1. Introduction

As the technological advancements in the manufacturing sector continue to progress, 3D printing, an emerging manufacturing technology, is experiencing rapid development. In just the past few years, FDM 3D printing technology has been widely used in the manufacturing industry, especially in the fields of rapid prototyping, mold manufacturing, and personalized customized products. However, temperature control during the FDM 3D printing process has a crucial impact on print quality and accuracy. To solve this problem, many researchers have conducted in-depth discussions on the temperature control of FDM 3D printers. This paper addresses the issue of maintaining accurate and stable temperature in FDM and proposes PID control as a solution. Using Simulink as a tool to simulate FDM heating, the study explores the significance of PID control in improving temperature accuracy and ensuring product quality.

2. Literature review

As one of the iconic technologies in modern industry, 3D printing has experienced rapid development in recent decades, with research being conducted both domestically and internationally [1]. In early studies, researchers mainly focused on investigating basic temperature control strategies, such as open-loop and closed-loop control. Although these temperature control strategies have a certain degree of rationality in their design, they exhibit poor control performance in practical applications and struggle to meet the demands of high-precision printing.

As research progresses, an increasing number of researchers have begun to pay attention to the application of PID control in temperature control for FDM 3D printers. For example, some studies compare different PID parameter tuning methods, such as the Ziegler-Nichols method and the Cohen-Coon method [2]. These studies demonstrate that PID control can effectively improve the temperature control performance of FDM 3D printers, thereby enhancing print quality.

In addition, some research attempts to introduce advanced control algorithms, such as adaptive PID control and fuzzy PID control, to further optimize the temperature control of FDM 3D printers. These advanced control methods can automatically adjust PID parameters based on actual working conditions, making temperature control more stable and accurate [3].

Although there is already a considerable amount of research focusing on temperature control and PID control for FDM 3D printers, many unresolved issues remain. For example, how to reduce energy consumption while ensuring print quality, how to minimize the impact of PID control on the lifespan of printer components, and how to design more advanced and intelligent control algorithms. These issues require further research and discussion to promote the widespread application of FDM 3D printing technology in the manufacturing industry.

3. FDM 3D printer working principle and structure introduction

FDM (Fused Deposition Modeling) is a novel printing method developed by Scott Crump in 1988. Its working principle involves the system controlling the nozzle to move to specified positions during printing, heating and melting the filamentous material inside the machine, and then extruding the material to form a cross-section. By stacking these cross-sections in three-dimensional space, the object gradually solidifies and takes shape [4]. FDM 3D printers mainly consist of high-precision mechanical systems, numerical control systems, injection systems, and molding environments, among other subsystems. They are complex mechatronic systems that integrate mechanical, control, and computer technologies [5]. However, they can generally be divided into three parts: control, mechanical, and heating.

The control part is composed of the main control board and is responsible for importing the model, inputting commands, and running the program. The mechanical part consists of four-axis belt screw, linear axes and optical axes, which are mainly responsible for feeding the filament, plastic molding, etc. Finally, the most crucial part, the heating component, is composed of the printer's nozzle, which controls the output of the filament in a molten state conducive to plasticity.

Currently, the mainstream FDM printers on the market can be divided into three categories: gantry type, box type, and delta type.

3.1. Working principle of gantry 3D printer

Gantry-type 3D printers are based on traditional numerical control machining technology. As shown in figure 1, they use a three-axis control system, consisting of the X, Y, and Z axes, to control the movement and positioning of the print head on the worktable. The print head of a gantry-type 3D printer is movable, and the three-axis control system precisely positions the print head's location and movement path, allowing the print head to move freely in three directions, thereby realizing the printing of complex three-dimensional structures.

The structure of a gantry-type 3D printer is similar to that of a bridge crane, with the print head suspended on the bridge frame and the bridge frame fixed on the columns on both sides. Through this structure, the gantry-type 3D printer can withstand larger weights and inertial forces, resulting in higher printing accuracy and faster printing speeds.

During printing, the gantry structure controls the X and Z axes, while the baseplate controls the movement of the Y axis. The advantages of this structure are its simplicity, ease of assembly, and convenience of maintenance. However, the disadvantages include insufficient Y-axis control precision, average print quality, relatively high noise, and limited choices of printing materials.

Figure 1. The structure of the gantry-style 3D printer [6].

3.2. Working principle of box 3D printer

As shown in figure 2, the drive in the X and Y-axis directions is controlled by two synchronized motors working together. The two motors are fixed to the surrounding frame and connected to the print head by belts, allowing it to move freely within the same plane. The advantages of this setup are high efficiency, high precision, low noise, and the ability to print larger sizes. The disadvantages are their larger size, higher cost, and more complex maintenance.

Figure 2. The structure of the box-type 3D printer [6].

3.3. Delta 3D printer working principle

The delta-type 3D printer consists of three arms with joints, as shown in figure 3. These arms are connected to fixed brackets, forming a series of parallelograms that control the target's movement in the X, Y, and Z axes. The print head is mounted at the bottom of the delta mechanism and can move along the structure. By precisely controlling the movement of the three arms, the print head can move to any position and deposit the molten printing material onto the print platform.

The advantages of this design include a lightweight structure, low noise during printing, high transmission efficiency, and high precision. The disadvantages are its complex structure, difficulty in debugging, and high maintenance complexity.

Figure 3. The structure of the delta-style 3D printer [6].

4. Early FDM 3D printer temperature control

In the early stages of FDM 3D printers, open-loop control and closed-loop control were used as their temperature control algorithms. Open-loop control systems are systems in which the output does not have any influence on the control of the system. Closed-loop control systems are systems that directly or indirectly feed the output back to the input, forming a closed loop to achieve automatic control. Since the system is controlled based on the principle of negative feedback according to deviation, that is, by comparing the deviation between system behavior (output) and desired behavior, and eliminating the deviation to obtain the expected system performance, it is also called a feedback control system or deviation control system [7].

4.1. Open-loop control

In open-loop control systems, the controller drives the actuators based on pre-set parameters and signals without the need for real-time monitoring of the system output. In early FDM 3D printers, the open-loop control method involved heating the print head using fixed-power heating elements. This made the open-loop control system relatively simple and inexpensive. However, there are some apparent drawbacks to open-loop control systems.

The first is the lack of feedback. Since there is no feedback on the output results, the open-loop control system cannot automatically correct errors or cope with environmental changes, such as voltage fluctuations, changes in friction forces, etc.

Secondly, there is the issue of accuracy. The accuracy of the open-loop control system is limited by the precision of the pre-set parameters. Errors in the pre-set parameters can lead to deviations in the output results.

4.2. Closed-loop control

In contrast to open-loop control, closed-loop control systems monitor output results in real-time, compare them with expected results, and automatically adjust control parameters to correct errors. This makes closed-loop control systems more stable and accurate. Compared to open-loop systems, closed-loop control systems have many advantages. The first is higher accuracy. Through real-time feedback and automatic adjustment, closed-loop control systems can improve system accuracy and stability. Second, they have excellent anti-interference capabilities. Closed-loop control systems can better cope with environmental changes and external disturbances, such as voltage fluctuations and temperature variations.

However, closed-loop control systems also have some drawbacks. The first is complexity. Compared to open-loop control, closed-loop control systems require more complex hardware and software designs, which increases the cost of the system. The second issue is potential stability problems. In some cases, if the design or adjustment of a closed-loop control system is inappropriate, it may cause system instability or even oscillation.

In summary, early FDM 3D printers used open and closed-loop control systems to achieve control in different aspects. With the advancement of technology, modern FDM 3D printers have made considerable progress in control strategies.

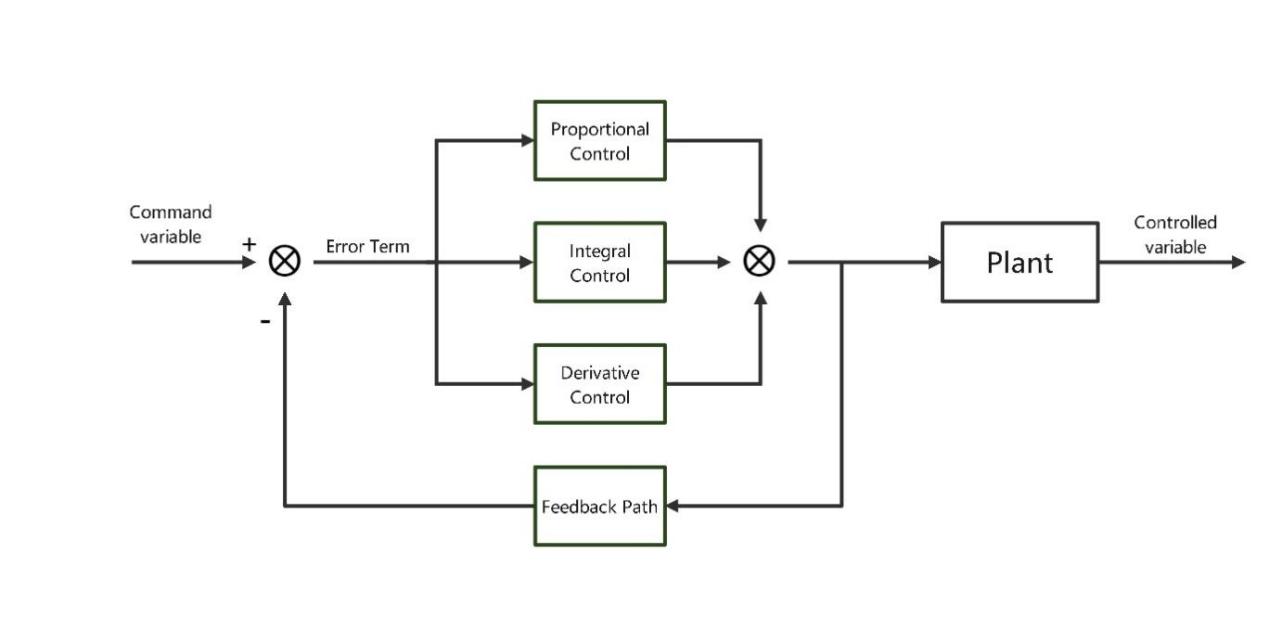

5. Introduction to PID Control

PID control is currently the most widely used type of controller in engineering, with its principle block diagram shown in figure 4.

Figure 4. Schematic diagram of PID control.

It is a control system composed of proportional, integral, and derivative units. It is a linear controller that can adjust the input value according to the deviation between the desired and current states, enabling it to achieve the desired state and maintain stability. It has the characteristics of a simple structure, clear principles, easy-to-adjust parameters, and stable system maintenance. The mathematical expression of the PID controller is:

\( u(t)={K_{p}}[e(t)+\frac{1}{{T_{1}}}\int _{0}^{t}e(t)dt+{T_{D}}\frac{de(t)}{t}] \)

Or using the transfer function representation:

\( G(s)=\frac{U(s)}{E(s)}={K_{p}}[1+\frac{1}{{T_{1}}s}+{T_{D}}s] \)

In the formula: \( {k_{p}} \) is the proportional coefficient; \( {T_{1}} \) is the integral time constant; \( {T_{D}} \) is the derivative time constant; \( u(t) \) represents the output; and \( e(t) \) represents the error.

Compared to the temperature control of early FDM 3D printers, PID control has improved FDM 3D printers in the following aspects:

Stability: The PID controller can maintain the target temperature more stably. Traditional control methods may cause temperature fluctuations, while PID controllers reduce fluctuations by continuously adjusting the power of heating elements.

Response speed: PID controllers can reach the set temperature more quickly. By adjusting the proportional, integral, and derivative parameters, the PID controller can reach the target temperature in the shortest possible time.

Adaptability: PID controllers can automatically adjust parameters to adapt to different working conditions. This means that PID controllers can maintain good performance in various environments without the need for manual intervention.

The size of the proportional coefficient in PID control affects the system's response speed and stability. When the proportional coefficient is larger, the system has a faster response speed but is also more likely to cause overshooting and oscillation. The size of the integral gain determines the ability to eliminate static errors. When the integral gain is larger, the ability to eliminate system static errors is stronger, but it may also cause integral saturation. Therefore, the performance of the PID controller is crucially dependent on the tuning of the PID parameters [3].

As the extruder head and heated bed of a fused deposition modeling 3D printer need to be maintained at a constant temperature, heating resistors are used to heat them, and then thermistors are used for temperature monitoring. The 3D printer's STM32F407 microcontroller has a 12-bit ADC module that can collect the voltage values of the CTCI Temp interface in real-time. The interface-connected thermistor realizes the voltage variation at the CTCI Temp interface with temperature change through voltage division. Moreover, the controller's ADC-collected analog voltage and the temperature change on the thermistor have a good linear relationship, and specific parameters can be calibrated through temperature calibration. The microcontroller converts the collected voltage into a temperature value, compares this temperature value with the system's set target temperature, and performs PID adjustment. The CTCI Heat pin outputs a signal to drive the power transistor's conduction and disconnection, thereby controlling whether the extruder and heated bed heating resistors are heated. The microcontroller keeps the temperature fluctuations of the extruder and heated bed within a certain range through PID control, forming a closed-loop temperature control system [8].

6. Simulation Results and Data Analysis

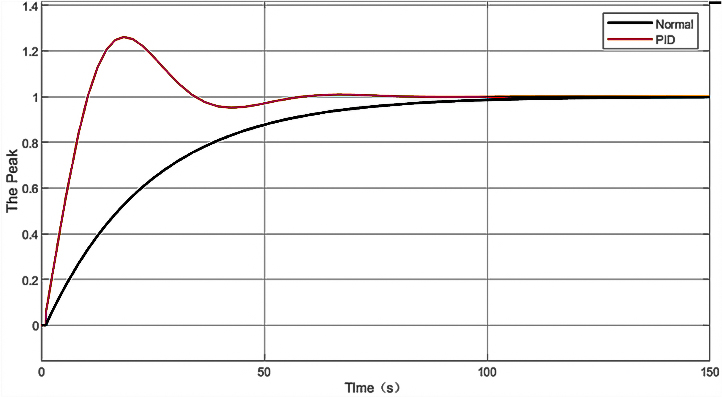

In this study, the PID control method was employed to control the temperature of the FDM 3D printer's extruder head, and the extruder head temperature control system was modeled and simulated using SIMULINK. Through data analysis of the simulation results, a deeper understanding of the advantages and limitations of PID control in temperature control can be achieved. In the following sections, these data will be discussed in detail to reveal the improvements of PID control on FDM 3D printer performance and potential areas for further improvement.

As can be seen from figure 5, under PID control, the time it takes to reach the desired temperature is 10.4s, and the time to continue rising to the peak is 18.5s, with an overshoot of 26.7%. The temperature stabilizes at 81.7s. Without PID control, the temperature rises slowly from the beginning and does not reach the desired temperature until 126.7s.

Figure 5. Comparison of temperature rise curves between standard and PID control.

From the experimental results, it can be observed that traditional open-loop and closed-loop control methods demonstrate inferior performance in temperature control for FDM 3D printers, making it difficult to meet the demands of high-precision printing. The PID control algorithm has a significant advantage in this regard, significantly improving the heating speed of the temperature.

7. Optimization and Improvement

In the experimental analysis section, we have discussed in detail the current issues with nozzle temperature control in FDM 3D printers and the effectiveness of PID controllers. By comparing experimental data, we found that the PID controller demonstrates a significant advantage in improving system stability and control accuracy. Today, the field of 3D printing faces many problems and challenges that need to be overcome gradually for further development [9]. Based on this study, we propose some areas for optimization in FDM 3D printers, considering future research directions.

7.1. Optimizing PID parameter tuning methods

To achieve better temperature control performance, more advanced PID parameter tuning methods can be tried, such as simulated annealing algorithms, genetic algorithms, and particle swarm optimization algorithms. These methods can find the optimal parameter combination in a large parameter search space, thus improving the precision and stability of temperature control.

7.2. Introducing adaptive control and intelligent control algorithms:

Considering factors such as environmental disturbances and equipment aging during the actual printing process, adaptive control and intelligent control algorithms can be introduced. For example, adaptive PID control and fuzzy PID control can automatically adjust PID parameters according to actual working conditions, making temperature control more stable and precise. Furthermore, artificial intelligence technology can be combined with control algorithms to further optimize control performance.

7.3. Optimizing the heating element and sensor layout:

By reasonably arranging heating elements and sensors, more effective temperature control can be achieved. For example, heating elements can be evenly distributed around the print bed and nozzle to improve heating efficiency. Meanwhile, multiple temperature sensors can be installed in key positions to achieve more accurate temperature detection and control.

7.4. Implementing real-time monitoring and feedback:

Developing real-time monitoring systems, such as those based on visual sensors and artificial intelligence technology, can detect temperature fluctuations and print quality issues during the printing process. Combining real-time monitoring data with the temperature control system can enable real-time optimization and adjustment of the printing process.

7.5. Improving equipment reliability and stability:

To ensure the long-term stable operation of the temperature control system, a series of measures can be taken to improve the reliability and stability of the equipment. For example, high-quality heating elements and sensors can be selected, periodic equipment maintenance and calibration can be carried out, and control algorithms can be optimized to reduce wear on printer components.

Future research directions should continue to focus on the optimization and innovation of FDM 3D printer temperature control. Studies can explore new control strategies, introduce artificial intelligence technology, and develop more efficient and reliable PID control algorithms. This will further enhance the breadth and depth of FDM 3D printing technology applications in the manufacturing industry.

8. Conclusion

This paper introduces the types and structures of FDM 3D printers, analyzes the differences between traditional temperature control methods and PID control, and simulates the process using SIMULINK. The conclusion is that, compared to 3D printers with traditional temperature control, the use of PID control can significantly reduce the heating time of 3D printer materials and improve the stability and control accuracy of the control system, thereby improving the precision and surface quality of printed products. However, this improvement also has some drawbacks, such as excessive overshoot. To address these issues, we propose several optimization strategies and envision the future direction of temperature control in FDM 3D printers.

References

[1]. Yuan Maoqiang, Guo Lijie, Wang Yongqiang, et al. (2016). Application of additive manufacturing technology and its development, Machine Tool & Hydraulics, (05), 183-188.

[2]. Ye Zheng. (2016). Research on PID controller parameter rectification method and its application, Beijing University of Posts and Telecommunications.

[3]. Hu Yanan, Qi Guangli, Huo Jiaofei & Wang Peng-Wen. (2017). Fuzzy PID-based temperature control system for FDM-type 3D printer nozzles, Packaging Engineering, (19), 173-178. DOI: 10.19554/j.cnki.1001-3563.2017.19.037.

[4]. Shu Xiaoyong.,Han Jiang. & Ding Fangting. (2016). Research on the principle and technology of three-dimensional fused deposition molding, Journal of Hunan City College (Natural Sciences), (05), 71-72.

[5]. Zhu Yanqing, Shi Jifu, Wang Leilei, et al. (2015). Current status of 3D printing technology development, Manufacturing Technology and Machine Tools, (12), 50-57.

[6]. Xian Ming. (2022). Introduction to FDM fused deposition molding. Online: https://zhuanlan.zhihu.com/p/575818798.

[7]. Yang Cui. (2015). Implementing technology to improve classroom effectiveness: An example of teaching "open-loop control system", Inventions and Innovations, (11), 50-52.

[8]. Wang, Xiaoliang. (2017). PID control of 3D printer heating system, Science and Technology Innovation and Application, (10), 63.

[9]. Zhao Qiansun, Chen Jifei, Wu Guifeng, et al. (2021). The development of 3D printer and its structural analysis, Rubber & Plastics Technology & Equipment (24), 44-48. DOI: 10.13520/j.cnki.rpte.2021.24.00.

Cite this article

Long,K. (2023). FDM 3D printer temperature control system based on PID control. Applied and Computational Engineering,28,72-79.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2023 International Conference on Mechatronics and Smart Systems

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Yuan Maoqiang, Guo Lijie, Wang Yongqiang, et al. (2016). Application of additive manufacturing technology and its development, Machine Tool & Hydraulics, (05), 183-188.

[2]. Ye Zheng. (2016). Research on PID controller parameter rectification method and its application, Beijing University of Posts and Telecommunications.

[3]. Hu Yanan, Qi Guangli, Huo Jiaofei & Wang Peng-Wen. (2017). Fuzzy PID-based temperature control system for FDM-type 3D printer nozzles, Packaging Engineering, (19), 173-178. DOI: 10.19554/j.cnki.1001-3563.2017.19.037.

[4]. Shu Xiaoyong.,Han Jiang. & Ding Fangting. (2016). Research on the principle and technology of three-dimensional fused deposition molding, Journal of Hunan City College (Natural Sciences), (05), 71-72.

[5]. Zhu Yanqing, Shi Jifu, Wang Leilei, et al. (2015). Current status of 3D printing technology development, Manufacturing Technology and Machine Tools, (12), 50-57.

[6]. Xian Ming. (2022). Introduction to FDM fused deposition molding. Online: https://zhuanlan.zhihu.com/p/575818798.

[7]. Yang Cui. (2015). Implementing technology to improve classroom effectiveness: An example of teaching "open-loop control system", Inventions and Innovations, (11), 50-52.

[8]. Wang, Xiaoliang. (2017). PID control of 3D printer heating system, Science and Technology Innovation and Application, (10), 63.

[9]. Zhao Qiansun, Chen Jifei, Wu Guifeng, et al. (2021). The development of 3D printer and its structural analysis, Rubber & Plastics Technology & Equipment (24), 44-48. DOI: 10.13520/j.cnki.rpte.2021.24.00.