1. Introduction

Radiofrequency identification (RFID) is a non-contact wireless identification technology that uses radio frequency communication [1]. This technology has a history of over 70 years. In 1948, Harry Stockman proposed a communication method that utilizes reflected power, laying the theoretical foundation for RFID technology [2]. Later, for a long time, RFID was in the laboratory research stage, and the theory was constantly enriched. Some of the earliest RFID applications appeared at that time. In 1970, Mario Cardullo submitted a patent application titled 'Transponder Devices and Systems', which is the first modern RFID prototype device [3]. Since the 1980s, RFID technology and products have entered the stage of commercial application. Research on RFID technology in various frequency bands continuously made progress. Since the 21st century, RFID products have been widely adopted, making them convenient for people's lives. RFID technology has been widely used in electronic documents, logistics, transportation, retail, anti-counterfeiting identification and other scenarios [1].

The RFID tag is an important component of the RFID system. Compared with traditional barcodes, RFID tags have the advantages of large data storage capacity, greater security, and high recognition speed [4]. However, traditional RFID tags are based on silicon and cannot meet the requirements of low cost, flexibility, and transparency. Therefore, it is necessary to explore new processes to manufacture RFID tags which are suitable for new application scenarios. In recent years, researchers have explored RFID tags based on thin film transistors (TFT), which can have advantages such as low cost, flexibility, transparency, etc. This article investigates the research progress of RFID tags based on TFT in recent years and looks forward to the development prospects of RFID tags based on TFT.

2. Composition and principle of RFID system

2.1. Composition of RFID system

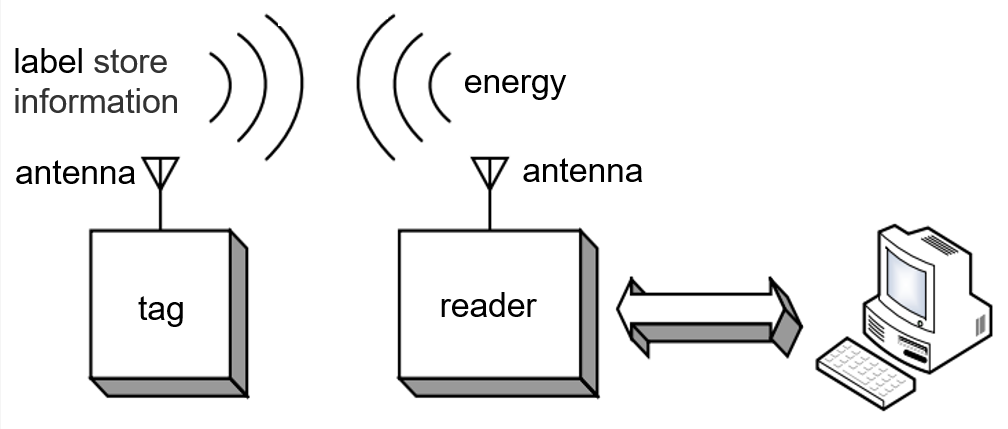

As shown in Figure 1, the RFID system generally consists of three parts: radio frequency tag, reader, and data processing system. Among them, the data processing system is mainly responsible for storing and managing data information and can control the reading and writing of tags. The reader is a bridge between the data processing system and the tag, typically composed of an RF transceiver circuit, control unit, and antenna. It communicates with tags through an antenna and transmits the information from the tags to the computer system for processing. Radiofrequency tags are usually bound to the identified item and contain specific information for identifying the target. General electronic tags can be composed of an RF unit, analogue front-end unit, digital back-end unit, and storage unit. The RF unit is used to receive modulated signals sent by the reader. The analogue front end is used to achieve demodulation and modulation functions. The digital back-end unit is used to achieve signal decoding, encoding, decryption, encryption, etc. The storage unit is used to store the information on electronic tags.

Figure 1. Composition of RFID system [5].

2.2. Classification of RFID tag

According to the power supply method, RFID tags can be divided into three categories: passive, half-active, and active. The passive tag doesn’t contain an electric source internally, and its electrical energy is obtained from the signal emitted by the reader. This type of label has a small size, lightweight, low cost, and long lifespan, but it needs to be close to the reader. The half-active tag is in a sleep state during normal times. It does not work to send RFID signals to the outside world. Only when it enters the range of activation signal, the tag is activated and starts working, increasing communication distance. The active tag contains a power supply inside, which can actively initiate interaction and transmit its own data to the reader without receiving a signal from the reader. This type of tag has a long communication distance, but it has a short lifespan and a high cost.

According to the different frequency bands in which the tags are applied, RFID tags can be divided into four types: low frequency, high frequency, super high frequency and microwave. The main operating frequencies of low-frequency RFID tags are 125 kHz and 134 kHz, and the communication distance is generally less than 10cm. The main operating frequency of high-frequency RFID tags is 13.54 MHz, and the communication distance is generally less than 1m. They can be used in fields such as electronic payment and access door control recognition. The working frequency range of super high-frequency RFID tags is 860 MHz-960 MHz. The communication distance can be up to a few meters, and the data transmission speed is fast. They are often used in logistics management and automatic payment scenarios. The main operating frequencies of microwave RFID tags are 2.45 GHz and 5.8 GHz. These tags have fast speed and communication distance of more than 10m, but they have high costs and poor anti-interference capabilities. This type of tag can be used in fields such as electronic toll collection (ETC) [6].

2.3. Working principle of RFID

In practical applications, radio frequency tags are affixed to the surface of the object to be identified, and radio frequency signals are transmitted between tags and readers through antennas: The reader sends a fixed frequency RF signal through its own antenna. If an item with an electronic tag is in the readable range of the reader, the query signal will activate the tag. The tag will modulate the corresponding data to be transmitted based on the received signal requirements onto a high-frequency signal carrier for transmission. After receiving the signal reflected from the tag, the reader will decode and recognize the data stored in the electronic tag, thereby achieving the goal of identifying the object.

The data transmission foundation between RFID readers and electronic tags is electromagnetic coupling, which can be roughly divided into inductive coupling and electromagnetic backscatter coupling. Generally, RFID with lower frequencies uses inductive coupling, which is actualized through high-frequency alternating magnetic fields in space, based on the law of electromagnetic induction. RFID with higher frequencies mostly adopts electromagnetic backscatter coupling, based on the spatial propagation law of electromagnetic waves. The emitted electromagnetic waves reflect upon encountering the target and carry back the information of the tag.

3. RFID tag based on TFT

3.1. Introduction to TFT

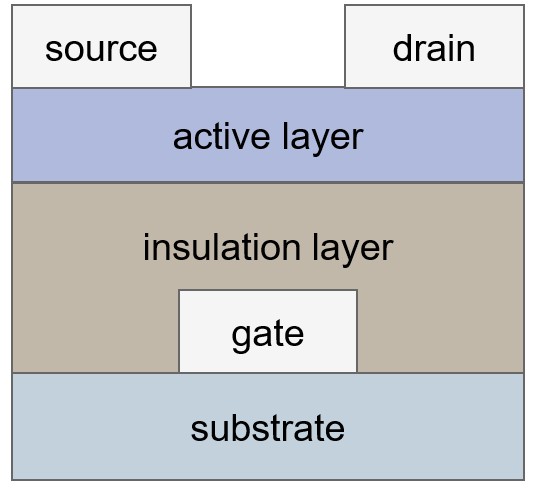

Thin film transistors (TFT) and metal oxide semiconductor field-effect transistors (MOSFET) are both field-effect transistors, which were invented and actually manufactured in the mid-20th century. The electrical performance of TFT is far inferior to that of MOSFET, but the production cost is relatively low, and it can be made on large-area substrates such as glass and plastic. Thin film transistors are mainly composed of components such as gate electrode, insulation layer, active layer, source electrode, and drain electrode, and are based on glass or plastic, stainless steel plates, etc. [7]. Figure 2 shows the structure of TFT. The change in voltage applied to the gate of TFT can influence the current between the source and drain electrodes. The structure of TFT can be classified from two perspectives. Firstly, it can be classified by the relative position between the active layer and the electrode: if the active layer is sandwiched between the gate electrode and source&drain electrode, it is a staggered structure; if the active layer is on the same side as the gate electrode and source&drain electrode, it is a coplanar structure. Moreover, it can also be classified by the position of the gate electrode in the TFT: if the gate electrode is in the upper part of the device, it is a normal structure, and if the gate electrode is in the lower part of the device, it is an inverted structure [8].

Figure 2. Structure of TFT.

3.2. Research status of RFID tags based on TFT

Compared to traditional ones, RFID tags based on TFT have the following advantages. Firstly, TFT can achieve processing on a large area substrate, and its thin-film manufacturing process can reduce costs. Secondly, applying flexible TFT to RFID tags can enable the tags to be attached to uneven items, expanding the applicability of the tags. In addition, many TFTs have good optical transparency and can be used to manufacture transparent RFID tags, meeting the needs of certain application scenarios.

In recent years, researchers have attempted various TFTs to explore the design and improvement of new RFID tags.

For a-Si TFT, in 2007, Gong Jingxuan proposed a scheme to use a-TFT to make RFID tags and introduced the method of capacitor excitation boost to improve the performance of each functional module circuit, making a-TFT more effective in the implementation of tag circuits. However, in the circuit design of tags, the logic circuit has not yet obtained a complete logic control unit due to the mutual interference of boost units [4].

For p-Si TFT, Yueh Hua Yu et al. proposed an Amplitude-shift keying (ASK) demodulator for RFID tags using Low-temperature polycrystalline silicon thin film transistor technology in 2009. The demodulator has a working voltage of 8 V and a power consumption of 1.6 mW. The input carrier frequency has been tested to reach 13.56 MHz, with a maximum ASK modulation data rate of 100 kb/s. This proves the feasibility of LTPS TFT in RF applications [9].

For OTFT, in 2007, Cantatore et al. first released an OTFT RFID tag with a working frequency of 13.56 MHz and a working frequency of 125 kHz, demonstrating the technical feasibility of using 13.56 MHz organic tags for commercial item level identification [10]. In 2015, Vincenzo Fiore et al. designed the first organic 13.56 MHz RFID tag printed on a flexible substrate. The tag uses organic complementary TFT technology and has a 24 V power supply voltage, a reading range of 2-5 cm, and a bit rate of up to 50 bit/s. This shows the feasibility of applying printed C-OTFT technology to RFID tags [11].

For MOTFT, in 2013, Yang et al. proposed a transparent logic circuit for RFID tags in amorphous indium gallium oxide zinc (a-IGZO) TFT technology. At a working voltage of 6V, the working frequency is 3.2kHz and the power consumption is 170 μW [12]. In 2017, Hung et al. designed an ultra-low power RFID tag on plastic foil. The low-power design makes RFID functionality easier to be actualized in flexible responders. The digital logic gate adopts a pseudo-CMOS type, and the chip is subjected to low-temperature treatment on aIGZO plastic film. Only 6.8 μW is consumed at ultra-low 1V power supply voltage, and the data rate is 148 bit/s. It has huge market potential and is very suitable for IoT applications [13]. In 2019, Qin et al. proposed a low-power differential logic (DL) row/column decoder with unipolar ITO-stabilized ZnO TFT technology and pull-up control loop oscillator (PUC-RO) for RFID code generators to reduce the power consumption of RFID. Compared with traditional pseudo-CMOS designs, the power consumption of code generators with DL decoders is decreased by over 20% at the same power supply voltage, and the power consumption of code generators using DL decoders and PUC-RO is decreased by over 40%. These results provide a new way for optimizing the power of RFID tags based on TFT [14].

Overall, MOTFT has better electrical performance, higher mobility, and lower operating voltage. Consequently, the data transmission of MOTFT tags is faster and it is now receiving widespread attention from researchers all over the world.

3.3. Application prospect

As an important technology in the era of IoT, RFID has been widely used in fields such as logistics, transportation, retail, and healthcare. Due to the excellent performance of RFID tags based on TFT, such as flexibility, transparency, and low cost, the future application market is extremely broad. For example, in the retail industry, due to the transparency, RFID tags based on TFT do not obscure the original text on the packaging, making it easier for customers to read the product information. At the same time, transparent tags are not easily found and removed, which can effectively prevent people from stealing goods after removing the labels, avoiding economic losses. In the medical field, flexible wearable devices can be manufactured using RFID tags based on TFT, which fit the human body better, making monitoring more stable and reliable.

4. Conclusion

This article introduces the composition and working principle of RFID and focuses on the tag part of the system. It summarizes the research progress of RFID tags based on various TFTs and prospects their application prospects. However, due to limited capabilities, the collected literature may not be comprehensive and some good research results may have been missed. In the future, exploring RFID tags with lower operating voltage, lower power consumption, and higher transmission rates will still be a research focus. With the continuous effort of researchers, RFID tags based on TFT will have better performance, promoting the widespread application of RFID technology.

Acknowledgement

The author sincerely thanks Professor S. Lucyszyn for his course and the supervisor for her paper guidance.

References

[1]. Wu Huanhuan, Zhou Jianping, Xu Yan, et al. Review of RFID Development and Application [J]. Computer Applications and Software,2013(12):203-206.

[2]. H. Stockman, Communication by Means of Reflected Power[J]. Proceedings of the IRE,1948,36 (10):1196-1204.

[3]. Lang Weimin, Chu Kaifeng, Wu Peiren, et al. The Development History of Radio Frequency Identification [J]. Telecom Express,2019(1):2-5.

[4]. Gong Jingxuan. The Study of Antenna and Circuit in the RFID Transponder based on Thin Film Transistor Technology [D]. Guangdong: Sun Yat-sen University, 2007.

[5]. Ma Xiaoyu. Research and hardware implementation of transparent RFID tag based on zinc oxide thin film transistor [D]. Zhejiang: Zhejiang University, 2022.

[6]. Zhang Xuzhi, Li Kang, Wang Fang, et al. A review on tag antenna design and its applications in RFID system [J]. Electronic Components and Materials,2022,41(1):1-8.

[7]. Feng Guofeng. Study on the Mechanism of Negative Bias Illumination Stability of Amorphous Oxide Semiconductor Thin Film Transistors [D]. Shanghai: Shanghai Jiao Tong University, 2021.

[8]. Cherie R K, Paul A. Thin-Film Transistors[M]. Taylor and Francis; CRC Press: 2003-02-25.

[9]. Yu Y H, Lee Y J, Li Y H, et al. An LTPS TFT Demodulator for RFID Tags Embeddable on Panel Displays[J]. IEEE Transactions on Microwave Theory & Techniques, 2009, 57(5):1356-1361.

[10]. Cantatore E, Geuns T C T, Gelinck G H, et al. A 13.56-MHz RFID System Based on Organic Transponders[J]. IEEE Journal of Solid-State Circuits, 2007,42(1):84-92.

[11]. V. Fiore et al. An Integrated 13.56-MHz RFID Tag in a Printed Organic Complementary TFT Technology on Flexible Substrate[J]. IEEE Transactions on Circuits and Systems, 2015, 62(6):1668-1677.

[12]. Yang B et al. A Transparent Logic Circuit for RFID Tag in a-IGZO TFT Technology[J]. ETRI Journal, 2013,35(4):610-616.

[13]. Ming-Hao Hung et al. Ultra low voltage 1-V RFID tag implement in a-IGZO TFT technology on plastic[J]. IEEE International Conference on RFID (RFID), 2017, pp. 193-197.

[14]. Qin Y, Yeung F S Y, Wong M, et al. Low-Power Design for Unipolar ITO-Stabilized ZnO TFT RFID Code Generator Using Differential Logic Decoder[J]. IEEE Transactions on Electron Devices, 2019,66(11):4768-4773.

Cite this article

Jialong,W. (2023). A review of RFID Tag based on TFT. Applied and Computational Engineering,25,292-296.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2023 International Conference on Functional Materials and Civil Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Wu Huanhuan, Zhou Jianping, Xu Yan, et al. Review of RFID Development and Application [J]. Computer Applications and Software,2013(12):203-206.

[2]. H. Stockman, Communication by Means of Reflected Power[J]. Proceedings of the IRE,1948,36 (10):1196-1204.

[3]. Lang Weimin, Chu Kaifeng, Wu Peiren, et al. The Development History of Radio Frequency Identification [J]. Telecom Express,2019(1):2-5.

[4]. Gong Jingxuan. The Study of Antenna and Circuit in the RFID Transponder based on Thin Film Transistor Technology [D]. Guangdong: Sun Yat-sen University, 2007.

[5]. Ma Xiaoyu. Research and hardware implementation of transparent RFID tag based on zinc oxide thin film transistor [D]. Zhejiang: Zhejiang University, 2022.

[6]. Zhang Xuzhi, Li Kang, Wang Fang, et al. A review on tag antenna design and its applications in RFID system [J]. Electronic Components and Materials,2022,41(1):1-8.

[7]. Feng Guofeng. Study on the Mechanism of Negative Bias Illumination Stability of Amorphous Oxide Semiconductor Thin Film Transistors [D]. Shanghai: Shanghai Jiao Tong University, 2021.

[8]. Cherie R K, Paul A. Thin-Film Transistors[M]. Taylor and Francis; CRC Press: 2003-02-25.

[9]. Yu Y H, Lee Y J, Li Y H, et al. An LTPS TFT Demodulator for RFID Tags Embeddable on Panel Displays[J]. IEEE Transactions on Microwave Theory & Techniques, 2009, 57(5):1356-1361.

[10]. Cantatore E, Geuns T C T, Gelinck G H, et al. A 13.56-MHz RFID System Based on Organic Transponders[J]. IEEE Journal of Solid-State Circuits, 2007,42(1):84-92.

[11]. V. Fiore et al. An Integrated 13.56-MHz RFID Tag in a Printed Organic Complementary TFT Technology on Flexible Substrate[J]. IEEE Transactions on Circuits and Systems, 2015, 62(6):1668-1677.

[12]. Yang B et al. A Transparent Logic Circuit for RFID Tag in a-IGZO TFT Technology[J]. ETRI Journal, 2013,35(4):610-616.

[13]. Ming-Hao Hung et al. Ultra low voltage 1-V RFID tag implement in a-IGZO TFT technology on plastic[J]. IEEE International Conference on RFID (RFID), 2017, pp. 193-197.

[14]. Qin Y, Yeung F S Y, Wong M, et al. Low-Power Design for Unipolar ITO-Stabilized ZnO TFT RFID Code Generator Using Differential Logic Decoder[J]. IEEE Transactions on Electron Devices, 2019,66(11):4768-4773.