1. Introduction

According to the law of economic development nowadays, people can clearly understand that the development of the e-commerce industry has been inseparable from the development of the supply chain. Take the electric car company Tesla as an example, its market value has reached a staggering 1.03 trillion U.S. dollars, and its car factories are all over the world, but such a high-tech enterprise which is one of the best in the world did not pay attention to the development of the supply chain in the early years, which led to the dilemma that it was once on the verge of bankruptcy. The company's experience has brought a strong signal to other industries, that is, it is necessary to develop a supporting supply chain. Thus, it also prompted the e-commerce industry to turn its development focus to the supply chain field, but in the process of development will still inevitably encounter some problems, so the research on the status quo of the supply chain of the e-commerce industry, problems, and countermeasures is particularly important.

2. Case Description

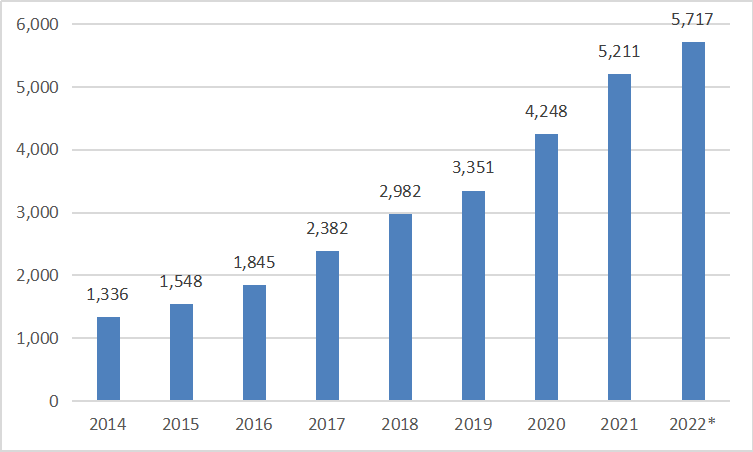

With the development of science and technology, the e-commerce industry has gradually entered into people's daily lives, and its development has brought about changes day by day, providing products and services to dazzle consumers, and the development of e-commerce cannot be separated from the supply chain protection. It can be said that the present e-commerce industry is only possible with a perfect supply chain, and supply chain concepts and technologies have been widely used in many aspects of the e-commerce industry. In the management and sharing of commodity information, through the e-commerce platform, enterprises can centralize the management of commodity information, including the name, specification, price, and other information of commodities, and each link in the supply chain can share this information in real-time, to improve the accuracy and timeliness of the information. Meanwhile, the e-commerce industry has been given an unprecedented opportunity for rapid growth against the backdrop of blockades, quarantines, and shop closures caused by the New Crown epidemic. Between 2014 and 2022, the market for the e-commerce industry, as represented by retail, almost tripled. in 2021, its sales were about $5.2 trillion, while by 2022 they were about $5.7 trillion. e-Marketer expects that figure to continue to grow in the coming years, i.e., to reach a target of about $8.1 trillion by 2026, with a promising future. The prospects for development are promising (See Figure 1).

Figure 1: Global retail e-commerce sales from 2014 to 2022 (in billions of dollars) (e Marketer.com)

However, with the continuous development and change of the market, the e-commerce industry supply chain is facing many challenges. Among them, the status quo problems faced at this stage are that e-commerce products are greatly affected by the market and cannot keep up with the changes, resulting in the backlog of excess commodity inventory; in the process of e-commerce industry supply chain operations, the loss of goods is large, resulting in economic losses; the products can not be delivered to the hands of the consumers on time, which has an impact on the e-commerce and the subsequent development of the supply chain. In the face of these imminent problems, it is necessary to propose correct countermeasures based on the e-commerce industry supply chain to solve the problem.

3. Problems

This paper first identifies the relevant problems, then proposes solutions and provides factual arguments to support them, i.e., starting from the e-commerce supply chain aspects of commodity backlogs, high commodity wastage rates, and the ability of commodities to be delivered on time and giving their views.

3.1. Excess Inventory

In the off-season of e-commerce trade, many related companies have the problem of excess inventory backlog of commodities, which leads to the rise of storage costs under supply chain management. And this inventory backlog of goods refers to the production, and circulation, beyond the reasonable inventory period, can still maintain the use of the value of the goods, due to changes in the market environment, sales of off-peak season conversion, and other factors, commodities cannot be sold, will cause inventory backlog phenomenon, but if the inventory exceeds a certain limit, it will result in the use of funds is too large, the cost of supply chain management rises [1]. At present, inventory backlog has become the top supply chain problem in the e-commerce industry, and large leading enterprises cannot avoid it. Take Huabao Xinneng as an example, the enterprise listed in 2022 valuation exceeded 20 billion yuan, while in 2023 its market valuation has shrunk by more than sixty percent, the market value from the previous more than 20 billion to just 8.29 billion. In addition to inflation and the energy crisis, the huge inventory backlog has become the most significant supply chain problem. According to the survey, the enterprise in the first half of the inventory turnover of up to 120 days, a large number of new and old products backlog in the warehouse, despite the remove inventories action has been continuing, but its European market inventory pressure always exists, the consumer market is saturated, cannot digest enough inventory of goods, its next stage of the goal is still to take the promotional and other means to reduce inventory.

3.2. Waste of Resources

With the rapid development of the e-commerce industry, e-commerce platforms are facing a series of challenges in supply chain management. One of the main problems is the increase in the rate of commodity wastage and the consequent waste of resources. High commodity wastage refers to the problems of damage, loss, or expiry in the process of supply chain operations such as storage, handling, and distribution, which also cause a certain degree of resource wastage. Commodity loss is a common phenomenon, due to the characteristics of commodities, natural conditions technical equipment and other factors caused by the loss is unavoidable [2]. This not only brings the e-commerce industry the rise of supply chain management costs and economic losses, but also affects the consumer experience, and even damages the brand image, which is not worth the loss. Therefore, it is crucial to solve the problem of e-commerce supply chain commodity loss. In the storage process of e-commerce platforms, many reasons lead to increased wastage. First, commodities may be damaged during storage. Improper stacking, unreasonable packaging methods, and problems in the warehouse environment may lead to commodity damage. Secondly, poor handling during the removal process is also an important factor. If the movers lack professional training, it is easy to cause commodity collision, fall, and commodity packaging damage. In addition, poor warehouse management under the supply chain can also lead to an increase in wastage. For example, the failure to establish a sound inventory management system leads to expired or lost goods, resulting in an increase in the rate of loss of goods, which in turn leads to a waste of resources.

3.3. Late Delivery

On-time delivery is a key factor in ensuring customer satisfaction and order fulfillment. Frequent late deliveries by suppliers can damage customer relationships and reduce customer satisfaction. According to the study, the failure of e-commerce companies to deliver products on time will have a huge impact on consumer loyalty. The study, which randomly surveyed 500 consumers on their shopping expectations, found that 69 percent of respondents would not consider purchasing any product from the same e-commerce channel again if their purchases were not delivered within two days of the promised date. In addition, 16 percent of respondents said they would abandon shopping in the e-commerce industry altogether if they received just one incorrect delivery. Amazon, as the world's largest e-commerce industry platform, has countless e-commerce companies selling their products on its platform to global consumers, and its supply chain management approach has its unique characteristics. It has its unique way of managing its supply chain. They lower the rankings and visibility of merchants who fail to deliver on time as a "penalty", which can have a significant impact on e-commerce businesses. The way this works is that Amazon takes into account factors such as speed of delivery and on-time delivery in the platform's search results. If a seller repeatedly fails to deliver on time, Amazon may reduce the seller's product ranking and visibility. This will make it difficult for the product to be found by potential buyers in a competitive marketplace, affecting overall product sales performance. Failure to deliver on time has a significant negative impact on an e-commerce business' reputation and potential growth opportunities. Improper supply chain management, errors in coordination and communication between the e-commerce business and its suppliers, failure to improve logistics and transport methods in response to changes in the market and consumer demand, and inability to ensure timely delivery of required raw materials and products. This will all affect the seller's business reputation and cause supply chain problems such as product inventory backlogs and rising costs, bringing incalculable economic losses to the enterprise.

4. Suggestions

4.1. Supply Chain Management

Most of today's e-commerce enterprises have supply chain problems caused by similar reasons to other industries in the market. Are due to the e-commerce enterprises on the market demand forecast inaccurate, not according to consumer demand changes to change their own inventory structure, the overall rigidity [3]; supply chain management system is not perfect, the whole chain from decision-making to production, transport, sales of the whole process there is a "broken chain" phenomenon occurs, cannot achieve standardization; e-commerce Improper management of the supply chain of e-commerce industry, cannot be based on the market peak season, off-season active warehousing; in the e-commerce off-season storage of too many products, the limited market cannot consume the e-commerce industry storage of products, resulting in an oversupply of products and the phenomenon of corporate losses; commodity demand plan is not accurate and commodity management is not standardised and other reasons, resulting in an increase in the backlog of inventory of commodities, the occupation of the storage capacity of the resources, inventory turnover rate has also declined, thus resulting in additional occupancy of liquidity, the use of the liquidity of the company. This causes additional occupation of liquidity, increases the cost of capital, also reduces the capital turnover rate, affecting the healthy development of the e-commerce enterprise itself [4]. The whole supply chain should be analyzed by the enterprise to find and understand the main reasons for the inventory backlog and the hazards and put forward the relevant enterprises should reduce the inventory backlog and improve the inventory turnover rate of the main measures, to enhance the overall inventory resource utilization efficiency, and promote the long-term healthy development of the e-commerce industry [4]. Therefore, if e-commerce enterprises want to achieve long-term development, they must establish perfect supply chain management specifications, increase basic service sites, reduce the occurrence of broken chain phenomenon, optimize forecasting and demand planning, strengthen cooperation with suppliers, and achieve accurate inventory control and timely adjustment. For retailers with inventory backlog risk avoidance, incentives need to be given, i.e., retailers will receive a risk premium, which is an incentive mechanism [5]. E-commerce enterprises should establish a complete set of perfect supply chain management systems, set up a market research department to discover market changes promptly; optimize the upper level's ability to perceive changes in market demand, produce and sell the right goods at the right market time, improve inventory turnover, and achieve active production and sales.

4.2. Wastage of Resources

According to the study, taking fresh food as an example, fresh food as a necessity of people's daily life, is an important part of the market, however, fresh food itself has the characteristics of seasonal production, easy to corrupt, high requirements for transport conditions, which make them suffer different degrees of loss in transit [6]. The resulting economic losses caused by e-commerce enterprises, increase the supply chain management costs, but as a daily necessity, e-commerce business is indispensable to the sale of this part of the product, so the control of fresh products as a representative of the rate of commodity depletion has become a major issue of e-commerce industry supply chain needs to be thought about and solved [6]. A high material loss rate may lead to the waste of resources, resulting in e-commerce enterprises in the whole supply chain operation to increase costs. To address the problem of high material loss rate, enterprises should treat different commodities in different ways, for example, fresh food adopts the cold chain transport mode in the supply chain technology in the transport process, meanwhile, in the context of the transport industry vigorously develops multi-modal transport, the cold chain transport should also be developed in the direction of multi-modal transport, and by adjusting the mode of transport organization and playing the combined utility of multiple modes of transport, to reduce the fresh commodities loss [7]. Enterprises can also improve the production process and equipment, with the use of advanced control technology and automation systems to minimize material waste. Establishing a set of perfect inventory management system, such as signing sales contracts with customers, i.e., by contacting potential customers and determining the orders and sales quantities and improving the refinement of the production process, strengthening staff training and skills upgrading, as well as regular inspection and maintenance of equipment and other measures can effectively reduce the rate of material wastage and alleviate the problem of resource wastage [8].

4.3. Improvement of On-time Delivery Rate

The e-commerce industry and other traditional industries have similar needs in terms of delivery time. Take the traditional industry represented by the "China paper industry" as an example, in recent years, the paper industry has completed the rapid expansion of production capacity by using advanced technology and capital investment, and the production level and product quality are gradually close to the world's leading level [9]. However, since 2020 the impact of the new crown epidemic began, the paper industry has encountered a lot of difficulties, with the implementation of a variety of favorable policies, China's industrial economy is stepping into the stage of rapid recovery, the social demand for paper products more and more, the quality is higher and higher, and along with the increase in profits of the industry, the major paper companies to become the head of the paper-making industry, to take the initiative in pricing, and have embarked on a new Paper projects, so the project delivery date and the ability to deliver on time has gradually become the main problem of each paper enterprise [9]. To improve the on-time delivery rate, enterprises should strengthen coordination and communication with suppliers, and improve logistics and transport methods to ensure timely delivery of required raw materials and products. This can support the steady development of enterprises in the market by strengthening their management and improving risk prevention and control [10]. This is achieved by establishing a more efficient supply chain network, optimizing transport routes, and improving the quality of logistics services. Improper supply chain management, poor coordination and communication between e-commerce enterprises and suppliers, inability to improve logistics and transport methods according to market changes and consumer demand, and inability to ensure timely delivery of required raw materials and products. This will all affect the reputation of the seller's business and cause supply chain problems such as product inventory backlogs and rising costs.

5. Conclusion

E-commerce as a sunshine industry closely related to people's lives and in the booming period of development, its development cannot be separated from the development of the supply chain, and the development process will inevitably encounter some problems, the only way to actively deal with the "excess inventory leads to product backlog, high commodity loss rate triggered by the waste of resources, cannot be on time delivery of the negative impact caused by the" and other existing supply chain problems and establish a complete set of perfect supply chain management norms and incentives to increase service sites to avoid losses caused by the phenomenon of broken chain The only way to deal with the existing supply chain problems is to actively deal with the "backlog of products due to excess inventory, waste of resources caused by the high rate of commodity loss, and negative impact caused by the failure to deliver on time" and to establish a complete set of perfect supply chain management norms and incentives, increase the number of service stations to avoid losses caused by the phenomenon of broken chains, set up a special market research department to optimize the enterprise's ability to perceive changes in the market, adopt cold chain transport technology for products, carry out the inter-modal transport model of a variety of transport modes, use the e-commerce automation system, establish an efficient Inventory management system, improve the production process, strengthen the training of relevant personnel, regular inspection and maintenance of relevant equipment; strengthen the management of the whole level, improve the risk control ability, establish an efficient supply network, optimize the transport, distribution routes and improve the quality of service, in order to achieve the purpose of "breaking through the bottleneck of the industry's development", and contribute to the progress from quantitative change to qualitative change of the industry. It is only possible to achieve the purpose of "breaking through the bottleneck of industrial development" and facilitate the progress from quantitative change to qualitative change so that the e-commerce industry can benefit people more efficiently and conveniently based on the sound development of supply chain technology.

References

[1]. Wang, Y.-G. (2020). Backlog commodity disposal problem and its response. Petroleum Business Technology, (06),84-85.

[2]. He, C. (2023). Research on Reliability Assessment of Logistics and Distribution Networks Considering Transport Losses. Master's Thesis, Chongqing University of Posts and Telecommunications.

[3]. Pan, X. X. (2018). Research on Inventory Backlog Problem in L Enterprises. Master's thesis, Ningbo University.

[4]. Mao, Z. (2018). Reducing Inventory Backlogs Improving Inventory Turnover. Communication World (11), 81-82.

[5]. Zhang, J., Zhao, J. & Zhang, S. Xiang. (2011). The impact of inventory backlog risk on buyback incentives and its countermeasures. Journal of Tongji University (Natural Science Edition), (01),139-145.

[6]. Zhang, T. B. (2019). Research on commodity loss problems and countermeasures in SD supermarket fresh logistics center. Master's thesis, China University of Petroleum (East China).

[7]. Li, Z. (2023). Research on Optimisation of Cold Chain Multimodal Transportation Paths Considering Loss Rate. Master's Thesis, Chongqing Jiaotong University.

[8]. Xia, W. J. & Ji, W. Y. (2023). Research and design of an inventory management system. China Cotton Processing (03), 10-11.

[9]. Li, H. T. (2023). Research on on-time delivery rate improvement strategy for suppliers of company V. Master's thesis, Shandong University.

[10]. Li, Y. (2023). Zero inventory implementation strategy of high-tech enterprises under supply chain management mode. Chinese Agricultural Accounting (02), 88-90.

Cite this article

Hou,J. (2024). E-commerce Industry Supply Chain: Status, Problems and Countermeasures. Advances in Economics, Management and Political Sciences,71,131-136.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 3rd International Conference on Business and Policy Studies

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Wang, Y.-G. (2020). Backlog commodity disposal problem and its response. Petroleum Business Technology, (06),84-85.

[2]. He, C. (2023). Research on Reliability Assessment of Logistics and Distribution Networks Considering Transport Losses. Master's Thesis, Chongqing University of Posts and Telecommunications.

[3]. Pan, X. X. (2018). Research on Inventory Backlog Problem in L Enterprises. Master's thesis, Ningbo University.

[4]. Mao, Z. (2018). Reducing Inventory Backlogs Improving Inventory Turnover. Communication World (11), 81-82.

[5]. Zhang, J., Zhao, J. & Zhang, S. Xiang. (2011). The impact of inventory backlog risk on buyback incentives and its countermeasures. Journal of Tongji University (Natural Science Edition), (01),139-145.

[6]. Zhang, T. B. (2019). Research on commodity loss problems and countermeasures in SD supermarket fresh logistics center. Master's thesis, China University of Petroleum (East China).

[7]. Li, Z. (2023). Research on Optimisation of Cold Chain Multimodal Transportation Paths Considering Loss Rate. Master's Thesis, Chongqing Jiaotong University.

[8]. Xia, W. J. & Ji, W. Y. (2023). Research and design of an inventory management system. China Cotton Processing (03), 10-11.

[9]. Li, H. T. (2023). Research on on-time delivery rate improvement strategy for suppliers of company V. Master's thesis, Shandong University.

[10]. Li, Y. (2023). Zero inventory implementation strategy of high-tech enterprises under supply chain management mode. Chinese Agricultural Accounting (02), 88-90.