1. Introduction

Chip products are mainly used in the automotive industry and electronic devices, car manufacturers and electronic technology companies need many chips to maintain the innovation, development, and production of products. The chip manufacturing process is very complex and requires a lot of high-tech equipment, such as photolithography machines, and only a few countries have mature chip manufacturing and research and development technology. As CNBC reported, semiconductors are an important technology, and more and more products can perform tasks they would not otherwise be able to perform [1]. However, the complexity of chip and semiconductor manufacturing processes, the scarcity of photolithography machines, the lack of raw materials for production, and the large amount of labor and capital required are slowing down the pace of production related to chip design. The network supply chain is fragile, and the production and fabrication of chip semiconductors play an important role in the supply chain system. From 2019 onwards, a huge number of electronic devices (such as headsets, cell phones and computers) will be required between the popular telecommuting. All these products need chips to be produced, and chips are essential as the most basic and important part of the supply chain. Apple, as a leader in the technology industry, needs to produce and sell a large number of electronic products every year. In addition to understanding Apple's business strategy in recent years and Apple's annual report for 2018-2021, this study will look at the entire chip supply chain and analyze the major factors contributing to supply chain shortages in the chip industry. More specifically, it will explore the impact and changes that the chip shortage has brought to Apple during the epidemic.

2. The Origins of Chips and the Vulnerability of Supply Chains

2.1. The Manufacturing Supply Chain of Chips — From Sand to Chip

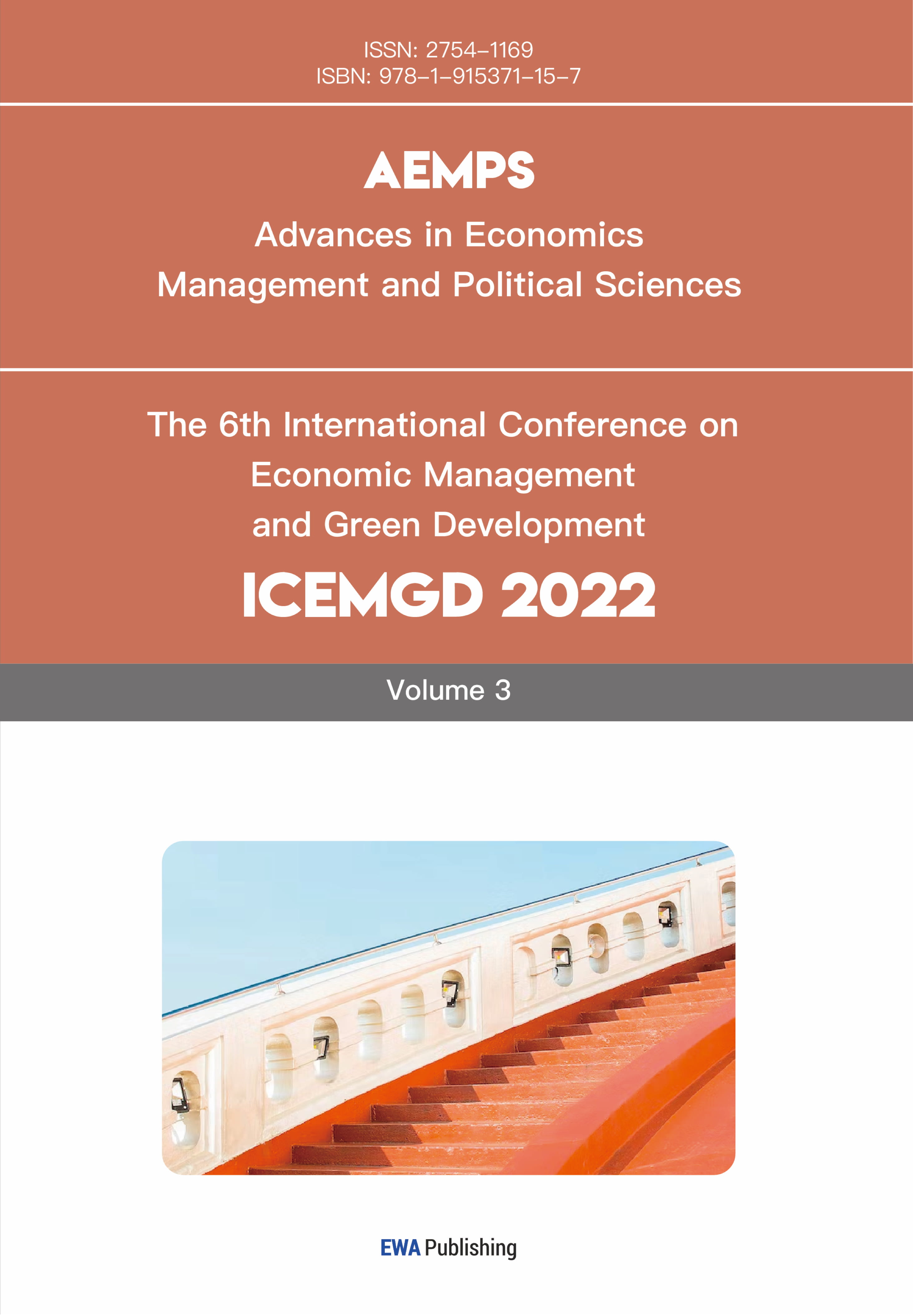

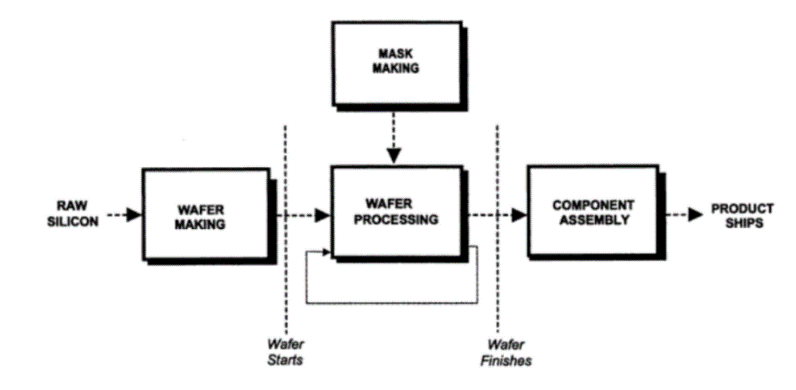

A chip goes from design to application, mainly through design, fabrication, packaging, and testing. Each stage is subdivided into several complex phases. Among them, the fabrication of wafers (silicon wafers used in the production of silicon semiconductor integrated circuits), in order of silicon refining and purification, single crystal silicon growth, and wafer forming are the three steps. The most difficult part is the purification, which requires a purity of 99.9999%. In addition, the amount of work that goes into the production of a chip from the selection of raw materials to its completion is enormous [2]. Besides, the book "Handbook of Semiconductor Manufacturing Technology" mentions the specific production steps of a semiconductor and shows the semiconductor fabrication process from VLSI. Figure 1 shows a complete semiconductor fabrication process with only four interconnected boxes in operation [3]. However, if the wafer processing area is further expanded, the processing cycle becomes apparent. Figure 2 provides a good illustration of an extended complex flow chart for a complete semiconductor fabrication steps [4].

Figure 1: Complete semiconductor fabrication process (4 interconnected boxes).

Figure 2: Generalized process diagram for semiconductor fabrication.

Therefore, the labor, material, and even time costs required to make just one chip are enormous. From the beginning of the design and manufacturing to the purification of the wafer, and then to the final packaging and testing, all require professional staff to operate strictly through complex and precise equipment.

2.2. Fragility of the Global Economic System and Collapse of Supply Chains

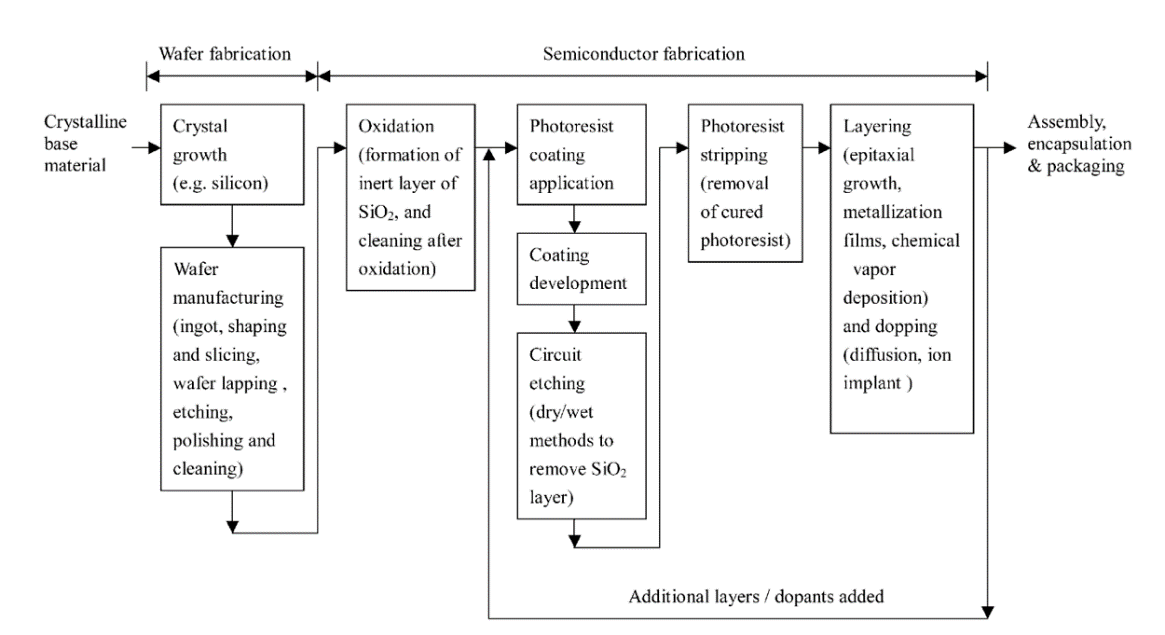

The supply chain is a functional network chain structure model that connects all relevant users and end users. There are different functions such as purchasing, production and production, differentiation, sales, logistic docking, and finance. Having a good supply chain requires mutual trust and close cooperation between companies [5]. Figure 3 also shows that a complete supply chain system needs to be taken seriously by every user in the system in order to function well.

Figure 3: Supply chain.

The spread of the epidemic had a huge and uncontrollable impact on global economic fluctuations, and most industries were irreversibly affected. As a result, most companies chose to lay off employees and reduce costs under the pressure of shutting down production, and some were even bought out or faced bankruptcy because they could not afford the expenses during the outbreak. The automotive industry is unable to produce cars because of the lack of chip supply, and the digital industry is unable to meet consumer demand for all products because of chips. Similarly, food suppliers and restaurants can have their food supply chains collapse because they are unable to match fresh ingredients in a timely manner. As you can see, although the industries are different, the main supply chain infrastructure is basically the same for each industry. The supply chains of each economic system are interconnected, and if one link fails or is damaged, the whole supply chain will be in trouble. The nature of the supply chain is fragile, and it is one of the cores of a good partnership between companies.

As mentioned in the literature "Supply Network Formation and Fragility", in most fragile supply chains, all production balances involve vulnerability, and no temporary policy can eliminate it. Instead, to solve this problem, permanent interventions in production costs or production technologies are required [6]. This is exactly the case in the chip industry, where the production supply chain cannot perfectly match the demand. The various limitations of the epidemic combined with the difficulty of making wafers prevented a significant increase in chip production in a short period of time. And along with the significant increase in demand for digital products, the inability to supply the chip semiconductors needed to produce the products in a timely manner led to the collapse of the production chain for most companies.

3. The Impact of the Pandemic's Economic Volatility on Apple Inc

3.1. What Changes in Apple Inc's Strategy for Chip Semiconductor Demand During the Epidemic

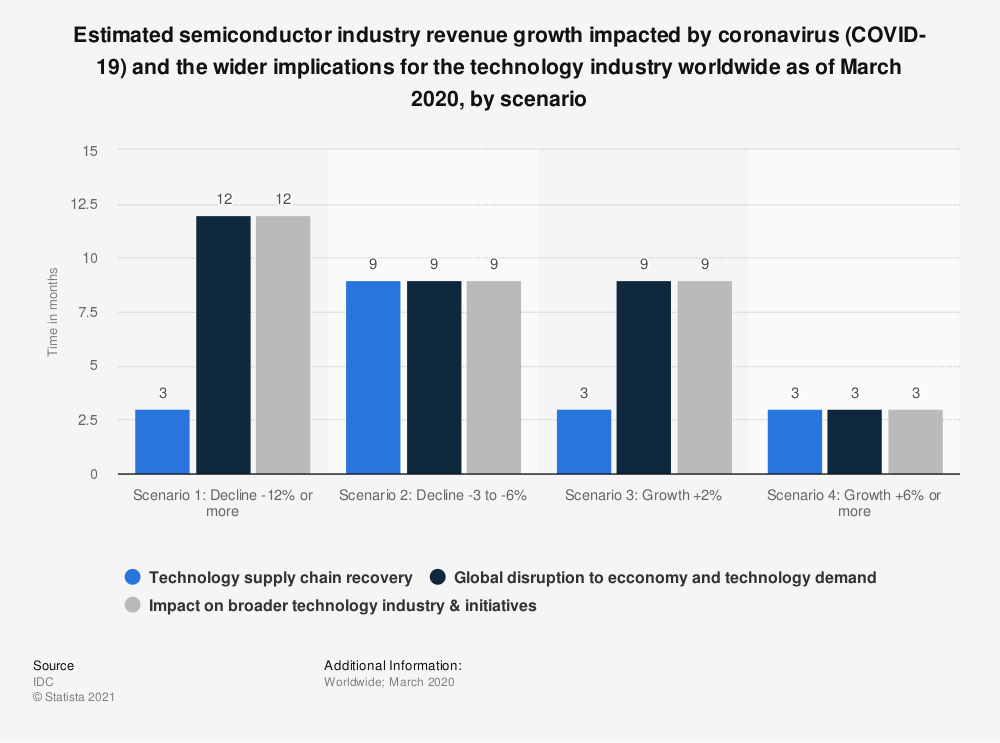

With the rapid development of the global digital economy, the demand for chips in the computer industry, high-tech industry, electronics industry, and automotive industry has risen sharply. In addition, the impact of the pandemic has disrupted the supply chain of the global chip semiconductor industry, resulting in excess demand for chips. Figure 4 shows that there is a shortage of chip supply under the impact of the pandemic, but the global demand for the digital economy has grown exponentially [7]. It is known that the demand for cell phones, computers, and other electronic products is rising every year. And in addition to electronic devices, the digital industrial industry and the automotive industry, among others, have a great demand for chips.

Figure 4: Estimated semiconductor industry revenue growth impacted by coronavirus (COVID-19) and the wider implications for the technology industry worldwide as of March 2020.

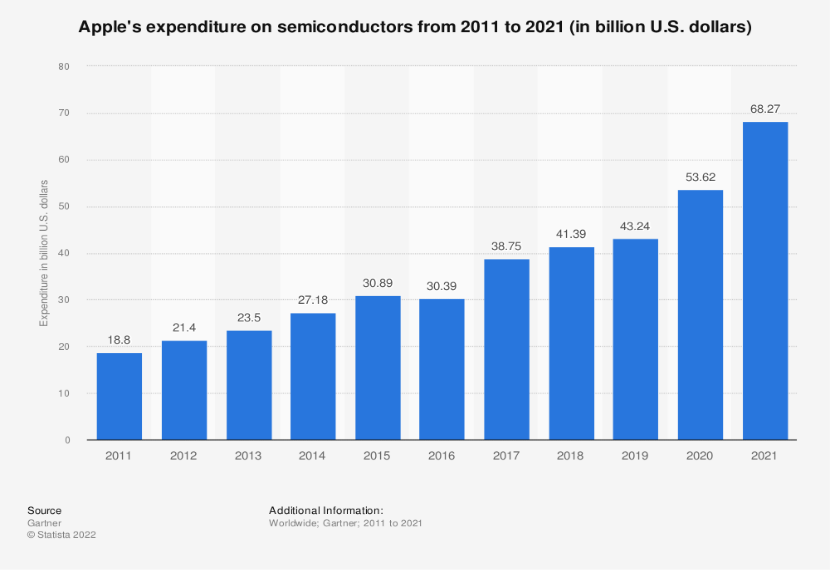

Figure 5: Apple's expenditure on semiconductors from 2011 to 2021.

For Apple, it is facing the same chip supply chain shortage as many other companies. The global shortage of computer chips has not reduced consumer demand for digital products, as evidenced by the growing value of Apple's annual costs spent on semiconductors. As a result, Apple has chosen to lower its production targets for the newly released iPhone 13 series of phones in 2021. Although sufficient to deal with the shortage of global chip semiconductor production chain in the short term, but not a long-term solution, the supply chain is still very fragile and easily collapsed. In addition, the semiconductor production supply shortage problem could affect products using its own M1 chips, including the new iPad Pro and iMac 2021 [8]. TSMC (the Taiwanese company that makes chips) has been producing chips for Apple for many years, and both the M1 chip and now the M2 chip are produced by TSMC Manufacturing Co. According to Apple CEO Tim Cook, Apple will be affected by the chip production side and chip supply shortage despite releasing its own M1 chip in 2021 [9]. Thus, the shortage of chip supply is not only affecting the production of products but is also continuing to reduce Apple's overall profits.

3.2. Apple's Competitive Advantage and Global Strategies

The New Crown Pneumonia outbreak caught the semiconductor industry and chip production supply chain ecosystem off guard. The massive demand for chips across industries has left most companies trapped in the "chip" trap. During the shortage of chip production chains, it is possible to make some strategic updates that are not so much related to chips.

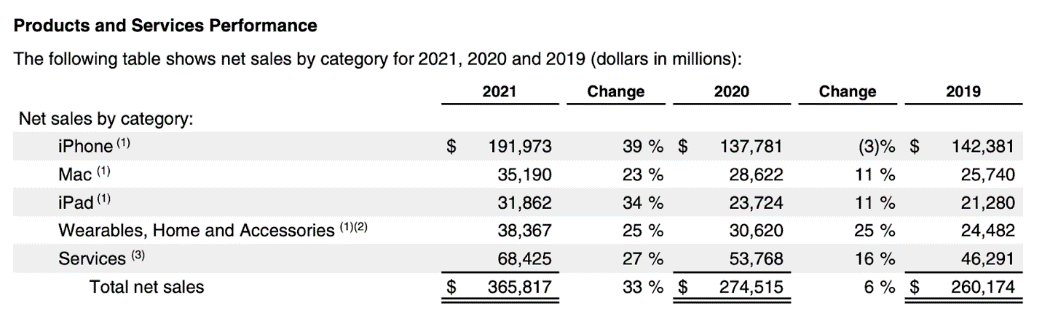

Due to the complexity and difficulty of the chip semiconductor production process, Apple is unable to make changes or optimize the entire chip production supply system. However, Apple can allocate the chips in its inventory that are not yet in use, and a correct and reasonable allocation can maximize the benefits of the company's products at this stage. Figure 6 from Apple's 2021 annual report shows that out of the service category [10], iPhone has the highest percentage of sales, followed by accessories and Mac, and finally iPad. With the fact that there is a shortage of chips, the company can allocate chips to each product for production in proportion. Thus, it can achieve freedom of product supply in a short period of time.

Figure 6: Apple Inc. 2021 Annual Report (Page 21).

On the other hand, by examining the key factors of Apple's success in the field of technology, it is possible to make strategic improvements and refinements to the company itself, and even to innovate and develop its own production chain despite the shortage of chip resources. First, Apple has its own unique and complete system (iOS) compared to its peers, which also allows customers to enjoy Apple's unique ecosystem. The idiosyncratic iOS system makes it expensive for users to switch, and if consumers want to switch to an Android phone, it is very difficult to transfer large amounts of data alone. Apple also has numerous after-sales services for its products, such as Apple Care+, trade-ins and interest-free installments. These have largely improved the customer's experience with the product and after-sales service, thus largely increasing customer loyalty. Based on these advantages, Apple can boldly try to innovate instead of focusing on the output of chips. Just as the M1 and M2 chips were born to attract the public's attention, Apple could try to innovate in other areas of technology or produce peripheral derivatives related to the company's brand or products. For example, Apple commemorative T-shirts can add elements about the M1 chip, not only without the need to wash the chip, but also to attract loyal customers of the Apple brand. Furthermore, even if the current supply of chips is insufficient, the company can continue to develop new products and technologies to prepare for the company's sustainable development in the future.

4. Conclusion

Based on all the above research and analysis, we can understand more deeply that the specific production process of chips is extremely complex. Due to the shutdown of the chip semiconductor chain caused by the epidemic, and with the increase in demand for chips in the digital market, the shortage of supply out of the production chain of chips accelerated the collapse of the entire supply chain system. To reduce the ongoing profit loss to Apple from this phenomenon, this could be achieved by promoting research and development in the company's other non-chip-related production chains, rather than focusing on chip supply issues. The use of chips could also be rationally allocated to maximize the utilization of chips. However, there is still room for improvement in this study. Although the impact of global economic fluctuations on the supply chain system is analyzed, it still cannot fundamentally change or even optimize the vulnerability of the entire supply chain structure. The study only analyzes how to solve the problems caused by chip supply chain shortages from a company's strategic point of view and maximize the benefits of chip semiconductor production supply shortages. Furthermore, the recommendations cited in the study have not been confirmed in practice. If the chip supply chain shortage problem persists because of the epidemic, the innovations and recommendations adopted by the study will not be successfully implemented. Therefore, considering the current economic market, the only way to maintain a complete and good supply chain system is to improve the overall supply chain and reduce costs as much as possible.

Acknowledgment

This research uses literature on expertise in chip production, as well as data and company reports from Apple Inc. In addition, special thanks to Prof. Matthew Elliott, University of Cambridge, UK, for his knowledge teaching in the topic: Development of Supply Chain Systems under Global Economic Fluctuations, in which numerous economic models taught are of great help in understanding supply chain vulnerability.

References

[1]. Shead, S. (2022, May 2). Chip supply issues are still giving some of world’s biggest companies a major headache. BBC News.

[2]. Microcontroller Division Applications. (n.d.). INTRODUCTION TO SEMICONDUCTOR TECHNOLOGY. N.p.: STMicroelectronics. Retrieved from https://www.st.com/resource/en/application_note/cd00003986-introduction-to semiconductor-technology-stmicroelectronics.pdf.

[3]. Nishi, Y., & Doering, R. (2000). Handbook of Semiconductor Manufacturing Technology (illustrated ed., pp. 23-25). N.p.: CRC Press.

[4]. Tsai, W., Chen, H., & Hsien, W. (2001, November 9). Journal of Loss Prevention in the Process Industries, 15(2002), 65-75. doi:https://www.sciencedirect.com/science/article/pii/S0950423001000675.

[5]. Stadtler, H. (2008). Supply Chain Management — An Overview. In: Stadtler, H., Kilger, C. (eds) Supply Chain Management and Advanced Planning. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-540-74512-9_2.

[6]. Elliott, Matthew and Golub, Benjamin and Leduc, Mathieu V., Supply Network Formation and Fragility (April 18, 2022). American Economic Review, forthcoming 2022, Available at SSRN: https://ssrn.com/abstract=3525459 or http://dx.doi.org/10.2139/ssrn.3525459.

[7]. IDC. (March 18, 2020). Estimated semiconductor industry revenue growth impacted by coronavirus (COVID-19) and the wider implications for the technology industry worldwide as of March 2020, by scenario [Graph]. In Statista. Retrieved August 16, 2022, from https://www.statista.com/statistics/1105939/covid-19-impact-on semiconductor-and-wider-technology-industries-worldwide/.

[8]. Apple's expenditure on semiconductors from 2011 to 2021 (n.d.). In Statista. Retrieved from https://www.statista.com/statistics/383194/apple-semiconductors-expenditure/.

[9]. Tim Cook warns of Apple product shortages. (2021, April 29). BBC News. Retrieved from https://www.bbc.com/news/technology-56929647.

[10]. Apple Inc. (2021). Apple Inc. Annual Report. Washington, D.C. 20549. 10-K.

Cite this article

Zhu,H. (2023). Apple Inc's Massive Demand for Chips and Semiconductors under COVID-19 and its Response Strategies. Advances in Economics, Management and Political Sciences,9,377-383.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2nd International Conference on Business and Policy Studies

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Shead, S. (2022, May 2). Chip supply issues are still giving some of world’s biggest companies a major headache. BBC News.

[2]. Microcontroller Division Applications. (n.d.). INTRODUCTION TO SEMICONDUCTOR TECHNOLOGY. N.p.: STMicroelectronics. Retrieved from https://www.st.com/resource/en/application_note/cd00003986-introduction-to semiconductor-technology-stmicroelectronics.pdf.

[3]. Nishi, Y., & Doering, R. (2000). Handbook of Semiconductor Manufacturing Technology (illustrated ed., pp. 23-25). N.p.: CRC Press.

[4]. Tsai, W., Chen, H., & Hsien, W. (2001, November 9). Journal of Loss Prevention in the Process Industries, 15(2002), 65-75. doi:https://www.sciencedirect.com/science/article/pii/S0950423001000675.

[5]. Stadtler, H. (2008). Supply Chain Management — An Overview. In: Stadtler, H., Kilger, C. (eds) Supply Chain Management and Advanced Planning. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-540-74512-9_2.

[6]. Elliott, Matthew and Golub, Benjamin and Leduc, Mathieu V., Supply Network Formation and Fragility (April 18, 2022). American Economic Review, forthcoming 2022, Available at SSRN: https://ssrn.com/abstract=3525459 or http://dx.doi.org/10.2139/ssrn.3525459.

[7]. IDC. (March 18, 2020). Estimated semiconductor industry revenue growth impacted by coronavirus (COVID-19) and the wider implications for the technology industry worldwide as of March 2020, by scenario [Graph]. In Statista. Retrieved August 16, 2022, from https://www.statista.com/statistics/1105939/covid-19-impact-on semiconductor-and-wider-technology-industries-worldwide/.

[8]. Apple's expenditure on semiconductors from 2011 to 2021 (n.d.). In Statista. Retrieved from https://www.statista.com/statistics/383194/apple-semiconductors-expenditure/.

[9]. Tim Cook warns of Apple product shortages. (2021, April 29). BBC News. Retrieved from https://www.bbc.com/news/technology-56929647.

[10]. Apple Inc. (2021). Apple Inc. Annual Report. Washington, D.C. 20549. 10-K.