1 Introduction

With the development of community group buying, the risk of food supply chain has gradually become an increasingly noticeable topic, which has been widely concerned by countries all over the world. Scholars from all over the world have conducted in-depth research on this hot topic. Food supply chain risk refers to the possibility of food supply chain collapse, operational obstacles, reputation and economic loss and customer loss caused by various uncertain factors within the system in the process of operation of enterprises at each node of the food supply chain [1]. It is of great significance to analyze the development of food supply chain of community group buying. It is very important to find a suitable method to prevent supply chain risk. By establishing risk indicators and comparing the weight of risk indicators, this paper obtains the scores of risk indicators, and then puts forward corresponding suggestions for the risk degree of each stage. Some scholars believe that the study of food supply chain risk is of great significance for establishing food safety risk early warning. For example, from the perspective of supply chain, the food quality and safety risk evaluation index system is established, and a safety warning model is established to provide reference for food quality and safety warning [2]. In addition, the study of food supply chain risks is helpful for the industry to improve product quality and provide reference for the management of relevant departments [3]. Food supply chain risk research is also conducive to the establishment of food circulation database. For example, comprehensive recording of information in all links of the supply chain is conducive to the establishment of food circulation database, thus contributing to food safety and quality control and national macro-control [4]. Although some methods have been proposed to assess the risk of the food supply chain, there are still some limitations, which lead to the inaccuracy of the risk assessment at each stage of the food supply chain. Therefore, it is very important to use limited resources to establish appropriate models to accurately assess the risk degree of each stage of the food supply chain.

At present, the research on food supply chain risk focuses on risk identification, assessment and management. In the source analysis of food supply chain risks, Liu Yongsheng [5] believes that the main sources of food supply chain risks are both exogenous and endogenous factors. In the food supply chain risk, the research Angle of food supply chain risk is different due to different research subjects. Zhang Qin et al. [6] identified four influencing factors from the three stages of raw material collection, processing and manufacturing and graded sales in the supply chain. Liu Yongsheng et al. [7] divided online food safety risks into risks in the supply stage and risks in the demand stage based on the perspective of supply chain. Jingxue Zhang[8] divided the risks in the supply chain of fresh electricity suppliers into external risks and internal risks. Compared with internal and external risks, Santeramo Fabio Gaetano et al. [9] divided risks in the food supply chain into objective risks and subjective risks for analysis. But pure food supply chain risk can be divided into two parts, easy to lose detail in specific research, therefore, zhang li [10] according to the characteristics of the two aspects of supply chain risk and food supply chain, according to the different perspective of the supply chain, the risk is divided into raw material commodity procurement, processing production risk, circulation sales link risk. Most of the above analyses classify risks from the overall food supply chain. Bouzembrak Yamine et al. [11] used The European dairy supply chain as an application case to identify chemical food safety risks related to abnormalities in Dutch milk by Using Bayesian networks, indicating that food safety problems may occur at the beginning of the supply chain. Using specific examples to analyze and identify risks helps to solve specific risks. Kalantari Fateme et al. [12] proposed a sustainable global food supply chain model considering the risk, considering that food is prone to deterioration without proper transportation and maintenance after production. Nurul Eiman Md Saad et al. [13] analyzed the impact of Novel Coronavirus on food safety and food supply chain, discussed and identified risks from the aspects of hygiene of food operators, complete vaccination requirements, kitchen hygiene and strict standard operating specifications, etc. In the above stages, food safety can be ensured. Preventing food safety risks from creeping up the supply chain.

Food safety risk assessment runs through the whole supply chain, and relevant research is extremely important, which is also an essential link in formulating food safety policies and measures. Zhang Min [14] took into account the complexity of the food supply chain network and the mutual transmission of risk factors among different enterprises, applied the analytic hierarchy process (AHP) to evaluate risks, and finally concluded that quality risk and logistics risk accounted for a large proportion in the evaluation of the food supply chain. Yao Qi [15] divided food supply chain risks into three categories according to the three layers of Internet of Things, namely, perception layer, network layer and application layer, and adopted OWA operator method to conduct modeling analysis on risk factors. Cui Shiying [16] used the improved interpretation structure model and hidden Markov model based on grey correlation analysis to conduct modeling to realize the risk assessment of food safety, and obtained the grading results of risk assessment. It can be seen from the above research of experts and scholars that the majority of studies on risk assessment in the food supply chain use the combination of qualitative and quantitative methods.

2 The Model Was Established Based on Analytic Hierarchy Process

2.1 Set Up Process

Establish Food Supply Chain Risk Indicators. Through the analysis of all links of the food supply chain under community group purchase, five first-level indicators and fifteen second-level indicators are determined[17], as shown in Table 1.

Construct the Judgment Matrix. The 1-9 scale method was used to compare the indicators, so as to determine the weight of each indicator, as shown in Table 2.

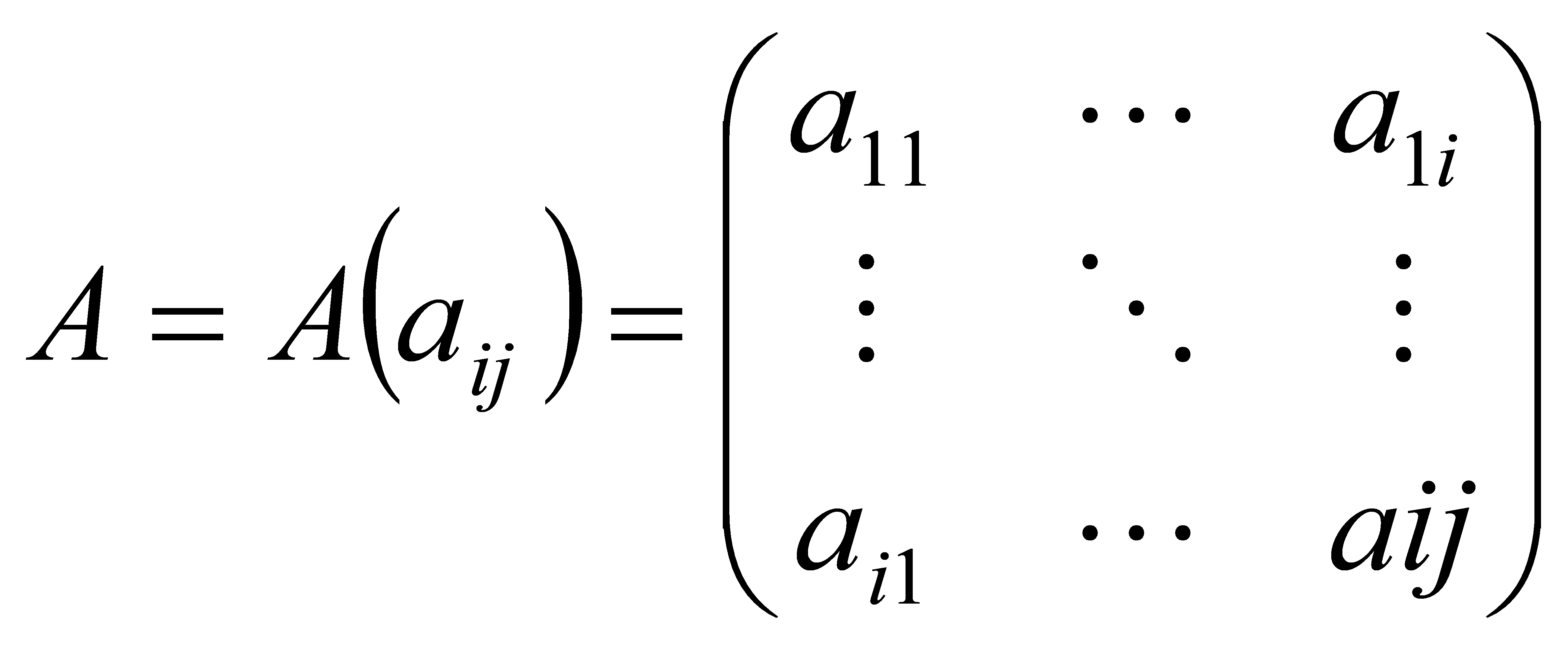

The judgment matrix is constructed as follows:

(1)

(1)

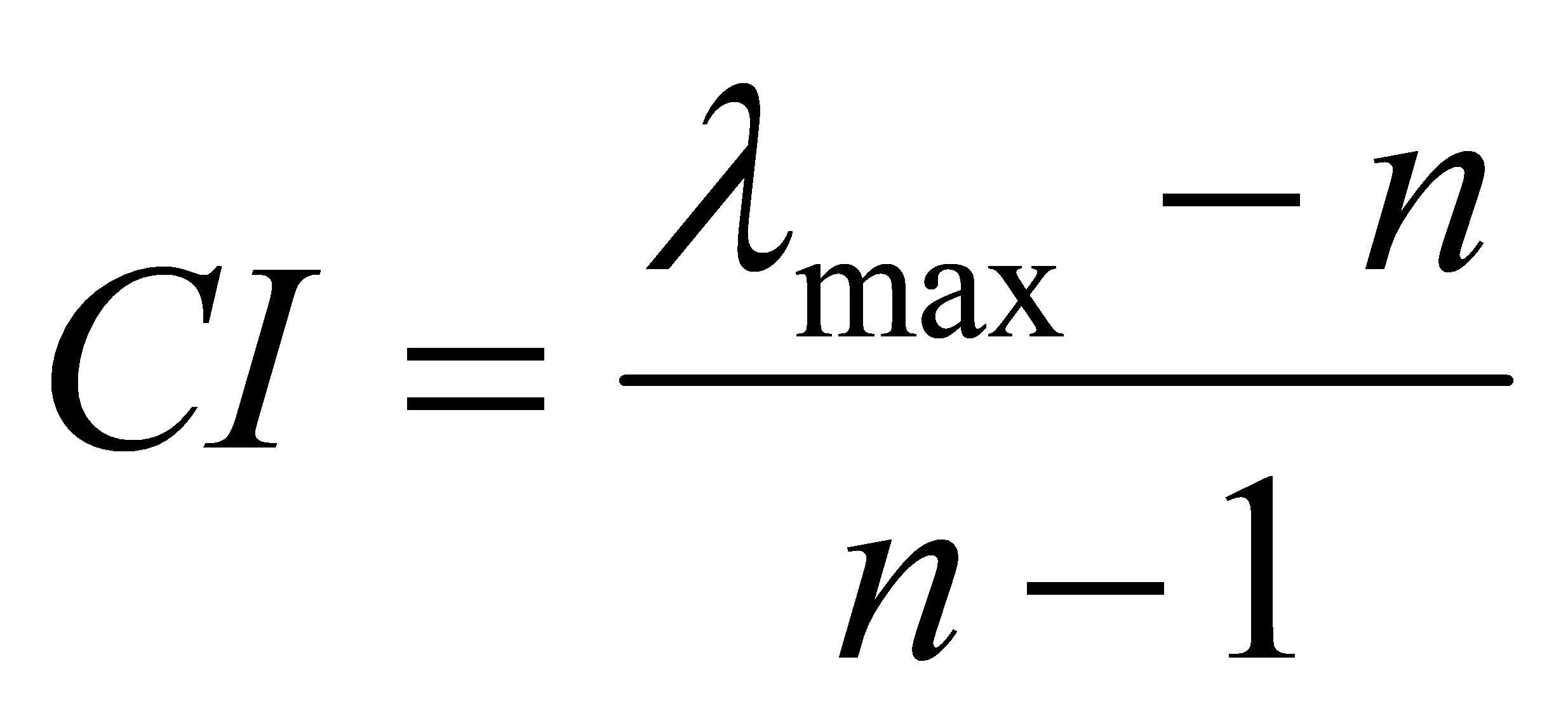

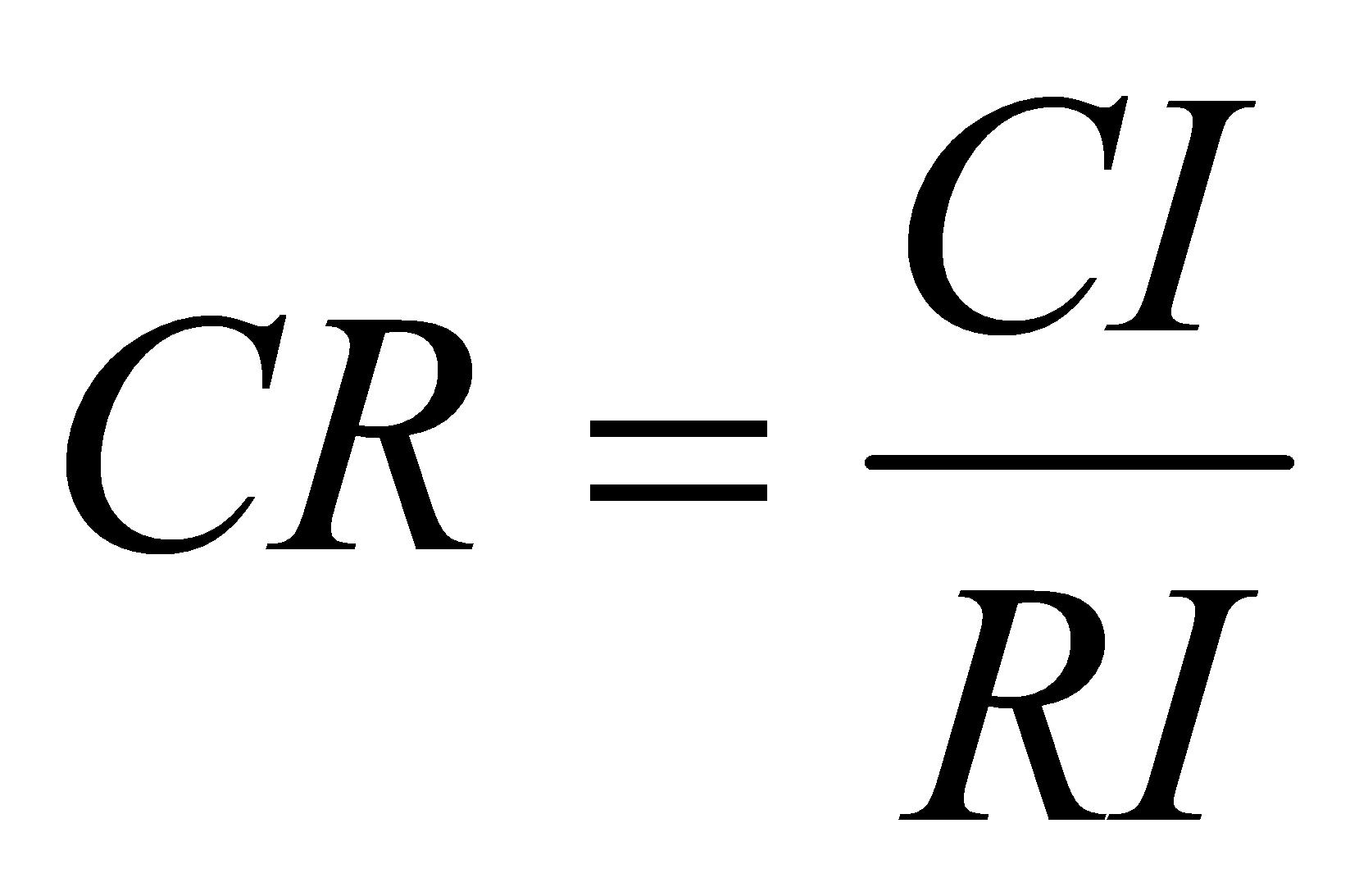

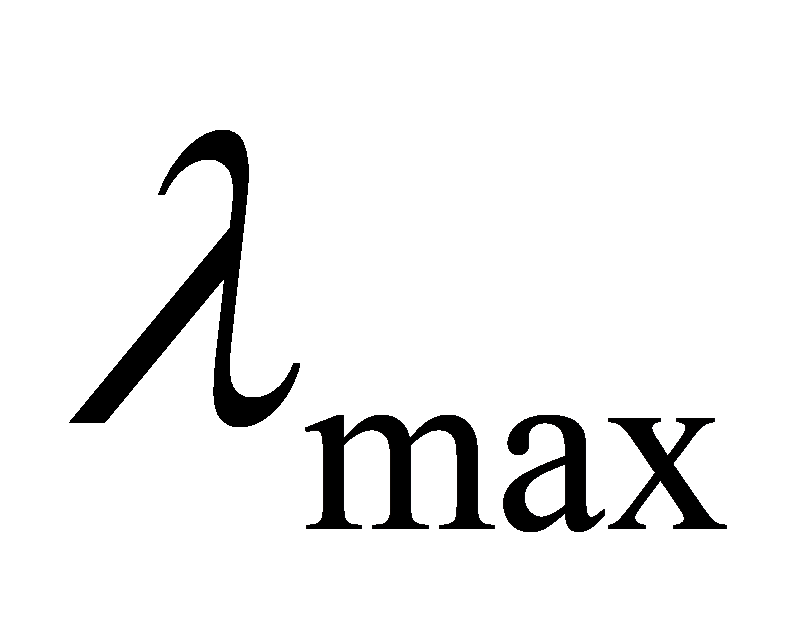

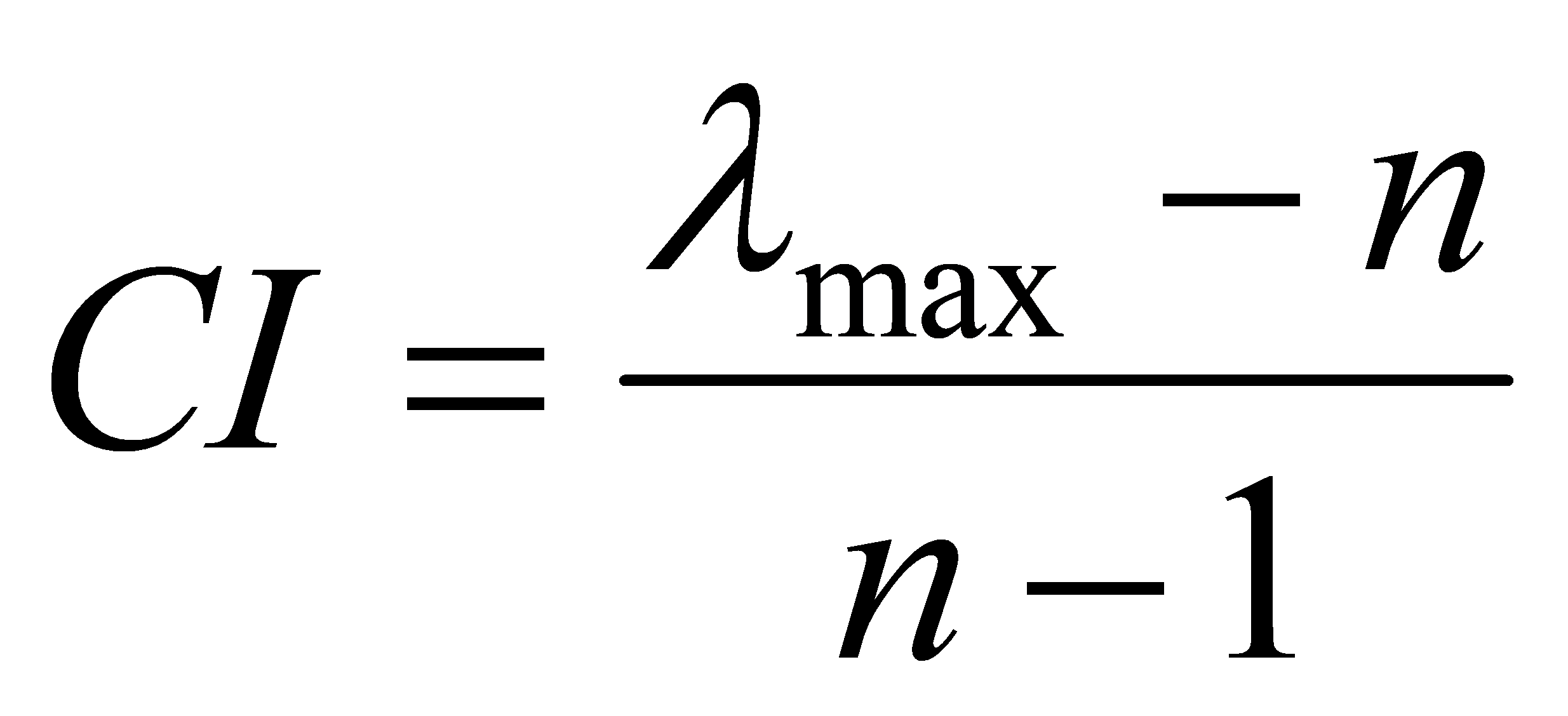

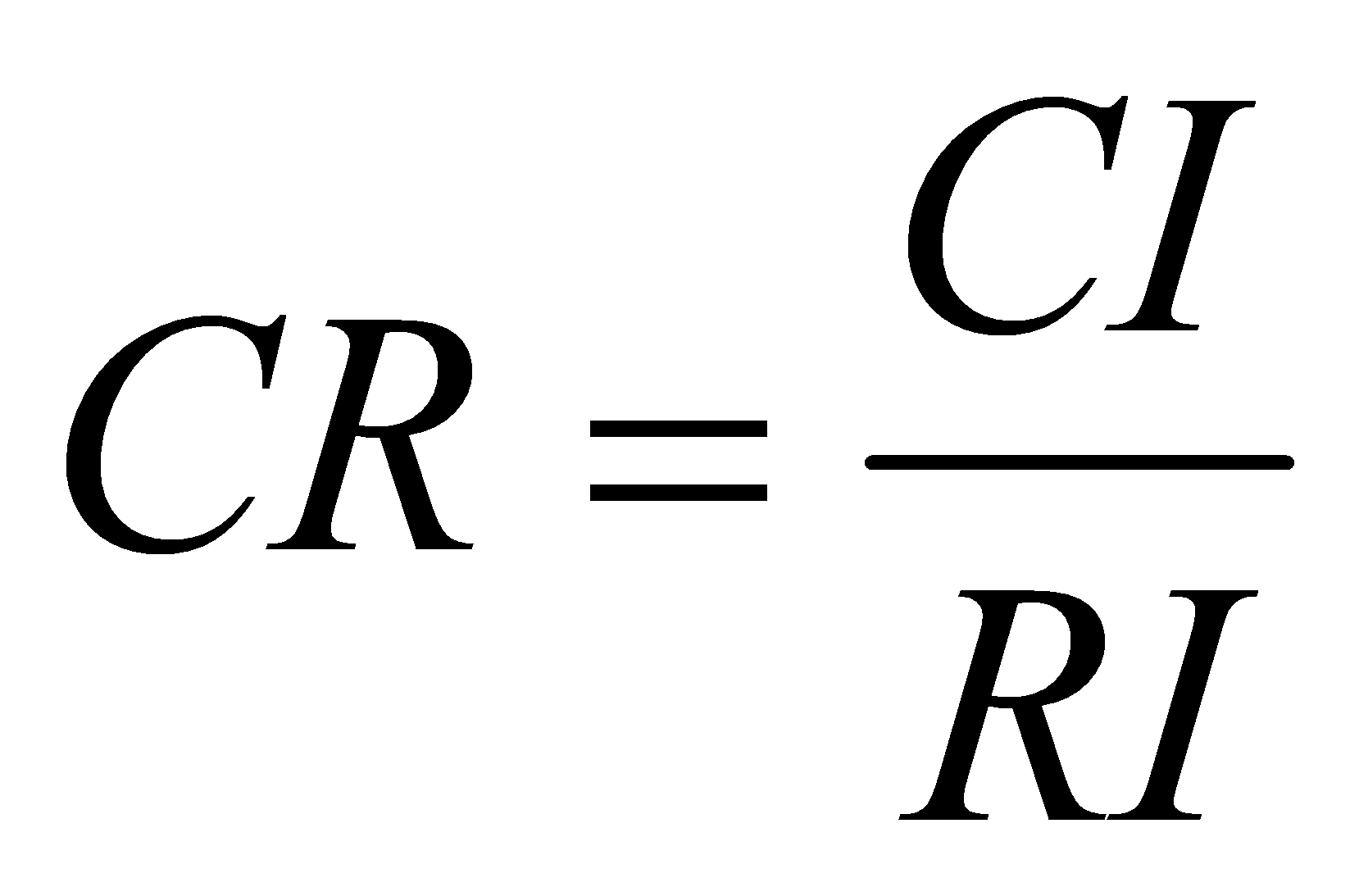

Test the Consistency of the Judgment Matrix. Firstly, the consistency index \( CI \) was calculated according to the maximum eigenvalue  of the judgment matrix and the number of dimensions of the judgment matrix, and then \( CR \) was calculated according to the \( RI \) sample mean of the 1-10 order matrix in Table 3.

of the judgment matrix and the number of dimensions of the judgment matrix, and then \( CR \) was calculated according to the \( RI \) sample mean of the 1-10 order matrix in Table 3.

(2)

(2)

(3)

(3)

2.2 Comprehensive Analysis

Determination of the Weight of First-Level Indicators. The maximum eigenroots of the matrix can be calculated from the above table:

=5.340.

=5.340.

=0.085

=0.085

Look-up table is  =1.120,so

=1.120,so  =0.076<0.10,meet the consistency test.

=0.076<0.10,meet the consistency test.

Determination of the Weight of Secondary Indicators. The judgment matrix, weight value and consistency test of the second-level indicators are shown in the following table.

Summary of Weights of Indicators at All Levels. It can be seen that the judgments of the first-level and second-level indicators meet the consistency test. According to the weight of each risk, the weights of evaluation indicators at all levels are summarized, and the weight vectors of the first-level and second-level indicators are determined as follows:

W=(0.247,0.404,0.185,0.056,0.108);

W1=(0.685,0.221,0.093);

W2=(0.312,0.490,0.198);

W3=(0.539,0.164,0.297);

W4=(0.123,0.320,0.557);

W5=(0.106,0.633,0.260).

3 The Construction of Fuzzy Comprehensive Evaluation Model

3.1 Analysis Process

Construct the Evaluation Factor Set. Factor set U={U1, U2, U3, U4, U5}, where U1 is commodity procurement risk, U2 is logistics distribution risk, U3 is leader service risk, U4 is information technology risk, and U5 is external environment risk. Set factor set U1={U11, U12, U13}, where U11 is unqualified food quality, U12 is unsuitable supplier, and U13 is not punctual delivery; Set factor U2={U21, U22, U23}, where U21 is slow transformation of logistics nodes, U22 is low sorting efficiency, and U23 is accidental emergencies. Set factors U3={U31, U32, U33}, where U31 is low operation capacity, U32 is low service quality, and U33 is improper after-sales treatment; Set factors U4={U41, U42, U43}, where U41 is information asymmetry, U42 is food not traceable, and U43 is distrust of buyers and sellers; Set factor concentration U5={U51, U52, U53}, where U51 is natural environment, U52 is policies and regulations, and U53 is fierce competition.

Determine the Theory Domain of Evaluation Grade. The evaluation set V={V1, V2, V3, V4, V5}, where V1 has the lowest risk, V2 has a low risk, V3 has a medium risk, V4 has a higher risk and V5 has a high risk. The relationship between evaluation level and evaluation score is shown in Table 10 below.

Table 10 Evaluation grade and evaluation score.

Rating | V1 | V2 | V3 | V4 | V5 |

Risk level | The minimum | Low | Medium | Higher | High |

Score | 0~20 | 20~40 | 40~60 | 60~80 | 80~100 |

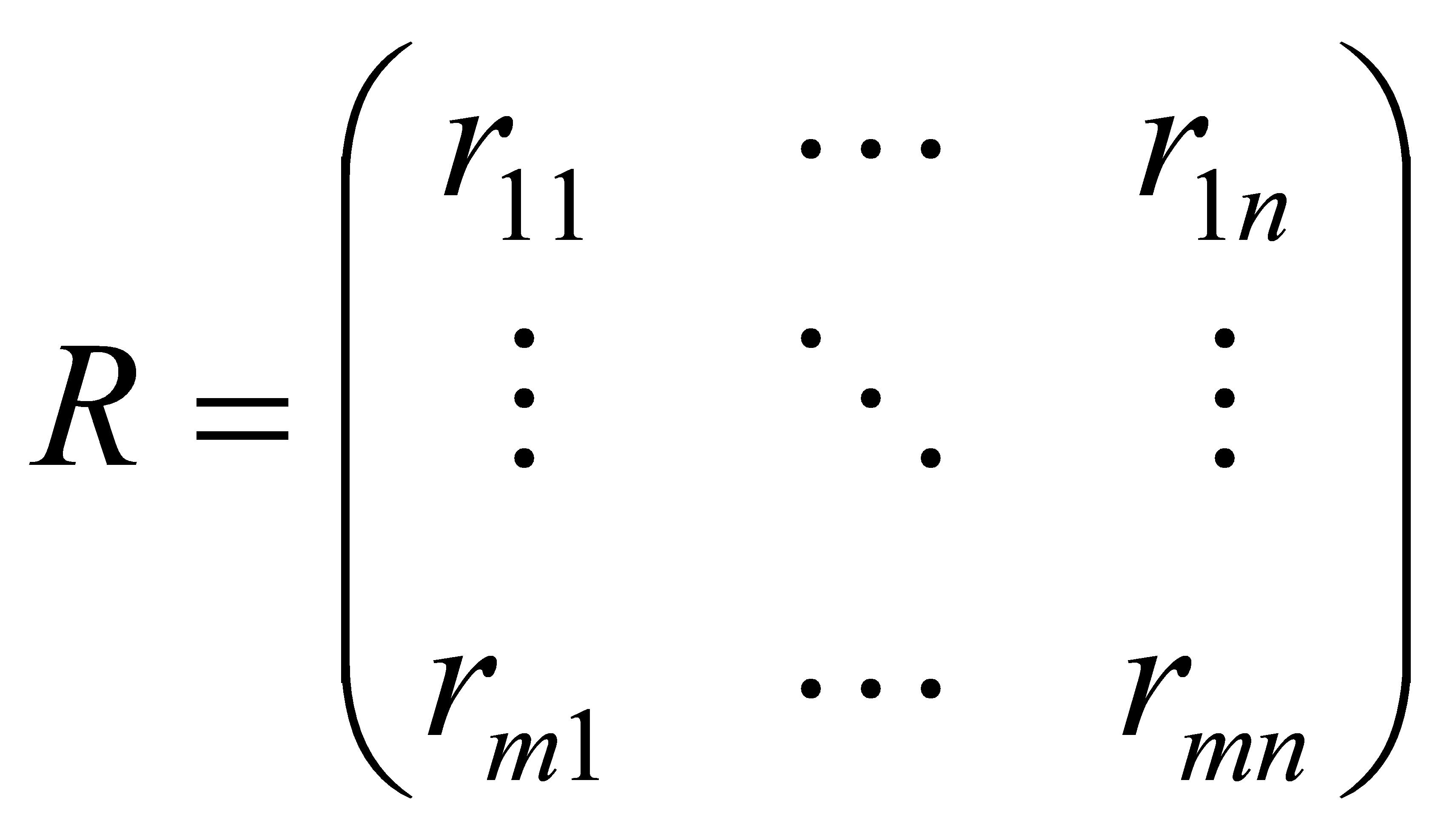

Establish Fuzzy Relation Matrix. The factors in the evaluation factor set constructed above are evaluated to determine the membership degree of the evaluation thing to the evaluation set V, and the fuzzy relation matrix is obtained, as shown in the figure below.

(4)

(4)

Where  represents the membership degree of the MTH index to the NTH evaluation grade.

represents the membership degree of the MTH index to the NTH evaluation grade.

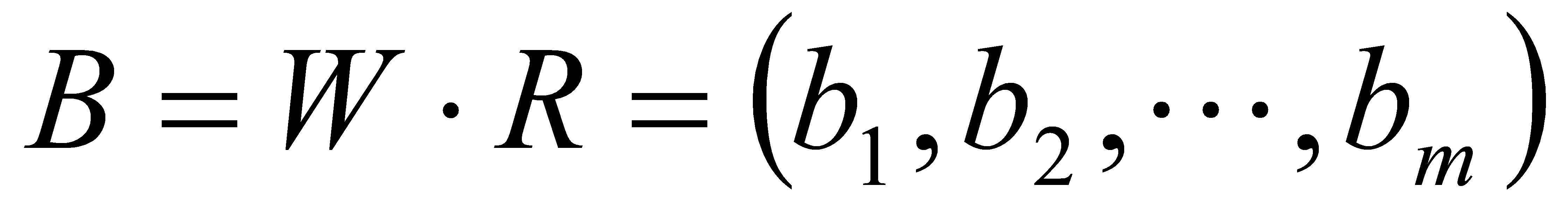

Fuzzy Comprehensive Analysis. The membership vector of index pair comment set can be obtained by the following formula:

(5)

(5)

Where is the weight vector of indicators at all levels  ;

;  represents the membership degree of factor

represents the membership degree of factor  to comment

to comment  .

.

Quantitative Evaluation Results. The comments set is divided into five grades and assigned, as shown in Table 10. The assignment matrix can be obtained as  , and

, and  , so the quantified value of food supply chain risk under community group purchase is:

, so the quantified value of food supply chain risk under community group purchase is:

(6)

(6)

Where is  fuzzy comprehensive evaluation vector;

fuzzy comprehensive evaluation vector;  is the assignment matrix.

is the assignment matrix.

3.2 Evaluation Results

Questionnaires were issued to 10 experts and related personnel on food supply chain risk under community group purchase to obtain relevant data. According to the obtained data, fuzzy evaluation results of first-level indicators can be obtained, as shown in Table 11:

4 Result analysis

From the above analysis of food supply chain risks under community group buying, it can be seen that in the risk of commodity purchase, the weight of unqualified food quality is 0.685, the weight of unsuitable supplier is 0.221, and the weight of unpunctual delivery is 0.093. In logistics distribution risk, the weight of low sorting efficiency is 0.490, the weight of slow transformation of logistics nodes is 0.312, and the weight of accidental emergencies is 0.198. In the risk of chief service, the weight of low operation capacity is 0.539, improper after-sales treatment is 0.297, and low service quality is 0.164. In the information technology risk, the weight of buyer and seller distrust, food traceability accounted for 0.320, information asymmetry accounted for 0.123; In the external environment risk, the weight of policies and regulations is 0.633, the weight of peer competition is 0.260, and the weight of natural environment is 0.106. It shows that in the five first-level risks, food quality is not qualified, sorting efficiency is low, operation capacity is not high, buyers and sellers do not trust, policy and regulation risks account for a high weight, we should pay special attention to these links, and try to avoid or reduce the possibility of their risk.

The score of commodity procurement risk in the first-level index is 64.23. Logistic distribution risk score is 62.75; The risk score of mission service was 57.47. The information technology risk score was 60.87; The score for external environmental risk was 63.80. We can see commodity procurement, logistics, information technology risk and the risk of external environment risk evaluation scores were more than 60, indicates that under the current community group in the food supply chain risk, in the commodity procurement, logistics, information technology and the external environment that several parts there are bigger problems, it is necessary to strengthen the management. Link to pay more attention, especially in the commodity purchase for food source must tighten the control at first, strictly put an end to unqualified food quality problems, in addition to the supplier of choice should also be strictly selected, verify the food suppliers from various perspectives, emphasizes the suppliers' delivery will be carried out in accordance with the stipulated time, in order to avoid unnecessary loss.

5 Revelation

5.1 Risk Prevention Measures for Commodity Procurement

Good quality control, improve food quality. In the selection of procurement of raw materials, procurement personnel to the field review, strictly control the quality of food, to eliminate source pollution; When choosing suppliers, we should pay attention to whether the suppliers have fixed supply channels, high-quality products and good after-sales service; Sign the contract with the supplier, make clear the delivery time and the action in case of abnormal delivery, etc [17]. To improve the supplier management system, the platform should select high-quality product suppliers for long-term cooperation due to the wide variety of food and uneven suppliers in community group buying.

5.2 Logistics Distribution Risk Prevention Measures

Advanced logistics equipment and technology [18]. In the future, goods conversion efficiency of each logistics node should be strengthened, periodic training of relevant personnel should be conducted, and standardized management should be improved. For fresh food, increase cold chain infrastructure to ensure that all aspects of food delivery to consumers are intact. In view of emergencies, on the one hand, we should strengthen the resilience of relevant personnel to deal with risks, and on the other hand, we should check logistics equipment regularly. In addition, enterprises can also cooperate with universities to cultivate talents of relevant majors, so as to achieve a win-win situation.

5.3 Information Technology Risk Prevention Measures

Establish information sharing system [19], realize two-way information transfer between "shared storehouse - central storehouse - grid storehouse", avoid bullwhip effect, resulting in information distortion. Establish food traceability management system, once food safety problems occur, suppliers can be quickly traced, the cause can be found and solved efficiently, so as to avoid further expanding risks.

5.4 Preventive Measures Against External Environmental Risks

Actively cooperate with relevant national policies, strictly observe and implement the "nine-no-no" policy during the epidemic period, and do not disturb the market order. At the same time, community group-buying platforms should strengthen their core competitiveness. When exposing food safety incidents, the government should guarantee the rights and interests of consumers, and consumers should also choose platforms with public trust [20]. In the special period, the platform should adjust personnel, formulate coping strategies, reduce or transfer risks, and look for new development opportunities. In the event of natural environmental risks, expert advice should be sought while monitoring the environment in real time, and alternative transportation routes should be selected to ensure that food supplies are not interrupted, thus reducing losses to the platform.

5.5 Risk Prevention Measures for Leader's Service

First of all, the leader, as the core figure of the community group buying, should cultivate the leader's sense of belonging to the platform. Only when the leader highly identifies with the brand values and concepts of the platform, can the business be done well. Secondly, the community group buying platform should train leaders regularly to improve their business ability, including how to operate community group buying mini program, how to operate the community, after-sales service and so on, so as to better maintain existing customers and develop potential customers. Finally, an incentive system should be established to link the income of the leader with the turnover to enhance the stickiness between the leader and the platform. Conduct regular performance assessment on the leader, optimize the whole team through survival of the fittest, and ensure long-term and stable development of the community group-buying platform.

6 Conclusion

In this paper, the risk assessment technology of community group-buying food supply chain combining analytic hierarchy process (AHP) and fuzzy comprehensive evaluation method is adopted to establish risk indicators and assign values. Because the food throughout the supply chain has complexity and ambiguity, so it is also using the fuzzy comprehensive evaluation method on the risk rating, make evaluation result more credible, and the risk of each stage is ranked, finally it is concluded that commodity procurement risk > External environmental risk > Logistics distribution risk > Information Technology Risk >Mission risk. To provide a basis for reducing the probability of food supply chain risk. Since the development of community group buying is not yet fully mature, the risk factors of food supply chain under it are also quite changeable. In the future, with the development of community group buying, the risk indicators of food supply chain can be gradually enriched, so as to make the risk evaluation results more reliable.

References

[1]. Dong Qianli, Li Chunhua, Guan Gaofeng. Construction and Application research of Food Supply Chain Risk Assessment Model [J]. Jiangsu Business Theory, 2012,(02):143-146.

[2]. Zeng Xinping, Lu Wei, Liu Dan. Research on food quality safety risk early warning of Dairy enterprises based on Supply chain and Extension matterelement Model [J]. Safety and environmental engineering, 2019,26(03):145-151.

[3]. Yang Kang, Hong Fan. Research on quality risk control of dairy supply chain based on system methodology [J]. Modern Food, 2020,(08):159-161.

[4]. Xu Huixin, Sheng Jiping, Xu Hong. Research on food circulation database based on supply chain risk management [J]. Journal of food safety and quality, 2020,11(18):6475-6481.

[5]. LIU Yongsheng. Analysis of concepts related to food supply chain risk [J]. Economic Issues, 2014(08):12-15.

[6]. Zhang Qin, SHI Xiaoyan. Evaluation of food supply chain Risk Factors based on ANALYTIC Hierarchy Process -- A Case study of fresh food [J]. Jiangsu Business Theory, 2014(10):21-24.

[7]. Liu Yongsheng, Mao Wulei, Ren Siqi Identification and evaluation of online food safety risks from the perspective of supply chain [j] Food and machinery, 2021,37 (06): 102-108

[8]. Jingxue Zhang. Risks and Strategies in Constructing Global Supply Chain for Fresh Food E-commerce[J]. Journal of Innovation and Social Science Research, 2021, 8(8).

[9]. Santeramo Fabio Gaetano, Lamonaca Emilia. Objective risk and subjective risk: The role of information in food supply chains[J]. Food Research International, 2021, 139:109962-109962.

[10]. Zhang L. Post-epidemic food safety risk management from the perspective of supply chain [J]. Food & machinery, 2020,36(12):53-55+170.

[11]. Liu Ningjing, Bouzembrak Yamine, van den Bulk Leonieke M., et al. Automated food safety early warning system in the dairy supply chain using machine learning[J]. Food Control, 2022, 136-137.

[12]. Kalantari Fateme, Hosseininezhad Seyed Javad. A Multi-objective Cross Entropy-based algorithm for sustainable global food supply chain with risk considerations: A case study[J]. Computers & Industrial Engineering, 2022, 164-166.

[13]. Nurul Eiman Md Saad, Aida Firdaus Muhammad Nurul Azmi, Mahmudiono Trias, et al. Systematic Review on Food Safety and Supply Chain Risk Assessment Post Pandemic: Malaysian Perspective; [J]. Frontiers in Sustainable Food Systems, 2021.

[14]. Zhang Min. Research on Risk Assessment of Food Supply Chain in China [J]. Enterprise Science, Technology and Development, 2017,(03):148-151.

[15]. Yao Qi. Research on food supply chain risk under the environment of Internet of things [J]. Food industry, 2018,39(05):282-286.

[16]. Cui Shiying. Research and application of food safety risk assessment method based on Hidden Markov model [D]. Beijing University of Chemical Technology, 2020.

[17]. Zhang Kexin. Research on supply chain risk evaluation of fresh food e-commerce under community group purchase [D]. Wuhan Textile University, 2021.

[18]. Zhang Meixi, OU Linwen, ZHANG Jinyuan, Guan Guan, Zhang Li. Research on safety risk management of supply-side food supply chain in 5G era [J]. Logistics engineering and management, 2020,42(11):102-105.

[19]. Zhang LI. Post-epidemic food safety risk management from the perspective of supply chain [J]. Food & machinery, 2020,36(12):53-55+170.

[20]. Wang Jining, TU Yiqing, Wang Wenyi. Research on whole-process risk management of food pigment supply chain [J]. China Condiment, 201,46(07):171-175.

Cite this article

Liu,Y. (2023). Food supply chain risk of community group buying in the post-epidemic era. Advances in Economics, Management and Political Sciences,4,660-670.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 6th International Conference on Economic Management and Green Development (ICEMGD 2022), Part Ⅱ

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Dong Qianli, Li Chunhua, Guan Gaofeng. Construction and Application research of Food Supply Chain Risk Assessment Model [J]. Jiangsu Business Theory, 2012,(02):143-146.

[2]. Zeng Xinping, Lu Wei, Liu Dan. Research on food quality safety risk early warning of Dairy enterprises based on Supply chain and Extension matterelement Model [J]. Safety and environmental engineering, 2019,26(03):145-151.

[3]. Yang Kang, Hong Fan. Research on quality risk control of dairy supply chain based on system methodology [J]. Modern Food, 2020,(08):159-161.

[4]. Xu Huixin, Sheng Jiping, Xu Hong. Research on food circulation database based on supply chain risk management [J]. Journal of food safety and quality, 2020,11(18):6475-6481.

[5]. LIU Yongsheng. Analysis of concepts related to food supply chain risk [J]. Economic Issues, 2014(08):12-15.

[6]. Zhang Qin, SHI Xiaoyan. Evaluation of food supply chain Risk Factors based on ANALYTIC Hierarchy Process -- A Case study of fresh food [J]. Jiangsu Business Theory, 2014(10):21-24.

[7]. Liu Yongsheng, Mao Wulei, Ren Siqi Identification and evaluation of online food safety risks from the perspective of supply chain [j] Food and machinery, 2021,37 (06): 102-108

[8]. Jingxue Zhang. Risks and Strategies in Constructing Global Supply Chain for Fresh Food E-commerce[J]. Journal of Innovation and Social Science Research, 2021, 8(8).

[9]. Santeramo Fabio Gaetano, Lamonaca Emilia. Objective risk and subjective risk: The role of information in food supply chains[J]. Food Research International, 2021, 139:109962-109962.

[10]. Zhang L. Post-epidemic food safety risk management from the perspective of supply chain [J]. Food & machinery, 2020,36(12):53-55+170.

[11]. Liu Ningjing, Bouzembrak Yamine, van den Bulk Leonieke M., et al. Automated food safety early warning system in the dairy supply chain using machine learning[J]. Food Control, 2022, 136-137.

[12]. Kalantari Fateme, Hosseininezhad Seyed Javad. A Multi-objective Cross Entropy-based algorithm for sustainable global food supply chain with risk considerations: A case study[J]. Computers & Industrial Engineering, 2022, 164-166.

[13]. Nurul Eiman Md Saad, Aida Firdaus Muhammad Nurul Azmi, Mahmudiono Trias, et al. Systematic Review on Food Safety and Supply Chain Risk Assessment Post Pandemic: Malaysian Perspective; [J]. Frontiers in Sustainable Food Systems, 2021.

[14]. Zhang Min. Research on Risk Assessment of Food Supply Chain in China [J]. Enterprise Science, Technology and Development, 2017,(03):148-151.

[15]. Yao Qi. Research on food supply chain risk under the environment of Internet of things [J]. Food industry, 2018,39(05):282-286.

[16]. Cui Shiying. Research and application of food safety risk assessment method based on Hidden Markov model [D]. Beijing University of Chemical Technology, 2020.

[17]. Zhang Kexin. Research on supply chain risk evaluation of fresh food e-commerce under community group purchase [D]. Wuhan Textile University, 2021.

[18]. Zhang Meixi, OU Linwen, ZHANG Jinyuan, Guan Guan, Zhang Li. Research on safety risk management of supply-side food supply chain in 5G era [J]. Logistics engineering and management, 2020,42(11):102-105.

[19]. Zhang LI. Post-epidemic food safety risk management from the perspective of supply chain [J]. Food & machinery, 2020,36(12):53-55+170.

[20]. Wang Jining, TU Yiqing, Wang Wenyi. Research on whole-process risk management of food pigment supply chain [J]. China Condiment, 201,46(07):171-175.