1. Introduction

The automotive industry in the entire world has been in constant need to minimize the weight of the vehicles, gain better fuel consumption, increase safety, and decrease environmental impact. In the last twenty years, the concept of nanotechnology, also termed the handling of materials at the nano-level, has become a key innovation factor within the nanometer (100 nm to 1 mm) domain [1]. The nanomaterials like carbon nanotubes, nano-ceramics, and nano-polymers have distinctive mechanical, thermal, and chemical characteristics compared to their counterparts [1]. These properties enable engineers to come up with better but lighter and stronger vehicle components, better wear resistance and better catalytic and energy storage systems. With the world experiencing increasingly higher demands for stricter regulations on emissions by governments, and consumers requiring a vehicle that is more efficient to perform in the market, the automotive industry has noticed the appeal of nanomaterials even more [2].

The latest research depicts the extent to which nanomaterials are utilized in the automobile industry. To give a case example, research conducted on the application of the nano-reinforced composites on automotive components has established that the composite has the ability to save weight by a percentage of 30 compared to the normal steel components [2]. In individual research of nano-coating on the basis of corrosion security of exhaust systems, it was thought that nano ceramic coating sustained the life span of elements and reduced envision conjecture costs. An additional discourse was done on the lithium-ion batteries through nano-engineered cathode material, and this achieved superior energy configuration as well as faster charge-discharge actions [3].

As the research center, the paper will take the literature review methodology to determine the existing uses of nanomaterials in the automotive industry. The paper also identifies the advancements in theory and innovation where real-world examples are produced by using the uncovered research and industrial case studies of the recent past. The study is noteworthy, as it determines how nanomaterials can be used at once to improve vehicle performance and maintain sustainability, which is a very important combination as the industry moves to electric mobility and the increase in the level of environmental policies [3].

2. Literature review

The advent of nanomaterials has revolutionized the field of material science and engineering, and their use in the automotive industry is one of the most relevant fields of research and development. Nanomaterials have been addressed by scholars and engineers, with a strong emphasis on a variety of materials in this category, which have produced unique performance improvements [4]. This literature review gives the overall list of nanomaterials as applied in the automotive industry, and specifically structural composites, coatings, lubricants, and energy systems.

The use of nanomaterials in nano-reinforced polymers and composites has been one of the oldest and most commonly studied in the automotive industry. The bodies of the traditional vehicles had been made out of steel and aluminum, but these materials provide a low chance of making the vehicle lighter; hence, they provide it with the restricted potential of making fuels more economical. It was also found that carbon nanotubes (CNTs) and nano clays, when used in polymer matrices, would increase the tensile performance and reduce weight considerably [3]. The researchers confirmed that the boards and dashboards manufactured using such nanocomposites have a maximum mass reduction of up to 25-30 percent than the normal thermoplastic ones [2]. This reduction of weight translates to less consumption of energy, which is used, and better acceleration. These results are in line with the reports given by the European Automotive Nanomaterials Consortium, which found the nanocomposites to be a central factor in achieving major targets required by the European Union on the reduction of CO2 emissions [3].

Apart from the structural components, nanomaterials have found applications in developing automotive surface treatments and coatings. Traditionally, coatings provide protection against corrosion and corrosion wear, and environmental damage. However, nano-engineered coatings possess superior barrier properties because of their very high surface area to volume ratio [2]. Studies on nanoceramic coatings for exhausts, which display improved resistance to oxidation at above 700oC [4]. Examinations of nano-silica additives in other coating formulations increase hardness and scratch resistance. The same coatings also have self-cleaning and hydrophobic properties because of the “lotus effect.” This reduces the frequency of washes and makes the aesthetics last longer [5]. Automakers are increasingly interested in such functional coatings because they help reduce maintenance costs and are more environmentally friendly because they obviate the need for heavy cleaning agents. Figure 1 shows a nano-ceramic coating structure for improved corrosion and heat resistance.

The nano ceramic coatings that are capable of imparting corrosion and heat resistance in automobiles and more are illustrated in the diagram above. Such coatings provide a strong protective shield that protects against surface wear, enhances heat stability, and increases the life of metals. This visualization shows how building materials engineered at the nanoscale perform better and offer protection in harsh environments.

Nano-lubricants enhance performance in a different way. Traditional engine oils are based on micron-level additives to lower the friction between moving parts. Nevertheless, studies also indicated that nanoparticles like molybdenum disulfide (MoS2), tungsten disulfide (WS2), and zinc oxide (ZnO) were also able to further minimize friction at the boundary surface [5]. In a comparison study, the addition of 1-2% of WS2 nanoparticles to synthetic motor oil also decreased the coefficient of friction by 30 percent and motor engine wear by 25 percent [6]. This is because the enhanced lubrication efficiency causes reduced fuel consumption and long engine life. Likewise, there was support in the experiments that nano-graphene additives to transmission fluids improve conductivity of heat and reduce heat retention, allowing transmission fluids to have long lives [5]. The findings are a suggestion that nano-lubricants could be promising in both internal combustion engines and electric vehicle drives, as in both cases, thermal management is also a major issue of concern [6].

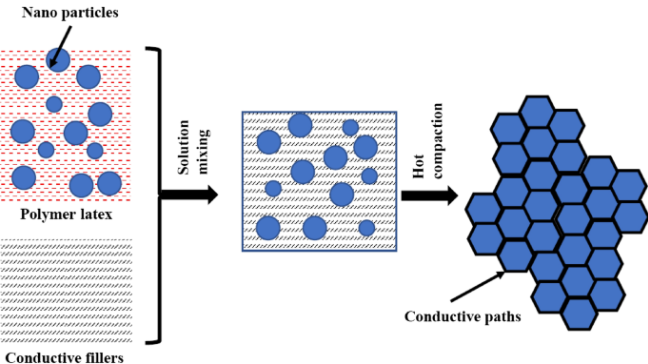

The application of nanomaterials in energy storage and powertrains has become what is remembered more as the automotive industry slowly transforms to electrification. The most common electric vehicle energy storage system is Li-ion batteries, and the energy density and charge rate of these batteries and their durability are the most troublesome factors [4]. One experiment conducted on the cathodes manufactured with lithium iron phosphate (LFP) realm nanoparticles saw the capacity rise by 20 percent and shortened charging durations than standard LFP cathodes [3]. Otherwise, similar studies have investigated nano-silicon anodes that have been explored, reporting energy densities of approximately twice that of graphite anodes [5]. This directly addresses the range anxiety and charging-related issues of people who own EVs. In the meantime, carbon nanotube or graphene-based supercapacitors have fast charge-discharge rates and high power density, which have the potential of supplementing battery systems in hybrid cars [7]. Figure 2 presents a detailed view of the nano-engineered battery electrodes. These advanced materials are designed to improve energy density by optimizing ion transport pathways and increasing surface area for electrochemical reactions. The visualization highlights how nanoscale engineering contributes to greater efficiency, stability, and overall performance in next-generation energy storage systems.

Another alternative technology (powertrain) that uses nanomaterials is fuel cells. Catalysts were platinum nanoparticles supported on carbon black used as standard catalysts in a proton exchange membrane fuel cells (PEMFC) [6]. However, they are also costly and degrade with time, and hence research has been conducted on alternative nanocatalysts [8]. The platinum-cobalt alloy nanoparticles provide increased catalytic activity and stability at a load of precious metals up to 50% decreased [9]. This operates in reducing the cost of the fuel cell stacks considerably, thereby rendering the hydrogen-powered vehicles more significant in the business realm.

Nanomaterials also increase the effectiveness of catalytic converters, necessary in innovative car engines for reducing gas emissions [10]. The conventional catalysts are based on expensive precious metals that including platinum, palladium, and rhodium that are spread on the alumina surface. Nevertheless, this is not true at the nanoscale, where they have a higher amount of surface area, thereby improving the rate at which they catalyze chemical reactions and are able to be loaded to a lesser extent [11]. Ceria-zirconia supports are microsystems and allow better oxygen storage capacity, as nitrogen oxides and unburned hydrocarbons at high temperatures can be converted properly to produce energy [5]. The new technology is essential in the achievement of Euro 6 and China 6 tightening in emission requirements.

The other significant use of nanomaterials is in automotive sensors and electronic systems. Technology-based vehicles are fitted with a lot of sensors in order to provide control, balance, performance, and in the monitoring of the environment. Nanostructured materials can improve sensor sensitivity, response time, and miniaturisation [8]. For example, graphene-based pressure sensors are being developed for tire pressure monitoring systems (TPMS), while nano-tin oxide (SnO2) sensors offer enhanced sensitivity for exhaust gas detection [12]. In the realm of advanced driver assistance systems (ADAS), nano-photodetectors improve low-light imaging, contributing to the reliability of autonomous driving technologies. The integration of such nano-enhanced sensors could ultimately lead to smarter, safer vehicles with predictive maintenance capabilities [11].

There are many researchers looking into self-healing materials and smart coatings through nanotechnology. These systems can automatically self-repair micro-scale fissures or stimuli from their surroundings. An example is a microcapsule, which is a nanofiller-containing nanocomposite, of an agent can be formed that deliver health benefits. If ruptured due to load, the agents can be released [13].

Nanomaterials may have lots of advantages, but their cost, scalability, and health, and environmental issues hinder their implementation. It is hard and expensive to make quality nanoparticles on an industrial scale. Workers in industries that aerosolize nanoparticles might inhale them, which may pose safety issues. The regulatory framework concerning nanomaterials used for the automotive industry is still being cultivated, but guidelines published by regulatory agencies in Europe, North America, and Asia concerning toxicity and environmental persistence [14]. More researchers are adopting what is called the “green synthesis” of nanoparticles involving closed-loop recycling to minimize harm overall.

The automotive design literature shows that nanomaterials are porous in nature in all aspects. Due to the use of these materials, the next generation of cars will probably be lighter, stronger, more efficient and maybe more sustainable [15]. To ensure safety, affordability, and the general public's acceptance of the production of batteries for electric vehicles, the cooperation of auto engineers, raw material scientists, and regulators is essential. Nanotechnology is now being successfully used in the automobile industry. To gain insight into the infiltration of nanotechnology within the automotive industry, refer to Table 1 describing the different types of nanomaterials used. Modern-day automobiles are enhanced in performance, life, and efficiency with the help of polymers.

|

Nanomaterial Type |

Automotive Use |

Main Benefits |

|

Carbon Nanotubes (CNTs) |

Structural composites, sensors |

Lightweight, high strength, electrical conductivity |

|

Nano-ceramics |

Coatings, exhaust systems |

Corrosion/heat resistance |

|

Nano-lubricants (MoS2, WS2) |

Engine oils, transmissions |

Reduced friction, improved thermal properties |

|

Nano-silicon anodes |

EV batteries |

Higher energy density |

|

Platinum-cobalt nanoparticles |

Fuel cell catalysts |

Lower cost, higher stability |

3. Case analysis

The literature portrays the potential of nanomaterials in the automotive industry in broad terms, but manufacturer-specific instances give a tangible idea of the impact that they can create. This part looks at automakers and suppliers who applied nanotechnology in vehicle manufacturing. The focus is on structural parts, coatings, lubricants, energy systems, and sensors [12].

3.1. Lightweight structural components

BMW Group utilizes carbon nanocomposites as one of the most touted examples of structural application of nanomaterials. The “i” series from BMW (especially the i3 and i8) uses nano-reinforced resins and a carbon fibre reinforced polymer (CFRP) to create strong but light passenger cell structures. As per the technical documentation of BMW, these CFRP components have a mass that is 50% less than that of steel. Incorporating carbon nanotubes and other nanofillers into the resin matrix enhances impact resistance and dimensional stability even further. Tesla Motors has also invested in nano-engineered aluminium alloys for battery pack casings and chassis components [5]. These materials offer enhanced energy absorption during collisions while reducing total vehicle weight, a critical advantage for electric vehicles whose range is constrained by battery mass [9].

3.2. Advanced coatings and paints

Volkswagen Group has pioneered the use of nano-ceramic clear coats in its production lines. These coatings, in which silica and alumina nanoparticles are co-integrated, have a very high level of scratch and UV protection compared to conventional paints [2]. A study conducted by Volkswagen indicated that gloss-stabilized cars that were coated with nanoceramics lasted twice as long during accelerated weathering as adjustments [5]. On the same note, Toyota has introduced self-cleaning of the nano-paint systems, which is based on the lotus leaf effect, which lowers the water droplet adhesion and enhances stain resistance [4]. These and other advantages of these coatings are not restricted to the aesthetic features since they prevent the need to spend on paint and cleaning chemicals, and also decrease the quantity of environmental footprint due to repainting and cleaning the items [7].

3.3. Nano-lubricants and thermal management

These nano-additive lubricants use tungsten disulfide (WS2) and molybdenum disulfide (MoS2) nanoparticles to enhance engine and transmission efficiency and only undergo testing by Ford Motor Company. The results in the internal tests were positive, with a 2-4 percent data improvement on fuel economy and a quantifiable decrease in engine wear under a high load condition [4]. For electric vehicles, where thermal management is critical for battery and motor longevity, General Motors has explored the use of graphene-based coolants in its Ultium battery systems. These coolants increase thermal conductivity, facilitating faster heat dissipation and stabilising cell temperatures during rapid charging [16].

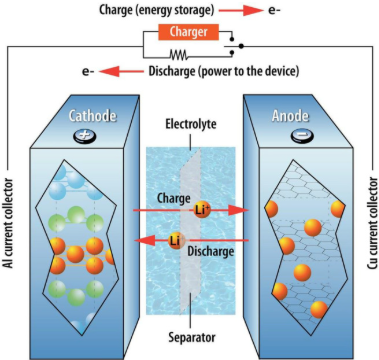

The figure below illustrates how nanoparticles function within lubricants to minimize friction and wear in engine components. These particles create protective coatings and fill up micro-surface defects that enhance the lubrication performance for the longer life of parts. Nanotechnology is increasingly being applied to improve the performance, energy efficiency, and overall reliability of engines. Figure 3 shows that nanoparticle-enhanced lubricants reduce engine friction.

![Figure 3. Nanoparticle-enhanced lubricants reduce engine friction. [6]](https://file.ewadirect.com/press/media/markdown/document-image3_lZVBNp2.png)

3.4. Energy storage, fuel cells, and sensors

Car manufacturers are quickly using nano-engineered electrodes in new batteries as an extended application in batteries [17]. Nissan developed lithium-ion cells with nano-structured cathodes via AESC, while Panasonic nano-silicon anodes for Tesla further improve battery performance [5]. Toyota's solid-state batteries that use specially designed nano electrolytes will have much better safety and power performance [17]. To save on costs and increase the life of the system, Honda and Hyundai are employing platinum-nanoparticle catalysts in the fuel cell technology [14]. Hyundai’s NEXO is deploying next-generation catalysts on carbon supports. According to Johnson Matthey and BASF, suppliers of internal combustion vehicle emission control technologies, nanostructured ceria-zirconia catalysers can reduce NOx and precious metal content. Benz is testing tire pressure sensors with graphene, and Bosch has developed an exhaust gas sensor using nano-tin oxide. The use of nano-enabled sensors for control functions in energy systems, emissions control, and smart vehicle platforms can enhance precision and safety as well as predictive maintenance [4].

Table 2 gives examples of case studies from selected automobile manufacturers to show the application of nanotechnology in the automobile industry. Different companies are using nanomaterials in the manufacture of coatings, composites, and energy systems in an effort to become more efficient and perform better while remaining sustainable.

|

Automaker/ Supplier |

Nanomaterial Application |

Benefits |

|

BMW |

CFRP with nano-enhanced resins |

Lightweight, high impact resistance |

|

Volkswagen |

Nano-ceramic clear coat |

Scratch/UV resistance, longer paint life |

|

Ford |

WS₂ nano-lubricants |

Improved fuel economy, reduced engine wear |

|

Tesla / Panasonic |

Nano-silicon anodes in batteries |

Higher energy density, faster charging |

|

Hyundai |

Platinum nanoparticle catalysts in fuel cells |

Reduced cost, enhanced durability |

3.5. Analysis of findings

The majority of exhibited examples illustrate that the large automobile companies have commenced using nanomaterials for producing cars and not experimenting. You can integrate nanotechnology in a way that has strong links to electrification,, lightweighting, and better sustainability. It does exhibit varying levels of ongoing costs and supply chain health challenges. Automakers typically add nanomaterials to luxury and/or limited versions first before choosing a regular mass-market version. This method will assist us in validating technology, securing regulatory approval, and gaining customer acceptance.

4. Conclusion

Nanomaterials are a new and important addition to automotive design and engineering. They allow for lighter, stronger, and more efficient vehicles. The structural components, paints, lubricants, and energy systems have a lightweight design as their common theme. Use the power of Nano. Car manufacturers can make cars more fuel-efficient and less polluting through a nano-enhanced composite. Having this can help expand the fleet of electric vehicles.

Nanomaterials also enhance efficiency and sustainability. We can apply components that can minimize friction to reduce wear of components so as to enhance their service life. Nano-catalysts help eliminate the need for precious metals in converters and fuel cells. Using nano-engineering, the electrodes and electrolyte of batteries are modified for better energy density and charging speed. Innovation sensors using nanomaterials like graphene and nano tin oxide for predictive maintenance and safer driving, and autonomy. But challenges remain. However, the price point and other challenges pose a large challenge that can cause health hazards and changing regulations. Only if safety checks, green synthesis, and efficient recycling methods are all transparent will people accept nano-enhanced materials. Using smart coatings and self-healing materials, technology will enhance your vehicle’s life by reducing damage to the environment.

To sum up, this paper highlights the role of nanomaterials in the automotive industry in improving performance and reducing emissions. The use of nanoparticles to solve important industrial problems and challenges, such as lightweight composites, coatings, lubricants, advanced batteries, and sensors. Current data, risk assessment, and health risk characterisation have limitations, but research, life-cycle analysis, and policy can accelerate a safe increase in the use of the nanoparticle. In summary, nanomaterials provide the automotive sector with an opportunity to shift from a dirty-stupid auto to a clean-smart automobile in the world.

References

[1]. H. N. Cheng, L. J. Doemeny, C. L. Geraci, and D. Grob Schmidt, “Nanotechnology Overview: Opportunities and Challenges, ” ACS Symposium Series, pp. 1-12, Jan. 2016, doi: https: //doi.org/10.1021/bk-2016-1220.ch001.

[2]. H. Presting and U. König, “Future nanotechnology developments for automotive applications, ” Materials Science and Engineering: C, vol. 23, no. 6-8, pp. 737-741, Dec. 2003, doi: https: //doi.org/10.1016/j.msec.2003.09.120.

[3]. K. Kumar, S. Das, R. Garg, and M. S. Goyat, “A Comprehensive Review on Enhancing the Strength of CFRPs Through Nano-reinforcements: Applications, Characterization, and Challenges, ” Journal of Failure Analysis and Prevention, vol. 24, no. 4, pp. 1588-1627, May 2024, doi: https: //doi.org/10.1007/s11668-024-01946-2.

[4]. S. Yadav, S. Gangwar, and S. Singh, “Micro/Nano Reinforced Filled Metal Alloy Composites: A Review Over Current Development in Aerospace and Automobile Applications, ” Materials Today: Proceedings, vol. 4, no. 4, pp. 5571-5582, 2017, doi: https: //doi.org/10.1016/j.matpr.2017.06.014.

[5]. K. L. Arun, M. Udhayakumar, and N. Radhika, “A Comprehensive Review on Various Ceramic Nanomaterial Coatings Over Metallic Substrates: Applications, Challenges and Future Trends, ” Journal of Bio- and Tribo-Corrosion, vol. 9, no. 1, Nov. 2022, doi: https: //doi.org/10.1007/s40735-022-00717-6.

[6]. R. Mukherjee, R. Krishnan, T.-M. Lu, and N. Koratkar, “Nanostructured electrodes for high-power lithium-ion batteries, ” Nano Energy, vol. 1, no. 4, pp. 518-533, Jul. 2012, doi: https: //doi.org/10.1016/j.nanoen.2012.04.001.

[7]. J. W. McAuley, “Global Sustainability and Key Needs in Future Automotive Design, ” Environmental Science & Technology, vol. 37, no. 23, pp. 5414-5416, Dec. 2003, doi: https: //doi.org/10.1021/es030521x.

[8]. M. C. Coelho, G. Torrão, N. Emami, and J. Gr´cio, “Nanotechnology in Automotive Industry: Research Strategy and Trends for the Future Small Objects, Big Impacts, ” Journal of Nanoscience and Nanotechnology, vol. 12, no. 8, pp. 6621-6630, Aug. 2012, doi: https: //doi.org/10.1166/jnn.2012.4573.

[9]. J. Schulte, “Nanotechnology, ” Wiley eBooks, Nov. 2005, doi: https: //doi.org/10.1002/0470021071.

[10]. A. S. Olawore, T. B. Asafa, K. O. Oladosu, A. Lateef, and M. O. Durowoju, “Enhancing functionalities of paints with nanoparticles: a review, ” Nano Plus: Science and Technology of Nanomaterials, vol. 2, no. 1, pp. 97-119, 2021, Accessed: Sep. 14, 2025. [Online]. Available: https: //www.ajol.info/index.php/nano/article/view/287850

[11]. S.-J. Lee, Y.-C. Sohn, and C.-L. Kim, “Tribological Effects of Water-Based Graphene Lubricants on Graphene Coatings, ” Materials, vol. 16, no. 1, p. 197, Dec. 2022, doi: https: //doi.org/10.3390/ma16010197.

[12]. Milton Garcia Tobar, R. Wilmer, Bryan Jimenez Cordero, and Julio Guillen Matute, “Nanotechnology in Lubricants: A Systematic Review of the Use of Nanoparticles to Reduce the Friction Coefficient, ” Lubricants, vol. 12, no. 5, pp. 166-166, May 2024, doi: https: //doi.org/10.3390/lubricants12050166.

[13]. G. C. Shivaraju, C. Sudakar, and A. S. Prakash, “High-rate and long-cycle life performance of nano-porous nano-silicon derived from mesoporous MCM-41 as an anode for lithium-ion battery, ” Electrochimica Acta, vol. 294, pp. 357-364, Jan. 2019, doi: https: //doi.org/10.1016/j.electacta.2018.10.122.

[14]. B. P. Vinayan, R. I. Jafri, R. Nagar, N. Rajalakshmi, K. Sethupathi, and S. Ramaprabhu, “Catalytic activity of platinum–cobalt alloy nanoparticles decorated functionalized multiwalled carbon nanotubes for oxygen reduction reaction in PEMFC, ” International Journal of Hydrogen Energy, vol. 37, no. 1, pp. 412-421, Jan. 2012, doi: https: //doi.org/10.1016/j.ijhydene.2011.09.069.

[15]. A. Shubair, “Tuning the Selectivity of Bimetallic NiBi Catalysts for Glycerol Electrooxidation into Value-Added Products, ” Uottawa.ca, Mar. 15, 2021. https: //ruor.uottawa.ca/items/5530404d-c533-40cc-ae30-7be0bb4560a4

[16]. J. Liu, S. Bao, and X. Wang, “Applications of Graphene-Based Materials in Sensors: A Review, ” Micromachines, vol. 13, no. 2, p. 184, Jan. 2022, doi: https: //doi.org/10.3390/mi13020184.

[17]. G. Regmi, “Unlocking Multifunctional Advantages with Nanocomposites Coatings for Solar Cells: A Comprehensive Review, ” Current Organic Chemistry, vol. 27, no. 22, pp. 1946-1959, Dec. 2023, doi: https: //doi.org/10.2174/0113852728281107231212044214.

Cite this article

Weng,J. (2025). The Application of Nanomaterials in the Automotive Industry. Applied and Computational Engineering,209,44-51.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of CONF-MCEE 2026 Symposium: Advances in Sustainable Aviation and Aerospace Vehicle Automation

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. H. N. Cheng, L. J. Doemeny, C. L. Geraci, and D. Grob Schmidt, “Nanotechnology Overview: Opportunities and Challenges, ” ACS Symposium Series, pp. 1-12, Jan. 2016, doi: https: //doi.org/10.1021/bk-2016-1220.ch001.

[2]. H. Presting and U. König, “Future nanotechnology developments for automotive applications, ” Materials Science and Engineering: C, vol. 23, no. 6-8, pp. 737-741, Dec. 2003, doi: https: //doi.org/10.1016/j.msec.2003.09.120.

[3]. K. Kumar, S. Das, R. Garg, and M. S. Goyat, “A Comprehensive Review on Enhancing the Strength of CFRPs Through Nano-reinforcements: Applications, Characterization, and Challenges, ” Journal of Failure Analysis and Prevention, vol. 24, no. 4, pp. 1588-1627, May 2024, doi: https: //doi.org/10.1007/s11668-024-01946-2.

[4]. S. Yadav, S. Gangwar, and S. Singh, “Micro/Nano Reinforced Filled Metal Alloy Composites: A Review Over Current Development in Aerospace and Automobile Applications, ” Materials Today: Proceedings, vol. 4, no. 4, pp. 5571-5582, 2017, doi: https: //doi.org/10.1016/j.matpr.2017.06.014.

[5]. K. L. Arun, M. Udhayakumar, and N. Radhika, “A Comprehensive Review on Various Ceramic Nanomaterial Coatings Over Metallic Substrates: Applications, Challenges and Future Trends, ” Journal of Bio- and Tribo-Corrosion, vol. 9, no. 1, Nov. 2022, doi: https: //doi.org/10.1007/s40735-022-00717-6.

[6]. R. Mukherjee, R. Krishnan, T.-M. Lu, and N. Koratkar, “Nanostructured electrodes for high-power lithium-ion batteries, ” Nano Energy, vol. 1, no. 4, pp. 518-533, Jul. 2012, doi: https: //doi.org/10.1016/j.nanoen.2012.04.001.

[7]. J. W. McAuley, “Global Sustainability and Key Needs in Future Automotive Design, ” Environmental Science & Technology, vol. 37, no. 23, pp. 5414-5416, Dec. 2003, doi: https: //doi.org/10.1021/es030521x.

[8]. M. C. Coelho, G. Torrão, N. Emami, and J. Gr´cio, “Nanotechnology in Automotive Industry: Research Strategy and Trends for the Future Small Objects, Big Impacts, ” Journal of Nanoscience and Nanotechnology, vol. 12, no. 8, pp. 6621-6630, Aug. 2012, doi: https: //doi.org/10.1166/jnn.2012.4573.

[9]. J. Schulte, “Nanotechnology, ” Wiley eBooks, Nov. 2005, doi: https: //doi.org/10.1002/0470021071.

[10]. A. S. Olawore, T. B. Asafa, K. O. Oladosu, A. Lateef, and M. O. Durowoju, “Enhancing functionalities of paints with nanoparticles: a review, ” Nano Plus: Science and Technology of Nanomaterials, vol. 2, no. 1, pp. 97-119, 2021, Accessed: Sep. 14, 2025. [Online]. Available: https: //www.ajol.info/index.php/nano/article/view/287850

[11]. S.-J. Lee, Y.-C. Sohn, and C.-L. Kim, “Tribological Effects of Water-Based Graphene Lubricants on Graphene Coatings, ” Materials, vol. 16, no. 1, p. 197, Dec. 2022, doi: https: //doi.org/10.3390/ma16010197.

[12]. Milton Garcia Tobar, R. Wilmer, Bryan Jimenez Cordero, and Julio Guillen Matute, “Nanotechnology in Lubricants: A Systematic Review of the Use of Nanoparticles to Reduce the Friction Coefficient, ” Lubricants, vol. 12, no. 5, pp. 166-166, May 2024, doi: https: //doi.org/10.3390/lubricants12050166.

[13]. G. C. Shivaraju, C. Sudakar, and A. S. Prakash, “High-rate and long-cycle life performance of nano-porous nano-silicon derived from mesoporous MCM-41 as an anode for lithium-ion battery, ” Electrochimica Acta, vol. 294, pp. 357-364, Jan. 2019, doi: https: //doi.org/10.1016/j.electacta.2018.10.122.

[14]. B. P. Vinayan, R. I. Jafri, R. Nagar, N. Rajalakshmi, K. Sethupathi, and S. Ramaprabhu, “Catalytic activity of platinum–cobalt alloy nanoparticles decorated functionalized multiwalled carbon nanotubes for oxygen reduction reaction in PEMFC, ” International Journal of Hydrogen Energy, vol. 37, no. 1, pp. 412-421, Jan. 2012, doi: https: //doi.org/10.1016/j.ijhydene.2011.09.069.

[15]. A. Shubair, “Tuning the Selectivity of Bimetallic NiBi Catalysts for Glycerol Electrooxidation into Value-Added Products, ” Uottawa.ca, Mar. 15, 2021. https: //ruor.uottawa.ca/items/5530404d-c533-40cc-ae30-7be0bb4560a4

[16]. J. Liu, S. Bao, and X. Wang, “Applications of Graphene-Based Materials in Sensors: A Review, ” Micromachines, vol. 13, no. 2, p. 184, Jan. 2022, doi: https: //doi.org/10.3390/mi13020184.

[17]. G. Regmi, “Unlocking Multifunctional Advantages with Nanocomposites Coatings for Solar Cells: A Comprehensive Review, ” Current Organic Chemistry, vol. 27, no. 22, pp. 1946-1959, Dec. 2023, doi: https: //doi.org/10.2174/0113852728281107231212044214.