1. Introduction

The uniqueness and importance of Tesla Inc.'s supply chain management model as a leader in the electric vehicle industry. Through its innovative supply chain management model, Tesla has realized efficient production and operation and promoted the development of the electric vehicle industry. Studying this issue also has a learning role for Chinese enterprises in related industries, which is conducive to promoting the development of the Chinese market. This paper focuses on Tesla's advanced supply chain management model and the benefits and advantages that this supply chain management model brings to Tesla Company. This dissertation conducts research through literature survey method. The research in this thesis is of reference significance to China's automobile manufacturing industry.

2. Background of Automotive Corporate Supply Chain

2.1. General Status of China's Automotive Supply Chain

In the past decades, China's automobile industry has realized rapid development. However, behind the development, there are also some problems that need to be improved, including: first, the lack of overall awareness of enterprise managers. At this stage, some enterprises in the nodes of the supply chain are overly pursuing immediate interests, and lack the necessary thinking about the interests of upstream and downstream enterprises, which leads to the difficulty of forming a good situation of mutual benefit within the supply chain [1]; secondly, the information exchange is not smooth enough. Due to the great complexity of the automobile industry, supply chain managers still have many barriers to information interaction when they master product design and development, raw material supply, manufacturing, sales, after-sales service, logistics and other related information with the help of information technology, resulting in a lot of missing and delayed effective information and other problems [2].

2.2. Importance of Supply Chain Management for Enterprises

2.2.1. Efficiency Gains

Supply chain management can effectively improve the flow of products, materials and information to optimize overall operations and promote enterprise efficiency through accurate analysis of demand and sales forecasts. Meanwhile, to optimize inventory management, enterprises adopt advanced demand forecasting methods and inventory models to accurately predict demand and inventory levels and avoid over-or under-stocking. In addition, by establishing supplier and customer partnerships and enhancing information sharing and communication, companies can achieve supply chain optimization and efficiency gains. To better reduce supply chain risks, companies reduce their dependence on a single supplier or region by diversifying suppliers and sourcing sources to ensure the stability and reliability of the supply chain.

2.2.2. Cost Reduction

Supply chain tends to monitor the inflow and outflow of funds, helping business managers keep a close eye on operations to control costs and allocate resources. Supply chain management effectively reduces the operating costs of enterprises by optimizing procurement, production and logistics. For example, through rational supplier selection and procurement strategies, enterprises can reduce procurement costs; through lean production and continuous improvement, reduce waste in the production process; through efficient logistics and distribution, reduce inventory backlog and transportation costs. These cost reductions will be directly reflected in the profits of the enterprise and improve its profitability.

2.2.3. Quality Control

Effectively managing the supply chain is more inclined towards monitoring the most important tasks such as timely delivery, quality of the final product, conducting supplier quality assessment, checking compliance, etc. so that the quality of the company's products and services is reliably guaranteed. Supply chain management helps to ensure the quality of the final product. By building an effective quality management system and implementing stringent quality control measures, companies are able to significantly reduce the risk of product quality issues and provide their customers with products that meet their expectations. This not only helps in enhancing the company's reputation in the market but also enhances the trust and loyalty of the customers.

2.2.4. Risk Assessment

Supply chain management helps enterprises to cope with various risk challenges and enhance their resilience. In the context of globalization, supply chains face many uncertainties, such as natural disasters, political risks and trade frictions. By establishing a sound supply chain risk management mechanism, enterprises can identify and respond to potential risks in a timely manner to ensure the stable operation of the supply chain. In addition, enterprises can reduce the impact of supply chain risks on their operations by diversifying supplier strategies and establishing emergency backup plans.

2.2.5. Enhancing Customer Satisfaction and Market Competitiveness

Supply chain management is critical to improving customer satisfaction. Through accurate demand forecasting and timely inventory adjustment, enterprises can ensure that the supply of products matches the market demand and reduce out-of-stock or backlog phenomenon. At the same time, an efficient logistics and distribution system can ensure that products are delivered on time and increase customer satisfaction. In addition, quality supply chain management can also help enterprises achieve timely response in after-sales service and further enhance customer loyalty. All these will help enterprises to stand out in the fierce market competition.

2.2.6. Improving the Quality of Communication

Supply chain management helps to improve the efficiency of information flow. Through the establishment of effective communication channels and information sharing mechanisms, each link in the supply chain can obtain and transmit key information in a more timely manner, reducing information delays and deviations. This enables enterprises to more accurately grasp the dynamic situation in the supply chain and make timely decisions and adjustments in quality management, which can lead to more efficient and effective communication between enterprises, promote supplier synergy, and maintain a stable relationship is one of the main advantages of supply chain management.

3. Tesla's Supply Chain Management Model

3.1. Management's Strategy for Supply Chain Management

First, they have established a global supply chain network and close partnerships with suppliers around the world to ensure timely supply of required parts and materials [3]; Tesla emphasizes vertical integration of the supply chain. By designing, producing, and selling its cars in-house, Tesla is able to better control product quality, production efficiency, and reduce production costs. This strategy enables Tesla to have greater voice and flexibility in the supply chain and to respond more quickly to market changes. Secondly, Tesla has been working with its suppliers through long-term cooperation and sharing production plans and demand forecast information with them so that suppliers can prepare in advance and meet Tesla's needs; finally, Tesla also uses advanced technology and data analysis to optimize the supply chain operations and is constantly searching for new strategic partners in key areas of the automated supply chain [4]. Tesla focuses on the informatization and digitalization of the supply chain. By adopting advanced supply chain management systems and technologies, Tesla is able to monitor and manage supply chain data in real time, improving the transparency and controllability of the supply chain. This information technology enables Tesla to more accurately predict market demand, optimize inventory and logistics, and further improve the efficiency and responsiveness of the supply chain. At the same time, Tesla also focuses on the sustainability and environmental protection of the supply chain. In the process of supply chain management, Tesla actively promotes environmental protection and sustainability measures and is committed to building environmentally friendly cars. This strategy not only helps to improve the social image of the company but also reduces operating costs and improves competitiveness.

To summarize, Tesla management's strategy for supply chain management is diversified and comprehensive. Through vertical integration, cooperation with excellent suppliers, informatization and digitization, as well as focusing on sustainability and environmental friendliness, Tesla continues to optimize and improve the efficiency and competitiveness of its supply chain.

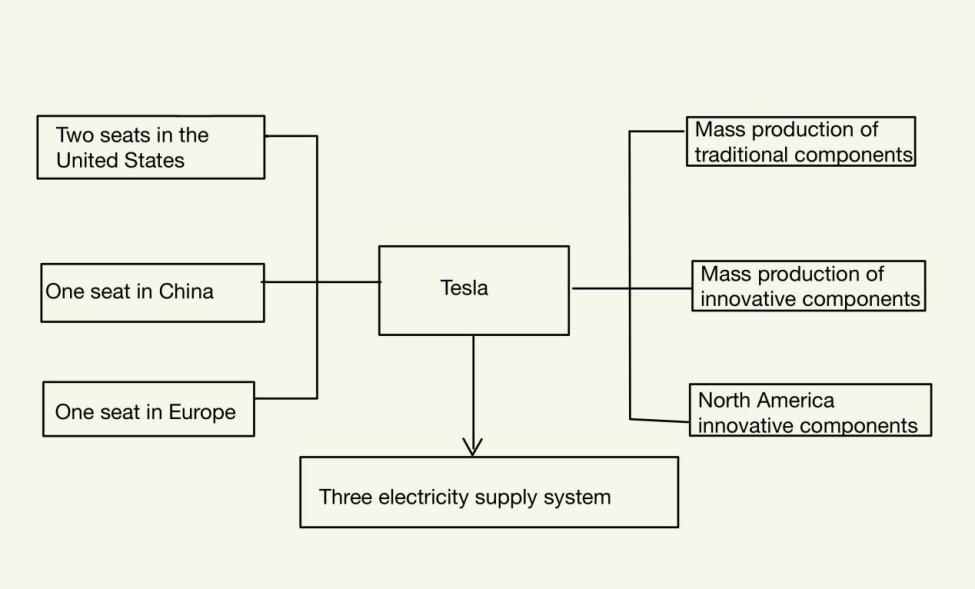

3.2. Adoption of Deep Vertically Integrated Supply Chains

The deeply vertically integrated supply chain model used by Tesla is a highly integrated and synergistic operation.This model enables Tesla to better control every step of the process from raw material procurement, manufacturing to product sales, thus optimizing production efficiency, reducing costs, and ensuring high product quality and consistency.This model enables Tesla to maintain its leading position in the fierce market competition, and at the same time, this model also lays a solid foundation for Tesla's future development and provides a strong guarantee for it to realize its longer-term goals. as shown in Figure 1, Tesla Inc. has supply chain layouts in China, the United States, and Europe, and the division of labor is very clear, with some supply chains manufacturing innovative parts and components, and some supply chains manufacture traditional parts and components.These components form another overarching triple power system supply chain.

Figure 1: Tesla Supply Chain Diagram

3.3. The Drive for Supply Chain Localization

First, establish close cooperation with local governments and enterprises to obtain policy and resource support; second, strengthen local R&D and innovation to adapt to different market demands and changes; in addition, optimize local supply chain management to ensure product quality and production stability. Tesla's parts localization rate in China has exceeded 95%, which means that more than 95% of the parts in Tesla's models produced in China are provided by local Chinese suppliers. This strategy not only strengthens Tesla's competitiveness in the Chinese market, but also promotes the development and internationalization of China's local supply chain. In addition, Tesla has signed contracts with more than 400 local Tier 1 suppliers, of which more than 60 have entered Tesla's global supply chain system. This in-depth cooperation model promotes the exchange of technology and experience and enhances the R&D and innovation capabilities and production efficiency of Chinese suppliers [5].

4. The Impact of Tesla's Strengthening of Supply Chain Management on Chinese Enterprises

4.1. Industrial Layout

New energy vehicles are not only the main direction for the transformation and upgrading of the global automobile industry but also a strategic choice for the high-quality development of China's automobile industry. In recent years, China has introduced a number of measures to strengthen policy support for new energy vehicles, and major automobile companies have significantly increased their R&D investment, which has enabled China's new energy vehicle industry to realize vigorous development. Tesla has laid out its production bases globally to meet the needs of different markets. This geographic distribution strategy helps to reduce transportation costs, shorten delivery time, and improve responsiveness to local markets.Meanwhile, Tesla's supply chain management also emphasizes environmental friendliness and promotes the use of renewable energy, providing a strong guarantee for the sustainable development of the industrial layout.

4.2. Increased Competitiveness and Earnings

Table 1: Comparison of Costs of Tesla Model 3 and BYD Song ProEV

Indicator models | Model 3 Standard Range Edition | Song ProEV Flagship |

Post-subsidy guide price | 24.9 | 21.98 |

Research and development costs | 4.54 | 3.28 |

Procurement costs | 6.45 | 5.46 |

Production costs | 6.23 | 6.44 |

Cost of sales | 5.02 | 4.23 |

Total cost | 22.24 | 19.41 |

Marginal profit | 2.66 | 2.57 |

In this thesis, two standard range versions of Tesla's most popular Model 3 and the flagship version of BYD's most popular Song ProEV were selected as comparisons of the above two models(see Table 1), respectively, and the data shows that Tesla's overall competitiveness is significantly better than that of BYD.

4.3. Industry Developments

In terms of production and sales, China's automobile hit a new record high in 2023, with production and sales both exceeding 30 million units, not only topping the world list for fifteen consecutive years, but also occupying nearly one-third of the global market share. Export momentum, 2023 new energy vehicle exports up to 1.2 million units, an increase of 77.6%, driving China's auto exports for the first time beyond Japan, jumped to the top of the world. In terms of policy support, the Central Economic Work Conference has pointed out the direction of boosting the consumption of new energy vehicles and other bulk consumption, and recently the National Development and Reform Commission, the Energy Bureau and other departments have also put forward the construction of "car network interaction" system with a clear goal.

5. Conclusion

This thesis focuses on the advanced supply chain management model of Tesla and the advantages of this supply chain management model for enterprise development, in addition, Chinese enterprises can learn this supply chain management model. Supply chain management can simultaneously pull raw material supply from upstream suppliers and promote product distribution from downstream distributors, as well as effectively balance customer service. Some of Tesla's successful marketing strategies are worth learning from, but the quality of its automobiles needs to be noted. The application and development of Tesla's supply chain management model have brought a lot of worthwhile thinking and reference to the Chinese automobile industry. In this way, domestic automobile enterprises need to combine the development of the actual, explore the supply chain management road in line with China's national conditions, market demand and their own needs, to help enterprises achieve faster and better development, and promote the prosperous development of China's automobile industry.

References

[1]. Lin Bo.Social Responsibility Challenges of Supply Chain Management in the Automotive Industry[J].WTO Economic Guide, 2018(11):48-50.

[2]. Wang Yu.Supply chain and logistics system upgrading in automotive industry[J].Logistics Technology and Application, 2018, 23(5):110-111.

[3]. Shen Wen, Yang Song, Li Mengying, et al.Research on Supply Chain Inventory View and Its Management Problems in Automotive Industry[J].Logistics Technology, 2017, 36(5):115-120, 142.

[4]. Mao Lijia.Research on supply chain management analysis and countermeasures in automobile industry [J].China Management Informatization, 2015, 18(20):125.

[5]. Zheng Qingting.Tesla Tao Lin Answer 21: Tesla's Production Advantage Cannot Be Separated from China's Supply Chain, 2023.

Cite this article

Xiang,J. (2024). Implications of Tesla's Supply Chain Management Model for Businesses. Advances in Economics, Management and Political Sciences,86,219-224.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2nd International Conference on Management Research and Economic Development

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Lin Bo.Social Responsibility Challenges of Supply Chain Management in the Automotive Industry[J].WTO Economic Guide, 2018(11):48-50.

[2]. Wang Yu.Supply chain and logistics system upgrading in automotive industry[J].Logistics Technology and Application, 2018, 23(5):110-111.

[3]. Shen Wen, Yang Song, Li Mengying, et al.Research on Supply Chain Inventory View and Its Management Problems in Automotive Industry[J].Logistics Technology, 2017, 36(5):115-120, 142.

[4]. Mao Lijia.Research on supply chain management analysis and countermeasures in automobile industry [J].China Management Informatization, 2015, 18(20):125.

[5]. Zheng Qingting.Tesla Tao Lin Answer 21: Tesla's Production Advantage Cannot Be Separated from China's Supply Chain, 2023.