1. Introduction

In the context of economic globalization, supply chain management is faced with problems such as low efficiency in information transmission and collaboration, and inaccurate demand forecasting, which often lead to increased costs. As a key innovation, big data technology can promote in-depth cooperation among the upstream and downstream of the supply chain and has become an important driving force for the development of various industries. Based on the characteristics of big data and the collaborative needs of the supply chain, building an efficient supply chain collaboration mechanism and maximizing the application value of big data has become a feasible solution for enterprises to promote the upgrading of supply chain collaboration at present.

This article will analyze the advantages of enterprises using big data and optimize the cooperation among various links from three aspects: establishing a shared warehousing model based on big data, prediction and plan collaboration, and risk warning and response collaboration, so as to improve the efficiency of supply chain collaboration. It aims to provide corresponding suggestions and theoretical support for the digital transformation of enterprises and further clarify the strategies and paths for the digital transformation of supply chain collaboration.

This article focuses on analyzing the current situation of Build Your Dreams (BYD) supply chain management. It uses literature research and the SWOT method to deeply analyze its current situation and existing problems and then puts forward strategies and suggestions. Previous studies focused on analyzing and researching the development process of BYD's supply chain, the competitive situation of new energy vehicles and the policy background, and also focused on the research on supply chain disruption risk management strategies. For example, Huang focused on discussing the development history and strategies of the supply chain status of Foton Motor and BYD, as well as the construction and interpretation of the supply chain disruption risk management model of automobile enterprises [1]. In addition, through the research on the review of relevant domestic and foreign literature, Li believes that how to use big data in the process of supply chain collaborative innovation and how big data can help node enterprises achieve effective supply chain collaborative innovation still need to be improved [2]. This article conducts an in-depth analysis of the specific problems in BYD's supply chain collaboration and puts forward corresponding solutions. It deeply explores how enterprises can use big data technology for prediction and risk warning. This can not only enrich the theoretical system of big data application but also provide enterprises with practical strategies to help them better cope with the challenges in supply chain management and improve the overall operational efficiency.

2. Case Analysis

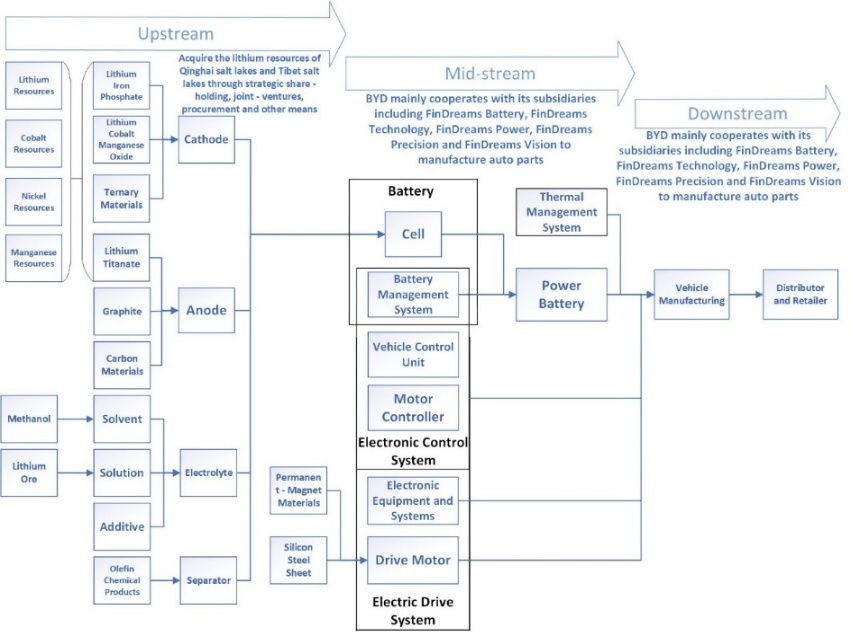

Influenced by the policies of the green transformation in global economic and social development, the current trend in the automotive industry is dominated by new energy and interconnection. For new energy vehicles, the "Three Electric" technologies, namely battery, motor and electronic control system technologies, are the core of the drive system in terms of structure, which makes the demand for parts in vehicle manufacturing more concentrated, thus forming an electric vehicle supply chain based on the "Three Electric" technologies [1]. Taking BYD's electric vehicle supply chain as an example, it covers multiple links such as raw material suppliers, component manufacturers, vehicle manufacturers, distributors and retailers. As shown in Figure 1, in this supply chain, BYD is in the core position. Through close cooperation with the upstream and downstream, it has achieved meeting the needs of customer service levels while minimizing the system cost as much as possible.

Figure 1: Analysis of the upstream, mid-stream and downstream of BYD's supply chain. (Picture credit: Original)

This article uses the SWOT analysis method to analyze BYD's supply chain's strengths, weaknesses, opportunities, and threats, as well as opportunity-strengths, opportunity-weaknesses, threat-strengths and threat-weaknesses. The specific details are shown in Table 1.

Table 1: SWOT analysis.

Strengths 1. Strong vertical integration 2. Advanced Research and Development (R & D) ability 3. Data Transparency 4. Economies of scale | Weaknesses 1. Poor supply chain coordination 2. Supplier - dependence risk 3. Imperfect global layout 4. Management system lags | |

Opportunities 1. NEV market growth potential 2. Policy support available 3. Tech - cooperation chances 4. Overseas market expansion | Opportunity-Strength Strategies (Use strengths to take advantage of Opportunities) 1. Expand with R & D & scale 2. Leverage data for cooperation | Opportunity-Weakness strategies (Overcome weaknesses by taking advantage of Opportunities) 1. Improve with market 2. Optimize layout via partners |

Threats 1. Competitor supply-chain threats 2. Raw material price swings 3. Trade frictions impact 4. Stricter environmental rules | Threat-Strength strategies (Use strengths to avoid Threats) 1. Counter with R & D & integration 2. Stabilize cost via scale | Threat- Weakness strategies (Minimize weaknesses and avoid threats) 1. Find alternatives for friction 2. Meet regs with the system upgrade |

Based on the above analysis, BYD's supply chain network is mainly characterized by a high level of informatization, an emphasis on collaborative cooperation and a focus on innovation-driven factors. BYD applies the intelligent supply chain, which is reflected in the application of the Warehouse Management System, the Transportation Management System and the Vehicle Management System, realizing the transparency of data on the supply chain [3]. It maintains a close cooperative relationship with partners through the vertical supply chain system, achieves information sharing and realizes the collaborative operation of the supply chain [4]. Meanwhile, BYD has increased its investment in technological innovation, promoted the intelligent development of the supply chain and improved the overall efficiency of the supply chain.

3. Challenges in Traditional Supply Chains in the Digital Economy

3.1. Insufficient Data Integration and Processing Capabilities

BYD has certain deficiencies in data integration and processing. This is mainly reflected in the overly long business chain caused by excessive vertical integration of its supply chain and the diversity of data sources and types in various links. The quality data of parts, warehousing data and sales data involved in BYD's production process all lack a unified standard format and integration mechanism, making it difficult to form an accurate enterprise view, thus affecting the efficiency and accuracy of decision-making [5]. In addition, the poor communication between BYD and its suppliers and dealers has further led to the phenomenon of "information silos", making it difficult to integrate data effectively and resulting in low data utilization efficiency.

In terms of data processing capabilities, especially during warehousing and transshipment, a large amount of sensor data generated needs to rely on advanced processing technologies to extract valuable information. However, due to insufficient R&D and investment by BYD, tools capable of processing these data have not been effectively developed, resulting in the potential of the data not being fully utilized. Meanwhile, with the changes in market demand and the economic environment, BYD's cost management system has failed to adapt in a timely manner. The scale and complexity of data are constantly increasing, requiring more refined processing means to optimize cost management. If the data processing needs are not effectively considered, it will lead to low processing efficiency. For example, in cost control, if data analysis is not used to optimize the production process and reduce inventory costs, it will ultimately affect the competitiveness of the enterprise.

3.2. Insufficient Supply Chain Collaboration

BYD has certain deficiencies in data integration and processing. This is mainly reflected in the overly long business chain caused by excessive vertical integration of its supply chain and the diversity of data sources and types in various links. The quality data of parts, warehousing data and sales data involved in BYD's production process all lack a unified standard format and integration mechanism, making it difficult to form an accurate enterprise view, thus affecting the efficiency and accuracy of decision-making [5]. In addition, the poor communication between BYD and its suppliers and dealers has further led to the phenomenon of "information silos", making it difficult to integrate data effectively and resulting in low data utilization efficiency.

3.3. Insufficient Data Security and Privacy Protection

Driven by big data, BYD's supply chain has the risk of data leakage. The leakage of supplier information will enable competitors to grasp the key supply information, triggering supply instability and a trust crisis. The leakage of production data will lead competitors to imitate technologies and processes, and the leakage of sales data will make competitors aware of the trend of market share. In addition, in terms of technology, the imperfection of data security technologies and the backwardness of data encryption technologies make data vulnerable to attacks [5]. In terms of management, the imperfect data security management system and the non-standard data security management process will all affect the effect of data privacy and data protection.

4. Coping Strategies

4.1. Establish a Shared Warehousing Platform Based on Big Data

There are roughly two types of warehousing models in the current market: the self-built warehousing model and the leased warehousing model. Whichever model it is, the warehousing resources it owns are fixed [6]. Therefore, when facing changes in demand and the bullwhip effect in the supply chain, there will be phenomena such as inventory backlogs and out-of-stock situations. To solve the occurrence of the above problems, a warehousing sharing model based on big data can be adopted. This model includes three layers: the data convergence layer, the information analysis layer and the intelligent decision-making layer. The core service of the data convergence layer is that the data collectors collect multi-source data of warehousing resources and goods, form files for sharing and release, form a unified resource catalog and ensure the authenticity of data sources, so as to facilitate external sharing. The information analysis layer is that the data receivers provide a stable cloud computing environment, quickly calculate data through various big data interactive sharing models, mine the value of data, and then conduct operations such as demand forecasting, allocation of warehousing resources and optimization of goods transportation routes. The intelligent decision-making layer is that the core enterprises realize the overall optimization of the daily operation and collaborative efficiency of enterprises according to the provided information.

From the perspective of the operation mode of warehousing sharing, the shared warehousing model of big data has built a platform connecting warehousing resource owners and users. Warehousing resource owners can upload information about warehousing space to the platform, and describe in detail the attributes such as the geographical location, area, facility equipment and storage conditions of the warehouse. While the relevant parties with warehousing needs can quickly search and screen out matching warehousing resources on the platform according to their own needs. The platform uses the intelligent matching algorithm of big data to conduct precise matching according to the needs and conditions of both sides and upload information.

4.2. Prediction and Plan Collaboration

To address the problem of insufficient supply chain collaboration, a big data sharing platform can be built for data analysis and prediction, and then a collaborative decision-making mechanism can be established. First, based on the sales data provided by the sellers and the prediction of market trends, adjust the production and inventory allocation in a timely manner, and consider the production and inventory capabilities of all parties when formulating production plans. Then, big data to analyze the delivery time and quality data of suppliers, so as to evaluate and select suppliers with strong comprehensive strength and good reputation and give priority to cooperating with them [7]. In addition, build a collaborative management mechanism, share production plans and quality standards through the data platform, and let suppliers participate in product design and development and time management, so as to better solve production problems.

In terms of logistics management, the big data platform can monitor logistics data in real time, optimize distribution routes and help enterprises reduce costs and increase efficiency. Meanwhile, the platform can also share inventory and sales data with suppliers, prompting them to prepare for distribution in advance and improve the timeliness and accuracy of distribution. Realizing information sharing and collaborative analysis through the big data platform not only helps to build an efficient, stable and intelligent supply chain system but also enhances the competitiveness and adaptability of enterprises in the market, promotes the collaborative progress of all links in the supply chain and realizes the optimal allocation of resources and the maximization of value.

4.3. Risk Warning and Response Collaboration

To deal with the problems of data and privacy leakage, a risk warning and collaborative mechanism can be established. Under the action of the collaborative mechanism, by monitoring the operation and transaction data of all links inside the supply chain through big data, including daily data such as production, inventory, sales and logistics, potential data security risks can be detected in a timely manner [8]. For example, if abnormal situations such as abnormal third-party data storage or sudden changes in transmission traffic are found, the system will immediately issue a warning. After receiving the warning, supply chain members can quickly check their own data and take security measures such as encryption for protection.

In addition, when selecting third-party partners, strict screening criteria should be formulated. Use the external data of the supply chain collected by the big data platform, including information such as news reports, social media comments and industry forums, as the basis for screening and evaluating partners. After that, during the cooperation process, it is still necessary to continuously supervise and monitor the security measures and data processing behaviors of partners to ensure the continuous protection of data security and privacy. Through such a risk warning and response mechanism, the risk of data leakage can be effectively reduced and the collaborative operation of all links in the supply chain can be ensured to be safe and reliable.

5. Conclusion

Big data plays a vital role in promoting the upgrading of supply chain collaboration and can effectively solve the deficiencies of traditional supply chains in aspects such as data integration and processing capabilities, collaborative efficiency, data security and privacy protection. By building a shared warehousing platform based on big data, strengthening prediction and plan collaboration, and establishing a risk warning and response collaborative mechanism, enterprises can significantly improve the collaborative effectiveness and stability of the supply chain.

On this basis, enterprises should increase their investment in big data technology and talents to ensure the effective construction and daily operation and maintenance of the big data platform. Meanwhile, great attention must be paid to data security and privacy protection, and security measures such as complete data encryption and access permission management systems should be established. While using big data to improve the collaborative efficiency of the supply chain, ensure the security of the core data assets of enterprises and lay a solid foundation for the digital transformation of the supply chain. This not only helps to improve the overall level of supply chain management but also provides strong support for enterprises in the fierce market competition.

References

[1]. Huang, H. (2023). Risk management strategies and their effectiveness in automotive supply chain disruptions (Master's thesis, Nanjing Audit University).

[2]. Li, G., & Fu, M. (2021). Research status and future prospects of supply chain collaborative innovation based on big data. Supply Chain Management, (03), 52-63.

[3]. Liu, Y., & Zhang, S. (2023). BYD's smart supply chain transformation and optimization strategies. Supply Chain Management, (04), 78-85.

[4]. Qu, Y. (2023). The advantages of supply chain integration in the electric-vehicle industry: Evidence from BYD. Highlights in Business, Economics and Management, 7, 179-185.

[5]. Yang, J. (2023). Analysis of BYD new energy vehicle cost management strategy. In Proceedings of the 2023 International Conference on Management Research and Economic Development (Part 2) (pp. 339-344). Shanghai Experimental School. https://doi.org/10.26914/c.cnkihy.2023.115248

[6]. Li, X., Guo, Y., & Hou, W. (2019). Research on warehouse sharing models based on big data. Value Engineering, (26), 14-16.

[7]. Liu, S. (2018). Research on supply chain collaboration based on big data (Master's thesis, Beijing University of Civil Engineering and Architecture).

[8]. Hung, J. L., He, W., & Shen, J. (2020). Big data analytics for supply chain relationships in banking. Industrial Marketing Management, 86, 144-153.

Cite this article

Zhang,D. (2025). Strategies for Big Data Empowered Supply Chain Synergy Upgrade. Advances in Economics, Management and Political Sciences,164,231-236.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 4th International Conference on Business and Policy Studies

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Huang, H. (2023). Risk management strategies and their effectiveness in automotive supply chain disruptions (Master's thesis, Nanjing Audit University).

[2]. Li, G., & Fu, M. (2021). Research status and future prospects of supply chain collaborative innovation based on big data. Supply Chain Management, (03), 52-63.

[3]. Liu, Y., & Zhang, S. (2023). BYD's smart supply chain transformation and optimization strategies. Supply Chain Management, (04), 78-85.

[4]. Qu, Y. (2023). The advantages of supply chain integration in the electric-vehicle industry: Evidence from BYD. Highlights in Business, Economics and Management, 7, 179-185.

[5]. Yang, J. (2023). Analysis of BYD new energy vehicle cost management strategy. In Proceedings of the 2023 International Conference on Management Research and Economic Development (Part 2) (pp. 339-344). Shanghai Experimental School. https://doi.org/10.26914/c.cnkihy.2023.115248

[6]. Li, X., Guo, Y., & Hou, W. (2019). Research on warehouse sharing models based on big data. Value Engineering, (26), 14-16.

[7]. Liu, S. (2018). Research on supply chain collaboration based on big data (Master's thesis, Beijing University of Civil Engineering and Architecture).

[8]. Hung, J. L., He, W., & Shen, J. (2020). Big data analytics for supply chain relationships in banking. Industrial Marketing Management, 86, 144-153.