1. Introduction

Over the past several decades, the Lean Supply Chain (LSC) paradigm—centered on the principles of extreme efficiency and cost minimization—has become deeply embedded in the operational logic of global manufacturing and procurement systems. Rooted in the Toyota Production System, the lean philosophy, through techniques such as Just-In-Time (JIT), process optimization, and the elimination of waste (Muda Elimination), has fundamentally reshaped how firms allocate resources and structure their operations. Particularly within procurement and raw material sourcing, lean strategies have enabled exceptional cost control and process coordination by minimizing inventories, streamlining workflows, and strengthening supplier relationships [1]

However, the very strengths of lean supply chains have also exposed them to significant vulnerabilities. As global supply networks become increasingly interdependent, their susceptibility to external disruptions has come to the fore [2]. In a context marked by rising geopolitical fragmentation and institutional instability, the efficiencies achieved by lean supply chains—often at the expense of redundancy—have given rise to structural limitations in adaptability [3]. Specifically in procurement and raw material supply, lean-preferred strategies such as single sourcing and near-zero inventory have proven fragile in the face of trade wars, sanctions, and tariff realignments, leading to structural disruptions and systemic failures [4].

The U.S.–China trade war of 2018–2019 marked a critical inflection point in this regard. As the United States imposed tariffs on key Chinese manufacturing categories and China responded with reciprocal measures, tariff escalation became a central policy instrument [5]. This new environment was accompanied by extreme volatility in raw material prices, supplier disruptions, and procurement delays—collapsing the lean procurement system’s core assumptions of cost advantage and temporal certainty [5-6]. Sectors with strong lean orientations, such as electronics manufacturing and automotive components, were among the first to reveal the risks of overdependence on single-country, single-supplier structures [7].

By 2025, the resurgence of protectionist policies has reignited trade tensions on a global scale [8]. Policy frictions between the United States, the European Union, and Japan have extended tariff measures even to those regions traditionally considered “stable sourcing zones” [9]. These emergent geoeconomic realities exhibit institutionalized, strategic, and asymmetric characteristics, rendering short-term adjustments insufficient to mitigate their impact [10-11]. For lean supply chains that rely on the JIT model, such “institutional uncertainty” poses a fundamental challenge to their long-assumed sustainability.

Prior research into supply chain resilience and agility has largely focused on “de-leaning” or transitioning toward redundant, multi-node networks as a solution. Such strategies, which emphasize redundancy and buffering, are exemplified by recent studies [12-13]. However, these approaches are not universally applicable, particularly for industries where lean procurement and cost competitiveness are core to the business model. The central question, then, is whether it is possible to develop a structurally adaptive procurement system that enhances resilience without entirely abandoning the principles of lean.

Against this backdrop, this study explores the impact of trade wars on procurement and raw material supply within lean supply chains and proposes a novel theoretical framework incorporating resilient supply chain management to explain and address these impacts. The aim is to offer a third pathway for firms caught in the tension between cost efficiency and security: a structurally adaptive lean procurement paradigm capable of navigating institutional uncertainty without fully diverging from lean tenets.

2. Literature review

This section reviews the literature across three key areas: lean supply chain theory, the impact of trade wars on supply chains, and the vulnerability and adaptability of lean procurement systems. Through a critical synthesis of existing research, this review aims to highlight current theoretical limitations and gaps in the literature.

2.1. Lean Supply Chain theory

Since the 1980s, the Lean Supply Chain has emerged as a natural extension of lean production, evolving into a dominant paradigm in supply chain management research and practice [14]. In their seminal work Lean Thinking: Banish Waste and Create Wealth in Your Corporation, Womack and Jones systematized the core principles of lean, centering on customer value creation, waste elimination, and the integration of continuous flow with pull-based control mechanisms [1]. Originally devised to optimize internal manufacturing processes, lean thinking quickly expanded to inter-organizational and cross-regional supply networks, becoming a central tool for firms seeking cost control and operational efficiency in the context of globalization [1].

At its core, lean supply chain management is driven by the pursuit of process efficiency and the systematic elimination of non-value-adding activities [1]. A key mechanism within this framework is the Just-In-Time (JIT) system, which emphasizes delivering the right materials in the right quantities at precisely the right time, thereby minimizing inventory and reducing warehousing costs [15]. JIT relies on accurate demand forecasting, reliable transportation systems, and highly synchronized supply networks—allowing the entire chain to function with the precision of a single integrated system [16]. Additionally, lean thinking promotes the identification and eradication of all forms of "waste" (Muda), extending beyond the factory floor to include hidden inefficiencies such as excess inventory, redundant transport, and process delays throughout the supply chain [1]. Through carefully designed workflows and a focus on value stream mapping, firms are able to maximize resource utilization [1]. Moreover, the lean supply chain is underpinned by a culture of continuous improvement (Kaizen), where iterative feedback loops, team collaboration, and problem-solving routines drive incremental optimization from individual processes to the entire network [1]. These improvements are embedded within daily operations, fostering adaptability and executional efficiency without requiring major capital investments.

In the domain of procurement and raw material management, lean thinking manifests through distinct strategic logics. First, in supplier management, lean emphasizes “single sourcing” or “few-sourcing” strategies, which advocate the cultivation of long-term strategic partnerships with a limited number of key suppliers [1]. Such relationships enhance quality control, delivery reliability, and bargaining power while promoting information sharing and process integration [17-18]. Practices such as joint product development, vendor-managed inventory (VMI), and collaborative quality standards foster mutually beneficial partnerships that reduce management complexity and improve overall supply chain performance [19]. However, this approach entails significant concentration risk—especially in environments marked by geopolitical volatility or frequent disruptions, where a supply failure from a single vendor can trigger cascading interruptions [2]. Second, lean supply chains often adopt a “zero-inventory” or “near-zero-inventory” philosophy [1]. By engaging in high-frequency collaboration with suppliers and logistics providers, firms aim to ensure that materials flow swiftly through the chain, minimizing holding time and storage costs [20]. While this fluidity enhances capital efficiency and inventory turnover, it simultaneously reduces buffer capacity, making the system highly vulnerable to unforeseen shocks [21].

Although lean strategies yield strong performance under stable conditions, their limitations in uncertain environments have become increasingly evident [22]. Scholars such as Christopher & Holweg and Ivanov have shown that JIT systems—due to their tight coupling and temporal sensitivity—are particularly susceptible to external disruptions, including natural disasters, political conflict, and trade disputes [2, 23]. In such contexts, fluctuations in raw material prices, rising tariff barriers, and geographic concentration of suppliers pose systemic risks to lean supply chains.

2.2. The impact of trade wars on procurement

Amid an increasingly volatile global political-economic landscape, trade wars have evolved from episodic bilateral conflicts into persistent instruments of geopolitical strategy, fundamentally reshaping the structure and logic of transnational supply chains [24-25]. Their impact extends beyond increased tariff burdens to include significant implications for procurement strategy, supplier portfolio management, and risk mitigation mechanisms [26]. The 2018–2019 U.S.–China trade war is widely recognized as the beginning of a new era of protectionism, characterized by sweeping punitive tariffs imposed by the United States on key Chinese exports—ranging from electronics and machinery to chemicals and steel [5]. In response, China implemented a Reciprocal Tariffs Policy, targeting American goods with symmetrical retaliatory duties. This tit-for-tat escalation not only inflated bilateral trade costs but also introduced structural distortions across global supply networks [5].

First, firms faced a rapid contraction in procurement flexibility. U.S. companies previously dependent on Chinese manufacturing were forced to source alternative suppliers under compressed timelines. While countries such as Vietnam or India offered cost advantages, they often lacked the production scale, technological maturity, or delivery reliability of China [27]. This supply source switching raised procurement costs and heightened the risk of supply chain disruptions. Second, reciprocal tariffs encouraged preemptive stockpiling and speculative purchasing behaviors [5]. In anticipation of tariff hikes, firms rushed to import critical inputs and components, resulting in port congestion, logistical delays, and inventory surges—directly undermining lean supply chain principles such as zero-inventory and just-in-time delivery [28-29]. The original procurement logic of high-frequency, low-volume, multi-batch purchasing came under pressure, forcing firms to make difficult trade-offs between efficiency and resilience. Third, the trade war prompted a strategic reassessment of global sourcing footprints. For instance, Apple has shifted away from a China-centric model toward a multi-country manufacturing strategy to hedge geopolitical risks [30-31]. This shift became more pronounced amid the resurgence of trade protectionism in 2025, as the United States expanded its tariff lists to include traditional allies in the European Union—illustrating the growing asymmetry and unpredictability of trade policy [9]. These developments pose systemic threats to lean supply chains that rely on centralized procurement and efficiency maximization. Finally, the trade war’s industry-specific impacts vary significantly. Electronics manufacturing, with its heavy reliance on country-specific components and integrated processes, was among the hardest hit [7]. Automotive supply chains, with their global dispersion and cross-border interdependencies, experienced rising production costs and frequent disruptions [32]. In contrast, labor-intensive sectors such as textiles and apparel, with more flexible and geographically mobile supply chains, displayed greater adaptability in the face of trade realignment [33].

2.3. Vulnerability and adaptability of lean procurement strategies under trade war conditions

While the lean supply chain has demonstrated outstanding efficiency in stable environments, its limitations in absorbing geopolitical shocks have become increasingly pronounced [34]. At the core of the lean philosophy—redundancy elimination, zero inventory, and supplier minimization—lies a structural fragility when subjected to trade war dynamics [35].

Lean’s greatest strength—its operational efficiency—is simultaneously its principal vulnerability. JIT procurement systems, while effective under stable delivery conditions, are rendered fragile when exposed to unpredictable tariff regimes or systemic disruptions [35]. In the context of trade wars, factors such as customs delays, increased border scrutiny, and volatile logistics undermine the timeliness and reliability upon which lean systems depend—resulting in production halts and missed delivery targets [36]. Moreover, lean’s emphasis on supplier concentration frequently results in overdependence on specific regions or vendors [1]. While such strategies offer scale economies and streamlined coordination, they expose firms to elevated single-point-of-failure risks in the face of geopolitical restrictions [2]. In addition, the rigidity inherent in lean process design—characterized by standardization and optimization—diminishes the system’s adaptive capacity. When confronted with sudden changes, lean structures lack the flexibility required for timely reconfiguration, giving rise to what scholars have termed the Efficiency–Adaptability Paradox [37].

Nevertheless, recent research and practice are beginning to explore how “resilience elements” might be integrated into lean systems. Studies such as Ivanov & Dolgui and Sheffi have proposed strategies that enhance lean supply chain robustness without abandoning core principles [22, 38]. For example, supplier redundancy advocates for geographic diversification and the use of multiple qualified vendors to mitigate political risk exposure [39]. Strategic buffer inventories, limited in scope and targeted at critical materials, have been suggested as safeguards to maintain continuity of production [40]. Furthermore, the development of dynamic response systems—incorporating cross-functional coordination, information sharing, and early-warning mechanisms—has emerged as an avenue for improving responsiveness [41].

In summary, while extensive scholarship has addressed the performance of lean and resilient supply chains in various contexts, few studies have systematically examined the specific vulnerabilities and adaptive strategies of lean procurement systems under trade war conditions. In particular, the question of how to embed resilience into lean procurement without undermining its foundational principles remains underexplored. This study seeks to address this gap by proposing a novel theoretical framework that reinterprets lean procurement through the lens of structural adaptability and institutional uncertainty.

3. Theoretical framework

3.1. Framework design logic

This study builds upon the core principles of the Lean Supply Chain—namely, the systematic identification and elimination of “waste” (Muda) to enhance overall supply chain efficiency [1]. However, the application of lean principles is facing unprecedented challenges, particularly in the context of intensifying geopolitical conflict. Three characteristics set trade wars apart from interruptions caused by pandemics or natural disasters: they are human-induced, sustained, and policy-driven [35]. First, they arise not from random shocks, but as strategic instruments of national policy. Second, trade wars typically span multiple years and introduce “institutional uncertainty.” Third, their primary forms—reciprocal tariffs and non-tariff barriers—exert direct and often severe impacts on procurement and raw material supply [42]. As a result, businesses must quickly reorganize global sourcing networks, adjust supplier relationships, and implement systematic process redesigns in addition to dealing with logistical delays and growing expenses.

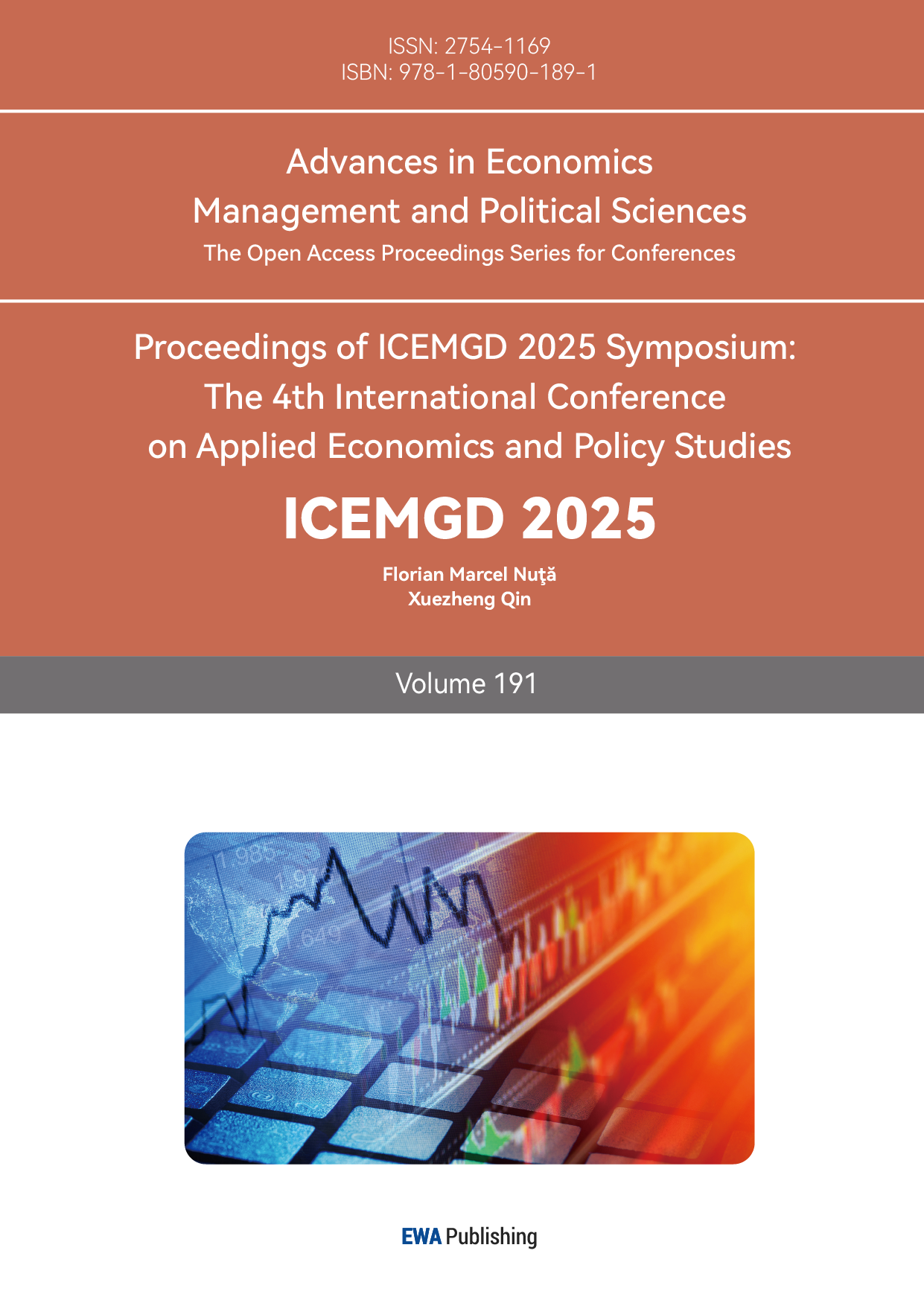

Given this level of complexity, traditional linear approaches to lean supply chain analysis appear insufficient. This study thus adopts a systems process-oriented framework design [43], structuring the procurement and raw material supply process into four distinct yet interdependent modules: Inputs, Processes, Outputs, and Feedback.

3.2. The proposed framework structure

As illustrated in Figure 1, the Input module represents the upstream resource base and environmental variables that initiate the procurement process. In this theoretical structure, the Input module captures all conditions—both internal and external—available to the firm prior to procurement execution. These include tangible inputs (e.g., material types, volumes, quality standards), supplier structures (e.g., number of suppliers, geographic distribution, historical collaboration), policy and institutional environments (e.g., tariff regimes, trade restrictions, compliance requirements), and the firm's existing procurement policies. Traditional lean logic often treats these inputs as stable and optimizable under cost-efficiency principles [23]. However, under trade war conditions, these inputs are highly susceptible to disruption, often characterized by concentration and dependency [35]. Despite being frequently considered a given, the input stage fundamentally shapes downstream procurement processes and outcomes.

The Process module refers to the transformation of input resources into actionable procurement operations and material flows. This includes demand forecasting and procurement planning, supplier scheduling, ordering and approval procedures, and logistics coordination. In lean supply chain management, this module is governed by the JIT principle—favoring small-lot, high-frequency, just-in-time deliveries to maximize capital efficiency and reduce inventory [1]. Through precise planning and standardized procedures, firms aim to synchronize procurement with production in a pull-based flow model [1]. However, this high-efficiency design depends heavily on environmental predictability and supply chain stability, rendering it sensitive to disruption [44]. When inputs are perturbed—due to price spikes, tariff impositions, or logistical delays—such tightly coupled systems can quickly unravel due to their lack of buffers. Hence, although the Process module is the operational core of lean procurement, its responsiveness under high uncertainty is limited by structural rigidity.

The Output module serves as the system’s performance reflection mechanism, assessing whether lean procurement strategies achieve their intended objectives. Common output indicators include procurement cost reductions, order fulfillment rates, procurement lead times, inventory turnover ratios, and product quality compliance [1]. In lean systems, these indicators represent the ultimate benchmarks for efficiency and cost control, with continuous measurement driving performance improvement [1]. However, this efficiency-focused output logic becomes problematic under global instability, potentially masking strategic vulnerabilities such as over-reliance on specific suppliers or exposure to regulatory shocks [2]. Thus, while outputs reflect operational success, they often fail to capture deeper systemic risks or future disruption potential.

The Feedback module constitutes the framework’s adaptive loop, reflecting the procurement system’s ability to self-monitor, self-correct, and continuously improve. Lean supply chains traditionally implement feedback via the Plan–Do–Check–Act (PDCA) cycle, with practices such as periodic performance reviews, supplier evaluation and adjustment, bottleneck analysis, and localized process improvements [45]. Its function is to channel output insights back into input and process redesign, guiding the system toward an ideal “waste-free” state [1]. Nevertheless, traditional feedback mechanisms often focus on endogenous, operational-level feedback and are ill-equipped to sense or respond to exogenous shocks [2]. When disruptions such as trade wars render inputs or processes invalid, feedback loops may fail due to delayed response, path dependency, or organizational inertia. Thus, although feedback is a critical enabler of system resilience, its effectiveness depends heavily on data quality, design robustness, and activation speed.

Together, these four modules constitute the fundamental operational logic of lean procurement under uncertain conditions: Inputs define the resource base, Processes implement strategy, Outputs evaluate performance, and Feedback ensures system evolution. Yet all are premised on assumptions of stability and controllability, assumptions increasingly challenged by intensified external volatility. Therefore, this study proposes the integration of an “Elastic Layer” into the framework to enhance the system’s adaptability under unforeseen conditions such as emergent trade wars.

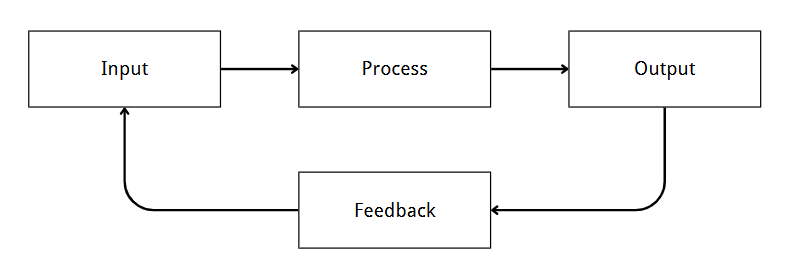

3.3. Integrating the elastic layer

As shown in Figure 2, the newly added Elastic Layer introduces a strategic modulation mechanism that transcends process optimization and addresses environmental uncertainty. Its primary function is to furnish the system with adaptive capabilities, transitioning the lean paradigm from “efficiency in stable environments” toward “resilience in dynamic contexts.” In the face of trade wars or other systemic shocks, the elastic layer serves as a strategic buffer and decision-modulation hub, capable of dynamically influencing each module’s configuration and enabling faster system-wide recovery.

In traditional lean logic, input configuration is driven primarily by cost considerations and long-term supplier partnerships—favoring streamlined, concentrated sourcing models [1]. However, under trade war conditions, this concentration increases systemic failure risk [46]. The Input function of the elastic layer therefore introduces geographic diversification strategies to mitigate regional exposure [47]. This inherently alters the lean ideal of full optimization with zero redundancy by introducing a “cost–security tolerance band.” Though such pre-emptive diversification may increase short-term costs in negotiation, management, and logistics—and risk being viewed as resource inefficiency—it should be seen as a non-routine contingency strategy, triggered by credible external signals (e.g., policy announcements, media reports).

In the Process module, the elastic layer incorporates Flexible Lot-Sizing Rules, enabling dynamic adjustments in order frequency, batch sizes, and emergency procurement workflows based on risk assessments or early warnings [48-49]. These mechanisms shift the process design from a fixed, linear system to a strategic process network with contingency paths. However, this added flexibility may create inconsistencies, disrupt supply cadence, or lead to confusion over procedural boundaries. Therefore, elastic process strategies require clearly defined activation thresholds, responsibility assignment, and post-event audit mechanisms to ensure that they serve as rational exceptions rather than systemic loopholes.

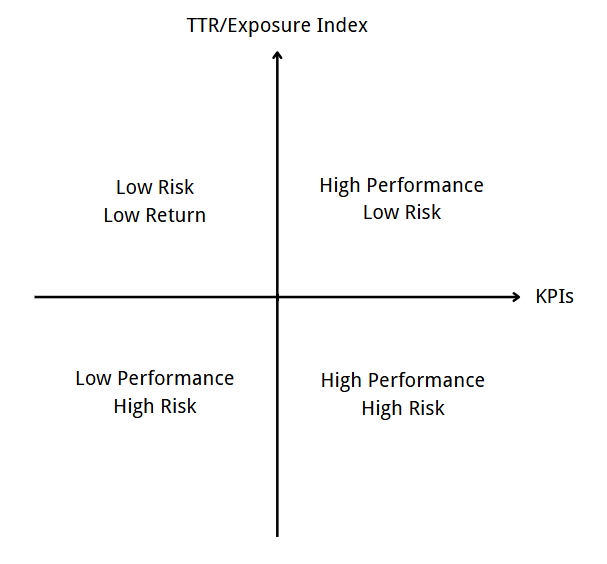

In the Output and Feedback modules, beyond conventional efficiency metrics [1], the elastic layer introduces resilience-focused indicators such as Time-to-Recover (TTR) and Exposure Index [50-51]. Leveraging historical trade war data and real-time public information, this study employs a weighted risk scoring system, as exemplified by Sodhi & Tang, to quantify the latent dangers associated with specific supply configurations [52]. These metrics can be incorporated into an enhanced Kraljic matrix, as illustrated in Figure 3, offering more informed decision support for procurement managers navigating complex environments [53].

In conclusion, through structural interventions in the Input, Process, Output, and Feedback modules, the Elastic Layer establishes a strategic, system-external modulation structure that engages with operational decisions while preserving strategic foresight. Its purpose is not to repudiate lean principles, but rather to retain their efficiency core while embedding a buffer against complexity. Moving forward, firms must reframe procurement and raw material sourcing systems to integrate both efficiency logic and resilience logic, avoiding trade-offs that sacrifice systemic security for local optimization.

4. Analysis and discussion

4.1. Applicability of the framework

The disruptive nature of trade wars is distinct from that of natural disasters or pandemics, due to their unique combination of predictability and uncontrollability [35]. This implies that resilience mechanisms within the supply chain cannot be purely reactive but must instead involve strategic, pre-emptive redundancy. The dual-structure framework proposed in this study—comprising a lean process core augmented by an elastic layer—redefines the procurement and raw materials domain, embedding a “structural adaptation path” within the lean system. Compared with conventional lean configurations, this framework demonstrates both structural advantages and operational feasibility when addressing challenges specifically triggered by trade wars.

As previously demonstrated, a shift from reactive supplier replacement to proactive strategic buffering is made possible by the elastic layer's inclusion across the Input, Process, and Output modules. Through the incorporation of geographically diversified sourcing strategies, flexible lot-sizing rules, bypass mechanisms for approval, and resilience-based performance metrics such as Time-to-Recover (TTR) and Exposure Index, the system reduces overreliance on stable forecasts—a foundational yet increasingly brittle assumption in traditional JIT logic. Furthermore, the transformation of static efficiency KPIs into dynamic risk-capacity assessments shifts managerial focus from short-term performance to long-term system robustness.

This paradigm is not a cure-all, though. Its efficacy depends on an organization's ability to sense its surroundings, coordinate across functional boundaries, and think strategically. Integrating resilience into current lean processes may face organizational and cultural obstacles for small and medium-sized manufacturing companies that are limited by scarce resources, compartmentalized mid-level hierarchies, and strict operating procedures [54]. In this sense, the framework carries a clear structural threshold—it is not universally adoptable across all enterprise types.

4.2. Internal tensions and theoretical challenges

At a philosophical level, lean supply chains and resilient supply chains rest on fundamentally opposing system paradigms. The former idealizes maximum efficiency by treating redundancy as waste, whereas the latter views redundancy as a necessary safeguard for survival in volatile environments [4-21]. The framework proposed here seeks a middle path—embedding a resilience layer to mitigate structural risk without abandoning lean principles entirely.

While conceptually integrative, this design faces deep-seated operational tensions. Lean management is grounded in minimal resource deployment and process optimization, whereas resilience entails upfront investments—such as safety stock, backup capacity, and diversified supplier networks. The trade-off between cost and security cannot be universally optimized; it must be contextually negotiated rather than resolved through abstract logic. Moreover, lean systems emphasize standardization and feedback loops, while resilience demands multi-path decision-making and feedforward anticipation [1]. This dual requirement necessitates that organizations operate under two distinct cognitive logics—an uncommon capability given that most firms remain focused on cost-minimization and lack the cross-process risk foresight embedded in robust information infrastructures.

In addition, lean systems often rely on stringent KPIs to compress cost and lead time, whereas resilience necessitates tolerance for apparent inefficiency—such as holding buffer stocks or maintaining safety margins [21]. In the absence of a clearly redefined performance framework, these contrasting value logics may lead to executional ambiguity and motivational distortion among employees and managers. Therefore, the framework proposed in this study is not intended as a replacement or refutation of the lean paradigm, but rather as an embedded correction—injecting a strategically protective layer into a mature optimization logic. It is, in essence, a practical reconciliation of a conceptual paradox through architectural innovation.

4.3. Theoretical contributions and scholarly positioning

This study contributes not only an operationally viable hybrid model but also a theoretical rearticulation of the lean supply chain paradigm, with implications across three dimensions: structural, mechanistic, and cognitive.

Structurally, it introduces a nested dual-layer design for lean procurement systems. While conventional lean research typically models supply chains as linear processes, it often overlooks the cross-process propagation of systemic risk [55]. By integrating an elastic layer above the traditional four modules, this framework elevates the adjustment mechanism to a meta-structural level, enabling dynamic correction capabilities within the managerial architecture.

Mechanistically, the study puts forward a coherent portfolio of procurement resilience strategies tailored to uncertain environments, including geographically distributed sourcing, flexible lot-sizing, and elasticity-based performance indicators. While individual elements of these strategies have been addressed sporadically in the literature, they have rarely been systematically synthesized into an operationally unified schema. This study offers a preliminary translation from conceptual abstraction to structural integration.

Cognitively, this research challenges the value boundary of lean as a managerial paradigm. In an era increasingly defined by the efficiency–adaptability paradox, the once-dominant lean ideal of singular optimization appears inadequate for ensuring strategic robustness [23]. The hybrid framework introduced here represents a transitional paradigm—a conceptual model for a future trajectory of “conditional lean” or “contextual lean.” Its central contribution lies not in presenting a flawless model, but in furnishing a more realistic theoretical language to reinterpret lean procurement systems under real-world uncertainty. It offers firms a deeper understanding: optimality does not guarantee resilience, and stability does not preclude flexibility.

5. Conclusion

In light of the ongoing disruptions caused by persistent trade wars, this study has examined the challenges faced by lean supply chain management in the procurement phase, particularly under conditions of institutional uncertainty. Focusing on the adaptive dilemmas and structural transformation needs of lean supply chains in the context of procurement and raw material sourcing, it proposes a novel, system-oriented theoretical framework. Building upon the conventional four-module lean architecture — Input, Process, Output, and Feedback — this research introduces an innovative cross-modular mechanism: the Elastic Layer. Designed as a strategic modulation structure, the elastic layer enhances system robustness and adaptability in highly uncertain environments.

Contrary to prevailing perspectives that position resilience as either antithetical or substitutive to lean logic, this study does not reject the foundational pursuit of efficiency inherent in lean thinking. Rather, it offers a structural approach to embedding minimal, yet necessary, structural resilience into the lean procurement system without disrupting its procedural integrity. At the input stage, it supports multi-sourcing and pre-emptive risk identification to mitigate supply concentration risks; second, At the process stage, it introduces flexible lot-sizing and emergency protocols to increase procedural agility. At the output and feedback stages, it redefines performance evaluation by incorporating resilience-oriented metrics such as Time-to-Recover (TTR) and the Exposure Index, thus facilitating a paradigm shift from static efficiency to dynamic robustness.

This framework contributes to reducing the vulnerability of lean procurement systems when confronted with structurally unpredictable events such as trade wars. Theoretically, it initiates a new trajectory of integration between lean supply chain principles and domains such as risk management and strategic adaptability. Nonetheless, it must be emphasized that this framework is not universally applicable across all enterprise types or industries. Its effectiveness is highly contingent upon an organization's strategic management capacity, information system maturity, and willingness to allocate resources toward anticipatory resilience.

Furthermore, this study does not address cost-related dimensions—an area that warrants further development. Given the significant heterogeneity across industries—ranging from raw material dependency and supplier network structures to ingrained inventory practices—sector-specific research is needed to enhance the contextual relevance and practical translatability of the theoretical framework.

Future research could expand the elastic layer across the entire supply chain network hierarchy to investigate synergistic effects and coupling logic among resilience mechanisms at various system levels. Such work would contribute to evolving the lean–resilience paradigm toward a more holistic theory of supply chain complexity and adaptive design.

References

[1]. Womack, J. P. , & Jones, D. T. (2013). Lean thinking: Banish waste and create wealth in your corporation (Revised and updated ed. ). Free Press. https://books. google. co. nz/books/about/Lean_Thinking. html?id=QZrZAAAAQBAJ

[2]. Ivanov, D. (2022). Viable supply chain model: Integrating agility, resilience and sustainability perspectives—Lessons from and thinking beyond the COVID-19 pandemic. Annals of Operations Research, 319(1), 1411–1431. https://doi. org/10. 1007/s10479-020-03640-6

[3]. Celestin, M. , & Sujatha, S. (2024). Impact of global supply chain disruptions on business resilience: Strategies for adapting to pandemics and geopolitical conflicts. International Journal of Advanced Trends in Engineering and Technology, 9(2), 44–53. https://doi. org/10. 5281/zenodo. 13887198

[4]. Tang, C. S. (2006). Perspectives in supply chain risk management. International Journal of Production Economics, 103(2), 451–488. https://doi. org/10. 1016/j. ijpe. 2005. 12. 006

[5]. Fajgelbaum, P. D. , Goldberg, P. K. , Kennedy, P. J. , & Khandelwal, A. K. (2020). The return to protectionism. The Quarterly Journal of Economics, 135(1), 1–55. https://doi. org/10. 1093/qje/qjz036

[6]. Amiti, M. , Redding, S. J. , & Weinstein, D. (2019). The impact of the 2018 trade war on U. S. prices and welfare (NBER Working Paper No. 25672). National Bureau of Economic Research. https://www. nber. org/papers/w25672

[7]. Nguyen, T. T. , Nguyen, H. T. , et al. (2022). Impacts of the US-China trade war on the global supply chain. International Journal of Advanced Multidisciplinary Research and Studies, 2(3), 346–354. https://www. researchgate. net/publication/361266421_Impacts_of_the_US-China_Trade_War_on_the_Global_Supply_Chain

[8]. Bouët, A. , Sall, L. M. , & Zheng, Y. (2025). Towards a trade war in 2025: Real threats for the world economy, false promises for the US (CEPII Working Paper No. 2025-03). Centre d'Études Prospectives et d'Informations Internationales (CEPII). CEPII - Towards a Trade War in 2025: Real Threats for the World Economy, False Promises for the US

[9]. BBC News. (2024, November 15). New Zealand's supply chain resilience tested amid global disruptions. https://www. bbc. com/news/articles/cvgql020y5lo

[10]. Aiyar, S. , Presbitero, A. F. , & Ruta, M. (Eds. ). (2023). Geoeconomic fragmentation: The economic risks from a fractured world economy. CEPR Press & International Monetary Fund. Geoeconomic Fragmentation: The Economic Risks from a Fractured World Economy | CEPR

[11]. Norring, A. (2024). The economic effects of geoeconomic fragmentation (BOFIT Policy Brief No. 8/2024). Bank of Finland Institute for Emerging Economies (BOFIT). https://hdl. handle. net/10419/304310

[12]. Habibi, F. , Chakrabortty, R. K. , Abbasi, A. , & Ho, W. (2025). Investigating disruption propagation and resilience of supply chain networks: Interplay of tiers and connections. International Journal of Production Research. Advance online publication. https://doi. org/10. 1080/00207543. 2025. 2470348

[13]. Zhu, Y. , Bao, Y. , et al. (2025). Resilience analysis based on multi-layer network community detection of supply chain network. Annals of Operations Research. Advance online publication. https://doi. org/10. 1007/s10479-024-06426-2

[14]. Hines, P. , Holweg, M. , & Rich, N. (2004). Learning to evolve: A review of contemporary lean thinking. International Journal of Operations & Production Management, 24(10), 994–1011. https://doi. org/10. 1108/01443570410558049

[15]. Ohno, T. (1988). Toyota production system: Beyond large-scale production (1st ed. ). Productivity Press.

[16]. Christopher, M. (2016). Logistics and supply chain management (5th ed. ). Pearson Education. https://books. google. co. nz/books/about/Logistics_and_Supply_Chain_Management. html?id=IQgWVahxO3UC&redir_esc=y

[17]. Carr, A. S. , & Smeltzer, L. R. (2002). Strategic purchasing: Leveraging the buyer-supplier interface for competitive advantage. International Journal of Operations & Production Management, 22(1), 1032–1053. https://doi. org/10. 1108/01443570210440528

[18]. Liker, J. , & Choi, T. Y. (2004, December). Building deep supplier relationships. Harvard Business Review. https://hbr. org/2004/12/building-deep-supplier-relationships

[19]. Simchi-Levi, D. , Kaminsky, P. , & Simchi-Levi, E. (2021). Designing and managing the supply chain: Concepts, strategies and case studies (4th ed. ). McGraw-Hill Education. https://books. google. co. nz/books/about/Designing_and_Managing_the_Supply_Chain. html?id=vXJ-kgEACAAJ&redir_esc=y

[20]. Vereecke, A. , & Muylle, S. (2006). Performance improvement through supply chain collaboration in Europe. International Journal of Operations & Production Management, 26(11), 1176–1198. https://doi. org/10. 1108/01443570610705818

[21]. Christopher, M. , & Peck, H. (2004). Building the resilient supply chain. The International Journal of Logistics Management, 15(2), 1–13. https://doi. org/10. 1108/09574090410700275

[22]. Sheffi, Y. (2005). The resilient enterprise: Overcoming vulnerability for competitive advantage. The MIT Press. https://books. google. co. nz/books/about/The_Resilient_Enterprise. html?id=bfh2QgAACAAJ&redir_esc=y

[23]. Christopher, M. , & Holweg, M. (2011). “Supply Chain 2. 0”: Managing supply chains in the era of turbulence. International Journal of Physical Distribution & Logistics Management, 41(1), 63–82. https://doi. org/10. 1108/09600031111101439

[24]. Baldwin, R. , & Freeman, R. (2022). Risks and global supply chains: What we know and what we need to know. Annual Review of Economics, 14, 153–180. https://doi. org/10. 1146/annurev-economics-051420-113737

[25]. Farrell, H. , & Newman, A. L. (2019). Weaponized interdependence: How global economic networks shape state coercion. International Security, 44(1), 42–79. https://doi. org/10. 1162/ISEC_a_00351

[26]. Li, F. (2020). Leading digital transformation: Three emerging approaches for managing the transition. International Journal of Operations & Production Management, 40(6), 809–817. https://doi. org/10. 1108/IJOPM-04-2020-0202

[27]. Chu, F. , Sridhar, M. , Mundra, N. , & Arora, S. (2024, September 5). Diversifying global supply chains: Opportunities in Southeast Asia. McKinsey & Company. https://www. mckinsey. com/industries/logistics/our-insights/diversifying-global-supply-chains-opportunities-in-southeast-asia

[28]. Carreras-Valle, M. J. , & Ferrari, A. (2025). The cost of delivery delays (AEA Papers and Proceedings 2025, Version 1). Pennsylvania State University & Universitat Pompeu Fabra. https://arxiv. org/abs/2501. 08728

[29]. Partridge, J. (2025, April 13). Terrible timing and huge uncertainty: How ports and shipping are handling tariff turmoil. The Guardian. https://www. theguardian. com/us-news/2025/apr/13/trump-tariff-uncertainties-global-supply-chains-pressure

[30]. Orr, A. (2025, January 14). Apple's global manufacturing expansion matters for your next iPhone purchase. AppleInsider. https://appleinsider. com/articles/25/01/14/apples-global-manufacturing-expansion-matters-for-your-next-iphone-purchase

[31]. Rudge, S. (2025, January 9). How Apple handles its China-dependent supply chain amid global tensions. Supply Chain World. https://scw-mag. com/news/how-apple-handles-its-china-dependent-supply-chain-amid-global-tensions/

[32]. Hahn, C. (2025, January 22). Driving into uncertainty: How Trump’s tariffs could derail Europe’s automotive powerhouse. Oxford Economics. https://www. oxfordeconomics. com/resource/driving-into-uncertainty-how-trumps-tariffs-could-derail-europes-automotive-powerhouse/

[33]. Fernandez-Stark, K. , Bamber, P. , & Couto, V. (2022). Analysis of the textile and clothing industry global value chains (IDB Technical Note No. 2624). Inter-American Development Bank. https://doi. org/10. 18235/0004638

[34]. Dong, L. , & Kouvelis, P. (2020). Impact of tariffs on global supply chain network configuration: Models, predictions, and future research. Manufacturing & Service Operations Management, 22(1), 25–35. https://doi. org/10. 1287/msom. 2019. 0802

[35]. Kancs, d’. (2024). Uncertainty of supply chains: Risk and ambiguity. The World Economy, 47(5), 2009–2033. https://doi. org/10. 1111/twec. 13534

[36]. Grossman, G. M. , Helpman, E. , & Redding, S. J. (2024). When tariffs disrupt global supply chains. American Economic Review, 114(4), 988–1029. https://doi. org/10. 1257/aer. 20211519

[37]. Morita, M. , Machuca, J. A. D. , Marin-Garcia, J. A. , & Alfalla-Luque, R. (2025). Drivers of supply chain adaptability: Insights into mobilizing supply chain processes. A multi-country and multi-sector empirical research. Operations Management Research, 18(3), 373–399. https://doi. org/10. 1007/s12063-024-00474-4

[38]. Ivanov, D. , & Dolgui, A. (2020). A digital supply chain twin for managing the disruption risks and resilience in the era of Industry 4. 0. Production Planning & Control, 32(9), 775–788. https://doi. org/10. 1080/09537287. 2020. 1768450

[39]. Shan, X. , Xiong, S. , & Zhang, C. (2023). Mitigating supply disruption risks by diversifying competing suppliers and using sales effort. International Journal of Production Economics, 255, 108637. https://doi. org/10. 1016/j. ijpe. 2022. 108637

[40]. Sharma, A. , Iyer, R. , & Deshmukh, P. (2025). Optimizing production and inventory strategies for enhanced supply chain resilience. International Journal of Creative Research Thoughts, 11(1). https://www. researchgate. net/publication/390495501

[41]. Wu, Q. , Zhu, J. , & Cheng, Y. (2023). The effect of cross-organizational governance on supply chain resilience: A mediating and moderating model. Journal of Purchasing and Supply Management, 29(1), 100817. https://doi. org/10. 1016/j. pursup. 2023. 100817

[42]. Chen, T. , Hsieh, C. -T. , & Song, Z. M. (2022). Non-tariff barriers in the U. S. -China trade war (NBER Working Paper No. 30318). National Bureau of Economic Research. https://www. nber. org/papers/w30318

[43]. Sithomola, T. , & Auriacombe, C. J. (2018). Developing a logic framework design as a methodological approach to monitoring and evaluation (M&E). African Journal of Public Affairs, 10(3), 82–101. https://www. researchgate. net/publication/332241008

[44]. Berger, S. L. T. , Frazzon, E. M. , & Danielli, A. M. C. (2018, November). Pull-production system in a lean supply chain: A performance analysis utilizing the simulation-based optimization. In 2018 13th IEEE International Conference on Industry Applications (INDUSCON) (pp. 1–6). IEEE. https://doi. org/10. 1109/INDUSCON. 2018. 8627187

[45]. Patel, P. M. , & Deshpande, V. A. (2017). Application of Plan-Do-Check-Act cycle for quality and productivity improvement – A review. International Journal for Research in Applied Science & Engineering Technology (IJRASET), 5(1), 197–201. https://www. researchgate. net/publication/318743952

[46]. Handley, K. , Kamal, F. , & Monarch, R. (2024). Supply chain adjustments to tariff shocks: Evidence from firm trade linkages in the 2018–2019 U. S. trade war. Economics Letters, 244, 112009. https://doi. org/10. 1016/j. econlet. 2024. 112009

[47]. Todo, Y. , & Inoue, H. (2021). Geographic diversification of the supply chains of Japanese firms. Asian Economic Policy Review, 16(2), 304–322. https://doi. org/10. 1111/aepr. 12337

[48]. Rafigh, P. , Akbari, A. A. , Bidhandi, H. M. , & Husseinzadeh Kashan, A. (2022). A sustainable supply chain network considering lot sizing with quantity discounts under disruption risks: Centralized and decentralized models. Journal of Combinatorial Optimization, 44, 1387–1432. https://doi. org/10. 1007/s10878-022-00891-w

[49]. Ventura, J. A. , & Lu, Q. (2023). Optimizing Supplier Selection and Order Lot-Sizing Decisions in a Two-Stage Supply Chain. Axioms, 12(7), 615. https://doi. org/10. 3390/axioms12070615

[50]. Khanna, G. , Morales, N. , & Pandalai-Nayar, N. (2025). Supply chain resilience: Evidence from Indian firms (NBER Working Paper No. 30689). National Bureau of Economic Research. https://www. nber. org/papers/w30689

[51]. Wieland, A. , & Durach, C. F. (2021). Two perspectives on supply chain resilience. Journal of Business Logistics, 42(3), 315–322. https://doi. org/10. 1111/jbl. 12271

[52]. Sodhi, M. S. , & Tang, C. S. (2012). Managing supply chain risk. Springer. https://doi. org/10. 1007/978-1-4614-3238-8

[53]. Kraljic, P. (1983). Purchasing must become supply management. Harvard Business Review, 61(5), 109–117. https://hbr. org/1983/09/purchasing-must-become-supply-management

[54]. Kumar, R. , & Singh, R. K. (2017). Coordination and responsiveness issues in SMEs supply chains: A review. Benchmarking: An International Journal, 24(3), 635–677. https://doi. org/10. 1108/BIJ-03-2016-0041

[55]. Ghadge, A. , Dani, S. , & Kalawsky, R. (2011). Systems thinking for modeling risk propagation in supply networks. In 2011 IEEE International Conference on Industrial Engineering and Engineering Management (pp. 1685–1689). IEEE. https://doi. org/10. 1109/IEEM. 2011. 6118203

Cite this article

Liu,L. (2025). Rethinking Lean Supply Chain Resilience: A Theoretical Framework for Procurement and Raw Material Sourcing under Trade War Disruptions. Advances in Economics, Management and Political Sciences,191,217-229.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of ICEMGD 2025 Symposium: The 4th International Conference on Applied Economics and Policy Studies

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Womack, J. P. , & Jones, D. T. (2013). Lean thinking: Banish waste and create wealth in your corporation (Revised and updated ed. ). Free Press. https://books. google. co. nz/books/about/Lean_Thinking. html?id=QZrZAAAAQBAJ

[2]. Ivanov, D. (2022). Viable supply chain model: Integrating agility, resilience and sustainability perspectives—Lessons from and thinking beyond the COVID-19 pandemic. Annals of Operations Research, 319(1), 1411–1431. https://doi. org/10. 1007/s10479-020-03640-6

[3]. Celestin, M. , & Sujatha, S. (2024). Impact of global supply chain disruptions on business resilience: Strategies for adapting to pandemics and geopolitical conflicts. International Journal of Advanced Trends in Engineering and Technology, 9(2), 44–53. https://doi. org/10. 5281/zenodo. 13887198

[4]. Tang, C. S. (2006). Perspectives in supply chain risk management. International Journal of Production Economics, 103(2), 451–488. https://doi. org/10. 1016/j. ijpe. 2005. 12. 006

[5]. Fajgelbaum, P. D. , Goldberg, P. K. , Kennedy, P. J. , & Khandelwal, A. K. (2020). The return to protectionism. The Quarterly Journal of Economics, 135(1), 1–55. https://doi. org/10. 1093/qje/qjz036

[6]. Amiti, M. , Redding, S. J. , & Weinstein, D. (2019). The impact of the 2018 trade war on U. S. prices and welfare (NBER Working Paper No. 25672). National Bureau of Economic Research. https://www. nber. org/papers/w25672

[7]. Nguyen, T. T. , Nguyen, H. T. , et al. (2022). Impacts of the US-China trade war on the global supply chain. International Journal of Advanced Multidisciplinary Research and Studies, 2(3), 346–354. https://www. researchgate. net/publication/361266421_Impacts_of_the_US-China_Trade_War_on_the_Global_Supply_Chain

[8]. Bouët, A. , Sall, L. M. , & Zheng, Y. (2025). Towards a trade war in 2025: Real threats for the world economy, false promises for the US (CEPII Working Paper No. 2025-03). Centre d'Études Prospectives et d'Informations Internationales (CEPII). CEPII - Towards a Trade War in 2025: Real Threats for the World Economy, False Promises for the US

[9]. BBC News. (2024, November 15). New Zealand's supply chain resilience tested amid global disruptions. https://www. bbc. com/news/articles/cvgql020y5lo

[10]. Aiyar, S. , Presbitero, A. F. , & Ruta, M. (Eds. ). (2023). Geoeconomic fragmentation: The economic risks from a fractured world economy. CEPR Press & International Monetary Fund. Geoeconomic Fragmentation: The Economic Risks from a Fractured World Economy | CEPR

[11]. Norring, A. (2024). The economic effects of geoeconomic fragmentation (BOFIT Policy Brief No. 8/2024). Bank of Finland Institute for Emerging Economies (BOFIT). https://hdl. handle. net/10419/304310

[12]. Habibi, F. , Chakrabortty, R. K. , Abbasi, A. , & Ho, W. (2025). Investigating disruption propagation and resilience of supply chain networks: Interplay of tiers and connections. International Journal of Production Research. Advance online publication. https://doi. org/10. 1080/00207543. 2025. 2470348

[13]. Zhu, Y. , Bao, Y. , et al. (2025). Resilience analysis based on multi-layer network community detection of supply chain network. Annals of Operations Research. Advance online publication. https://doi. org/10. 1007/s10479-024-06426-2

[14]. Hines, P. , Holweg, M. , & Rich, N. (2004). Learning to evolve: A review of contemporary lean thinking. International Journal of Operations & Production Management, 24(10), 994–1011. https://doi. org/10. 1108/01443570410558049

[15]. Ohno, T. (1988). Toyota production system: Beyond large-scale production (1st ed. ). Productivity Press.

[16]. Christopher, M. (2016). Logistics and supply chain management (5th ed. ). Pearson Education. https://books. google. co. nz/books/about/Logistics_and_Supply_Chain_Management. html?id=IQgWVahxO3UC&redir_esc=y

[17]. Carr, A. S. , & Smeltzer, L. R. (2002). Strategic purchasing: Leveraging the buyer-supplier interface for competitive advantage. International Journal of Operations & Production Management, 22(1), 1032–1053. https://doi. org/10. 1108/01443570210440528

[18]. Liker, J. , & Choi, T. Y. (2004, December). Building deep supplier relationships. Harvard Business Review. https://hbr. org/2004/12/building-deep-supplier-relationships

[19]. Simchi-Levi, D. , Kaminsky, P. , & Simchi-Levi, E. (2021). Designing and managing the supply chain: Concepts, strategies and case studies (4th ed. ). McGraw-Hill Education. https://books. google. co. nz/books/about/Designing_and_Managing_the_Supply_Chain. html?id=vXJ-kgEACAAJ&redir_esc=y

[20]. Vereecke, A. , & Muylle, S. (2006). Performance improvement through supply chain collaboration in Europe. International Journal of Operations & Production Management, 26(11), 1176–1198. https://doi. org/10. 1108/01443570610705818

[21]. Christopher, M. , & Peck, H. (2004). Building the resilient supply chain. The International Journal of Logistics Management, 15(2), 1–13. https://doi. org/10. 1108/09574090410700275

[22]. Sheffi, Y. (2005). The resilient enterprise: Overcoming vulnerability for competitive advantage. The MIT Press. https://books. google. co. nz/books/about/The_Resilient_Enterprise. html?id=bfh2QgAACAAJ&redir_esc=y

[23]. Christopher, M. , & Holweg, M. (2011). “Supply Chain 2. 0”: Managing supply chains in the era of turbulence. International Journal of Physical Distribution & Logistics Management, 41(1), 63–82. https://doi. org/10. 1108/09600031111101439

[24]. Baldwin, R. , & Freeman, R. (2022). Risks and global supply chains: What we know and what we need to know. Annual Review of Economics, 14, 153–180. https://doi. org/10. 1146/annurev-economics-051420-113737

[25]. Farrell, H. , & Newman, A. L. (2019). Weaponized interdependence: How global economic networks shape state coercion. International Security, 44(1), 42–79. https://doi. org/10. 1162/ISEC_a_00351

[26]. Li, F. (2020). Leading digital transformation: Three emerging approaches for managing the transition. International Journal of Operations & Production Management, 40(6), 809–817. https://doi. org/10. 1108/IJOPM-04-2020-0202

[27]. Chu, F. , Sridhar, M. , Mundra, N. , & Arora, S. (2024, September 5). Diversifying global supply chains: Opportunities in Southeast Asia. McKinsey & Company. https://www. mckinsey. com/industries/logistics/our-insights/diversifying-global-supply-chains-opportunities-in-southeast-asia

[28]. Carreras-Valle, M. J. , & Ferrari, A. (2025). The cost of delivery delays (AEA Papers and Proceedings 2025, Version 1). Pennsylvania State University & Universitat Pompeu Fabra. https://arxiv. org/abs/2501. 08728

[29]. Partridge, J. (2025, April 13). Terrible timing and huge uncertainty: How ports and shipping are handling tariff turmoil. The Guardian. https://www. theguardian. com/us-news/2025/apr/13/trump-tariff-uncertainties-global-supply-chains-pressure

[30]. Orr, A. (2025, January 14). Apple's global manufacturing expansion matters for your next iPhone purchase. AppleInsider. https://appleinsider. com/articles/25/01/14/apples-global-manufacturing-expansion-matters-for-your-next-iphone-purchase

[31]. Rudge, S. (2025, January 9). How Apple handles its China-dependent supply chain amid global tensions. Supply Chain World. https://scw-mag. com/news/how-apple-handles-its-china-dependent-supply-chain-amid-global-tensions/

[32]. Hahn, C. (2025, January 22). Driving into uncertainty: How Trump’s tariffs could derail Europe’s automotive powerhouse. Oxford Economics. https://www. oxfordeconomics. com/resource/driving-into-uncertainty-how-trumps-tariffs-could-derail-europes-automotive-powerhouse/

[33]. Fernandez-Stark, K. , Bamber, P. , & Couto, V. (2022). Analysis of the textile and clothing industry global value chains (IDB Technical Note No. 2624). Inter-American Development Bank. https://doi. org/10. 18235/0004638

[34]. Dong, L. , & Kouvelis, P. (2020). Impact of tariffs on global supply chain network configuration: Models, predictions, and future research. Manufacturing & Service Operations Management, 22(1), 25–35. https://doi. org/10. 1287/msom. 2019. 0802

[35]. Kancs, d’. (2024). Uncertainty of supply chains: Risk and ambiguity. The World Economy, 47(5), 2009–2033. https://doi. org/10. 1111/twec. 13534

[36]. Grossman, G. M. , Helpman, E. , & Redding, S. J. (2024). When tariffs disrupt global supply chains. American Economic Review, 114(4), 988–1029. https://doi. org/10. 1257/aer. 20211519

[37]. Morita, M. , Machuca, J. A. D. , Marin-Garcia, J. A. , & Alfalla-Luque, R. (2025). Drivers of supply chain adaptability: Insights into mobilizing supply chain processes. A multi-country and multi-sector empirical research. Operations Management Research, 18(3), 373–399. https://doi. org/10. 1007/s12063-024-00474-4

[38]. Ivanov, D. , & Dolgui, A. (2020). A digital supply chain twin for managing the disruption risks and resilience in the era of Industry 4. 0. Production Planning & Control, 32(9), 775–788. https://doi. org/10. 1080/09537287. 2020. 1768450

[39]. Shan, X. , Xiong, S. , & Zhang, C. (2023). Mitigating supply disruption risks by diversifying competing suppliers and using sales effort. International Journal of Production Economics, 255, 108637. https://doi. org/10. 1016/j. ijpe. 2022. 108637

[40]. Sharma, A. , Iyer, R. , & Deshmukh, P. (2025). Optimizing production and inventory strategies for enhanced supply chain resilience. International Journal of Creative Research Thoughts, 11(1). https://www. researchgate. net/publication/390495501

[41]. Wu, Q. , Zhu, J. , & Cheng, Y. (2023). The effect of cross-organizational governance on supply chain resilience: A mediating and moderating model. Journal of Purchasing and Supply Management, 29(1), 100817. https://doi. org/10. 1016/j. pursup. 2023. 100817

[42]. Chen, T. , Hsieh, C. -T. , & Song, Z. M. (2022). Non-tariff barriers in the U. S. -China trade war (NBER Working Paper No. 30318). National Bureau of Economic Research. https://www. nber. org/papers/w30318

[43]. Sithomola, T. , & Auriacombe, C. J. (2018). Developing a logic framework design as a methodological approach to monitoring and evaluation (M&E). African Journal of Public Affairs, 10(3), 82–101. https://www. researchgate. net/publication/332241008

[44]. Berger, S. L. T. , Frazzon, E. M. , & Danielli, A. M. C. (2018, November). Pull-production system in a lean supply chain: A performance analysis utilizing the simulation-based optimization. In 2018 13th IEEE International Conference on Industry Applications (INDUSCON) (pp. 1–6). IEEE. https://doi. org/10. 1109/INDUSCON. 2018. 8627187

[45]. Patel, P. M. , & Deshpande, V. A. (2017). Application of Plan-Do-Check-Act cycle for quality and productivity improvement – A review. International Journal for Research in Applied Science & Engineering Technology (IJRASET), 5(1), 197–201. https://www. researchgate. net/publication/318743952

[46]. Handley, K. , Kamal, F. , & Monarch, R. (2024). Supply chain adjustments to tariff shocks: Evidence from firm trade linkages in the 2018–2019 U. S. trade war. Economics Letters, 244, 112009. https://doi. org/10. 1016/j. econlet. 2024. 112009

[47]. Todo, Y. , & Inoue, H. (2021). Geographic diversification of the supply chains of Japanese firms. Asian Economic Policy Review, 16(2), 304–322. https://doi. org/10. 1111/aepr. 12337

[48]. Rafigh, P. , Akbari, A. A. , Bidhandi, H. M. , & Husseinzadeh Kashan, A. (2022). A sustainable supply chain network considering lot sizing with quantity discounts under disruption risks: Centralized and decentralized models. Journal of Combinatorial Optimization, 44, 1387–1432. https://doi. org/10. 1007/s10878-022-00891-w

[49]. Ventura, J. A. , & Lu, Q. (2023). Optimizing Supplier Selection and Order Lot-Sizing Decisions in a Two-Stage Supply Chain. Axioms, 12(7), 615. https://doi. org/10. 3390/axioms12070615

[50]. Khanna, G. , Morales, N. , & Pandalai-Nayar, N. (2025). Supply chain resilience: Evidence from Indian firms (NBER Working Paper No. 30689). National Bureau of Economic Research. https://www. nber. org/papers/w30689

[51]. Wieland, A. , & Durach, C. F. (2021). Two perspectives on supply chain resilience. Journal of Business Logistics, 42(3), 315–322. https://doi. org/10. 1111/jbl. 12271

[52]. Sodhi, M. S. , & Tang, C. S. (2012). Managing supply chain risk. Springer. https://doi. org/10. 1007/978-1-4614-3238-8

[53]. Kraljic, P. (1983). Purchasing must become supply management. Harvard Business Review, 61(5), 109–117. https://hbr. org/1983/09/purchasing-must-become-supply-management

[54]. Kumar, R. , & Singh, R. K. (2017). Coordination and responsiveness issues in SMEs supply chains: A review. Benchmarking: An International Journal, 24(3), 635–677. https://doi. org/10. 1108/BIJ-03-2016-0041

[55]. Ghadge, A. , Dani, S. , & Kalawsky, R. (2011). Systems thinking for modeling risk propagation in supply networks. In 2011 IEEE International Conference on Industrial Engineering and Engineering Management (pp. 1685–1689). IEEE. https://doi. org/10. 1109/IEEM. 2011. 6118203