1. Introduction

The finite resource of water has been one of the greatest environmental concerns for years as the world's consumption of water continues to rise. Among all issues around water resources, the treatment of wastewater is essential for sustainable production by recycling water for various industrial uses.

Existing treatment methods, including membrane processes, adsorption, and activated sludge, have already treated a considerable amount of wastewater, yet encounter numerous issues, such as membrane fouling [1] [2] [3] [4], scaling [5] [6], and refractory compounds [7] [8]. As these methods struggle to accomplish wastewater treatment goals, an integrated system would be more effective.

EC, compared to other electrochemical treatment approaches, including electrooxidation and eletrofloatation, achieved a considerable amount of advances in wastewater treatment for its absence of secondary chemical pollution, simplicity of equipment, formation of larger flocs than chemical coagulation/flocculation (CC/CF), and etc. [9]. Although water treatment using electricity was found impractical due to its high cost two decades ago, studies from recent years have shown that now EC-integrated system not only solve problem encountered by existing technologies, but also render an overall enhancement of treatment efficiency.

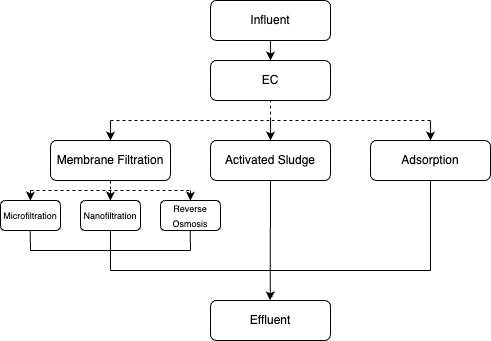

This passage, as demonstrated in Figure 1, reviews recent studies on the integration of electrocoagulation and other technologies, by introducing the principle and theory of electrocoagulation, identifying its potential benefits of integration, and examining and evaluating the current combination of electrocoagulation and other technologies. The advantages and limitations of integration are assessed, and the challenges and future directions are summarized. To comprehensively assess the integration, the underlying theory of EC must be fully studied, which is covered in the following chapter.

Figure 1. A schematic flow chart of the research approach used in this literature review

2. Principles of EC

Similar to CC, EC treats wastewater by the idea of forming large flocs of suspended solids by the reaction between dissolved solids and coagulants. Whereas other aspects, including the use of electric current instead of additive chemicals and the in-situ formation of coagulants with metal ions distinguish EC from CC fundamentally. A detailed examination of EC theory and its characteristics is followed.

2.1. Theory of EC

The destabilization of colloidal particles makes up the fundamental theory of EC. There are colloidal particles in both naturally occurring and artificial settings, and the stability of the particles depends on the strength of the electrical charges that repel one another on their surfaces as well as the forces that bind the particles together. Due to the dominance of the forces that cause particles to reject one another, the particles are stabilized. The particles, on the other hand, are destabilized since the forces of contact are what cause the particles to coagulate or flocculate.

The colloidal particles in water carry similar charges, often negative, and are destabilized and suspended. The goal of EC is to destabilize the particles, which is to reduce the repulsive forces among particles by compressing the electron double layer, thus decreasing the charge difference between the first two layers and causing particles to interact with each other. To achieve above, coagulants are used as the providers of counter charges. Coagulants are usually metal (Fe, Al) hydroxides that release metal ions when dissolved in water, reacting with outer layers of the particles and destroying the original charge equivalence on the layers. The repulsive force therefore reduces, and the particles interact with each other.

In CC, chemical coagulants are added to the water, while in EC, coagulants are synthesized in-situ.

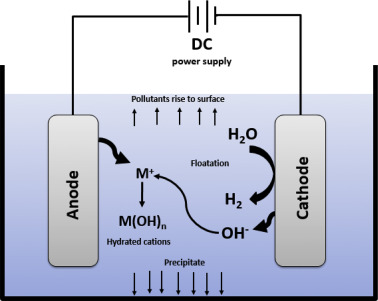

Figure 2. A graphic representation of a typical EC unit [9]

A regular EC unit is consisted of a pair of metal electrodes (typically iron and aluminum) that are immersed in water and externally linked to a direct current (DC) (Fig. 2.). The anode plays a role as coagulant that dissociates to provide metal cations as electrons are passed through the cell, which then react with water molecules to form metal hydroxide. Metal hydroxide then reacts with colloidal particles, forming large flocs as precipitate. Several side reactions also occur simultaneously with the anode dissociation including pH increase resulting from OH- formation and evolution of hydrogen bubbles (flotation).

2.2. Previous Studies on EC

EC has been studied prolifically for the last two decades. In 2004, Holt et al. advanced the potential of EC to become a “localized water treatment technology” in the future by examining a framework of EC that focuses on processes explained in 2.1. And through years of development, various wastewater types, which included paper [3], tannery [4], and textile [10] industry, were treated successfully by EC on a laboratory scale, which greatly enhanced the technology’s potential to become a commonly used mass water treatment method.

From the perspective of the environment, EC is free from adding chemicals into the system which reduces the risk of secondary pollution. Furthermore, compared to CC, EC forms larger and more stable flocs that are easier for disposal, and produce less sludge that reducing the cost of disposal as well. Despite of the benefits, the problems around EC stumble against the further development. The primary disadvantage of EC is the passivation of sacrificial metal-ion-giving cathode. After the usage of a certain time frame, cathode passivation occurs and decreases EC efficiency. Hence regular replacement of cathodes is required, and the operational cost will also significantly increase due to high electricity use, which weakens its practicality. Acknowledged with the two sides of EC, a mediate method of integrating EC with other existing commonly used technologies has been proven to solve the problems and enhance the feasibility of EC as an effective approach.

3. Combining EC with other technologies

Studies in recent years have shown the practicality of integrated hybrid system of EC and other technologies. Case studies will be reviewed and discussed accordingly in the next few sections, with the visual representation (Fig. 3.) of their general working principle.

Figure 3. General workflow of EC integrated wastewater treatment system

3.1. Integrated system of EC and membrane filtration

There are substantial number of studies on the EC-membrane filtration integration in the field, all of which suggest the experimental feasibility of the combined system. Membrane filtrations use a membrane barrier to separate two phases from each other by selectively restricting their behaviors. In this section, the EC-integrated systems are accompanied with membrane filtration approaches: microfiltration, nanofiltration, and reverse osmosis. In the combined systems, EC is followed by the membrane filtration processes due to the necessity to build large flocs that enhance the efficiency of filtration. The following subsections will cover case studies on sample integrated systems.

3.1.1. EC and microfiltration (MF)

Microfiltration is a low-pressure membrane method of separating liquid and solid in the wastewater. This method is known for its benefits in eradicating bacteria, turbidity, and numerous hazardous microorganisms. However, substances such as waterborne viruses and natural organic matter (NOM) can travel through the membrane without hindrance, and MF is prone to fouling after extensive use, which reduces permeate flux and thus overall effluent quality. Hence, a pretreatment of EC is necessary for reducing the effects of shortcomings.

Studies carried out by Keerthi et al. in 2013 [4] examined three integrated membrane-EC treatment methods: EC-MF, membrane bioreactor, and EC-membrane bioreactor. These three methods were evaluated for their capacity to minimize fouling, remove chromium and COD from tannery effluent. The results showed a higher performance by EC-MF integrated system on fouling reduction but less efficiency on COD removal.

Studies by Chellam and Sari in 2015 [2] examined aluminum EC’s performance as a pretreatment for microfiltration of surface water on NOM removal. The researchers also observed that electroflotation, which boosted the flux to 27%, produced even greater performance by drastically reducing MF fouling by EC, which improved the final flux by 15% from initial value. From their research, water quality after aluminum EC treatment was greatly improved with 40% removal of dissolved organic carbon and 52% reduction of UV absorbance. However, the researchers also concluded that the potential of the aluminum flocs from EC would compact or compress and relatively deteriorate MF fouling.

Changmai et al. [1] examined a drilling site wastewater treatment with EC-MF integrated system. EC process succeeded in removing oily rejects from wastewater and thus was chosen to be a preliminary process for microfiltration. The experiment was conducted on a drilling well with a depth of 3364 m, which contained a high number of TDS, suspended solids, and other toxic pollutants. After 20 minutes of operation, the result showed the decrease of TDS from 3230 to 2780 mg/L and of oil-grease concentration from 35 to 10.2 mg/L, which is suitable for following MF treatment.

3.1.2. EC and nanofiltration (NF)

Nanofiltration was a more refined membrane process for water treatment yet requires more strict conditions for influent. It follows similar procedures as MF, therefore EC-NF integrated system was studied by multiple scholars as well.

Gönder et al. [11] studied NF-EC integrated system for carwash wastewater. The effectiveness of wastewater treatment utilizing the integrated system and the impacts of various operational factors were assessed. According to the findings, the best EC conditions are 25 °C, 250 rpm strring speed, and MP-P mode of electrode connection. When EC-sludge was analyzed, it was discovered that iron complexes had precipitated along with wastewater pollution. The effluent was treated with NF membranes NF 270 and Desal 5 DL, and the resultant effluents' quality was compared to that of tap water. With its excellent permeate quality, comparatively consistent flux value, and little rise in contact value, Desal 5 DL shown a greater capacity to lower total hardness (by 90%), chloride concentration (by 92%), and conductivity (by 80%).

Textile industry wastewater treatment using NF-EC integrated system was experimented by Aouni et al. [10]. The focus for the experiment is the reduction of high COD values and toxic organic compounds. The results highlighted that for textile wastewater treatment the desired conditions for EC are 1-hour time for electrolysis, 40 mA cm-2 current density, and optimum condition for NF is transmembrane pressure of 10 bar. By combining two methods at their respective optimum conditions, the treatment can achieve the efficiency of more than 92% retention rate for turbidity, COD, and other chemicals, accompanied with a total decolorization.

3.1.3. EC and reverse osmosis (RO)

RO is another membrane filtration process for wastewater treatment, which also encounters issues such as scaling and fouling that decrease pressure and reduce water flow through membranes. Therefore, EC was introduced as a pretreatment method to produce better influent for RO.

Sadeddin et al. [5] performed an experiment with EC-RO combined system to test ability of EC on removing total suspended solids (TSS) and turbidity. EC was conducted first and followed by EC to gather information. The experiment showed that the pretreatment of influent for RO by EC had achieved a significant reduction of turbidity (98%) and TSS (99%). The feed water quality was proved adequate for further treatment of RO with lower than 3%/min silt density index.

In 2014, Zhao et al. [6] examined the efficiency of EC-RO integrated system on removing COD, hardness, and turbidity. The experiment was conducted with produced water, which is the by-product of natural gas and crude oil recovery. The level of fouling and scaling prevention by EC is the aim of the experiment. They noted that under desired conditions, the system achieved the efficiencies of removals of 66.64% for COD, 93.80% for turbidity, and 85.81% for hardness. Results also highlighted that Conducting RO on EC pretreated water achieved more stable transmembrane permeate flux than on raw oily wastewater, which suggests EC pretreatment reduced membrane fouling/scaling and yield suitable water for RO.

3.2. Integrated system of EC and adsorption

Adsorption (AD) is usually considered a cost-effective and environmentally friendly method for wastewater treatment. In order to achieve adsorption, solutes or other removable species, which are in a runny phase, must be mass transferred to a solid surface (Graça & Rodrigues, 2022). The absorbents are usually activated carbon or silica gel, which are low-cost and recycling, and also achieve high pollutants removal efficiency. EC-AD integrated treatment was studied by scholars about its performance.

Ika Pratiwi et al. [12] have studied the integration of multiple treatment methods, which highlighted the performance of EC and AD. The initial feed water was neutralized into pH of 7 and transferred to EC tank with the current density of 41 A/m2. The AD filter tank, using silica and activated carbon combined absorbent, further treated the water sample after EC and other steps. The performance of the system was tested with jewelry industry wastewater, which contained a high amount of COD, heavy metals, TDS/TSS, etc.. The results highlighted the removal COD by EC (69%) and adsorption (33%). On the other hand, the result points out the total reduction of copper, the main heavy metal pollutants in the sample. The average operation time of EC was 60 min, which suggested the technology was cheap and convenient. However, it is also proved the reduction of cyanide was not significant thereby requiring more research.

Jean Claude et al. [13] investigated EC-AD treatment on synthetic wastewater. In this study, AD filter was made with cheap, and reusable activated green tea residue. The aim for this combined system is to remove ions of copper and nickel. The results showed nearly 100% removal efficiency on both ions. The combined process reduced the use of adsorbent and electricity, which proved its cost-effectiveness.

3.3. Integrated system of EC and activated sludge

Activated sludge (AS) is a type of biological treatment method that is commonly used to treat industry treatment waters due to superior effectiveness, economy, and environmental friendliness. Similar to other treatment methods mentioned above, it is necessary for AS feed water to be pretreated when encountering issues that affects its efficiency, usually namely low ratio of biochemical oxygen demand (BOD)/COD or bio-refractory organic compounds. Thereby EC was combined with AS and studied by scientists to test the efficiency of EC to improve feed water quality for AS.

A continuous system of EC-AS was studied by Moisés et al. [8] The changes of turbidity, pH, color, and COD were studied to determine if EC pretreatment would produce suitable water for AS. As the results showed, after EC process, color values declined from Pt-Co of 2700 ± 300 to 160 ± 10, yielding a 94% efficiency. A significant decline was shown in turbidity from 120 ± 50 to 10 ± 2 FAU. The decrease of COD was also reported to be from 2100 to 460 mg/L. The water was followed by AS and achieved water quality that meets local requirements.

The study in 2022 by Akrasu et al. [7] examined the EC-AS integrated system on the treatment of vegetable oil. Using settings including electrode type, pH, current density, and electrolysis time, the material was processed using electrocoagulation. The findings revealed that electrocoagulation using Al-Al electrode pairs at pH of 2, current density of 300 A/m2, and 180 min of reaction time effectively eliminated all the oil-grease, 90% of COD, and 66.2% of color. The electrocoagulation effluent was then treated with activated sludge. The activated sludge method, according to the results, enhanced color removal efficiency by 79.2% and COD removal efficiency by 98.9% when treating wastewater that contained vegetable oils. The integrated system produced the desired outcome, and the researchers proposed that more mathematical and statistical studies would increase the effectiveness even further.

4. Challenges and Future Directions

The primary goal of studies on EC-integrated wastewater treatment system is the feasibility of EC as a pre-treatment method for common existing approaches. While all studies above confirmed that EC can be an adequate pre-treatment method, they also concluded some challenges of integrated system, in which they suggested new directions of future research. Some main challenges countered by these researches include their real-world applicability on wastewater of varied composition, namely the practical scaling-up of these integrated system. The researches also mentioned the concerns on maintenance and operational cost of integrated system, as well as the optimization of treatment processes.

Most issues appeared in experiments that comprise integrations of membrane process and EC. Most studies have stated that the energy consumption of EC would become high given the various kind of wastewater to prevent fouling in the following membrane process [10] [1] [11]. Further research should focus on addressing the balance between minimizing operational costs and maintaining treatment efficiency. Another notable challenge encountered membrane-EC system is the effect of accumulation of aluminum flocs formed from EC at high pressure [10] [2]. The addition of aluminum flocs from EC would cause NF to overcome the issue by utilizing more energy or even additional chemicals, which offsets the eco-friendliness of EC [10]. Therefore, managing the use of chemicals in the integrated system to minimize environmental impact is a challenge that needs to be considered. In addition, other challenges, such as overcoming limited removal of certain contaminants and disposing by-products and sludge caused by the integrated systems [3] [6] [4], also need to be concerned in future research.

Challenges also emerged in the studies on EC-integrated system with adsorption and activated sludge. While most of their challenges are concentrated in the scaling-up workability and the need for more mathematical and statistical processes to improving the material and cleaning processes [7] [8] [14] [12] [13], individual challenges still exist. For instance, Ika Pratiwi et al. highlighted in their research on EC-integrated system with adsorption on jewelry wastewater that cyanide was a challenging parameter in initial affluent to treat by EC [12]. In their research, only one sample met the minimum reduction ability of 99%. Besides that, the researchers also concerned about the long-term performance and cost-effectiveness of the integrated system given that adsorption itself is a costly operation that requires constant regeneration of adsorbents [14].

5. Conclusion

In conclusion, this literature review has provided a comprehensive overview of electrocoagulation integrated systems and their applications across various sectors. Through the analysis of numerous scholarly works, the effectiveness and efficiency of EC in treating wastewater have been established. The integration of electrocoagulation with other technologies such as membranes, adsorption, and activated sludge units has shown promising potential for further improving system performance. Additionally, this review has shed light on the factors influencing electrocoagulation performance, including pH, current density, and initial pollutant concentration. Despite the wealth of knowledge available, further research is needed to optimize system design, operating parameters, and scaling-up ability. Nevertheless, the literature reviewed here undoubtedly emphasizes the relevance and importance of electrocoagulation-integrated systems in addressing water pollution and managing wastewater. Considering the growing global concern over water scarcity and environmental degradation, the application of electrocoagulation integrated systems represents a viable and indispensable solution for sustainable water management.

[1] C. Akarsu, Z. Bilici and N. Dizge, “Treatment of vegetable oil wastewater by a conventional activated sludge process coupled with electrocoagulation process,” Water Environment Research, vol. 94, no. 2, p. e10692, 2022. https://doi.org/10.1002/wer.10692.

[2] A. Aouni, C. Fersi, M. Ben Sik Ali and M. Dhahbi, "Treatment of textile wastewater by a hybrid electrocoagulation/nanofiltration process," Journal of Hazardous Materials, vol. 168, no. 2, pp. 868-874, 2009. https://doi.org/10.1016/j.jhazmat.2009.02.112.

[3] M. Changmai, M. Pasawan and M. K. Purkait, “Treatment of oily wastewater from drilling site using electrocoagulation followed by microfiltration,” Separation and Purification Technology, vol. 210, pp. 463-472, 2019. https://doi.org/10.1016/j.seppur.2018.08.007.

[4] S. Chellam, “Microfiltration,” in In Encyclopedia of Membrane Science and Technology, John Wiley & Sons, Ltd., 2013, pp. 1-21. https://doi.org/10.1002/9781118522318.emst075.

[5] S. Chellam and M. A. Sari, “Aluminum electrocoagulation as pretreatment during microfiltration of surface water containing NOM: A review of fouling, NOM, DBP, and virus control,” Journal of Hazardous Materials, vol. 304, pp. 490-501, 2016. https://doi.org/10.1016/j.jhazmat.2015.10.054.

[6] Z. B. Gönder, G. Balcıoğlu, I. Vergili and Y. Kaya, “An integrated electrocoagulation–nanofiltration process for carwash wastewater reuse,” Chemosphere, vol. 253, p. 126713, 2020. https://doi.org/10.1016/j.chemosphere.2020.126713.

[7] C. Gong, H. Huang, Y. Qian, Z. Zhang and H. Wu, “Integrated electrocoagulation and membrane filtration for PAH removal from realistic industrial wastewater: Effectiveness and mechanisms,” RSC Advances, vol. 7, no. 83, pp. 52366-52374, 2017. https://doi.org/10.1039/C7RA09372A.

[8] N. S. Graça and A. E. Rodrigues, “The Combined Implementation of Electrocoagulation and Adsorption Processes for the Treatment of Wastewaters,” Clean Technologies, vol. 4, no. 4, 2022. https://doi.org/10.3390/cleantechnol4040063.

[9] P. K. Holt, G. W. Barton and C. A. Mitchell, “The future for electrocoagulation as a localised water treatment technology,” Chemosphere, vol. 59, no. 3, pp. 355-367, 2005. https://doi.org/10.1016/j.chemosphere.2004.10.023.

[10] N. Ika Pratiwi, A. Mukimin, N. Zen and I. Septarina, “Integration of electrocoagulation, adsorption and wetland technology for jewelry industry wastewater treatment,” Separation and Purification Technology, vol. 279, p. 119690, 2021. https://doi.org/10.1016/j.seppur.2021.119690.

[11] Keerthi, V. Vinduja and N. Balasubramanian, “Electrocoagulation-integrated hybrid membrane processes for the treatment of tannery wastewater,” Environmental Science and Pollution Research, vol. 20, no. 10, pp. 7441-7449, 2013. https://doi.org/10.1038/s41598-022-07475-y.

[12] T.-P. Moisés, P. B.-H. C. E. Barrera-Díaz, R.-M. Gabriela and R. Natividad-Rangel, “Treatment of industrial effluents by a continuous system: Electrocoagulation - Activated sludge,” Bioresource Technology, vol. 101, no. 20, pp. 7761-7766, 2010. https://doi.org/10.1016/j.biortech.2010.05.027.

[13] N. Jean Claude, L. Shanshan, J. Khan, W. Yifeng, H. Dongxu and L. Xiangru, “Waste tea residue adsorption coupled with electrocoagulation for improvement of copper and nickel ions removal from simulated wastewater,” Scientific Reports, vol. 12, no. 1, 2022. https://doi.org/10.1038/s41598-022-07475-y.

[14] D. T. Moussa, M. H. El-Naas, M. Nasser and M. J. Al-Marri, “A comprehensive review of electrocoagulation for water treatment: Potentials and challenges,” Journal of Environmental Management, vol. 186, pp. 24-41, 2017. https://doi.org/10.1016/j.jenvman.2016.10.032.

[15] E. Obotey Ezugbe and S. Rathilal, “Membrane Technologies in Wastewater Treatment: A Review,” Membranes, vol. 10, no. 5, 2020. https://doi.org/10.3390/membranes10050089.

[16] K. Sadeddin, A. Naser and A. Firas, “Removal of turbidity and suspended solids by electro-coagulation to improve feed water quality of reverse osmosis plant,” Desalination, vol. 268, no. 1, pp. 204-207, 2011. https://doi.org/10.1016/j.desal.2010.10.027.

[17] S. Zhao, G. Huang, G. Cheng, Y. Wang and H. Fu, “Hardness, COD and turbidity removals from produced water by electrocoagulation pretreatment prior to Reverse Osmosis membranes,” Desalination, vol. 344, pp. 454-462, 2014. https://doi.org/10.1016/j.desal.2014.04.014.

References

[1]. C. Akarsu, Z. Bilici and N. Dizge, “Treatment of vegetable oil wastewater by a conventional activated sludge process coupled with electrocoagulation process,” Water Environment Research, vol. 94, no. 2, p. e10692, 2022. https://doi.org/10.1002/wer.10692.

[2]. A. Aouni, C. Fersi, M. Ben Sik Ali and M. Dhahbi, "Treatment of textile wastewater by a hybrid electrocoagulation/nanofiltration process," Journal of Hazardous Materials, vol. 168, no. 2, pp. 868-874, 2009. https://doi.org/10.1016/j.jhazmat.2009.02.112.

[3]. M. Changmai, M. Pasawan and M. K. Purkait, “Treatment of oily wastewater from drilling site using electrocoagulation followed by microfiltration,” Separation and Purification Technology, vol. 210, pp. 463-472, 2019. https://doi.org/10.1016/j.seppur.2018.08.007.

[4]. S. Chellam, “Microfiltration,” in In Encyclopedia of Membrane Science and Technology, John Wiley & Sons, Ltd., 2013, pp. 1-21. https://doi.org/10.1002/9781118522318.emst075.

[5]. S. Chellam and M. A. Sari, “Aluminum electrocoagulation as pretreatment during microfiltration of surface water containing NOM: A review of fouling, NOM, DBP, and virus control,” Journal of Hazardous Materials, vol. 304, pp. 490-501, 2016. https://doi.org/10.1016/j.jhazmat.2015.10.054.

[6]. Z. B. Gönder, G. Balcıoğlu, I. Vergili and Y. Kaya, “An integrated electrocoagulation–nanofiltration process for carwash wastewater reuse,” Chemosphere, vol. 253, p. 126713, 2020. https://doi.org/10.1016/j.chemosphere.2020.126713.

[7]. C. Gong, H. Huang, Y. Qian, Z. Zhang and H. Wu, “Integrated electrocoagulation and membrane filtration for PAH removal from realistic industrial wastewater: Effectiveness and mechanisms,” RSC Advances, vol. 7, no. 83, pp. 52366-52374, 2017. https://doi.org/10.1039/C7RA09372A.

[8]. N. S. Graça and A. E. Rodrigues, “The Combined Implementation of Electrocoagulation and Adsorption Processes for the Treatment of Wastewaters,” Clean Technologies, vol. 4, no. 4, 2022. https://doi.org/10.3390/cleantechnol4040063.

[9]. P. K. Holt, G. W. Barton and C. A. Mitchell, “The future for electrocoagulation as a localised water treatment technology,” Chemosphere, vol. 59, no. 3, pp. 355-367, 2005. https://doi.org/10.1016/j.chemosphere.2004.10.023.

[10]. N. Ika Pratiwi, A. Mukimin, N. Zen and I. Septarina, “Integration of electrocoagulation, adsorption and wetland technology for jewelry industry wastewater treatment,” Separation and Purification Technology, vol. 279, p. 119690, 2021. https://doi.org/10.1016/j.seppur.2021.119690.

[11]. Keerthi, V. Vinduja and N. Balasubramanian, “Electrocoagulation-integrated hybrid membrane processes for the treatment of tannery wastewater,” Environmental Science and Pollution Research, vol. 20, no. 10, pp. 7441-7449, 2013. https://doi.org/10.1038/s41598-022-07475-y.

[12]. T.-P. Moisés, P. B.-H. C. E. Barrera-Díaz, R.-M. Gabriela and R. Natividad-Rangel, “Treatment of industrial effluents by a continuous system: Electrocoagulation - Activated sludge,” Bioresource Technology, vol. 101, no. 20, pp. 7761-7766, 2010. https://doi.org/10.1016/j.biortech.2010.05.027.

[13]. N. Jean Claude, L. Shanshan, J. Khan, W. Yifeng, H. Dongxu and L. Xiangru, “Waste tea residue adsorption coupled with electrocoagulation for improvement of copper and nickel ions removal from simulated wastewater,” Scientific Reports, vol. 12, no. 1, 2022. https://doi.org/10.1038/s41598-022-07475-y.

[14]. D. T. Moussa, M. H. El-Naas, M. Nasser and M. J. Al-Marri, “A comprehensive review of electrocoagulation for water treatment: Potentials and challenges,” Journal of Environmental Management, vol. 186, pp. 24-41, 2017. https://doi.org/10.1016/j.jenvman.2016.10.032.

[15]. E. Obotey Ezugbe and S. Rathilal, “Membrane Technologies in Wastewater Treatment: A Review,” Membranes, vol. 10, no. 5, 2020. https://doi.org/10.3390/membranes10050089.

[16]. K. Sadeddin, A. Naser and A. Firas, “Removal of turbidity and suspended solids by electro-coagulation to improve feed water quality of reverse osmosis plant,” Desalination, vol. 268, no. 1, pp. 204-207, 2011. https://doi.org/10.1016/j.desal.2010.10.027.

[17]. S. Zhao, G. Huang, G. Cheng, Y. Wang and H. Fu, “Hardness, COD and turbidity removals from produced water by electrocoagulation pretreatment prior to Reverse Osmosis membranes,” Desalination, vol. 344, pp. 454-462, 2014. https://doi.org/10.1016/j.desal.2014.04.014.

Cite this article

Tang,G. (2024). A literature review of electrocoagulation integrated systems on wastewater treatment. Theoretical and Natural Science,47,102-109.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2nd International Conference on Environmental Geoscience and Earth Ecology

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. C. Akarsu, Z. Bilici and N. Dizge, “Treatment of vegetable oil wastewater by a conventional activated sludge process coupled with electrocoagulation process,” Water Environment Research, vol. 94, no. 2, p. e10692, 2022. https://doi.org/10.1002/wer.10692.

[2]. A. Aouni, C. Fersi, M. Ben Sik Ali and M. Dhahbi, "Treatment of textile wastewater by a hybrid electrocoagulation/nanofiltration process," Journal of Hazardous Materials, vol. 168, no. 2, pp. 868-874, 2009. https://doi.org/10.1016/j.jhazmat.2009.02.112.

[3]. M. Changmai, M. Pasawan and M. K. Purkait, “Treatment of oily wastewater from drilling site using electrocoagulation followed by microfiltration,” Separation and Purification Technology, vol. 210, pp. 463-472, 2019. https://doi.org/10.1016/j.seppur.2018.08.007.

[4]. S. Chellam, “Microfiltration,” in In Encyclopedia of Membrane Science and Technology, John Wiley & Sons, Ltd., 2013, pp. 1-21. https://doi.org/10.1002/9781118522318.emst075.

[5]. S. Chellam and M. A. Sari, “Aluminum electrocoagulation as pretreatment during microfiltration of surface water containing NOM: A review of fouling, NOM, DBP, and virus control,” Journal of Hazardous Materials, vol. 304, pp. 490-501, 2016. https://doi.org/10.1016/j.jhazmat.2015.10.054.

[6]. Z. B. Gönder, G. Balcıoğlu, I. Vergili and Y. Kaya, “An integrated electrocoagulation–nanofiltration process for carwash wastewater reuse,” Chemosphere, vol. 253, p. 126713, 2020. https://doi.org/10.1016/j.chemosphere.2020.126713.

[7]. C. Gong, H. Huang, Y. Qian, Z. Zhang and H. Wu, “Integrated electrocoagulation and membrane filtration for PAH removal from realistic industrial wastewater: Effectiveness and mechanisms,” RSC Advances, vol. 7, no. 83, pp. 52366-52374, 2017. https://doi.org/10.1039/C7RA09372A.

[8]. N. S. Graça and A. E. Rodrigues, “The Combined Implementation of Electrocoagulation and Adsorption Processes for the Treatment of Wastewaters,” Clean Technologies, vol. 4, no. 4, 2022. https://doi.org/10.3390/cleantechnol4040063.

[9]. P. K. Holt, G. W. Barton and C. A. Mitchell, “The future for electrocoagulation as a localised water treatment technology,” Chemosphere, vol. 59, no. 3, pp. 355-367, 2005. https://doi.org/10.1016/j.chemosphere.2004.10.023.

[10]. N. Ika Pratiwi, A. Mukimin, N. Zen and I. Septarina, “Integration of electrocoagulation, adsorption and wetland technology for jewelry industry wastewater treatment,” Separation and Purification Technology, vol. 279, p. 119690, 2021. https://doi.org/10.1016/j.seppur.2021.119690.

[11]. Keerthi, V. Vinduja and N. Balasubramanian, “Electrocoagulation-integrated hybrid membrane processes for the treatment of tannery wastewater,” Environmental Science and Pollution Research, vol. 20, no. 10, pp. 7441-7449, 2013. https://doi.org/10.1038/s41598-022-07475-y.

[12]. T.-P. Moisés, P. B.-H. C. E. Barrera-Díaz, R.-M. Gabriela and R. Natividad-Rangel, “Treatment of industrial effluents by a continuous system: Electrocoagulation - Activated sludge,” Bioresource Technology, vol. 101, no. 20, pp. 7761-7766, 2010. https://doi.org/10.1016/j.biortech.2010.05.027.

[13]. N. Jean Claude, L. Shanshan, J. Khan, W. Yifeng, H. Dongxu and L. Xiangru, “Waste tea residue adsorption coupled with electrocoagulation for improvement of copper and nickel ions removal from simulated wastewater,” Scientific Reports, vol. 12, no. 1, 2022. https://doi.org/10.1038/s41598-022-07475-y.

[14]. D. T. Moussa, M. H. El-Naas, M. Nasser and M. J. Al-Marri, “A comprehensive review of electrocoagulation for water treatment: Potentials and challenges,” Journal of Environmental Management, vol. 186, pp. 24-41, 2017. https://doi.org/10.1016/j.jenvman.2016.10.032.

[15]. E. Obotey Ezugbe and S. Rathilal, “Membrane Technologies in Wastewater Treatment: A Review,” Membranes, vol. 10, no. 5, 2020. https://doi.org/10.3390/membranes10050089.

[16]. K. Sadeddin, A. Naser and A. Firas, “Removal of turbidity and suspended solids by electro-coagulation to improve feed water quality of reverse osmosis plant,” Desalination, vol. 268, no. 1, pp. 204-207, 2011. https://doi.org/10.1016/j.desal.2010.10.027.

[17]. S. Zhao, G. Huang, G. Cheng, Y. Wang and H. Fu, “Hardness, COD and turbidity removals from produced water by electrocoagulation pretreatment prior to Reverse Osmosis membranes,” Desalination, vol. 344, pp. 454-462, 2014. https://doi.org/10.1016/j.desal.2014.04.014.