Volume 209

Published on November 2025Volume title: Proceedings of CONF-MCEE 2026 Symposium: Advances in Sustainable Aviation and Aerospace Vehicle Automation

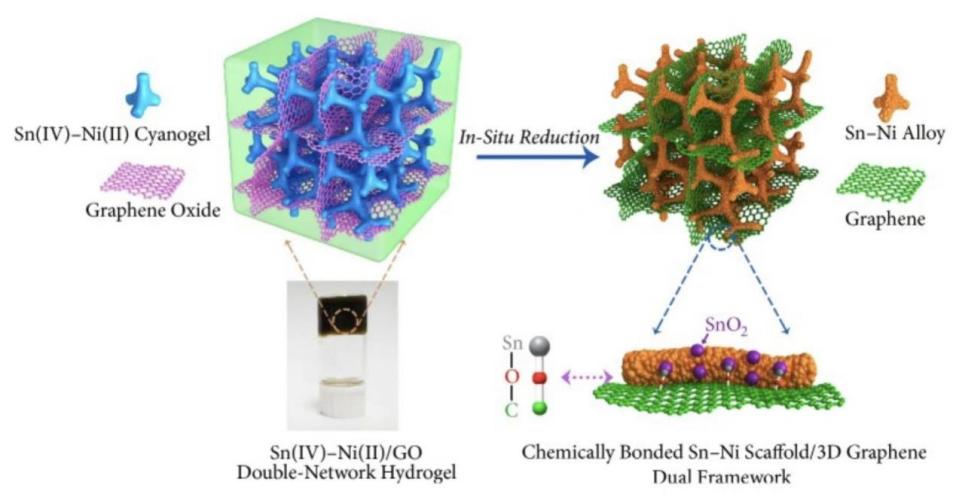

Lithium batteries power our daily devices, but they're hitting a wall. The graphite material in today's batteries can only store so much energy. Lithium metal promises a breakthrough - it can store ten times more power in the same space. The catch? It grows dangerous spikes called dendrites during use, has stability issues with its protective layer, and swells like a balloon. Surprisingly, graphene - the wonder material made of carbon sheets - might hold the key to taming lithium metal. This paper explores three smart ways researchers are using graphene: building 3D sponge-like structures to safely house lithium, creating artificial protective coatings, and designing surfaces that guide lithium to grow evenly. The results show graphene could be the missing piece for next-generation batteries.

View pdf

View pdf

In the era of artificial intelligence, Internet of things and big data, processing massive data puts forward unprecedented requirements for the throughput and energy efficiency of computing systems. In traditional von Neumann architectures, frequent data movement between processor and memory results in significant energy consumption and latency, known as the“Memory Wall” problem. In this paper, the principle, application and performance of variable resistance random-access memory (RRAM), magnetoresistive random-access memory (MRAM) and ferroelectric random-access memory (Feram) in the memory computing (CIM) structure are studied in depth. CIM technology is considered to be the key to overcome the“Memory wall” bottleneck inherent in the traditional von Neumann architecture. Firstly, the physical mechanism and characteristics of these three storage technologies are systematically described. Subsequently, a detailed analysis of their effectiveness in various application scenarios is provided through innovative simulation designs: RRAM-based neuromorphic chips (neurrams) exhibit superior energy efficiency in simulation calculations; MRAM exhibits performance close to conventional memory in non-volatile caching and in-memory logic applications; while FeRAM has unique advantages in ultra-low-power binary neural networks (BNNS). A comprehensive comparative analysis demonstrates the complementarity of their technical paths, and proposes future integration strategies for heterogeneous computing systems. This study adopts a co-design perspective across device, circuit, and architecture levels to provide important theoretical foundations and design insights for the development of next-generation efficient heterogeneous computing systems.

View pdf

View pdf

This paper explores the aerodynamic optimisation of racing vehicles, with a specific focus on drag reduction and downforce generation. The study outlines fundamental aerodynamic principles affecting racing performance, such as drag coefficient, wake turbulence, ground effect, and pressure distribution. Optimisation methods, including CFD simulations, wind tunnel testing, and machine learning applications, are discussed in detail. Each method’s advantages and limitations are analysed in the context of practical implementation. The paper highlights the importance of balancing aerodynamic efficiency with handling stability, especially in high-speed environments where marginal improvements can significantly influence performance. Case studies from Formula 1, Formula E, and hypercar design are examined, illustrating the application of technologies like DRS systems, active rear wings, and energy recovery integration. These examples demonstrate how manufacturers optimise airflow to reduce drag while maintaining or enhancing downforce for improved control. While significant progress has been made, challenges remain in developing cost-effective, adaptive, and efficient aerodynamic systems. The paper concludes with a discussion on the future of racing aerodynamics, emphasising the role of intelligent systems and real-time optimisation in shaping the next generation of racing vehicle design.

View pdf

View pdf

Organic semiconductors are regarded as ideal material systems for developing the next generation of flexible spintronic devices due to their excellent flexibility, low preparation cost and unique long-spin relaxation characteristics. This paper systematically reviews the significant progress made in the research of FM/OSC spin interfaces in recent years and discusses it from three aspects: material systems, physical mechanisms, and device structures. At the material level, the focus is on the research of the development and application of new two-dimensional ferromagnetic electrodes, high-mobility organic semiconductors, and functional interface modification layers. At the physical mechanism level, key scientific issues such as interface energy level alignment, magnetic proximity effect and spin-related transport were deeply explored; At the device level, the structural innovation and performance improvement strategies of devices such as organic spin valves, magnetic tunnel junctions and spin transistors were elaborated in detail. Current research has achieved remarkable results in improving the room-temperature performance of devices and extending the spin diffusion length. Finally, this paper points out the main challenges that this field will face in its future development, especially the technical bottlenecks in achieving efficient spin injection, remote spin transport, and chip-level scalable fabrication, and looks forward to potential application directions such as flexible storage and neuromorphic computing.

View pdf

View pdf

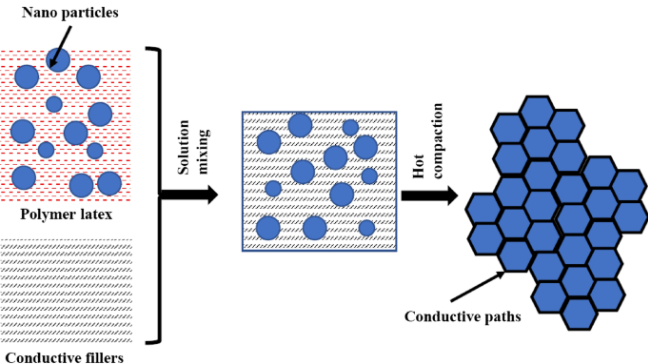

The rapid increase in power density in modern electronic devices has elevated thermal management to a critical technological challenge. Thermal interface materials (TIMs) are essential for efficient heat dissipation, and their performance is highly dependent on the incorporation and optimization of functional fillers. Numerous modification strategies have been developed, but there remains a lack of systematic guidance for selecting and integrating these approaches based on specific application requirements. This review categorizes TIM enhancement strategies into three primary approaches: filler selection, surface modification, and structural design. Filler selection is analyzed with respect to material type, morphology, and thermal conductivity, highlighting their suitability for different operational scenarios. Surface modification techniques are examined for their ability to reduce interfacial thermal resistance and improve filler-matrix compatibility. Structural design strategies, including three-dimensional networks and hierarchical architectures, are discussed for their role in overcoming intrinsic performance limitations. Integrating these strategies, a three-step decision framework is proposed, linking material choice, interface engineering, and structural optimization in a coherent workflow. This framework provides a practical guide for the rational design of high-performance TIMs and offers insights into tailoring materials to meet the thermal management demands of diverse electronic applications. The review aims to bridge theoretical understanding and practical implementation, supporting more efficient and reliable electronic device operation.

View pdf

View pdf

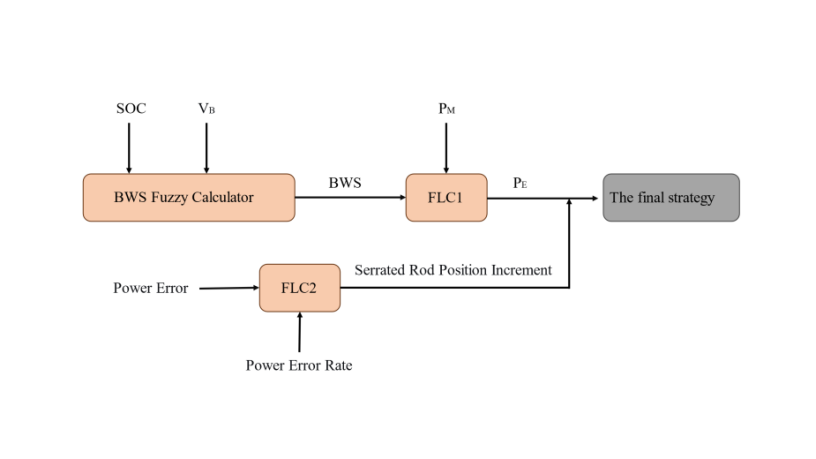

Electric vehicles (EVs) are gaining increasing attention due to their environmental friendliness. However, EVs still suffer from issues such as short driving range. Plug-in Hybrid Vehicles (PHEVs) have emerged as an intermediate step in the transition from fuel-powered vehicles to electric vehicles, utilizing both gasoline and batteries. The proper allocation of these two energy sources has become a key issue for PHEVs. This paper mainly summarizes and analyzes rule-based energy management strategies through literature analysis, case analysis, and review methods. By contrasting with the energy management based on optimization algorithm, the advantages and problems of rule-based energy management strategies are explored. This paper finds that rule-based energy management strategies offer advantages such as robustness, simple algorithms, and strong real-time performance, but they cannot achieve global optimization, and rule formulation relies heavily on the designer's experience. In addition, rule-based energy management strategies can be combined with multiple algorithms and have high improvement potential.

View pdf

View pdf

Nanomaterials are the most prominent revolutionary wave that has taken place in various industries, of which the automotive industry is not an exception. Nanomaterials used in the automotive industry produce positive outcomes on performance, efficiency, safety, and environmental sustainability, and therefore, the use of literature review methodology will survey this paper on the application of subsequent. It explores the different types of nanomaterials, such as carbon nanotubes, nano-reinforced polymer, nano-coating, nano-lubricants, and nano-enabled sensors, as well as the ways in which they are incorporated into designing a car, powertrain systems, or both car energy storage systems. The results indicate that nanomaterials allow one to achieve a noticeable reduction of weight, greater mechanical strength, greater thermal and corrosion resistance, and higher efficiency. The paper also presents the example of automakers that have already applied nanotechnology in their products, and elaborates on the difficulties of a widespread implementation process, like the cost, health issues, and regulations. Comprehensively, the paper comes up with a conclusion that nanomaterials are transforming the world of cars and provide a way to lighter, cleaner, and more efficient cars, and look into the aspect of sustainable production and recycling of the end-of-life products.

View pdf

View pdf

Foam concrete, as a porous lightweight material, is widely used in construction, transportation, and geotechnical engineering. Based on a review of relevant literature, this article systematically summarizes the physical and mechanical properties, functional characteristics, and application progress of foam concrete in civil engineering. The study shows that the physical properties of foam concrete have significant tunability, and density, pore size, and ratio are the key factors affecting its strength and durability; in terms of functional characteristics, it performs excellently in insulation, fire resistance, freeze resistance, and energy absorption, especially showing unique advantages in cold regions and seismic engineering. In terms of engineering applications, foam concrete has evolved from a traditional insulation filling material to a composite material with both structural and functional properties, and is widely used in building envelope structures, road subgrades, abutment backfill, and underground linings, etc. With the advancements in material modification technology, carbon dioxide curing, and 3D printing construction technology, foam concrete has great potential for high-performance and green low-carbon development. Future research should focus on optimizing pore structure, strengthening interfaces, and exploring the coupling mechanism of multiple functions to promote its in-depth application and sustainable development in civil engineering.

View pdf

View pdf

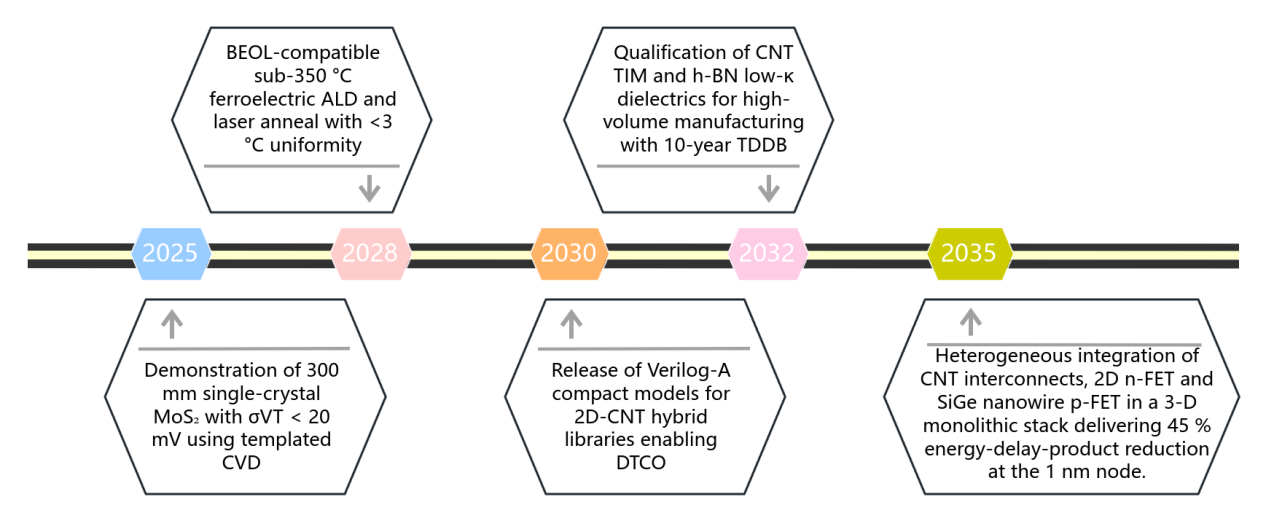

As silicon CMOS approaches the 10 nm gate-length ceiling, short-channel effects, escalating power density and interconnect RC delays erode the traditional performance–power–area dividend. Zero- to two-dimensional nanomaterials—quantum dots, carbon nanotubes, nanowires, graphene and transition-metal dichalcogenides—offer atomically thin channels, ballistic transport and widely tunable band gaps, and are therefore intensively explored to extend Moore’s law beyond pure geometrical scaling. This timely review synthesises experimental and theoretical advances reported from 2020 to 2025, benchmarks key figures-of-merit for logic, memory, interconnect and thermal-management applications, and highlights critical gaps between laboratory demonstrations and 300 mm fab transfer. Sub-1 nm 2D gate-all-around nanoribbon FETs achieving 6 mV dec⁻¹ sub-threshold swing, carbon-nanotube vias sustaining >10¹² A cm⁻² current density and 0.3 V RRAM arrays with 10⁹ endurance cycles exemplify recent breakthroughs, yet wafer-scale uniformity, sub-400 °C BEOL thermal budgets and long-term reliability remain open challenges. A design-technology co-optimisation roadmap targeting the 1 nm node is proposed to guide material scientists, device engineers and EDA developers toward energy-efficient, heterogeneous integrated electronics.

View pdf

View pdf

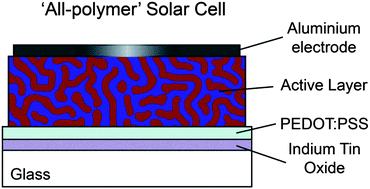

All-polymer solar cells (all-PSCs) have emerged as a promising branch of organic photovoltaics, characterized by the use of both polymer donors and polymer acceptors in the active layer. This structure offers distinct advantages over conventional organic solar cells that incorporate small-molecule acceptors. Despite their potential, all-PSCs still face challenges in achieving high power conversion efficiency (PCE) and long-term stability compared to silicon-based solar cells. This review systematically examines the fundamental principles, material innovations, and morphological control strategies that are central to enhancing the performance of all-PSCs. It also addresses key technical barriers such as limited charge mobility, energy loss, and environmental stability, which currently hinder their commercialization. Recent developments in novel polymer acceptors, particularly Y6-derivatives and double-cable polymers, have led to significant improvements in PCE, with some devices reaching over 17%. Furthermore, the inherent flexibility and roll-to-roll processability of all-PSCs provide notable cost and adaptability benefits, making them suitable for applications in versatile and portable electronics. This study also evaluates the environmental impact of all-PSCs through life cycle assessment, highlighting their low energy payback time and potential for eco-friendly manufacturing, while acknowledging concerns regarding material sourcing and end-of-life management. In conclusion, although all-PSCs still lag behind silicon-based cells in efficiency, ongoing advances in material design and processing techniques are steadily narrowing this gap. With their unique combination of mechanical resilience, cost-effectiveness, and scalability, all-PSCs are positioned to become a viable and sustainable contributor to the future renewable energy landscape.

View pdf

View pdf