1. Introduction

Stroke is a common neurological disorder that has become an important global health problem. The number of stroke deaths climbed to 6.2 million in 2017, while there were an estimated 18.7 million stroke-related disabilities worldwide. The overall lifetime risk of stroke in China is 39.9%, ranking first in the world [1]. Moreover, in recent years, the problem of population aging in China has become increasingly serious, and nearly 10 million elderly people over 60 years old are added every year [2]. Stroke often leads to hand motor dysfunction, which seriously affects the patients' activities of daily living and social function. Rehabilitation training is essential, and the index finger is one of the most important parts [3].

The index finger provides a strong grip and is the main source of tactile perception in daily life, helping us to achieve small manipulations of objects. The distal interphalangeal joint (DIP), proximal phalangeal joint (PIP), and metacarpophalangeal joint (MCP) are the three joints on the index finger [4]. The muscles of the hand of stroke patients are in a state of contracture, which causes some joints to be unable to move autonomously, and the joints' range of motion and degree of freedom are significantly diminished.

In order to restore hand function, it is necessary to carry out a series of hand rehabilitation training for stroke patients. With the diversification of the industry, a kind of robotic equipment collectively known as exoskeleton has received widespread attention. In the medical industry, the use of exoskeletons for rehabilitation training has gradually become mainstream [5]. Existing research has identified three types of hand exoskeletons for rehabilitation: soft exoskeletons, soft-rigid exoskeletons, and rigid exoskeletons. [6]. Clinical experiments have proved that hand exoskeleton robots are hardly effective in helping stroke patients recover [7].

Talat et al.studied a new index finger exoskeleton that uses series elastic actuation (SEA) [3]. Xu et al. created a brand-new index finger exoskeleton device for people with brachial plexus injuries [8]. To improve the therapeutic effectiveness of robotic hand exoskeletons for rehabilitation, Zhang used a one-wheel, two-way system combining a sliding guide rod and SEA tandem elastic drive to model and create an exoskeleton hand [4]. Using Bowden-cable-based series elastic actuation, Priyanshu et al. offer a unique index finger exoskeleton that enables bidirectional torque control of the device with great backdrivability and low reflected inertia [9]. Many other studies have described various hand exoskeleton structures for rehabilitation [10, 11]. However, many of them have a disadvantage, the design of the exoskeleton model is fixed, can not well meet all patients, and patients need to customize the model.

In combination with the above content, we further optimized the hand exoskeleton structure, applied a telescopic connecting rod that can adjust the size, and integrated it with the exoskeleton to accommodate the needs of patients with various hand sizes. In addition, in order to achieve the purpose of lightweight and safety. We also considered that the exoskeleton needs to be compatible with the finger joints and the finger bones, so joint flexibility is also critical. Series elastic actuator (SEA) has the advantages of high joint flexibility, low output impedance and cushioning excessive contact force [12]. These requirements can be well met, so we combined it with SEA on the basis of institutional improvement.

Our ultimate objective is to create an exoskeleton robot for the index finger that can accommodate various patient hand sizes to aid in stroke victims' finger rehabilitation. The remainder of this essay is structured as follows. Section 2 describes the anatomy of the human hand, Section 3 models the design of human hand exoskeleton and explains its main mechanism. In Section 4, the kinematic simulation test of the built model was carried out with solid works, and the rotation Angle, speed and acceleration of the exoskeleton and fingers were obtained. The motion of the exoskeleton robot was analyzed by DH method.

2. Institutional design of index finger rehabilitation exoskeleton robot

2.1. Analysis of the physiological properties and degree of freedom of the fingers

The biological anatomy of the human hand, which is a multi-articular system made up of 27 bones, is exceedingly complicated., mainly including phalanges, metacarpals and carpal bones. With rich functions and flexible movements, it is an important organ for people to engage in various kinds of work and activities. The thumb is made up of two phalanges and one metacarpal bone, and the phalanges and phalanges are connected by various joints. According to the classification of physiological anatomy, the human index finger, middle ring finger, and little finger are similar in structure and are composed of three phalanges and one metacarpal bone.

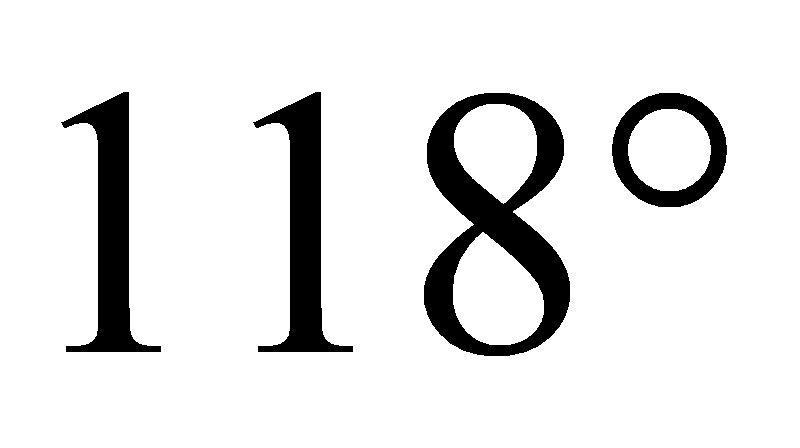

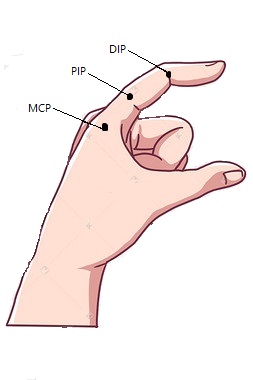

The index finger not only aids in providing a firm grasp in limbs or joints that may require rehabilitation, but it can also rely on its keen tactile sensory signals in daily life to help us accomplish minute manipulations of things. Like the middle finger, ring finger, and little finger, The distal interphalangeal joint (DIP), proximal phalangeal joint (PIP), and metacarpophalangeal joint (MCP) are the three joints on the human index finger, as shown in Figure 1 and Figure 2.

Figure 1. Human finger structure (front).

When the rehabilitation manipulator assists the patient in hand recovery, the position of the hand and the rehabilitation manipulator is constantly changing. Ideally, the activity route of the rehabilitation manipulator is consistent with that of the hand, so that the patient can have a better human-computer interaction experience. It can be seen that the motion function analysis of the hand joint Angle and motion trajectory plays a key role in the design of rehabilitation manipulator. For patients with hand motor dysfunction caused by stroke, the realization of hand grasping function is their main demand. Therefore, the analysis of hand motion in this paper includes the analysis of the motion range of each joint and fingertip of the fingers [13].

Figure 2. Human finger structure (side).

Determine the proper degree of flexibility in order to make the index finger's rehabilitation movement possible, joint motion range and joint driving torque, among which the DIP joint can achieve 1 degree of freedom of flexion/extension with a range of 60°, the PIP joint can achieve 1 degree of freedom of flexion/extension with a range of 90°, and the MCP joint can achieve 2 degrees of freedom of flexion/extension and retraction/extension. The range of motion is 100° [4]. The DIP joint is restricted to moving in conjunction with the PIP joint while the MCP joint and PIP joint can both move freely at the same time. For the design requirements of the index finger, the index finger has four degrees of freedom, which can complete flexion and extension adduction and abduction. Previous research on the physical evaluation of hand function has demonstrated that daily living activities are not significantly affected by the absence of adductor and abduction finger mobility. Additionally, the active abduction-adductor joint combination adds a great deal of complexity and a lack of utility to the design of our finger exoskeleton. These considerations led to the decision to exclude the abductor adductor joint's secondary function as a design goal for the index finger exoskeleton. Table 1 showed the human index finger’s parameters.

Table 1. The human index finger's joint flexibility, range of movement, and driving torque. | |||

Joint | Degree of freedom | Range of movement (°) | Driving torque |

MCP | Bend/straighten | 0-100 | 60 |

Adduction/abduction | -20-20 | 40 | |

PIP | Bend/straighten | 0-90 | 50 |

DIP | Bend/straighten | 0-60 | 30 |

After investigation, the approximate range of adult male and female index finger length [2, 3] is obtained. The rehabilitation exoskeleton robot's length is calculated by the length of the index finger. Although exoskeleton robot designed in this paper can adjust the distance between joints according to the user's index finger length, the data provided in the table can still provide reference value. The length range of adult index finger was shown in the Table 2.

Table 2. Length range of adult index finger. | |||||||

Sex | Index finger length | ||||||

Male | 62 | 64 | 66 | 67 | 70 | 71 | 75 |

Female | 56 | 58 | 62 | 65 | 67 | 70 | 73 |

3. Finger exoskeleton optimization

3.1. Design reason

At present, some issues with the rehabilitative hand exoskeleton robot exist, including the inability to bend the finger to change the length of the extended arm, the lack of enough freedom limits the full treatment of the hand, and the non-vertical with the finger surface leads to soft tissue damage. These problems have caused some problems for hand rehabilitation. However, we believe that through public participation, these issues in hand rehabilitation can be addressed, while at the same time alleviating the pressure faced by the shortage of rehabilitation doctors in China.

The main objective of this study is to study the problem of rehabilitation robotic exoskeleton hand, especially the adjustment of the size of the patient's hand. Through public contributions and participation, we hope to improve the design of the exoskeleton robotic hand so that it can better adapt to the hand characteristics and rehabilitation needs of different patients. This will provide more effective tools for rehabilitation treatment, improve rehabilitation results, and reduce the burden on doctors.

3.2. Requirements for exoskeleton

1) Bending adaptation: When designing the exoskeleton hand structure, the normal bending range of the index finger should be considered to ensure that the patient can freely bend the finger.

2) Affected area protection: In the design of the exoskeleton robot, secondary damage to the affected area should be avoided.

3) Size adjustment: The exoskeleton robot should have an adjustable size to adapt to the requirements of different patients' finger lengths and other treatment options. This can be achieved through retractable construction, adjustable joints, or exoskeleton assemblies equipped with multiple sizes.

To ensure that the exoskeleton robot can satisfy patients' rehabilitation needs and deliver efficient therapeutic support, these solutions necessitate substantial engineering and research and development work. At the same time, close cooperation with rehabilitation experts and doctors is also key to ensure that the exoskeleton robot can meet the individual treatment plan.

3.3. Functional analysis

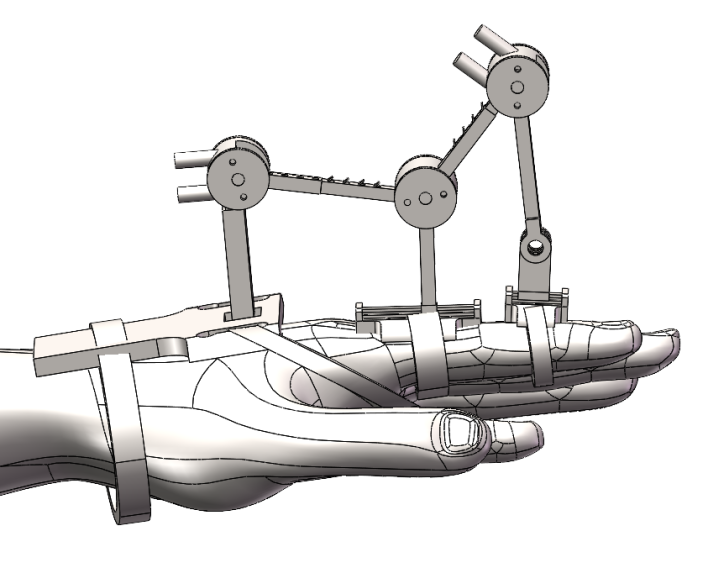

Hand exoskeleton is a mechanical assistive device designed to enhance the functionality and performance of the human hand the overall structure and wearing appearance of hand exoskeleton robot was shown in the Figure 3

Figure 3. Overall structure.

The exoskeleton joints are designed to mimic the Angle and function of a normal human hand. Through precise engineering and mechanical construction, exoskeleton joints can achieve a range of motion and flexibility similar to normal fingers. This includes the voluntary movements of MCP and PIP and the coordinated activities of DIP according to the movements of MCP and PIP. This design can better match the biological movements of the fingers.

The analysis results in the figure show that the MCP and PIP joints can achieve independent movement, while the DIP joints perform corresponding activities according to the movement of the MCP and PIP. The action of the exoskeleton robot is more coordinated and more natural with the natural motion of the finger thanks to this design, which is more in line with the biological motion pattern of the finger.

In the rehabilitation process, in order to avoid finger damage due to the change of movement Angle, we use the design of slide rail and guide rail. The purpose of the guide rail is to ensure that the force applied by the exoskeleton robot always acts vertically on the finger, avoiding unnecessary lateral force or torque. This can support the rehabilitation process more effectively, reduce additional damage to the finger, and provide a more precise therapeutic effect.

By using the scientific design and mechanism described above, we can give the exoskeleton robot joint its normal range of motion and functionality, follow the finger's biological motion law, and guarantee the security and efficacy of the therapeutic procedure by using the slide rail and guide rail. Such a design can better meet the rehabilitation needs and promote the rehabilitation process of patients.

3.4. Slot locking structure

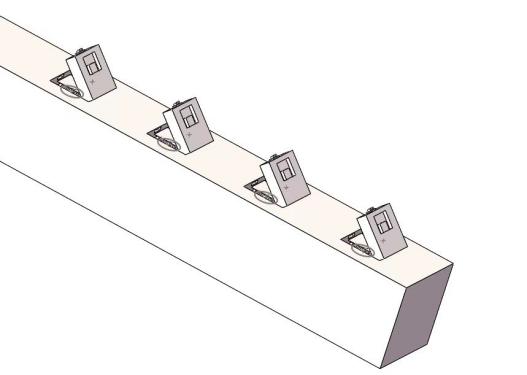

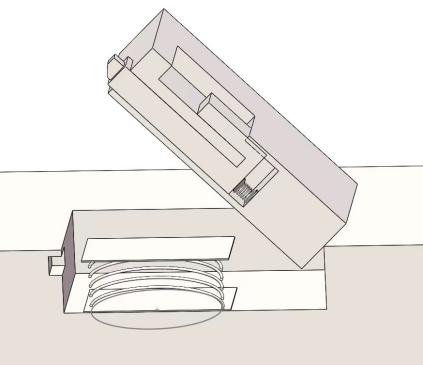

In response to the patient's finger bending needs, we introduced a retractable slide mechanism into the exoskeleton design. As shown in Figure 4, this mechanism realizes the adjustment of finger size by adding retractable slide in the position of the rod of the exoskeleton structure. By adjusting the telescopic degree of the slide, we can meet the normal finger bending needs of different patients.

We included a clasp mechanism at the joint location of the rod to guarantee the exoskeleton's dimensional stability. The clasp system consists of a plurality of clasp, each clasp corresponding to a specific size. The inner slide of the buckle is designed with a raised structure, while the outer slide is provided with corresponding card slots. By combining the clasps with the slides, the exoskeleton can be fixed to a specific size and provides the flexibility to choose from multiple sizes.

Through these designs and mechanisms, we achieve the goals of satisfying the index finger bending of the exoskeleton robot, avoiding secondary damage and size adjustment. This solution not only meets the individual treatment needs of patients, but also provides rehabilitation physicians with a flexible and reliable tool to complement other treatment options to provide comprehensive rehabilitation support for patients. The purpose of changing the size is achieved by the extension and contraction of the rod on the slide content was shown in the Figure 4.

Figure 4. Locking structure.

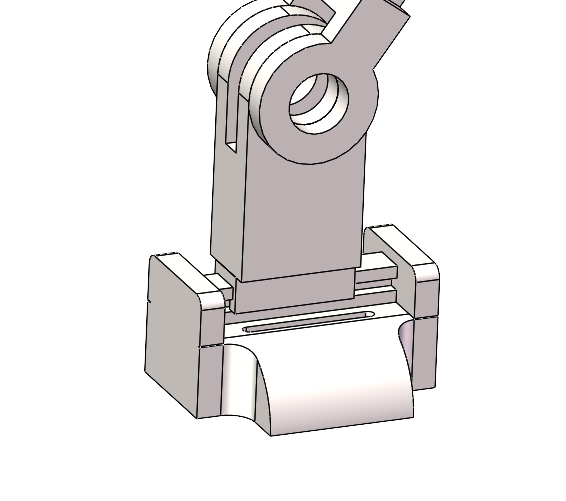

The finger exoskeleton card slot is equipped with a spring mechanism that can be triggered by pressing a button to make the convex slot pop out of the card slot. At the same time, grooves are also set in the design of the exoskeleton to accommodate these convex grooves, which reduces the space occupied by the exoskeleton structure and can be more convenient for storage content was shown in the Figure 5.

Figure 5. Buckle details.

3.5. Slide structure

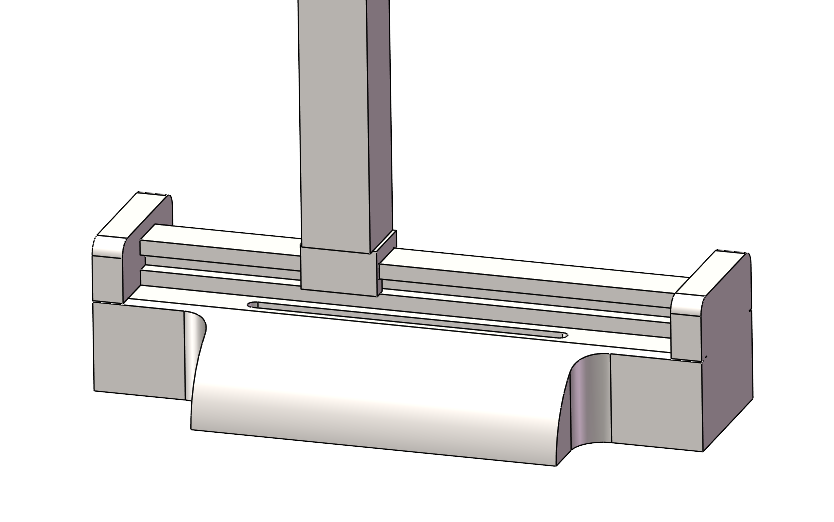

The slide is fastened to the skin on the upper surface of the finger by a strap and is divided into two sections. As shown in Figure 5 and Figure 6, the front slide is in charge of regulating DIP movement, while the middle slide is in charge of regulating PIP movement. By sliding the track, the force applied on the exoskeleton robot is able to act vertically on the finger, rather than applying an undirected force at a specific point in the finger. This design helps prevent unnecessary soft tissue damage during rehabilitation, as the force is always applied in the correct direction and Angle.

At the same time, the application of this slide also makes the movement of the exoskeleton robot more in line with the biological movement pattern, making the finger movement more natural and coordinated. By fixing the slide rail on the finger, we are able to provide more accurate and stable force transmission, making the exoskeleton robot's motions more similar to how a finger moves naturally. A design like that enhances the effectiveness of rehabilitation therapy, and enables patients to obtain a more natural and smooth finger movement experience during rehabilitation. Reduce force imbalance through sliding content was shown in the Figure 6 and 7, respectively.

Figure 6. Intermediate rail.

Figure 7. Front rails.

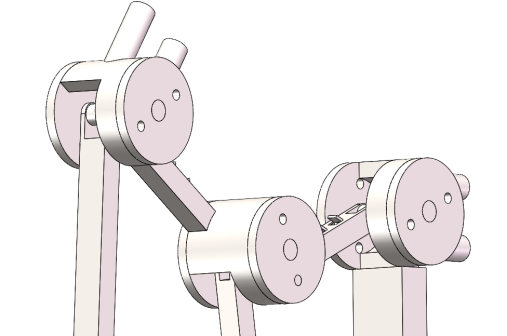

3.6. Series elastic actuator

The joint is Compliant actuator. Compliant actuator is a robot drive unit that integrates passive elastic elements, also known as flexible actuators. The application of Compliant actuator at the joint can bring a series of advantages and characteristics to the exoskeleton robot in rehabilitation hands.

Compliant actuator has the following characteristics and advantages: 1) Strong cushioning/impact resistance; 2) Compact structure; 3) Absorb and store energy; 4) High security; 5) Mechanical properties. Therefore, Compliant actuator is widely used in wearable robots, rehabilitation robots, intelligent prosthetics, humanoid robots and other fields, providing important technical support and innovation for the design and performance of rehabilitation hand exoskeleton robots. Flexible actuators are a type of robot's integrated drive unit that combines passive elastic components with intrinsic safety content was shown in the Figure 8.

Figure 8. Actuator device.

3.7. Safety of software and machinery

The use of the brake device at the joint drive is a very important safety measure designed to prevent the machine from causing danger to the user at any anti-human Angle or working form, to ensure that the machine can stop and maintain a fixed position when it is not necessary to perform normal work. When the user needs to intervene or there is any dangerous situation, the brake device can respond quickly and prevent the machine from continuing to move to ensure the safety of the user.

In addition, to further improve safety, sensors and monitoring systems can be used to monitor the position, strength and speed of the robot in real time. If any abnormal or dangerous situation is detected, the system can immediately take appropriate control measures, including stopping the robot movement, alerting or issuing an emergency shutdown signal.

In scenarios where humans and robots work together, safety is Paramount, and all designs and measures should be designed with the primary goal of ensuring human safety. With proper braking and safety control systems, potential hazards can be minimized and cooperation with robots is always safe and reliable.

4. Kinematic simulation analysis

4.1. The selection of exoskeleton

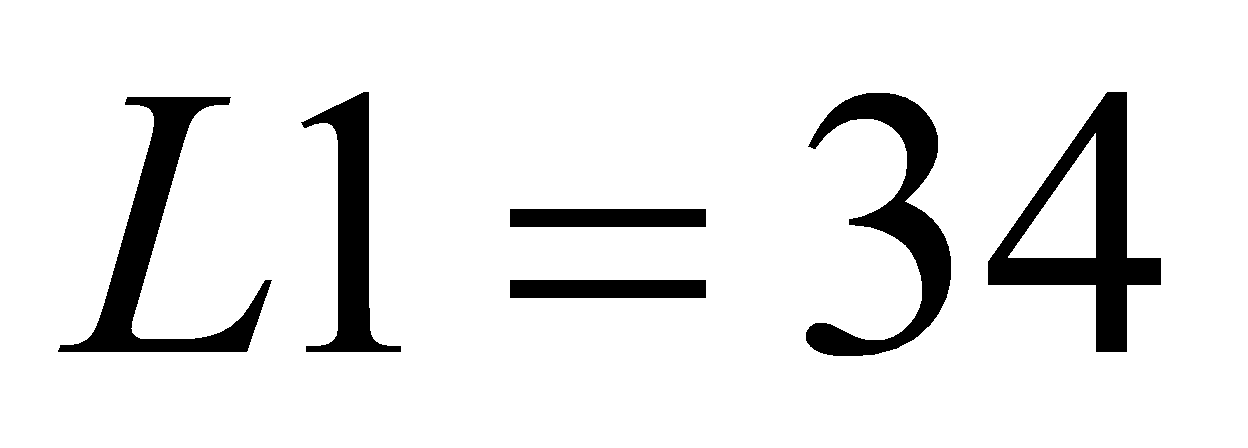

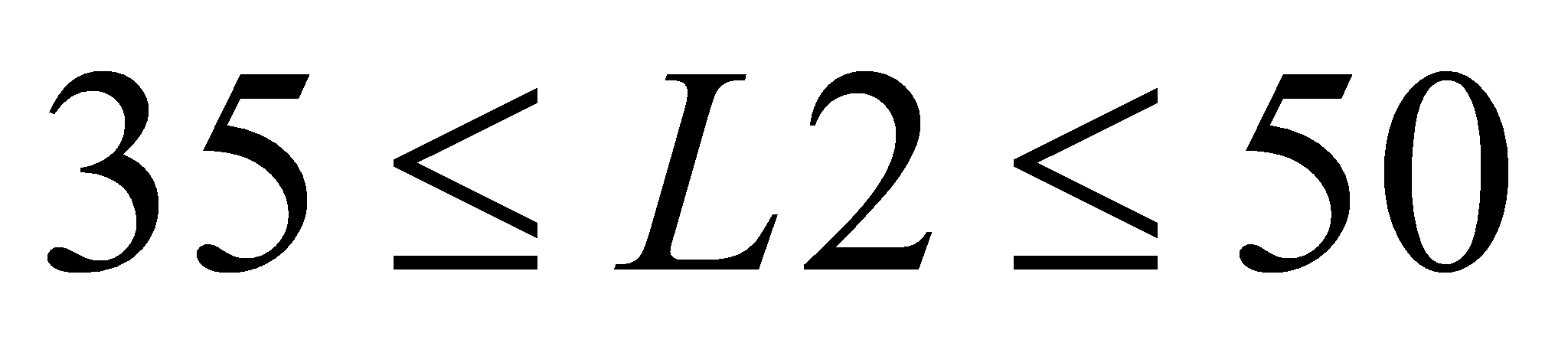

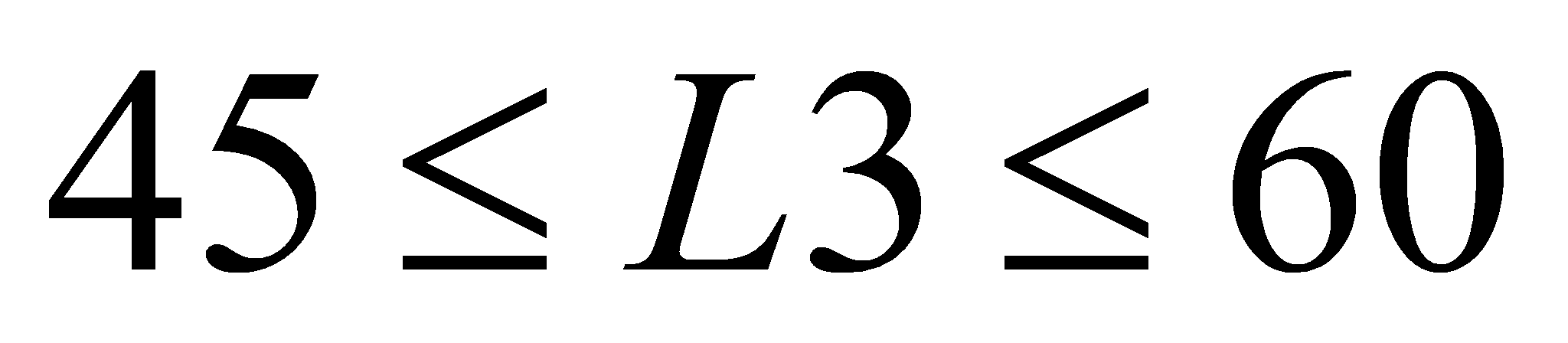

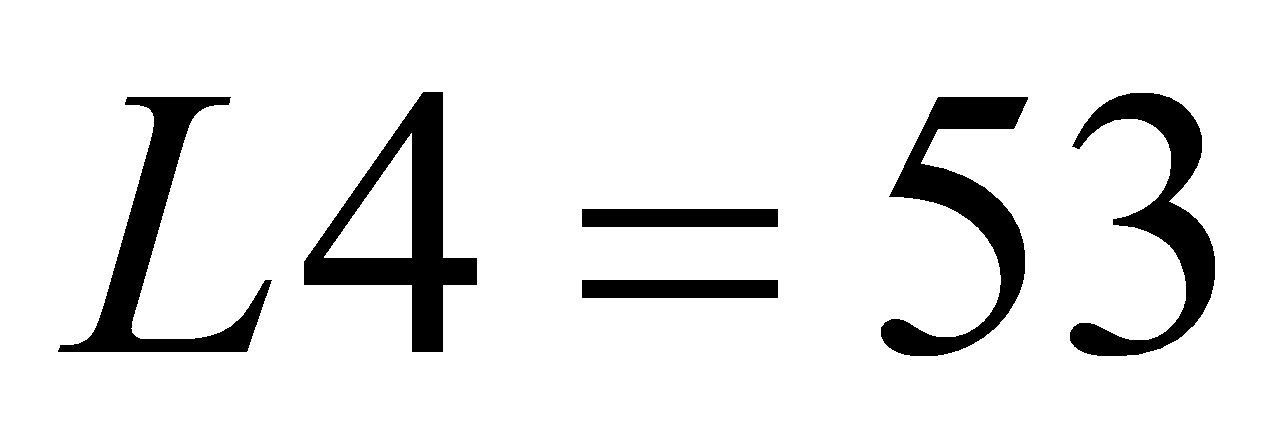

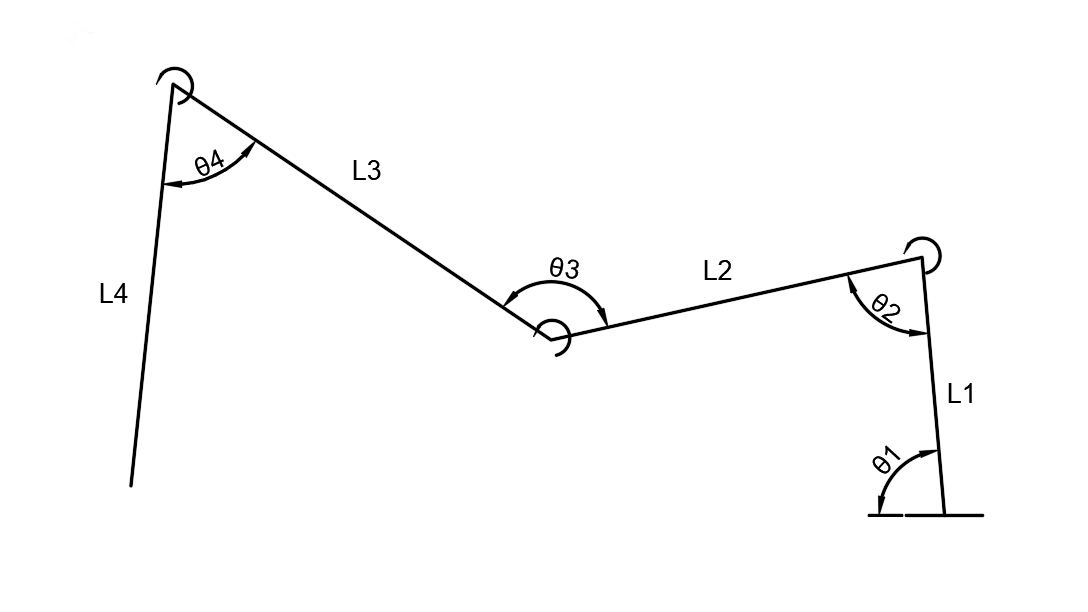

Before the simulation experiment, we first determined the geometric parameters of the simulation object, and the following points were mainly referred to when selecting the geometric parameters. 1) The torque to drive the joint should be as small as possible; 2) The selected geometric parameters must meet the required range of motion; 3) Mutual interference such as collision or squeezing is not allowed between the selected institutions. Finally, in addition to these factors, we also need to ensure that the overall size of the mechanism is not too large, so as not to increase the weight of the patient's hand. Therefore, the parameters are as follows:  ;

; ;

; ;

; . Simplified model of main connecting rod and Angle was shown in the Figure 9.

. Simplified model of main connecting rod and Angle was shown in the Figure 9.

Figure 9. Simplified diagram of motion structure.

When L takes the maximum value:

;

;  ;

;  ;

;

;

;  ;

;  ;

;

4.2. Improved DH parameter method to establish exoskeleton model

Exoskeleton robot model and corresponding coordinate system Exoskeleton robot model and corresponding coordinate system was shown in the Figure 10 and 11, respectively.

Figure 10. Transmission model.

Figure 11. Coordinate system based on improved DH parameter method.

In the simplified diagram of the model, it can be seen that the Z-axis direction of the index finger exoskeleton coordinate system is always outward. Table 3 showed the motion coordinate parameters.

Table 3. Motion coordinate parameter. | ||||

i | Shift along the X-axis | Rotate around the X-axis | Shift along the Z-axis | Rotate around the Z-axis |

1 | 0 | 0 | 0 |

|

2 | 34 | 0 | 0 |

|

3 | 50 | 0 | 0 |

|

4 | 60 | 0 | 0 |

|

5 | 53 | 0 | 0 | 0 |

The formula of improved DH parameter method is shown as follows:

The formula of improved DH parameter method is shown as follows:

(1)

In the formula:

(2)

(2)

(3)

(3)

We get the following equation:

(4)

(4)

(5)

(5)

(6)

(6)

(7)

(7)

(8)

(8)

(9)

(9)

(10)

(10)

(11)

(11)

(12)

(12)

(13)

(13)

(14)

(14)

4.3. Simulation of object motion with solid works

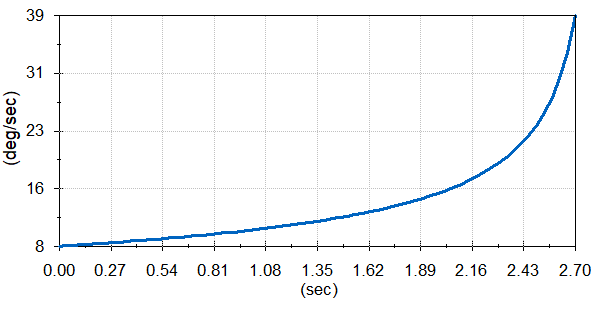

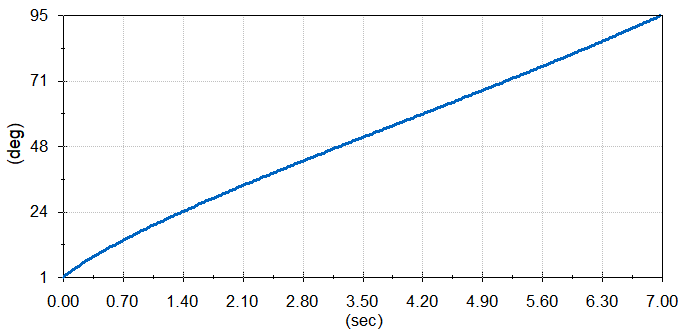

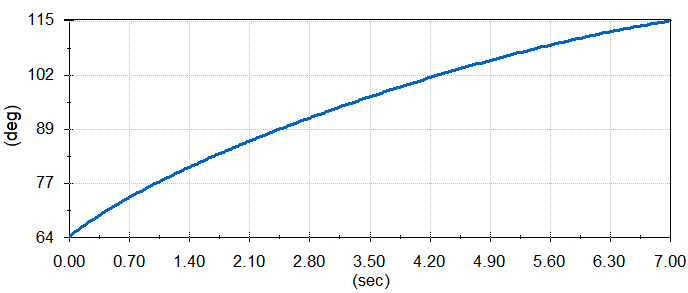

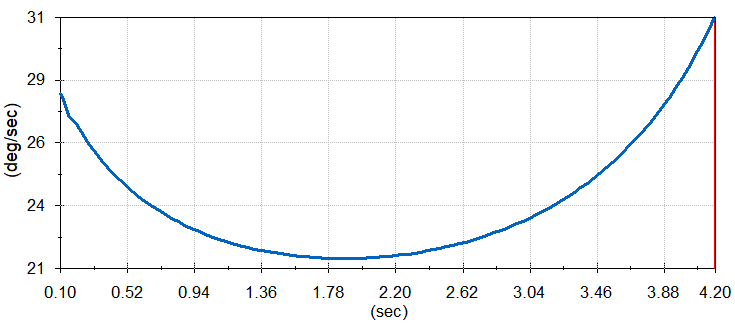

The experiment ran a kinematic simulation of the model to ensure the viability of the design. The experiment successively analysed the relationship between Angle, angular velocity, angular acceleration and the amount of time spent throughout each joint in the index finger bending process when the exoskeleton is working. The rotation angles and rotation velocities of the MCP and PIP joints and the rotation angles of joint 1 and 3 corresponding to their rotation was shown in the Figure 12 to 17.

Figure 12. MCP joint rotation angle.

Figure 13. The changes of joint 1 during rotation of the MCP joint.

Figure 14. Y-axis component of angular velocity of MCP joint.

Figure 15. PIP joint rotation angle.

Figure 16. The changes of joint 3 during rotation of the PIP joint.

Figure 17. Y-axis component of angular velocity of PIP joint.

5. Conclusion

In this study, an exoskeleton robot for hand rehabilitation of stroke patients was designed and modeled. The main results and conclusions of this study are as follows: First, this study demonstrates that the exoskeleton robot can provide strength support and assisted movement for patients, thereby restoring motor function of the hand and improving daily activity ability. Secondly, in order to guarantee the precision and stability of the motion, a control system and kinematics modeling technique for the exoskeleton robot are put forward in this study. The exoskeleton robot can provide personalized rehabilitation training according to the needs of patients and improve the rehabilitation effect. At the same time, this study considers the wearing comfort of the exoskeleton robot and the design of the operating interface, which has been affirmed by the users. But there are some limitations. For example, the cost and complexity of exoskeleton robots still limit their large-scale application and popularity. The size and diversity of the study sample also need to be further expanded to verify the effects of exoskeleton robots in different stroke patient populations. Future research directions should include further efforts to achieve wider applications by reducing costs and improving wearability. At the same time, emphasis should be placed on long-term clinical practice and efficacy evaluation to verify the long-term effects of exoskeleton robots in the rehabilitation of stroke patients. In conclusion, we are confident in the potential of exoskeleton robots to provide strength support, restore motor function, and improve the rehabilitation experience. We hope that this study can provide reference and inspiration for future stroke rehabilitation work, and lay a foundation for further research and application.

References

[1]. Lou J A, Chen Q X, Liu C, Xiao L & Yang H M. (2023). Visual analysis of research hotspots in extended stroke care. Journal of Advanced Nursing, 38(03), 209-215.

[2]. Wang L D, Peng B, Zhang H Q, Wang Y L, Liu M, Shan C L & Ma M. (2022). Summary of China Stroke Prevention Report 2020. Chinese Journal of Cerebrovascular Diseases, 19(02), 136-144.

[3]. Talat, H., Munawar, H., Hussain, H., & Azam, U. (2022). Design, modeling and control of an index finger exoskeleton for rehabilitation. Robotica, 40(10), 3514-3538.

[4]. Zhang, H. (2022). Design, modeling, and characteristic analysis of an index finger exoskeleton for rehabilitation. In Journal of Physics: Conference Series 2405(1), 012012.

[5]. Liao B, Huang Y, Zou X & Li G. (2022). Finger exoskeleton design based on connecting rod mechanism. Science Technology & Engineering, 17, 6958-6965.

[6]. Li, G., Cheng, L., and Sun, N. (2022). Design, manipulability analysis and optimization of an index finger exoskeleton for stroke rehabilitation. Mechanism and Machine Theory, 167, 104526.

[7]. Khor, K. X., Chin, P. J. H., Yeong, C. F., Su, E. L. M., Narayanan, A. L. T., Rahman, H. A., & Khan, Q. I. (2017). Portable and reconfigurable wrist robot improves hand function for post-stroke subjects. IEEE Transactions on Neural Systems and Rehabilitation Engineering, 25(10), 1864-1873.

[8]. Xu, W., Liu, Y., and Ben-Tzvi, P. (2022). Design, analysis, and prototyping of a novel single degree-of-freedom index finger exoskeleton mechanism. In International Design Engineering Technical Conferences and Computers and Information in Engineering Conference. 86281, V007T07A047.

[9]. Agarwal, P., Fox, J., Yun, Y., O’Malley, M. K., and Deshpande, A. D. (2015). An index finger exoskeleton with series elastic actuation for rehabilitation: Design, control and performance characterization. International Journal of Robotics Research, 34(14), 1747-1772.

[10]. Haarman, C. J., Hekman, E. E., Rietman, J. S., and Van Der Kooij, H. (2023). Mechanical design and feasibility of a finger exoskeleton to support finger extension of severely affected stroke patients. IEEE Transactions on Neural Systems and Rehabilitation Engineering, 31, 1268-1276.

[11]. Li, J., Wang, S., Wang, J., Zheng, R., Zhang, Y., & Chen, Z. (2012). Development of a hand exoskeleton system for index finger rehabilitation. Chinese Journal of Mechanical Engineering, 25(2), 223-233.

[12]. Shao N, Zhou Q, Shao C, and Zhao Y. (2020). Research on flexibility characteristics of robot joints based on SEA. Combined Machine Tools and Automated Processing Technology, 11, 33-37.

[13]. Zheng L. (2021). Research on flexible wearable rehabilitation manipulator based on Vital interface (Master's thesis, Yanshan University).

Cite this article

Lu,X.;Wang,K.;Yu,H. (2024). Design, modeling and analysis of a novel index finger exoskeleton for stroke rehabilitation. Applied and Computational Engineering,31,303-317.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2023 International Conference on Machine Learning and Automation

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Lou J A, Chen Q X, Liu C, Xiao L & Yang H M. (2023). Visual analysis of research hotspots in extended stroke care. Journal of Advanced Nursing, 38(03), 209-215.

[2]. Wang L D, Peng B, Zhang H Q, Wang Y L, Liu M, Shan C L & Ma M. (2022). Summary of China Stroke Prevention Report 2020. Chinese Journal of Cerebrovascular Diseases, 19(02), 136-144.

[3]. Talat, H., Munawar, H., Hussain, H., & Azam, U. (2022). Design, modeling and control of an index finger exoskeleton for rehabilitation. Robotica, 40(10), 3514-3538.

[4]. Zhang, H. (2022). Design, modeling, and characteristic analysis of an index finger exoskeleton for rehabilitation. In Journal of Physics: Conference Series 2405(1), 012012.

[5]. Liao B, Huang Y, Zou X & Li G. (2022). Finger exoskeleton design based on connecting rod mechanism. Science Technology & Engineering, 17, 6958-6965.

[6]. Li, G., Cheng, L., and Sun, N. (2022). Design, manipulability analysis and optimization of an index finger exoskeleton for stroke rehabilitation. Mechanism and Machine Theory, 167, 104526.

[7]. Khor, K. X., Chin, P. J. H., Yeong, C. F., Su, E. L. M., Narayanan, A. L. T., Rahman, H. A., & Khan, Q. I. (2017). Portable and reconfigurable wrist robot improves hand function for post-stroke subjects. IEEE Transactions on Neural Systems and Rehabilitation Engineering, 25(10), 1864-1873.

[8]. Xu, W., Liu, Y., and Ben-Tzvi, P. (2022). Design, analysis, and prototyping of a novel single degree-of-freedom index finger exoskeleton mechanism. In International Design Engineering Technical Conferences and Computers and Information in Engineering Conference. 86281, V007T07A047.

[9]. Agarwal, P., Fox, J., Yun, Y., O’Malley, M. K., and Deshpande, A. D. (2015). An index finger exoskeleton with series elastic actuation for rehabilitation: Design, control and performance characterization. International Journal of Robotics Research, 34(14), 1747-1772.

[10]. Haarman, C. J., Hekman, E. E., Rietman, J. S., and Van Der Kooij, H. (2023). Mechanical design and feasibility of a finger exoskeleton to support finger extension of severely affected stroke patients. IEEE Transactions on Neural Systems and Rehabilitation Engineering, 31, 1268-1276.

[11]. Li, J., Wang, S., Wang, J., Zheng, R., Zhang, Y., & Chen, Z. (2012). Development of a hand exoskeleton system for index finger rehabilitation. Chinese Journal of Mechanical Engineering, 25(2), 223-233.

[12]. Shao N, Zhou Q, Shao C, and Zhao Y. (2020). Research on flexibility characteristics of robot joints based on SEA. Combined Machine Tools and Automated Processing Technology, 11, 33-37.

[13]. Zheng L. (2021). Research on flexible wearable rehabilitation manipulator based on Vital interface (Master's thesis, Yanshan University).