1. Introduction

The notion of reverse logistics first emerged in the 1980s, but due to limited early research interest and a lack of practical implementation, progress in this area was initially slow and predominantly descriptive. Entering the 21st century, as environmental awareness expanded and global recycling policies were introduced, reverse logistics garnered increasing attention from both academia and industry, leading to a rapid proliferation of related research. In recent years, fueled by heightened emphasis on environmental sustainability, legislative mandates, corporate social responsibility (CSR), and the drive for sustainable competitive advantage, reverse logistics has become an indispensable element of corporate strategic planning. Many companies now view it as a strategic tool that not only enhances economic benefits but also improves corporate image [1].

The rapid rise of e-commerce and evolving consumer behavior have led to increasingly diverse purchasing channels and a significant increase in return rates. Notably, the return rate in the e-commerce sector far exceeds that of traditional retail, resulting in higher logistics costs and increased product loss [2]. Against the backdrop of increasing global resource constraints, improving the resource recovery rate has become a focal point of societal concern. Consequently, effectively managing product returns in e-commerce channels and minimizing associated losses have emerged as critical challenges for enterprises.

Throughout the literature in the past decade, research on reverse logistics has made significant progress and provided valuable insights into areas such as network design and supply chain coordination. However, it has not directly addressed the optimization of loss reduction within the reverse logistics process. This year, Procter & Gamble (P&G) and Jingdong Group(JD), as leaders in supply chain and logistics management, leveraged their extensive experience and advanced technical support to jointly launch the "Pampers Newborn Project" for the return processing of specialized baby diapers. This initiative enabled JD to establish the industry's first brand-collaborative reverse logistics chain, achieving efficient operation across the entire chain to minimize losses. It also serves as a valuable practical case for the entire industry.

This paper uses the "Pampers Newborn Project" as a case study to explore how to achieve efficient reverse logistics operations through comprehensive loss reduction strategies. By analyzing the project's implementation process, this research aims to provide theoretical guidance and practical recommendations for enterprises to optimize overall reverse logistics efficiency, reduce resource waste, and enhance operational efficiency and sustainable development capabilities.

2. Case Background

According to industry data, the return rate for e-commerce transactions is currently two to three times higher than that of physical offline sales, ranging from 20% to 50%. During holidays and special promotional periods, this figure can escalate to as high as 30% on average across e-commerce platforms [3]. JD, as one of the largest self-operated e-commerce platforms in China, is at the forefront of reverse logistics solutions. Meanwhile, P&G as the world's largest fast-moving consumer goods company, has a strategic partnership with JD that holds significant importance. Through the Pampers Newborn Project, P&G and JD leveraged their mature supply chain systems and deep cooperation to establish end-to-end supply chain synergies. This collaboration successfully addressed long-standing reverse logistics challenges in the e-commerce industry, reducing losses across the entire chain and operationalizing a Standard Operating Procedure (SOP) that can be replicated for other brands.

The JD platform, for instance, currently handles consumer returns in two primary ways. One approach is to return products to the supplier, with the brand bearing the associated loss. The other method involves reselling returned items at a discount through secondary platforms, with JD absorbing the loss. However, neither of these methods fundamentally eliminates losses. By analyzing the reasons for returns of mother and baby products, JD found that nearly 70% of Pampers returns were due to incorrect size selection or mismatch, while approximately 60% of returned items had only damaged packaging or were returned in their original boxes [3]. Based on these findings, JD proposed an improvement strategy: first, enhance preventive measures by optimizing page information and customer service guidance to assist consumers in selecting the correct size, thereby reducing returns and exchanges; second, establish a reverse box exchange process where products meeting specific criteria are sent back to the P&G box exchange center. After quality control by the brand, these products can be resold as new if they meet factory standards. This strategy not only effectively reduces resource waste and product return losses but also enhances supply chain efficiency and product reuse rates, forming the core operational model of the JD Pampers Newborn Project.

3. Case Analysis

During the project preparation phase, both parties reached a consensus on strategic cooperation regarding exchange standards, contract details, operational SOPs, and the requirement to standardize operating protocols. Standardized SOPs were issued to guide the national returns centers.

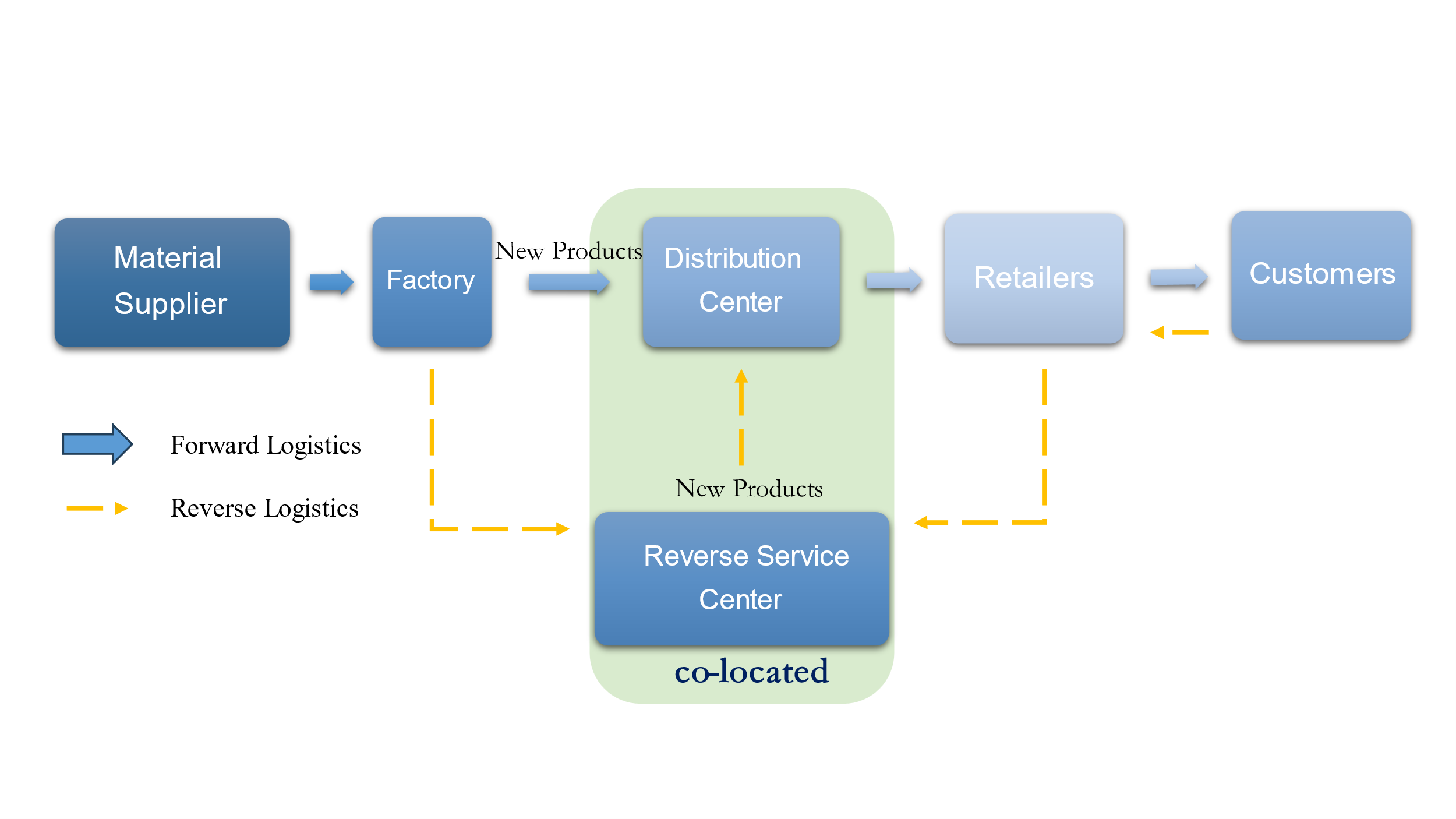

In the project operation phase, three initiatives were promoted concurrently. The end-to-end supply chain collaboration process for the project is illustrated in Figure 1.

Figure 1: JD-P&G Supply Chain Collaboration Framework (Picture credit: Original).

3.1. Supplier-Brand Synergy

After P&G's 2C product quality standard training, the box replacement center will screen returned products that meet the criteria for box replacement according to the established standards. Following quality inspection and statistical analysis, these products will be transported by JD Logistics to the P&G box replacement center. After maintenance at the box replacement center confirms that the products fully comply with the standard requirements for normal 2C product sales, they will undergo factory identification and confirmation. JD Logistics will then collect the goods and return them to the JD Returns Center for a second quality inspection before being sent back to the JD main warehouse for resale.

Returned products may be subject to outright disposal if they cannot be recycled or refurbished, resulting in a significant waste of resources. The complexity of operational processes and inefficiencies within recycling and remanufacturing networks exacerbate this issue, further increasing the risk of resource wastage [4]. This establishes a clear process for returning products to the box exchange center, ensuring that all eligible products are repaired and reintegrated into the main warehouse for re-entry into the sales chain, thereby improving the reuse rate of returned products. By centralizing quality inspection and repair operations at the box exchange center, processing efficiency is enhanced, and the cost associated with individual product returns is reduced.

It is worth noting that reverse logistics frequently lack SOPs, leading to extended lead times for returns or repairs. This issue may be further exacerbated by logistical delays and processing bottlenecks within complex recovery networks [5]. P&G's maintenance and quality inspection of returned products may introduce time delays, potentially causing products to be stranded during the maintenance process, thereby affecting the rapid turnover of returned items. Meanwhile, JD Logistics plays a pivotal role in the transportation and distribution process, with overall efficiency heavily reliant on logistics performance. However, during peak periods or when logistics capacity is insufficient, delays in distribution can occur. This necessitates robust standardization and processes for both parties to ensure effective implementation and operational strategies. Leveraging big data and artificial intelligence for predictive analysis of returned products, enhancing inventory information sharing between the box exchange center and the main warehouse, and issuing early warnings can help ensure efficient product flow and further improve overall efficiency.

3.2. Efficient Management of Reverse Service Centers

Upon arrival at the reverse service center, products to be exchanged are subject to stringent SKU hierarchical management. Different quality statuses within each SKU are categorized and stored in sub-regional areas. All operational areas comply with P&G's management standards for its products, ensuring process control and quality control from receipt of goods through processing, carton selection, coding, and labeling. Meanwhile, JD's returns warehouse begins accumulating the next batch of customer returns. Specialized teams handle batch-to-batch communication interfaces between parks, vehicles, and warehouses, ensuring seamless coordination across all stages. This "people and goods field" tandem coupling ensures the entire process remains reasonable and efficient.

Due to prolonged processing times and inadequate collection and utilization of data on return reasons, returned merchandise may miss the optimal window for re-sale, leading to depreciation. This is particularly problematic in time-sensitive industries such as food and pharmaceuticals, where delays can make it more challenging for companies to refurbish and redistribute products, resulting in lost market opportunities [6]. This phased management approach facilitates the gradual processing of return backlogs, ensuring that each batch of products is handled in the shortest possible time. This method also prevents inventory loss due to prolonged stock accumulation, which can lead to stagnation or obsolescence.

Since a typical inventory system often contains a vast number of items, each with unique characteristics such as price, demand, and physical attributes, analyzing each item individually would exceed any manager's capacity and resources. Therefore, SKU hierarchical management is a critical lever in effective inventory management [7]. However, SKU hierarchical management necessitates significant time, manpower, and technical support for the detailed classification of product quality. Optimizing the coupling between human and cargo fields requires precise deployment of park, vehicle, and warehouse resources, which imposes extremely high demands. Products with different quality statuses must be stored and operated in separate areas, leading to increased management complexity. To mitigate this, redundancy in the technical system can be enhanced to prevent information loss or transmission errors due to system failures. Additionally, dynamic adjustment and cross-regional coordination mechanisms can be established to reduce over-reliance on a single region and ensure flexible adjustments in the connection between batches based on actual return volumes.

3.3. Optimize Inventory Allocation

In reverse logistics, the uncertainty surrounding the quality and quantity of returned products often presents companies with challenges such as increased handling costs, difficulties in inventory management, and resource wastage [6]. JD and P&G have successfully optimized inventory allocation through collaborative warehousing by deeply co-creating the warehouse network. The main warehouse of P&G and its box exchange center are located at the same address, while JD's main warehouse is situated in the same park as P&G's main warehouse. This collaborative warehousing setup allows P&G's exchanged products to be directly transferred from its box exchange center to JD's main warehouse within a 50-meter distance, achieving an ultra-short supply chain. The sharing of warehousing and logistics facilities between JD and P&G centralizes and streamlines the handling of product returns, thereby avoiding resource wastage across multiple warehouses and transportation nodes. Through this collaborative warehousing model and precise inventory management, excessive return backlogs in the warehouse can be reduced, preventing expired or unsalable products from occupying valuable storage space and thus minimizing losses.

In addition, in this case, cartons were delivered from the factory to the reverse service center using a "forward finished goods + reverse cartons" approach. Optimizing efficiency and performance necessitates integrating both customer and supplier processes to facilitate interaction, with trust significantly moderating the relationship between supply chain partner integration and organizational performance [8]. Collaboration between customer reverse return and exchange demands and positive product supply planning ensures timely and appropriate allocation of on-hand carton inventory to support high-frequency carton exchanges and rapid goods flow while minimizing additional costs associated with carton shortages for minimum order quantities.

Collaborate with sustainable forward and reverse logistics providers to effectively manage both upstream and downstream flows concurrently [9]. This combined transportation mode can theoretically reduce resource waste, but in practice, forward supply and reverse carton exchange demands may have conflicting timing or priorities. It is essential to prioritize core demand, ensuring the protection of critical business operations (e.g., forward product supply) in case of conflicts. Contingency plans should be developed to rapidly activate alternate suppliers or alternatives in the event of tight carton inventory, thereby ensuring that both forward and reverse demand remain unaffected.

4. Industry Insights and Reference Value

Through an in-depth analysis of the Pampers Newborn Project, this study has derived several valuable insights that offer significant guidance for the industry as a whole.

First and foremost, the program underscores the critical role of end-to-end supply chain collaboration. Establishing a seamless closed-loop process from consumer returns through product repackaging to resale in the main warehouse, not only enhances operational efficiency but also significantly reduces logistics costs. This demonstrates that in reverse logistics, data sharing, process standardization, and shortening the logistics chain can markedly improve resource utilization and minimize unnecessary losses. This comprehensive optimization model serves as a valuable reference for enterprises in the same industry.

Secondly, the implementation of SKU hierarchical management in this project underscores the importance of granular management. By meticulously categorizing the quality status of returned products and applying targeted measures to address them, it not only accelerates inventory turnover but also prevents resource wastage due to varying quality levels. This demonstrates that enterprises in the same industry can leverage intelligent management tools to finely classify returned products, enabling rapid decision-making and efficient operations.

The use of collaborative warehouse models reveals significant potential for resource integration. Leveraging technologies such as warehouse robots, the Internet of Things (IoT), the Internet of Services (IoS), and enhanced web collaboration, this approach has transformed the structure of traditional warehouse systems. By sharing warehousing and logistics facilities, this case achieves the optimization of both forward and reverse logistics, thereby reducing resource wastage in warehousing and transportation [10]. Enterprises in other industries can explore the adoption of collaborative warehouses or shared logistics resources to reduce costs and enhance operational efficiency.

Finally, data-driven forecasting and dynamic adjustment mechanisms are crucial in this project. The effectiveness of model-based decision support relies significantly on the quality of the data, including its completeness, comprehensiveness, validity, consistency, and timeliness [11]. By accurately forecasting return volumes and resource flows, enterprises can not only proactively deploy resources but also flexibly respond to demand fluctuations. To achieve this, enterprises should enhance the application of digital technologies, leveraging real-time data monitoring and artificial intelligence to optimize the supply chain process and build a more agile and efficient reverse logistics system.

5. Conclusions

This paper summarizes the key role of the collaborative warehouse model in optimizing reverse logistics by analyzing the Pampers Newborn Project implemented by P&G in cooperation with JD. The study demonstrates that through the design of short-chain logistics and the sharing of warehouse resources, enterprises can significantly enhance the processing efficiency of returned products, reduce resource wastage caused by backlogs or delays in handling returns, and simultaneously lower inventory management and transportation costs. The implementation of SKU hierarchical management further refines the classification of returned products, ensuring the efficient flow and reuse of items with varying quality statuses, thereby greatly improving the operational efficiency of the reverse logistics chain.

Moreover, the convergence of forward and reverse logistics leverages shared resources to reduce overall logistics expenses, yet it also necessitates more sophisticated priority management and resource allocation strategies. The collaborative warehouse framework successfully mitigates key challenges in return handling and inventory optimization, highlighting the potential of data-driven short-chain logistics solutions. Nonetheless, practical implementation reveals several hurdles, including heightened operational complexity, significant dependence on robust logistics infrastructure, and inadequate supply chain adaptability. In particular, when faced with uncertain volumes and variable quality of returns, the current processes may be strained by volatile demand patterns and unexpected events.

To optimize reverse logistics efficiency further, it is imperative to integrate sophisticated intelligent forecasting systems that can accurately anticipate return volumes and demand trends. This foresight facilitates proactive resource deployment and adaptive inventory management. Additionally, enhancing the application of digital technologies through improved data sharing and real-time monitoring can significantly bolster collaborative efforts and ensure the accuracy and timeliness of resource allocation. Furthermore, within the context of a sustainable supply chain, encouraging the use of eco-friendly materials and implementing a closed-loop recycling process can not only enhance economic performance but also contribute to achieving long-term sustainability goals.

References

[1]. Agrawal, S., Singh, R. K., & Murtaza, Q. (2015). A Literature Review and Perspectives in Reverse Logistics. Resources Conservation and Recycling, 97, 76–92.

[2]. Nanayakkara, P. R., Jayalath, M. M., Thibbotuwawa, A., & Perera, H. N. (2022). A Circular Reverse Logistics Framework for Handling E-Commerce Returns. Cleaner Logistics and Supply Chain, 5, 100080.

[3]. China Chain-Store & Franchise Association. (2024.06.24). 2024 Retail Supply Chain Best Practices Casebook. http://www.ccfa.org.cn/portal/cn/xiangxi.jsp?id=445775&type=10004

[4]. Anon, S. Y., Amin, S. H., & Baki, F. (2024). Third-Party Reverse Logistics Selection: A Literature Review. Logistics, 8(2), 35.

[5]. Dabo, A.-A. A., & Hosseinian-Far, A. (2023). An Integrated Methodology for Enhancing Reverse Logistics Flows and Networks in Industry 5.0. Logistics, 7(4), 97. https://doi.org/10.3390/logistics70400976

[6]. Biancolin, M. (2023). Reverse Logistics and Circular Economy: A Literature Review. European Transport/Trasporti Europei, 94, 1–14.

[7]. Jackson, I. (2022). AutoML Approach to Stock Keeping Units Segmentation. Journal of Theoretical and Applied Electronic Commerce Research, 17(4), 1512–1528.

[8]. Alshurideh, M. T., Kurdi, B. A., Alzoubi, H. M., Obeidat, B., Hamadneh, S., & Ahmad, A. (2022). The Influence of Supply Chain Partners’ Integrations on Organizational Performance: The Moderating Role of Trust. Uncertain Supply Chain Management, 10(4), 1191–1202.

[9]. Govindan, K., Agarwal, V., Darbari, J. D., & Jha, P. C. (2017). An Integrated Decision-Making Model for the Selection of Sustainable Forward and Reverse Logistic Providers. Annals of Operations Research, 273(1–2), 607–650.

[10]. Dusadeerungsikul, P. O., He, X., Sreeram, M., & Nof, S. Y. (2021). Multi-Agent System Optimisation in Factories of the Future: Cyber Collaborative Warehouse Study. International Journal of Production Research, 60(20), 6072–6086.

[11]. Ivanov, D., Dolgui, A., Das, A., & Sokolov, B. (2019). Digital Supply Chain Twins: Managing the Ripple Effect, Resilience, and Disruption Risks by Data-Driven Optimization, Simulation, and Visibility. In International Series in Management Science/Operations Research/International Series in Operations Research & Management Science (pp. 309–332)

Cite this article

Li,Y. (2025). Strategies for Minimizing Losses in Reverse Logistics. Advances in Economics, Management and Political Sciences,164,204-210.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 4th International Conference on Business and Policy Studies

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Agrawal, S., Singh, R. K., & Murtaza, Q. (2015). A Literature Review and Perspectives in Reverse Logistics. Resources Conservation and Recycling, 97, 76–92.

[2]. Nanayakkara, P. R., Jayalath, M. M., Thibbotuwawa, A., & Perera, H. N. (2022). A Circular Reverse Logistics Framework for Handling E-Commerce Returns. Cleaner Logistics and Supply Chain, 5, 100080.

[3]. China Chain-Store & Franchise Association. (2024.06.24). 2024 Retail Supply Chain Best Practices Casebook. http://www.ccfa.org.cn/portal/cn/xiangxi.jsp?id=445775&type=10004

[4]. Anon, S. Y., Amin, S. H., & Baki, F. (2024). Third-Party Reverse Logistics Selection: A Literature Review. Logistics, 8(2), 35.

[5]. Dabo, A.-A. A., & Hosseinian-Far, A. (2023). An Integrated Methodology for Enhancing Reverse Logistics Flows and Networks in Industry 5.0. Logistics, 7(4), 97. https://doi.org/10.3390/logistics70400976

[6]. Biancolin, M. (2023). Reverse Logistics and Circular Economy: A Literature Review. European Transport/Trasporti Europei, 94, 1–14.

[7]. Jackson, I. (2022). AutoML Approach to Stock Keeping Units Segmentation. Journal of Theoretical and Applied Electronic Commerce Research, 17(4), 1512–1528.

[8]. Alshurideh, M. T., Kurdi, B. A., Alzoubi, H. M., Obeidat, B., Hamadneh, S., & Ahmad, A. (2022). The Influence of Supply Chain Partners’ Integrations on Organizational Performance: The Moderating Role of Trust. Uncertain Supply Chain Management, 10(4), 1191–1202.

[9]. Govindan, K., Agarwal, V., Darbari, J. D., & Jha, P. C. (2017). An Integrated Decision-Making Model for the Selection of Sustainable Forward and Reverse Logistic Providers. Annals of Operations Research, 273(1–2), 607–650.

[10]. Dusadeerungsikul, P. O., He, X., Sreeram, M., & Nof, S. Y. (2021). Multi-Agent System Optimisation in Factories of the Future: Cyber Collaborative Warehouse Study. International Journal of Production Research, 60(20), 6072–6086.

[11]. Ivanov, D., Dolgui, A., Das, A., & Sokolov, B. (2019). Digital Supply Chain Twins: Managing the Ripple Effect, Resilience, and Disruption Risks by Data-Driven Optimization, Simulation, and Visibility. In International Series in Management Science/Operations Research/International Series in Operations Research & Management Science (pp. 309–332)