

4.4. Environmental impact and lifecycle analysis

The pursuit of renewable energy technologies is fundamentally driven by the need to mitigate climate change and reduce environmental footprint. Therefore, beyond performance and cost, evaluating the environmental impact of all-PSCs through a holistic Life Cycle Assessment (LCA) is crucial to confirm their credentials as a truly green technology.

Life Cycle Assessment (LCA) serves as a methodology for evaluating environmental impacts and resource consumption across all stages of a product’s lifespan — from raw material extraction, through manufacturing and utilization, to end-of-life treatment and disposal [8]. LCA is a comprehensive methodology that quantifies the environmental effects linked to every phase of a product’s life cycle, ranging from raw material acquisition (“cradle”) through production and utilization to ultimate disposal (“grave”). For all-PSCs, this analysis offers several positive insights but also highlights key areas for improvement.

4.4.1. Advantages and positive indicators

Low Energy Payback Time (EPBT): A significant advantage of all-PSCs is their potentially very short EPBT—the time required for a system to generate the same amount of energy that was consumed throughout its lifecycle. Their low-temperature, solution-processable manufacturing is far less energy-intensive than the high-vacuum, high-temperature processes used for silicon cells. Studies suggest that optimized roll-to-roll production could lead to EPBTs of less than one year, significantly outperforming silicon technologies [9].

4.4.2. Challenges and areas of concern

Material Toxicity and sourcing: The environmental profile of all-PSCs is influenced by the materials used. While polymers themselves are often based on carbon, hydrogen, and oxygen, the synthesis of some high-performance materials may involve toxic solvents (e.g., chlorinated solvents) or scarce elements (e.g., indium in ITO electrodes). The use of these materials raises concerns about toxicity during manufacturing and resource scarcity [10].

End-of-Life Management: A critical, often overlooked, aspect is the end-of-life phase. Currently, there are no established large-scale recycling streams for organic electronic waste. If landfilled, valuable materials are lost, and some components may leach into the environment. Developing efficient recycling protocols, such as chemical separation of polymer layers or energy recovery, is essential to close the material loop and achieve a circular economy model for all-PSCs [11].

4.5. Pathways to greener all-PSCs

Developing Green Solvent Processing: Replacing hazardous halogenated solvents with more environmentally benign alternatives (e.g., ortho-xylene, toluene) without compromising device performance.

Designing for Recyclability: Synthesizing polymers with cleavable ester or imine bonds that can be easily broken down at end-of-life to recover monomers.

Avoiding Critical Materials: Replacing ITO with more abundant alternatives like silver nanowires, conductive polymers (e.g., PTAA), or carbon nanotubes.

In summary, while all-PSCs hold immense promise for low-impact energy generation, realizing their full green potential requires a concerted effort from material scientists and engineers to design not only for high efficiency and stability but also for minimal environmental impact across their entire lifecycle.

5. Conclusion

This paper has examined the key aspects of all-polymer solar cells (all-PSCs), including their structural principles, advantages in flexibility and cost, recent progress in materials and morphology control, and persistent challenges such as limited efficiency and environmental stability. Despite lower power conversion efficiency (PCE) compared to silicon-based cells, all-PSCs have achieved notable improvements, with top-performing devices now reaching over 17% PCE, thanks to innovations in polymer design such as Y-series acceptors and double-cable polymers. Their compatibility with low-cost and large-area processing, along with compelling mechanical properties, underscores their potential for use in flexible and wearable electronics.

However, this paper has certain limitations. It primarily focuses on material and device-level progress while offering less systemic discussion on module integration, large-scale manufacturing uniformity, and real-world operational data. Furthermore, environmental assessments remain somewhat conceptual, lacking quantitative comparisons of different recycling strategies or full life-cycle carbon accounting under industrial production scenarios.

Future research should prioritize enhancing the intrinsic stability of photoactive layers and electrodes under continuous illumination and varying environmental conditions. On the manufacturing side, developing greener solvent systems and scaling roll-to-roll printing processes will be essential to reduce costs and ecological footprint. From an end-of-life perspective, designing polymers with built-in recyclability—such by introducing dynamic bonds—could greatly support circular economy models. In addition, further integration with emerging applications, such as building-integrated photovoltaics (BIPV) and indoor energy harvesting, may open new avenues for commercial adoption.

In summary, while all-PSCs are not yet ready to outright replace conventional photovoltaics, they represent a highly promising complementary technology. With continued research focus on closing the PCE gap, improving durability, and enabling scalable eco-production, all-polymers are positioned to become a sustainable and adaptable energy solution in the renewable transition.

References

[1]. Facchetti A. (2013) Polymer donor–polymer acceptor (all-polymer) solar cells [J]. Materials Today, 16(4): 123-132.

[2]. Kim T., Kim J. H., Kang T. E., et al. (2015) Flexible, highly efficient all-polymer solar cells [J]. Nature communications, 6(1): 8547.

[3]. Krebs F. C., Tromholt T., Jørgensen M. (2010) Upscaling of polymer solar cell fabrication using full roll-to-roll processing [J]. Nanoscale, 2(6): 873-886.

[4]. Brabec, C., Scherf, U., & Dyakonov, V. (Eds.). (2011) Organic photovoltaics: materials, device physics, and manufacturing technologies [M]. John Wiley & Sons.

[5]. Ryu M. S., Cha H. J., Jang J. (2010) Effects of thermal annealing of polymer: fullerene photovoltaic solar cells for high efficiency [J]. Current Applied Physics, 10(2): S206-S209.

[6]. Fan Q., Xiao Z., Wang E., et al. (2021) Polymer acceptors based on Y6 derivatives for all-polymer solar cells [J]. Science Bulletin, 66(19): 1950-1953.

[7]. Zhang, Z., Li, Y., Cai, G., Zhang, J., & Wei, Z. (2022). Double-cable conjugated polymers: Toward advanced polymer acceptors for all-polymer solar cells. Advanced Materials, 34(15), 2108358.

[8]. Finnveden G., Hauschild M. Z., Ekvall T., et al. (2009) Recent developments in life cycle assessment [J]. Journal of environmental management, 91(1): 1-21.

[9]. Espinosa, N., Hosel, M., Angmo, D., & Krebs, F. C. (2016). Life Cycle Assessment of ITO-free flexible polymer solar cells prepared by roll-to-roll coating and printing. Solar Energy Materials and Solar Cells, 145, 342-348.

[10]. Anctil, A., Lee, E., & Lunt, R. R. (2020). The role of embodied energy and carbon in the environmental assessment of organic photovoltaic systems. Solar Energy Materials and Solar Cells, 215, 110606.

[11]. Corbellini, S., Spanò, S., & Menozzi, R. (2023). End-of-Life Management Strategies for Organic Photovoltaic Panels: A Review. Recycling, 8(2), 30.

Cite this article

Jin,J. (2025). All Polymer Solar Cells: Challenges and Opportunities. Applied and Computational Engineering,209,65-72.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of CONF-MCEE 2026 Symposium: Advances in Sustainable Aviation and Aerospace Vehicle Automation

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Facchetti A. (2013) Polymer donor–polymer acceptor (all-polymer) solar cells [J]. Materials Today, 16(4): 123-132.

[2]. Kim T., Kim J. H., Kang T. E., et al. (2015) Flexible, highly efficient all-polymer solar cells [J]. Nature communications, 6(1): 8547.

[3]. Krebs F. C., Tromholt T., Jørgensen M. (2010) Upscaling of polymer solar cell fabrication using full roll-to-roll processing [J]. Nanoscale, 2(6): 873-886.

[4]. Brabec, C., Scherf, U., & Dyakonov, V. (Eds.). (2011) Organic photovoltaics: materials, device physics, and manufacturing technologies [M]. John Wiley & Sons.

[5]. Ryu M. S., Cha H. J., Jang J. (2010) Effects of thermal annealing of polymer: fullerene photovoltaic solar cells for high efficiency [J]. Current Applied Physics, 10(2): S206-S209.

[6]. Fan Q., Xiao Z., Wang E., et al. (2021) Polymer acceptors based on Y6 derivatives for all-polymer solar cells [J]. Science Bulletin, 66(19): 1950-1953.

[7]. Zhang, Z., Li, Y., Cai, G., Zhang, J., & Wei, Z. (2022). Double-cable conjugated polymers: Toward advanced polymer acceptors for all-polymer solar cells. Advanced Materials, 34(15), 2108358.

[8]. Finnveden G., Hauschild M. Z., Ekvall T., et al. (2009) Recent developments in life cycle assessment [J]. Journal of environmental management, 91(1): 1-21.

[9]. Espinosa, N., Hosel, M., Angmo, D., & Krebs, F. C. (2016). Life Cycle Assessment of ITO-free flexible polymer solar cells prepared by roll-to-roll coating and printing. Solar Energy Materials and Solar Cells, 145, 342-348.

[10]. Anctil, A., Lee, E., & Lunt, R. R. (2020). The role of embodied energy and carbon in the environmental assessment of organic photovoltaic systems. Solar Energy Materials and Solar Cells, 215, 110606.

[11]. Corbellini, S., Spanò, S., & Menozzi, R. (2023). End-of-Life Management Strategies for Organic Photovoltaic Panels: A Review. Recycling, 8(2), 30.