1. Introduction

Apple Inc. and its wholly-owned subsidiaries (collectively referred to as Apple or the Company) design, develop, manufacture, and sell a wide range of electronic products and services, including smartphones, personal computers, tablets, wearables, and accessories. Apple sells a wide variety of electronic devices and accessories, such as the iPhone, iPad, Mac, Apple Watch, AirPods, AirPods Max, Apple TV, Beats headphones and speakers, HomePod, iPod touch, and many more. You may find and download digital material including books, songs, films, games, and podcasts through the company's many platforms, including the App Store®. Apple also offers a variety of other services, including AppleCare®, iCloud®, Apple Card®, and Apple Pay®, in addition to its many subscription-based digital content services, such as Apple Arcade®, Apple Music®, Apple News+®, Apple TV+®, and Apple Fitness+SM. The majority of our clients are regular individuals as well as small and medium-sized businesses, institutions of higher learning, huge businesses, and public institutions. In the vast majority of its primary markets, the company's retail stores, online marketplaces, and direct sales force provide direct access to the company's products and those of third parties for consumers, small and medium-sized businesses, educational institutions, and government agencies. The business also makes use of indirect channels of distribution including distributors, retailers, and resellers. Apple is managing its energy and natural gas consumption at its facilities as part of its effort to reduce its carbon emissions impact. When Apple cuts its electricity consumption, it helps ease strain on local power grids and protects itself from rising utility bills. Motion detectors and new, more energy-efficient light bulbs are two examples of what may be done through these programs. Apple computers are known for their efficiency, and the company's HVAC systems are always being upgraded to be more eco-friendly.

2. Managing Energy at Facilities

For almost a decade, Apple's Austin, Texas, facility has been an active participant in Austin's "Green Choice" Power Program, helping to increase the demand for renewable energy in the state. With its help, the local power system has received around 44 million kilowatt-hours of renewable energy. If the same amount of energy had been purchased from conventional power plants, 64 million pounds (29 million kilograms) of carbon dioxide equivalent would have been released into the atmosphere (CO2e) [1].

Apple's Cork, Ireland, factory has been using renewable energy since 2007. This project began in 2008 and has successfully converted the facility to using only renewable energy generated inside the state, such as wind power, for all of its energy needs. This renewable energy plan avoided the release of almost 1.8 million kilograms (4 million pounds) of carbon dioxide in 2008. Apple has created commuter transit systems at each factory to lessen the environmental toll of employees traveling from home to the office. Apple's U.S. Commute Alternative program promotes carpooling and other alternatives to driving alone. Everyone who works for Apple in the United States can get a monthly transportation subsidy of up to $100 USD [1], and the company actively promotes carpooling. At its main factory in Cupertino, California, Apple has reduced the usage of single-occupancy automobiles by offering employees with a number of shuttle options, including free bus service from train stations and bus service from metropolitan districts. Every day, up to 600 workers take use of the company's free biodiesel commuter buses [2]. Because of this, roughly 4 million yearly miles of single-occupant car traffic on U.S. roadways have been avoided. Furthermore, each year a growing number of Apple employees take advantage of the public transit incentives provided by the corporation. In 2008, 140,737 metric tons of CO2 equivalents were produced through international and domestic air travel, the United States automobile fleet, and employee commuting [3].

3. Water Use

The majority of Apple's water usage is for hygiene and gardening, while the company's global operations require very little water.

Apple has installed high-tech irrigation systems at its Cupertino, California, and Austin, Texas, campuses, which respond to changes in temperature and humidity to adjust watering times for the landscaping. Water use for landscaping was cut by 40% thanks to this strategy [4]. In addition, xeriscaping (drought-tolerant landscaping) and drip watering are used at Apple's Sacramento and Cupertino stores to reduce water use and waste. By replacing all of the faucets and other water-using fixtures in an Apple factory in Singapore, the company was able to reduce water use by 40 percent. The California headquarters has also undergone similar changes.

Apple's data center in Maiden, North Carolina, has a clever cooling system that recycles water 35 times before it is flushed down the drain, cutting water use by 20% [4]. The data center takes other measures to minimize its overall water usage, including the utilization of rainwater to irrigate the landscaping on site.

4. Waste and Recycling

Apple's operations do not generate a sizable amount of hazardous or solid waste. The company has adopted many recycling and composting systems to reduce the environmental effect of the small amount of trash it produces. In 2007, Apple Cupertino began a cafeteria composting program in an effort to decrease food waste sent to landfills. The majority of the company's disposable plates, cups, and containers have been replaced with compostable or biodegradable alternatives as part of its composting initiative. Successfully reusing materials that would have been thrown away is the goal of this employee-designed and -promoted program.

In order to facilitate recycling efforts worldwide, segregated containers are used. There can be up to five different types of trash cans at any given place, including those for recyclables, regular garbage, compostable materials, and glass. As a result, the company can measure, sort, and prepare recyclables for their next life in the most efficient way possible.

Apple offers and supports several product take-back and recycling programs in 95% of the regions where its wares are sold [5].

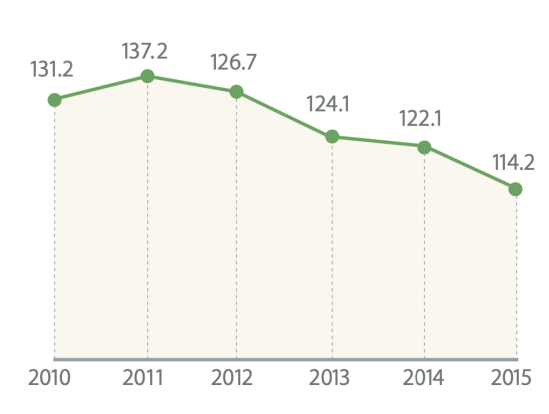

The regulations governing renewable energy sources have led to significant progress. Its worldwide headquarters consumed 75% more green power in 2013 than it did in 2010 [5].

5. Climate Change

As a global corporation responsible for producing some of the world's most sought-after products, Apple Inc. is cognizant of the fact that the vast quantities of energy and materials it consumes result in emissions of greenhouse gases that exacerbate global warming. It has developed methods to reduce wasteful use of resources, get power from renewable sources, and produce electrical products that are among the world's most energy-efficient. Apple Inc. is the only electronics manufacturer whose data centers run on 100% renewable energy and whose complete product range not only satisfies but far surpasses ENERGY STAR criteria [6].

The company is always working to better its processes for analyzing the life cycle impact of greenhouse gases. Additionally, the corporation reevaluates the layout of a product, process, or facility when studies reveal that using a certain material, method, or system significantly increases the firm's carbon footprint.

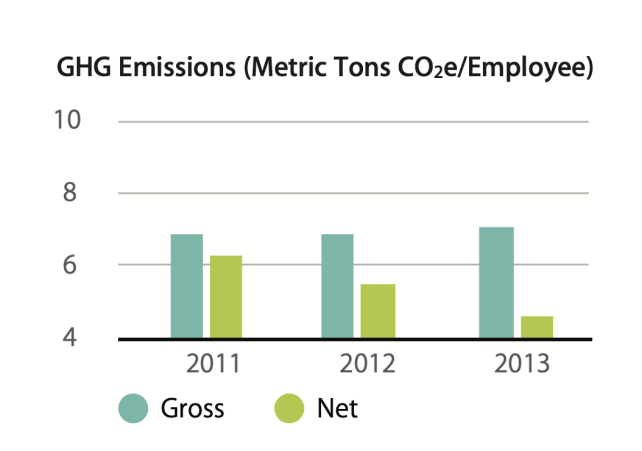

Sales of Apple's iPhone, MacBook Pro, and MacBook Air increased dramatically from 2013 to 2014, and Apple's overall sales increased as well [7]. The company's carbon impact grew significantly due to this. The carbon intensity of the company's production and usage of its products has dropped, despite an increase in output. Apple's carbon efficiency, measured as the company's emissions per dollar of revenue, has been continuously declining since 2008.

Figure 1: GHG Emissions from 2011 to 2013 [8].

In 2015, 93% of the business' energy came from renewable resources. Moreover, Apple is continually exploring new avenues to expand its market share. In Singapore, Apple uses a 32-megawatt solar array that is spread across more than 800 roofs to power its activities. Currently, it is constructing 170 MW of solar power in China to begin balancing the energy used in production [9]. And all those iMessages, Siri queries, and iTunes downloads? They're powered by renewable energy in Apple's data centers across the world.

Figure 2: CO2e emissions per product (kg) from 2010 to 2015 [10].

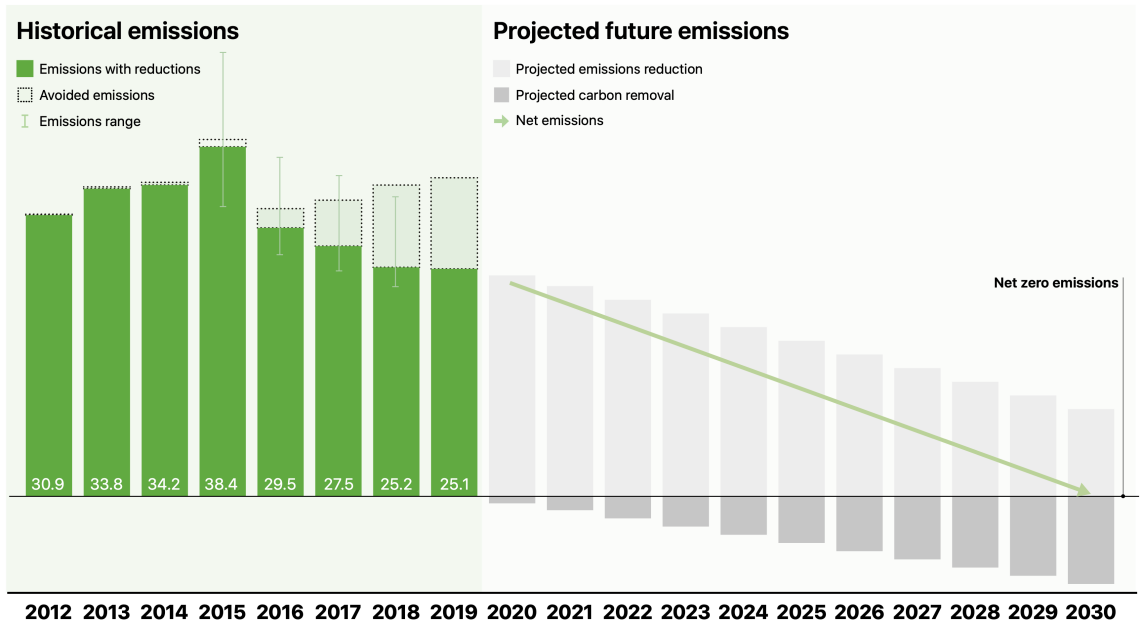

The full extent of the company's impact on the environment is quantified using a life cycle approach. They use as many Apple-specific metrics as they can muster, falling back on industry norms only when necessary. They are committed to transparency and accuracy, thus they regularly update their product life cycle evaluation techniques and data sets. As an example, they have recently obtained more exact data on the amount of energy required to manufacture a number of components, including on-board electronics, bare boards and flexes, and a number of module assemblies. Consequently, their annual carbon output for 2019 went up.

Their 2019 carbon emissions would have been about 23 million metric tons if they had utilized the same data and methods as in 2018, which would have been a 7% drop [11]. Their whole carbon footprint is certified annually by an outside organization, proving the reliability and thoroughness of their methodology. They plan to keep analyzing their impact on the environment and revising their climate roadmap to reflect the most up-to-date information.

Figure 3: Apple’s historical and projected future emissions from 2012 to 2030 [12].

6. Resources

Companies like Apple would cease to exist if the planet's resources were depleted. To this end, the company prioritizes the ethical sourcing of its raw materials, the efficient use of its water resources, and the minimization of its waste output. Apple has promised to become carbon neutral by the year 2030. Their dependency on particular resources to make their products has a considerable influence on this purpose. This is just another argument in favor of businesses developing recycling technology to wean themselves off carbon-intensive mining, creating long-lasting products with smaller carbon footprints, and generally making better use of the resources they use. These actions help preserve the Earth's precious resources. Apple is adjusting the designs of its products to reduce the amount of raw materials required. By switching from an extrusion process to a sheet forging one, for instance, they were able to cut down on the quantity of aluminum required by 73% for the 12.9-inch iPad Pro's chassis. Additionally, they have decreased their primary aluminum consumption by 23% since 2015 [13], despite increasing sales.

Aluminum is employed extensively in the manufacturing of their electronic gadgets. In order to use only recycled aluminum, a new approach has to be created. Each time ordinary recycled aluminum is recycled, it adds pollutants. To address this issue, they created an alloy that can be made from recycled aluminum yet has the same durability, strength, and aesthetic appeal. They apply powerful computer models to estimate an alloy's chemical composition that can endure an endless number of recycling cycles. Daisy's reclaimed iPhone enclosures are only one example of their products and processes that provide aluminum scrap for our secret alloy. In the fall of 2018, Apple introduced new versions of the MacBook Air and Mac mini with aluminum cases that are 100 percent recyclable. The carbon footprint of each item is cut by nearly half when recycled materials are used. More than 900,000 metric tons of bauxite-containing aluminum won't need to be mined in 2019 [14].

Magnets for audio equipment, cameras, and haptic feedback devices all make use of rare earth elements including neodymium, praseodymium, and dysprosium. Since these rare earth elements are only needed in trace amounts, and the technology needed to recover them is still in its infancy, traditional recyclers are unable to gather them. Apple, however, built the ingenious robot Daisy to save the iPhones' tiny rare earth component parts. By gathering these resources together, we may give cutting-edge equipment an opportunity to develop more effective methods of extraction.

In 2016, they anticipate using plastic for just 4% of their packaging [15]. Since 2015, their focus has been on developing fiber alternatives to large plastic trays, wraps, and foam cushioning that have higher recovery rates and smaller environmental footprints. Also, they continue to be dedicated to completing the project. The iPhone 13 and iPhone 13 Pro, introduced by Apple in 2021, were the first iPhones to be sold without plastic packing materials. The polypropylene wrapper was cut off of each box in order to do this. Since the introduction of the iPhone 8, this plastic wrap has been used to prevent the container from being tampered with or damaged. User surveys were conducted, materials were weighed and analyzed for their individual qualities, and design prototypes were developed. They came up with a solution including two extremely small fiber-based pull tabs for the 2021 iPhone release. This new method of packaging reduces plastic waste by an estimated 600 metric tons per year while still providing a tamper-evident seal [16]. They came up with an alternative to the polyethylene foam that was previously utilized to ship and protect individual iMacs. Before, they manufactured fiber-molding parts to switch out the foam padding on iMac Pro boxes. Instead of using traditional packing foam, they worked to create a material that could take shocks without losing its shape or resilience. A fiber-based corrugated spring was the answer they came up with. Taking cues from origami, they came up with a design that has the potential to outperform standard foam while being less wasteful to produce. The use of corrugated cardboard, a familiar packing material, in this design allowed them to continue utilizing their previous suppliers. Until now, normal packing foam has never been replaced with a material like their fiber-based corrugated spring. Due to this approach, Apple was able to cut its plastic use by 400 tons [16].

7. Liam System

Project Liam at Apple is a research and development effort to provide advanced disassembly tools. It uses an autonomous, eco-friendly disassembly technique to free and separate parts for recycling into niche commodity products. Automated disassembly technology developed specifically for the iPhone 6 has the potential to dismantle 1.2 million iPhones annually [17]. Elements that cannot be recovered at the required scale or purity at present are used for research on end-processing recycling systems, and Liam's output components are used for this purpose. Liam demonstrates Apple's dedication to preprocessing technology. Apple, and the industry as a whole, has to be more innovative. Because of the challenges inherent in material recovery and the need to increase the usage of recycled components in new devices, Apple initiated the Liam project. Because the clean disassembly approach results in streams of components that are all the same, automated disassembly is a valuable process [18]. It is possible to send these products directly to the recycler who will complete their processing. The disassembly and, hence, the recyclable nature of obsolete electronics can be enhanced in other ways besides automation. Additional methods exist with the same goal in mind, which is to preserve a product's maximum value for its next cycle of use. Finally, it is critical that producers and recyclers maintain funding for technologies that recover the full range of embedded materials, and that we give preference to approaches that do not lead to the down-cycling or degradation of valuable materials.

8. Conclusion

As one of the most influential and extensive electrical technology companies in the world, Apple Inc. is dedicated to protecting the well-being of its employees, customers, and the local communities in which it works throughout the globe. To provide cutting-edge goods and services while also protecting and enhancing the planet's natural resources for future generations, the company has adopted EHS management practices that are second to none. Improves are made all the time to Apple's EHS management systems and the environmental quality of its goods, processes, and services. conform to or exceed all health, safety, and environmental regulations. Through the combination of continuous monitoring of performance outcomes and occasional management reviews, they will evaluate our EHS effectiveness. In cases when existing laws and regulations do not offer sufficient safeguards for people and the planet, activists and innovators will create their own policies. In order to improve environmental quality, public health, and safety, we need to back and promote scientifically-based concepts and economically-sensible public policies. Advocate for their partners in the supply chain to adopt safe and healthy working conditions and environmental standards. Share Apple's health, safety, and environmental policies with the public. Prioritizing safety, energy efficiency, and environmental preservation should be at the forefront of the design, management, and operation of such facilities. Design, manufacture, use, and dispose of products in a manner that protects people and the environment from harm over the product's entire life cycle. Make sure everyone at Apple understands what is expected of them in terms of contributing to Apple's environmental, health, and safety management systems and regulations. It is clear that the company's continued efforts for environmental preservation are aimed at developing an ever-more-perfect environmental protection system to better aid in the progress of all of human civilization.

References

[1]. Apple Propels Environmental Business Solutions Forward with Second Impact Accelerator Class - Apple.” Apple Newsroom, 25 Aug. 2022, www.apple.com/newsroom/2022/08/apple-propels-environmental-business-solutions-forward-with-second-impact-accelerator-class.

[2]. “Apple Helps Suppliers Rapidly Accelerate Renewable Energy Use around the World - Apple.” Apple Newsroom, 14 Apr. 2022, www.apple.com/newsroom/2022/04/apple-helps-suppliers-rapidly-accelerate-renewable-energy-use-around-the-world.

[3]. The Global Reporting Initiative (GRI) Sustainability Reporting Guidelines (G3): www.globalreporting.org/ReportingFramework/G3Online.

[4]. More information on Austin green energy: www.austinenergy.com/index.htm.

[5]. “Supplier Responsibility - Apple.” Apple, www.apple.com/supplier-responsibility. Accessed 26 Sept.2022.

[6]. Carbon emissions equivalences calculated using U.S. Energy Information Administration, 2019 data: www.eia.gov/electricity/sales_revenue_price/pdf/ table5_a.pdf.

[7]. “Apple Reports Third Quarter Results - Apple.” Apple Newsroom, 28 July 2015, www.apple.com/newsroom/2015/07/apple-reports-third-quarter-results.

[8]. Faludi, J., T. Hoang, P. Gorman, and M. Mulvihill, “Aiding alternatives assessment with an uncertainty-tolerant hazard scoring method”, Journal of Environmental Management, 182, 111–125, 2016. https://doi.org/10.1016/j.jenvman.2016.07.028

[9]. A Protocol for Prioritizing Chemicals of Concern in the Electronics Industry , 2018 https://www.apple.com/environment/pdf/Apple_Prioritizing_Chemicals_2018.pdf

[10]. CO2e Emissions per Product (kg), 2016, https://www.apple.com/environment/pdf/Apple_Environmental_Responsibility_Report_2016.pdf

[11]. United Nations Economic Commission for Europe, Globally harmonized system of classification and labelling of chemicals (6th Revised Edition), New York and Geneva, (2015). http://www.unece.org/trans/danger/publi/ghs/ghs_rev06/06files_e.htm

[12]. Clean Production Action, GreenScreen® for Safer Chemicals Hazard Assessment Criteria. Version 1.3, 2017. http://www.greenscreenchemicals.org/

[13]. Sustainable Fiber Specification, Version C, https://www.apple.com/environment/pdf/Sustainable_Fiber_Specification_April2016.pdf

[14]. Environmental Responsibility Report, 2019 Progress Report, covering fiscal year 2018, https://www.apple.com/environment/pdf/Apple_Environmental_Responsibility_Report_2019.pdf

[15]. Apple’s Paper and Packaging Strategy, October 2017, https://www.apple.com/environment/pdf/Packaging_and_Forestry_September_2017.pdf

[16]. National Research Council (US), A framework to guide selection of chemical alternatives, The National Academies Press, Washington, D.C., 2014. http://www.nap.edu/catalog/18872/a-framework-to-guide-selection-of-chemical-alternatives

[17]. Liam - An Innovation Story, Charissa Rujanavech, Joe Lessard, Sarah Chandler, Sean Shannon, Jeffrey Dahmus, Rob Guzzo, September 2016, https://www.apple.com/environment/pdf/Liam_white_paper_Sept2016.pdf

[18]. Mitchell, J., N. Pabon, Z.A. Collier, P.P. Egeghy, E. Cohen-Hubal, et al., “A decision analytic approach to exposure-based chemical prioritization”, PLoS ONE, 8(8): e70911, 2013. https://doi.org/10.1371/journal.pone.0070911

Cite this article

Chen,Z. (2023). Analysis and Synthesis of the Environmental Progress of Apple Inc. from 2008 to 2022. Advances in Economics, Management and Political Sciences,27,97-103.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 7th International Conference on Economic Management and Green Development

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Apple Propels Environmental Business Solutions Forward with Second Impact Accelerator Class - Apple.” Apple Newsroom, 25 Aug. 2022, www.apple.com/newsroom/2022/08/apple-propels-environmental-business-solutions-forward-with-second-impact-accelerator-class.

[2]. “Apple Helps Suppliers Rapidly Accelerate Renewable Energy Use around the World - Apple.” Apple Newsroom, 14 Apr. 2022, www.apple.com/newsroom/2022/04/apple-helps-suppliers-rapidly-accelerate-renewable-energy-use-around-the-world.

[3]. The Global Reporting Initiative (GRI) Sustainability Reporting Guidelines (G3): www.globalreporting.org/ReportingFramework/G3Online.

[4]. More information on Austin green energy: www.austinenergy.com/index.htm.

[5]. “Supplier Responsibility - Apple.” Apple, www.apple.com/supplier-responsibility. Accessed 26 Sept.2022.

[6]. Carbon emissions equivalences calculated using U.S. Energy Information Administration, 2019 data: www.eia.gov/electricity/sales_revenue_price/pdf/ table5_a.pdf.

[7]. “Apple Reports Third Quarter Results - Apple.” Apple Newsroom, 28 July 2015, www.apple.com/newsroom/2015/07/apple-reports-third-quarter-results.

[8]. Faludi, J., T. Hoang, P. Gorman, and M. Mulvihill, “Aiding alternatives assessment with an uncertainty-tolerant hazard scoring method”, Journal of Environmental Management, 182, 111–125, 2016. https://doi.org/10.1016/j.jenvman.2016.07.028

[9]. A Protocol for Prioritizing Chemicals of Concern in the Electronics Industry , 2018 https://www.apple.com/environment/pdf/Apple_Prioritizing_Chemicals_2018.pdf

[10]. CO2e Emissions per Product (kg), 2016, https://www.apple.com/environment/pdf/Apple_Environmental_Responsibility_Report_2016.pdf

[11]. United Nations Economic Commission for Europe, Globally harmonized system of classification and labelling of chemicals (6th Revised Edition), New York and Geneva, (2015). http://www.unece.org/trans/danger/publi/ghs/ghs_rev06/06files_e.htm

[12]. Clean Production Action, GreenScreen® for Safer Chemicals Hazard Assessment Criteria. Version 1.3, 2017. http://www.greenscreenchemicals.org/

[13]. Sustainable Fiber Specification, Version C, https://www.apple.com/environment/pdf/Sustainable_Fiber_Specification_April2016.pdf

[14]. Environmental Responsibility Report, 2019 Progress Report, covering fiscal year 2018, https://www.apple.com/environment/pdf/Apple_Environmental_Responsibility_Report_2019.pdf

[15]. Apple’s Paper and Packaging Strategy, October 2017, https://www.apple.com/environment/pdf/Packaging_and_Forestry_September_2017.pdf

[16]. National Research Council (US), A framework to guide selection of chemical alternatives, The National Academies Press, Washington, D.C., 2014. http://www.nap.edu/catalog/18872/a-framework-to-guide-selection-of-chemical-alternatives

[17]. Liam - An Innovation Story, Charissa Rujanavech, Joe Lessard, Sarah Chandler, Sean Shannon, Jeffrey Dahmus, Rob Guzzo, September 2016, https://www.apple.com/environment/pdf/Liam_white_paper_Sept2016.pdf

[18]. Mitchell, J., N. Pabon, Z.A. Collier, P.P. Egeghy, E. Cohen-Hubal, et al., “A decision analytic approach to exposure-based chemical prioritization”, PLoS ONE, 8(8): e70911, 2013. https://doi.org/10.1371/journal.pone.0070911