1. Introduction

With the rapid development of the global economy and the increasingly fierce market competition, enterprises have put forward higher requirements for the efficiency and cost control of supply chain management. As a key link in supply chain management, the efficiency of inventory management directly affects the inventory turnover rate, capital occupation and customer satisfaction of enterprises [1]. In recent years, the rapid development of artificial intelligence technology has provided new possibilities for optimizing inventory management. Compared with humans, artificial intelligence has the ability to integrate data, accurately and quickly handle problems, thereby optimizing each link to improve overall efficiency. In this regard, this article will take Amazon as an example to explore the ideas and applications of artificial intelligence in optimizing supply chain inventory management, aiming to provide enterprises with effective solutions to improve inventory management efficiency and reduce costs, and provide new perspectives and ideas for the research on artificial intelligence applications in the field of supply chain management.

2. Overview of Supply Chain

The supply chain plays a vital role in the success of an enterprise, ensuring timely, cost-effective delivery of products to customers [2]. Inbound management involves coordinating the transportation of goods from suppliers to manufacturers or warehouses, which is a complex and challenging task. Traditional inbound management methods rely on manual processes and human decision-making, which is time-consuming and error-prone [3]. Artificial intelligence technologies such as machine learning, natural language processing, and predictive analysis provide new opportunities for automating and optimizing inbound management processes.

Amazon, one of the world's largest e-commerce companies, is a pioneer in using artificial intelligence technology to optimize supply chain operations. The company uses artificial intelligence algorithms to predict demand and improve transporting routes. By analyzing massive amounts of data in real time, Amazon makes smart decisions to streamline the inbound process and efficiently meet customer needs. This case study provides valuable insights into the potential of AI in transforming warehouse management.

3. Background of Amazon

As the world's leading e-commerce platform, Amazon's supply chain management system relies heavily on artificial intelligence technology. In terms of warehousing management, Amazon uses intelligent warehousing robots and automated sorting systems to achieve fast and accurate warehousing of goods. At the same time, through big data analysis and machine learning algorithms, Amazon can predict inventory demand in the future, optimize warehousing plans and procurement strategies, and reduce inventory backlogs and out-of-stock phenomena [4]. Amazon uses big data analysis and machine learning algorithms for intelligent forecasting to achieve accurate demand planning. By analyzing historical sales data, market trends and consumer behavior, machine learning models can generate more accurate demand forecasts to help reduce excess inventory or out-of-stock situations. According to Amazon data, after applying intelligent forecasting technology, inventory turnover has increased significantly and out-of-stock rates have decreased by about 30%.

At the same time, Amazon launched a warehousing configuration service, allowing sellers to choose sub-warehouse or lock-warehouse services according to demand to optimize inventory distribution [5]. This service is based on AI algorithm analysis and provides sellers with the best inventory configuration plan based on product sales, transportation costs and consumer distribution. Datas from website show that sellers who choose sub-warehouse services have shortened their average product delivery time by 20% and reduced transportation costs.

Amazon's robotic warehousing system stands as a hallmark of innovation in the logistics and supply chain industry. By integrating advanced robotics, artificial intelligence, and automation, Amazon has transformed its fulfillment centers into highly efficient ecosystems that can meet the demands of modern consumers.

At the heart of this system are robotic units, such as the Kiva robots, which play a crucial role in inventory management [6]. These robots are designed to navigate the expansive warehouse floors, transporting shelves filled with products directly to human pickers. This dramatically reduces the time workers spend walking between shelves, allowing them to focus on the task of picking items for customer orders. The efficiency gained from this system is staggering which enables Amazon to process a higher volume of orders in a shorter timeframe, ultimately leading to faster delivery times for customers.

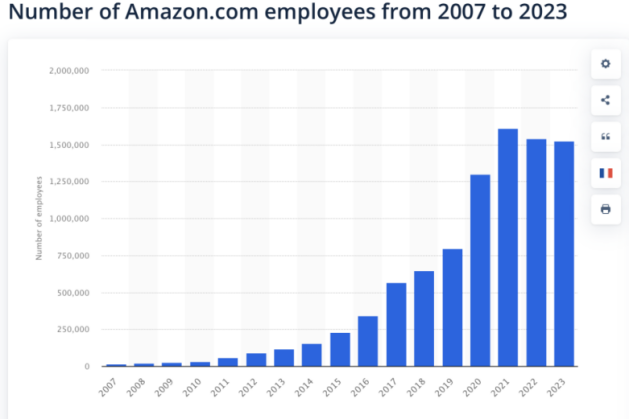

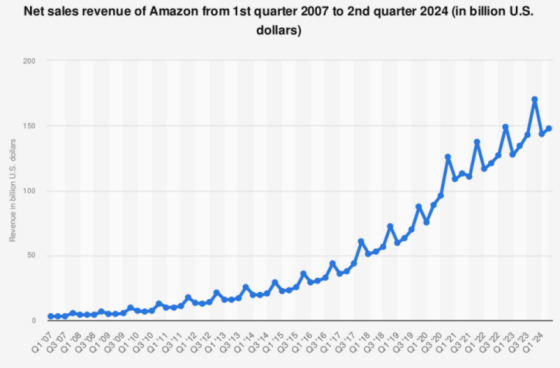

In addition to robotic picking, automated guided vehicles (AGVs) and conveyor systems enhance the flow of goods within the warehouse. AGVs transport items to various locations, while conveyor belts streamline the sorting and shipping processes. This interconnected network of automation not only accelerates operations but also minimizes human error, ensuring a more reliable order fulfillment process. Amazon has reduced labor costs and significantly increased its net income after introducing artificial intelligence. As can be seen in figure 1 and figure 2.

Figure 1: Number of employees in Amazon from 2007 to 2023.

Figure 2: Net sales revenue of Amazon from 1st quarter 2007 to 2nd quarter 2024 in billion U.S. dollars.

3.1. Amazon’s Robotic Warehousing System

Amazon uses a self-developed logistics system that combines robotics technology with artificial intelligence to achieve intelligent management of warehouses and significantly improve distribution efficiency. Amazon's robotic warehousing system is mainly composed of an unmanned robot called AGV (automatic guided vehicle). These robots are responsible for the handling of goods in the warehouse, thereby minimizing the need for manpower in the warehouse. Through wireless communication and navigation systems, robots can efficiently and accurately complete the tasks of picking up and storing goods without human intervention.

In Amazon's warehouses, the speed and intelligence of robots are amazing. Robots can move at high speed in busy warehouses, avoid collisions through infrared sensors, accurately pick up goods taken from shelves, and then deliver them to designated locations [7]. This intelligent warehousing system operates quickly and accurately, greatly improving the efficiency and productivity of Amazon warehouses. In addition, Amazon's robotic warehousing system is also combined with artificial intelligence technology, which can store goods in warehouses in an orderly manner according to the purchasing preferences and purchasing habits of different users, so as to achieve fast and accurate delivery. Based on user needs and purchase history, robots can move goods according to the optimal path and shortest time, improving delivery efficiency.

3.2. Application of The Shortest Path in Warehousing

In the dynamic environment of warehouse management, efficiency and speed are essential to maintaining a competitive advantage. The shortest-path problem is one of the most effective

mathematical concepts, which aims to determine the most efficient route between points in a network. It involves finding the shortest path or minimum distance between two nodes (or vertices), and it has many applications in optimizing warehouse operations. By utilizing the shortest path algorithm, warehouses can improve picking efficiency, streamline inventory management, optimize the use of automated guided vehicles (AGVs), and improve overall resource allocation. In the above article, Amazon uses automated guided vehicles in warehouse management, so the shortest path can be applied to improve management efficiency.

3.2.1. Optimize Picking Routes

One of the main applications of the shortest path problem in warehouse management is to optimize picking routes. In a typical warehouse, items are stored in various locations, and order pickers must travel through aisles to collect products for shipment. By applying the shortest path algorithm, the warehouse can calculate the most efficient route for pickers to follow. This not only reduces the time required to collect items, but also minimizes the physical exertion required by workers. With a more efficient picking process, warehouses can significantly increase order fulfillment speed, thereby improving customer satisfaction and reducing labor costs.

In the intricate labyrinth of a warehouse, where merchandise is meticulously organized across diverse shelves and storage locations, the challenge lies in designing a strategy that enables order pickers to swiftly navigate from point A to point B, accumulating the required products along the way with minimal delay or redundancy. By harnessing the power of shortest-path algorithms, warehouses can unlock a new level of precision and efficiency in route planning. These algorithms, often drawing upon advanced mathematical models like the Dijkstra’s Algorithm for Mobile Robot Path Planning, and optimization techniques, meticulously analyze the warehouse layout, including the position of every item, the dimensions of aisles, and even potential obstructions, to devise the optimal path for each order. This process considers the shortest distance between points and factors in other critical variables such as traffic congestion, weight distribution across a picker's route, and even the likelihood of finding items in their designated locations without having to backtrack or search extensively.

3.2.2. Promote Effecient Warehousing

The shortest path also enables efficient warehousing. By analyzing the frequency of picking items, warehouse managers can identify patterns and trends in product movement. The shortest path algorithm can then be used to strategically rearrange inventory, placing frequently picked items in closer locations. This optimization reduces the distance workers must travel to retrieve products, thereby improving overall operational efficiency. When items are arranged in a way that minimizes travel time, warehouses can maintain higher throughput levels, ultimately achieving better resource utilization.

As mentioned above, many warehouses now use automated guided vehicles (AGVs) to efficiently transport goods. The movement of these vehicles can be optimized by the shortest path algorithm, which calculates the most efficient route for the AGV to follow when delivering items to various locations within the warehouse. By ensuring that the AGV takes the shortest path, warehouses can reduce delivery times, avoid congestion in high-traffic areas, and enhance overall goods flow. This not only improves operational efficiency, but also reduces operating costs related to vehicle maintenance and energy consumption. In addition to optimizing individual picking routes, the shortest path can also solve the problem of order batching processes. When an order contains multiple items, merging orders for efficient picking can save a lot of time. By analyzing the location of the items and applying the shortest path algorithm, the warehouse can determine the best batch of orders to pick together. This strategy minimizes the total travel distance, allowing pickers to collect items faster and more efficiently. The result is a streamlined picking process that helps speed up order processing and improve service levels.

3.2.3. Dijkstra’s Algorithm for Mobile Robot Path Planning

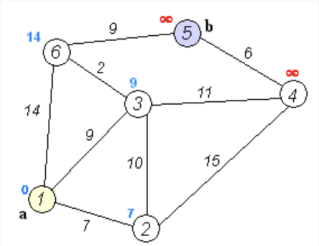

Shortest-path problem entails determining the minimal distance between two vertices in a weighted graph. Formally, given a graph G=(V, E), where V represents a set of vertices and E denotes a set of edges with weights w(u,v), the objective is to ascertain the shortest path from a source vertex s to a destination vertex d [8]. The figure 3 shows the diagram of this algorithm’s module.

Figure 3: Graphical method of Shortest-Path Problem. Source from Wikipedia.

Dijkstra's algorithm is widly used to solve the shortest-path problem in graphs with non-negative weights. Dijkstra's algorithm initializes distances from the source to all vertices as infinity, except for the source itself, which is set to zero [9]. It uses a priority queue to iteratively extract the vertex with a minimal distance. For each extracted vertex, updating the distances to its neighbors and repeat until all vertices have been processed. Let G=(V,E) represent the warehouse layout, where each vertex corresponds to a location (e.g., storage shelf, packing station) and each edge represents the path between locations with a weight corresponding to distance or time.

Let:

d[v] = shortest distance from source s to vertex v

prev[v] = predecessor of vertex v in the path

The update rule can be mathematically represented as follow:

\( d[v] =min(d[v],d[u]+w(u,v) \) (1)

The temporal complexity of Dijkstra's algorithm employing a priority queue (binary heap) is O( (V+E) log V), with V representing the number of vertices and E denoting the number of edges [10]. In Amazon's fulfillment centers, products are stored in various locations. When an order is placed, the warehouse management system can quickly determine the optimal picking route through this algorithm to minimize time and maximize efficiency.

The adoption of this algorithms translates into tangible benefits for both the warehouse and its customers. Firstly, the reduced travel time for order pickers directly leads to a faster turnover of orders, enabling warehouses to fulfill customer demands more promptly. This Accelerated order fulfillment speed is a key differentiator in today's competitive retail landscape, where speed and reliability are paramount to maintaining customer satisfaction and loyalty. Secondly, by minimizing the physical exertion required of workers, the shortest path approach promotes a safer and healthier work environment. By optimizing routes to limit unnecessary walking or lifting, warehouses can help prevent injuries and burnout, ensuring a more sustainable and motivated workforce. Moreover, the enhanced operational efficiency unlocked by shortest-path algorithms has the potential to significantly reduce labor costs. By reducing the time and effort needed to complete orders, warehouses can potentially allocate resources more effectively, such as reducing the number of pickers needed for a given workload or reallocating them to other value-added tasks.

4. Challenges and Future Development

4.1. Data Security Issues and Uncertainty

With the application of artificial intelligence and big data technologies, SCM needs to process a large amount of sensitive data, including customer transaction records, supplier information and inventory levels. The unauthorized disclosure of this data could result in the theft of trade secrets, erosion of customer trust, and potential legal liabilities. In the future, companies need to strengthen data protection measures and adopt encryption technology, multi-factor authentication and other means to ensure data security. At the same time, the improvement of policies and regulations (such as GDPR) will also prompt companies to be more standardized and transparent in data management.

AI technology is updated rapidly, and new algorithms, tools and platforms are constantly emerging, making it difficult for companies to keep up with the pace of technological development. This uncertainty may lead to increased investment risks and affect corporate decision-making and strategic planning. After introducing a new AI inventory management system, a manufacturing company found that the system was not compatible with its existing ERP system, resulting in interruptions in business processes and eventually having to re-evaluate technology investment. In order to cope with the rapid changes in technology, companies should establish a flexible technology architecture and choose modular and compatible solutions. In addition, continuous training and learning will enable employees to quickly adapt to new technologies and reduce the risks brought about by technological changes.

4.2. Dynamic Handling Problem of Multiple Robots

In picking operations, with the increase in the number of handling robot sizes, problems such as obstacle avoidance, congestion coordination, and conflict handling need to be considered at the same time, which greatly increases the complexity of path planning. Before this, some researchers have carried out preliminary research work on some simplified subproblems in intelligent warehouse systems, including scholars such as Hazard [11], who studied the static goods allocation problem, and Li [12], who studied the static task assignment and path planning problems. However, these research works are for the static situation and do not consider the continuity of the actual order picking process and the correlation between the various links. There are fewer studies on cooperative operation and dynamic obstacle avoidance of handling robots in dynamic environments, and a single algorithm is difficult to solve the multi-handling robot path planning problem with progressively higher complexity. And the existing research is less to run the shortest time as the optimisation goal, the busy degree of the path, the handling robot's start-stop, steering times for the robot's running time also has a great impact on the shortest distance as the objective function to solve the path planning problem is difficult to meet the actual needs of e-commerce enterprises. Therefore, the company can refer to the research of Xinmiao Wang in the dynamic path optimisation of multiple handling robots in warehouse operations [13].

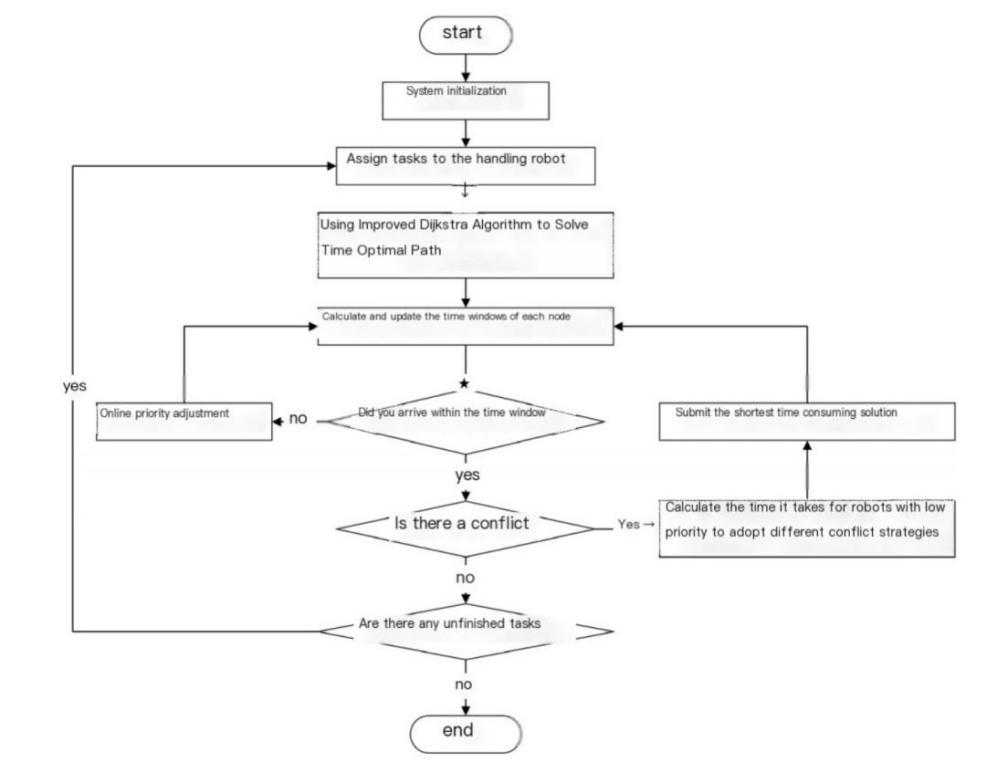

To eliminate the problem, it was suggested to add path heat to the Dijkstra algorithm to generate the global time-optimal path. The online phase performs real-time scheduling based on the priority of the handling robots to avoid and resolve path conflicts. The flow of the two-phase dynamic path planning algorithm for multiple handling robots with time windows is shown in figure 4 below.

Figure 4: Flowchart of multi-handling robot path planning algorithm.

In this way, Amazon can optimise the dynamic paths of multiple handling robots in warehouse operations to improve the efficiency and safety of AVG.

4.3. Problems of collaboration between AI and employees

Applying AI in supply chain may cause employees worrying about job security, especially in links with a high degree of automation. This fear may lead employees to resist new technologies, thus affecting the effective implementation of AI. In the face of this problem, companies need to take measures to promote the collaboration between AI and employees, for example, by training employees to improve their skills so that they can work with AI systems, while emphasizing the auxiliary nature of AI rather than its replacement. Establishing a good communication mechanism and enhancing employees' understanding and acceptance of new technologies will help achieve better synergy.

5. Conclusion

The application of AI in optimizing supply chain inventory management, as demonstrated by Amazon, has provided valuable insights into the potential of robotic technology in transforming traditional supply chain operations. By leveraging AI algorithms for demand prediction, inventory optimization, and transportation planning, Amazon has successfully increased its efficiency in warehousing.

Through the integration of robotic warehousing systems and automated guided vehicles, along with the utilization of shortest path algorithms for route optimization, has revolutionized warehouse operations, enabling faster order fulfillment and improved resource utilization. Furthermore, the implementation of Dijkstra's algorithm for mobile robot path planning has enhanced the efficiency and safety of warehouse operations, facilitating faster turnover of orders and reducing labor costs. Despite the challenges such as data security issues, technological uncertainty, and employee resistance, companies can address these by strengthening data protection measures, adopting flexible technology architectures, and promoting collaboration between AI and employees. The future development of AI in supply chain management will require companies to continuously adapt to technological advancements, implement efficient path planning solutions for multiple robots, and foster a harmonious relationship between AI systems and human workers.

Overall, integrating AI technologies into supply chain management presents significant opportunities for optimizing inventory processes, and enhancing operational efficiency. By adopting AI-driven innovations, the company improves the satisfaction of customers with the products and services they provide. Organizations can maintain competitiveness in the rapidly evolving global market and achieve sustainable growth in the digital era.

References

[1]. Arntzen, B., Brown, G., Harrison, T., & Trafton, L. (1995). Global supply chain management at digital equipment corporation. Interfaces, 25(1), 69-93.

[2]. Chopra, S., & Meindl, P. (2019). Supply chain management: strategy, planning, and operation (7th ed.). Pearson.

[3]. Heizer, J., & Render, B. (2019). Operations management: sustainability and supply chain management (12th ed.). Pearson.

[4]. Li, S., Ragu-Nathan, B., Ragu-Nathan, T. S., & Rao, S. S. (2006). The impact of supply chain management practices on competitive advantage and organizational performance. Omega, 34(2), 107-124.

[5]. Gunasekaran, A., & Ngai, E. W. (2005). Build-to-order supply chain management: a literature review and framework for development. Journal of Operations Management, 23(5), 423-451.

[6]. Simchi-Levi, D., Kaminsky, P., & Simchi-Levi, E. (2008). Designing and managing the supply chain: concepts, strategies, and case studies (3rd ed.). McGraw-Hill.

[7]. Ivanov, D., Dolgui, A., Sokolov, B., & Werner, F. (2018). A comprehensive framework for substitution-based supply chain planning and its application in pharmaceutical industry. Omega, 74, 1-18.

[8]. Dijkstra, E.W. (1959). A Note on Two Problems in Connexion with Graphs. Numerische Mathematik, 1(1), 269-271.

[9]. Cormen, T. H., Leiserson, C. E., Rivest, R. L., & Stein, C. (2009). Introduction to Algorithms. MIT Press.

[10]. Lee, J., & Lee, D. (2020). Dynamic Shortest Path Algorithms: A Survey. Journal of Combinatiorial Optimization.

[11]. Hazard, C.J. and Wurman, P.R. (2006). Alphabet Soup: A Testbed for Studying Resource Allocation in Multi-Vehicle Systems. Proceedings of the 2006 AAAI Workshop on Auction Mechanisms for Robot Coordination. 23-30.

[12]. Li, W., Jiang, L. and Li, Z. (2016) Research on the Task Assignment Problem of Warehouse Robots in the Smart Warehouse. 12th International Symposium on Operations Research and Its Applications in Engineering, Technology and Management. 29-33.

[13]. Wang, X.M. (2019). Dynamic path optimisation of multiple handling robots in warehouse operations[J]. Artificial Intelligence and Robotics Research. 8(2), 68-82.

Cite this article

Li,Z. (2024). Review of Application of AI in Amazon Warehouse Management. Advances in Economics, Management and Political Sciences,144,1-8.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of ICFTBA 2024 Workshop: Finance's Role in the Just Transition

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Arntzen, B., Brown, G., Harrison, T., & Trafton, L. (1995). Global supply chain management at digital equipment corporation. Interfaces, 25(1), 69-93.

[2]. Chopra, S., & Meindl, P. (2019). Supply chain management: strategy, planning, and operation (7th ed.). Pearson.

[3]. Heizer, J., & Render, B. (2019). Operations management: sustainability and supply chain management (12th ed.). Pearson.

[4]. Li, S., Ragu-Nathan, B., Ragu-Nathan, T. S., & Rao, S. S. (2006). The impact of supply chain management practices on competitive advantage and organizational performance. Omega, 34(2), 107-124.

[5]. Gunasekaran, A., & Ngai, E. W. (2005). Build-to-order supply chain management: a literature review and framework for development. Journal of Operations Management, 23(5), 423-451.

[6]. Simchi-Levi, D., Kaminsky, P., & Simchi-Levi, E. (2008). Designing and managing the supply chain: concepts, strategies, and case studies (3rd ed.). McGraw-Hill.

[7]. Ivanov, D., Dolgui, A., Sokolov, B., & Werner, F. (2018). A comprehensive framework for substitution-based supply chain planning and its application in pharmaceutical industry. Omega, 74, 1-18.

[8]. Dijkstra, E.W. (1959). A Note on Two Problems in Connexion with Graphs. Numerische Mathematik, 1(1), 269-271.

[9]. Cormen, T. H., Leiserson, C. E., Rivest, R. L., & Stein, C. (2009). Introduction to Algorithms. MIT Press.

[10]. Lee, J., & Lee, D. (2020). Dynamic Shortest Path Algorithms: A Survey. Journal of Combinatiorial Optimization.

[11]. Hazard, C.J. and Wurman, P.R. (2006). Alphabet Soup: A Testbed for Studying Resource Allocation in Multi-Vehicle Systems. Proceedings of the 2006 AAAI Workshop on Auction Mechanisms for Robot Coordination. 23-30.

[12]. Li, W., Jiang, L. and Li, Z. (2016) Research on the Task Assignment Problem of Warehouse Robots in the Smart Warehouse. 12th International Symposium on Operations Research and Its Applications in Engineering, Technology and Management. 29-33.

[13]. Wang, X.M. (2019). Dynamic path optimisation of multiple handling robots in warehouse operations[J]. Artificial Intelligence and Robotics Research. 8(2), 68-82.