1. Introduction

The structure of the scramjet engine was firstly come up in the 50s last century. The basic operating principle in scramjets is converting the significant kinetic energy of the incoming air into pressure energy. Unlike the traditional turbojet engine, it has only three simple components: the compression part, the combustion part, and the expansion part. That leads the scramjet engine has several features including the simple structure, light. Besides, the scramjet engine does not need the oxidizing agent because the engine can take the abundant surrounding air in the supersonic work environment. The hypersonic air flow can be compressed easily because the change of the cross-section area in the compression part. Thus, the scramjet engine does not need the rotational components such as the turbine and compressor and the main shaft. The super simple structure be considered as a reliable design [1].

There are several future applications of scramjet engines, including civil supersonic aircrafts, space exploration as a stage for access to Earth orbit, and military hypersonic weapons. As the author said, “Despite many impressive achievements obtained in the field since the early sixties, still today there are no scramjet engines being used in practical devices: many developments including experimental flights and ground-based tastings are currently in progress” [2].

The design of scramjet engine is a very complex engineering program including the fluid mechanics, thermodynamic, physics of gas, combustion fluid field and so on. The combustion at supersonic or even hypersonic field will become very different. The combustion flow field is full of shock waves, mixing, turbulence, and boundary layer. All of these enable the work mechanism very complex. Thus, many problems as above prevent the development of the scramjet engine. The most two important problems are how to maximize the positive thrust and how to enable the combustion stable. Because the drag force in the hypersonic flight for the aircraft is extremely big, the engine should produce a big thrust to gain a positive net drive force. For the combustion instability problem, that is a common phenomenon with the high combustion pressure. Thus, how to find a proper pressure ratio become a vital problem [3].

This report focuses on the analysis of the above mentioned two problems: the effective thrust and the combustion stability. Besides, the low thermal efficiency of the scramjet engine is also a problem. This research also gives a possible way to improve the efficiency of scramjet engine: use a kind of fuel with high combustion product pressure and low momentum, control the fuel reactivity. To gain a more real result, the report analyzes the possible maximum speed of aircraft equipped with the scramjet engine.

All the experiment data and simulation methods come from the previous literatures, this report just gives a reasonable analysis and integrate the conclusions based on the results.

2. Research Methods and Physical Models

2.1. The Approach of Simulation

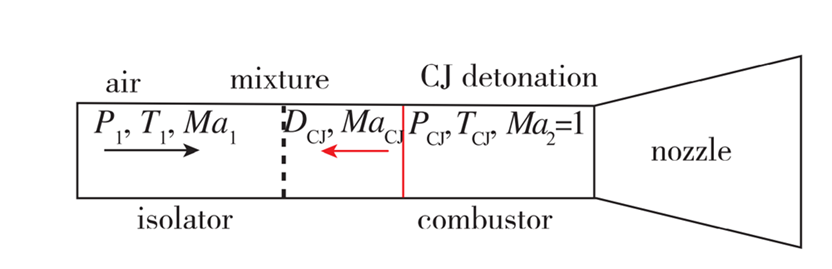

Using the H2/Air mixed gas, according to the work process of scramjet engine, to do the simulation which take the combustion pressure ratio as a result by changing the inlet flow temperature and the speed. Because of the complex working process of real scramjet engine, here the author used the theoretical model of CJ detonation engine to simulate combustion process which is the core process of the scramjet engine as shown in figure.1 [4]. To find the reason of the combustion instability, the author did a comparison between the wave caused by CJ detonation and the nonreactive shock. Here the CJ detonation represent a detonation process with combustion whereas the nonreactive shock represents the detonation without combustion. According to the CJ detonation theorem hypothesis: flow is one-dimensional, regardless of the heat conduction, heat radiation and viscous friction dissipation effect; the detonation wave as strong discontinuity; after the detonation wave through chemical reaction and discharge instantaneous chemical reaction heat, reaction products in the thermal chemical equilibrium and thermodynamic equilibrium state; detonation wave front propagation process is stationary [5].

|

Figure 1. Theoretical model of CJ detonation engine as a simulation of the scramjet engine. |

2.2. The Optimization for Scramjet Engine

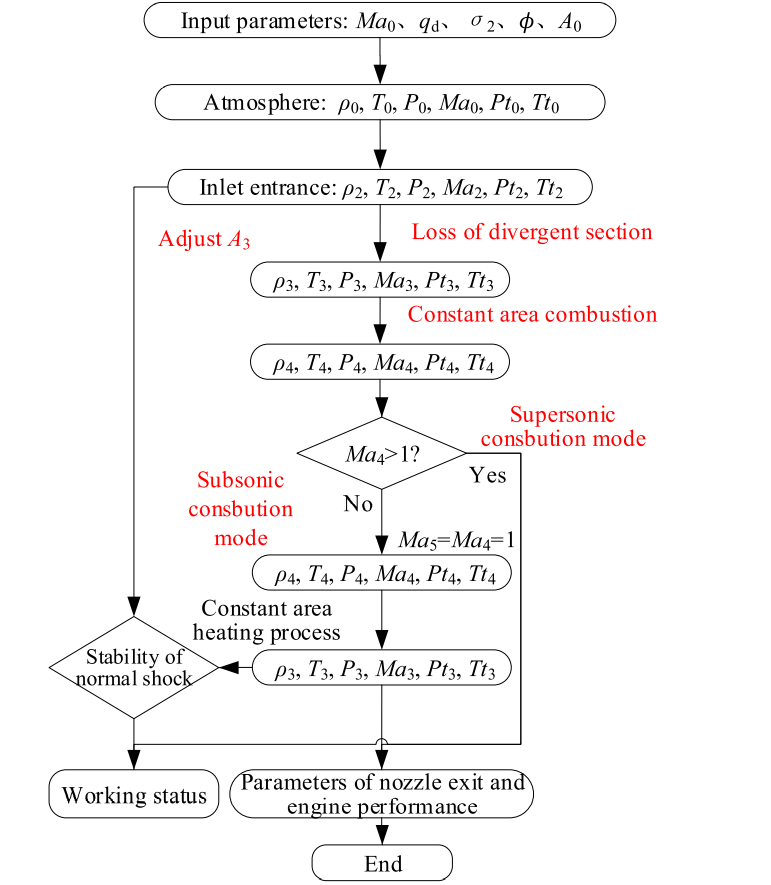

To find possible improvements of scramjet engine, this report shows a kind of more efficiency fuel to drive the engine. Furthermore, there are previous literatures shows “a concept of controlling the self-starting characteristics and propulsion performance of a scramjet via fuel reactivity modification” [6]. The other simulation shows that the specific thrust and maximum speed of the aircraft with different area ratio between the hypersonic vehicle reference area to the inlet capture area of scramjet engine. The aerodynamic data process shown as followings [7].

|

Figure 2. Performance calculation process of scramjet engine. |

The method of aerodynamic data process has shown as following,

\( D=\frac{1}{2}{ρ_{0}}u_{0}^{2}{C_{D}}S \) | (1) | |

\( T=\frac{1}{2}{ρ_{0}}u_{0}^{2}{C_{T}}S \) | (2) | |

\( {C_{T}}=\frac{T}{\frac{1}{2}{ρ_{0}}u_{0}^{2}S}=\frac{{I_{sp}}f{ρ_{0}}{u_{0}}{A_{0}}φg}{\frac{1}{2}{ρ_{0}}u_{0}^{2}S}=\frac{2{I_{sp}}f{A_{0}}φg}{{u_{0}}S} \) | (3) | |

\( a=\frac{Tcosα-D}{m}-gsin(θ-α) \) | (4) | |

\( \dot{α}=\frac{-Tsinα-D}{m}+\dot{θ}+\frac{gcos(θ-α)}{u} \) | (5) | |

\( L=\frac{1}{2}{ρ_{0}}u_{0}^{2}{C_{L}}S \) | (6) | |

\( \dot{α}=0, \dot{θ}=0 \) | (7) | |

\( \frac{Tsinα+L}{m}=g \) | (8) | |

\( Tcosα-D=0 \) | (9) |

3. Result and Discussion

Experiments have shown that the pressure of combustion products in the combustion chamber is up to about 4.4 times the inlet pressure, and most of them are about 2.4 times the inlet pressure at a static temperature of about 950 K and a Mach number of about 2.6. The ability to generate high pressure gas by exothermic combustion at supersonic speed is very limited [8]. The pressure in the combustion chamber is not enough at this state, that can also lead the thrust is too small. The final simulation result also shows that.

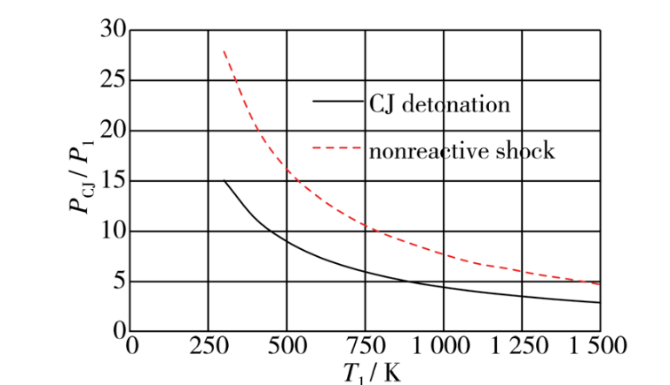

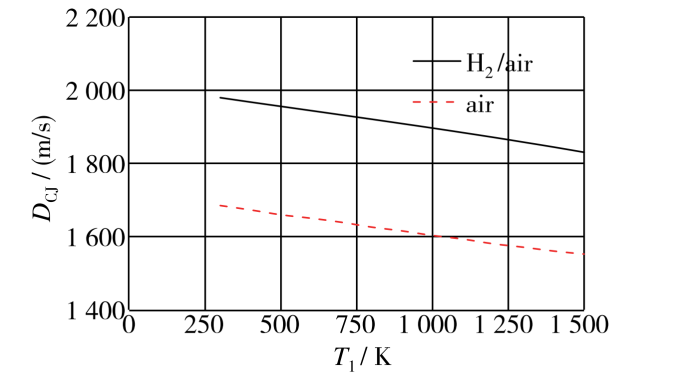

The simulation result shows the data of incoming flow temperature varies from 300 K to 1,500 K with an initial pressure of 1 atm. Table 1 gives the Mach number, pressure and burst velocity of the CJ blast wave at different isolated incoming flow temperatures [4].

Table 1. Parameters of stoichiometric H2/air CJ detonation under different initial temperatures.

\( {T_{1}}/K \) | \( {M_{{a_{CJ}}}} \) | \( {P_{CJ}}/{P_{1}} \) | \( {D_{CJ}}/(m/s) \) | \( {P_{2}}/{P_{1}}(shock) \) |

300 | 4.85 | 15.08 | 1979.3 | 27.85 |

400 | 4.18 | 11.28 | 1976.3 | 20.55 |

500 | 3.72 | 9.02 | 1955.6 | 16.18 |

600 | 3.39 | 7.49 | 1943.9 | 13.43 |

700 | 3.13 | 6.42 | 1932.2 | 11.41 |

800 | 2.92 | 5.61 | 1920.4 | 9.88 |

900 | 2.75 | 4.96 | 1908.4 | 8.74 |

1000 | 2.59 | 4.46 | 1896.3 | 7.72 |

1100 | 2.46 | 4.04 | 1883.8 | 6.85 |

1200 | 2.35 | 3.71 | 1871.1 | 6.32 |

1300 | 2.24 | 3.41 | 1857.8 | 5.72 |

1400 | 2.15 | 3.15 | 1844.3 | 5.25 |

1500 | 2.06 | 2.93 | 1830.1 | 4.73 |

For the data row of 1000K, the results roundly correspond to the experiments mentioned in the first paragraph of the current part. This result can prove the low thrust at this state again and shows the correctness of this simulation experiment. Furthermore, the higher inlet temperature brings the lower pressure ratio. That will cause the sharp decline of the thrust of scramjet engine. In other words, the engine thrust can be improved by lowering the static temperature of the combustion chamber inlet air. The low pressure ratio maybe cause the work instabilities or stalls or even hard to start.

|

|

Figure 3. Pressures of stoichiometric H2/ air CJ detonation under different initial temperatures. | Figure 4. Velocities of stoichiometric H2/air CJ detonation under different initial temperatures. |

Previous research shows that the combustion instability does not due to the high back pressure from the combustion chamber [9]. Figure 3 shows the pressure ratio comparison of the CJ detonation and the nonreactive shockwave. The results of CJ detonation represent the situation with combustion. It is obvious that, the back pressure of nonreactive shockwave even higher than the combustion situation. That can prove the above research and show the correctness of the experiment data.

Excitation and compression waves can be propagated upstream, that may be a reason about why the combustion become instability at high pressure ratio. “The detonation wave generated in the combustion chamber propagates into the air in the isolation section. Since the velocity of detonation wave is higher than that of incoming air as figure 4, the detonation wave is not stationary, but propagates upstream” [4]. The shock wave will decay continuously during the upstream spread. When the velocity of the shock wave decays to less than the velocity of the incoming air, it will be transmitted down into the combustion chamber to generate oscillating shock waves.

The hydrocarbon fuel can provide much big thrust than the traditional hydrogen fuel. The hydrocarbon can product high combustion pressure with low momentum. Besides, “Fuel reactivity modification is an effective way to control the self-starting characteristics of jet burners. By reducing the activation energy of hydrogen, the characteristic ignition length is significantly reduced at low flight Mach number conditions. The minimum flight Mach number required for self-start was reduced from 6.2 to 5.1 when the activation energy was reduced by 50%” [6]. That is a good way to improve the start difficulty and the combustion instability. Just from the fuel perspective, both two problems can be optimized.

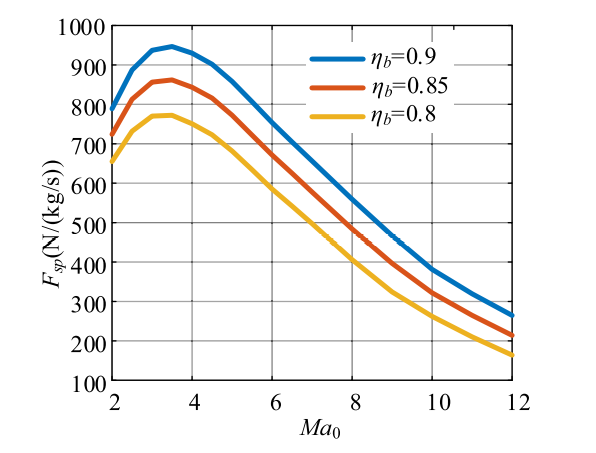

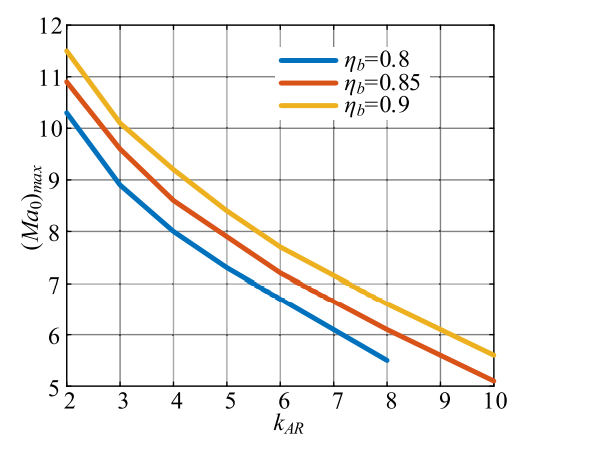

For the aerodynamic simulation experiment, the biggest thrust occurs around 3.5 Mach as shown as figure 5. However, the lowest start speed of scramjet engine must more than a very high speed [10]. That needs more than 5 Mach around. That has no real meaning. Nevertheless, lower speed in the scramjet speed range means longer travel life. Because of the high start speed of the scramjet engine, the area ratio must smaller than 7 at least to gain a stable work speed range as shown as figure 6. The influence of the area ratio to the maximum speed is very big. Low area ratio can even own the ability to accelerate more than 10 Mach.

|

| |

Figure 5. Specific thrust vs. freestream Mach number under different combustion efficiency. | Figure 6. Maximum flight Mach number at different combustion efficiency and k_AR when the angle of attack is 10°. |

4. Conclusion

Too low pressure in the combustion chamber causes the low thrust and too high pressure causes the combustion instability. It is important to find a proper combustion pressure.

The higher inlet temperature brings the lower pressure ratio. The engine thrust can be improved by lowering the static temperature of the combustion chamber inlet air

From the pressure ratio comparison of the CJ detonation and the nonreactive shockwave, the high back pressure is not the reason of combustion instability.

The oscillating shock waves in the combustion chamber which caused by the spread of shockwave upstream and downstream may be a reason why the combustion is instable in high pressure.

Hydrocarbon fuel can help to improve the thrust and the activity control of the fuel can help to solve the start difficulty and combustion instability problems.

At around 3.5 Mach, the scramjet engine has biggest thrust. The area ratio between the hypersonic vehicle reference area to the inlet capture area of scramjet engine must less than 7 to ensure the engine can work.

References

[1]. Curran E T. 2001 Scramjet Engines: The First Forty Years. Journal of Propulsion and Power, 17: 1138-148.

[2]. Eugênio R, Fábio H, Radouan B, Arnaud M. 2020 Highly-resolved Large-eddy Simulations of Combustion Stabilization in a Scramjet Engine Model with Cavity Flameholder. Computers & Fluids, 197: 104344.

[3]. Allison A, Patton M, Kraig F, Justin W. 2017 Investigation of Supersonic Combustion Dynamics via 50 kHz CH Chemiluminescence Imaging. Proceedings of the Combustion Institute, 36: 2849-2856.

[4]. Shen H, Zhang Z, Liu Y, Jiang Z. 2018 Theoretical Analysis of Scramjet propulsion Performance. Gas Physics, 3: 12-19.

[5]. Tai J. 2016 Numerical Study on Three-dimensional CJ Detonation Waves Interacting with Isotropic Turbulence. Science Bulletin (Beijing), 22: 1756-765.

[6]. Li X, Huang H, Liu H, Du J. 2020 Fuel Reactivity Controlled Self-starting and Propulsion Performance of a Scramjet: A Model Investigation. Energy (Oxford), 195: 116920.

[7]. Wang Y, Cheng K, Tang J, Liu X, Bao W. 2020 Analysis of the Maximum Flight Mach Number of Hydrocarbon-fueled Scramjet Engines under the Flight Cruising Constraint and the Combustor Cooling Requirement. Aerospace Science and Technology, 98: 105594.

[8]. McGilvray M, Kirchhartz R, Jazra T. 2010 Comparison of Mach 10 scramjet measurements from different impulse facilities. AIAA Journal, 48(8): 1647-1651.

[9]. Mitani T, Tani K, Miyajima H. 2007 Flow choking by drag and combustion in supersonic engine testing. Journal of Propulsion and Power, 23(6): 1177-1184.

[10]. Amati V C, Bruno D, Simone E. 2008 Exergy Analysis of Hypersonic Propulsion Systems: Performance Comparison of Two Different Scramjet Configurations at Cruise Conditions. Energy (Oxford), 33: 116-29.

Cite this article

Wang,S. (2023). Analysis and Possible Improvements of Scramjet Engines: The Effective Thrust and the Combustion Stability Problems. Theoretical and Natural Science,5,204-209.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2nd International Conference on Computing Innovation and Applied Physics (CONF-CIAP 2023)

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Curran E T. 2001 Scramjet Engines: The First Forty Years. Journal of Propulsion and Power, 17: 1138-148.

[2]. Eugênio R, Fábio H, Radouan B, Arnaud M. 2020 Highly-resolved Large-eddy Simulations of Combustion Stabilization in a Scramjet Engine Model with Cavity Flameholder. Computers & Fluids, 197: 104344.

[3]. Allison A, Patton M, Kraig F, Justin W. 2017 Investigation of Supersonic Combustion Dynamics via 50 kHz CH Chemiluminescence Imaging. Proceedings of the Combustion Institute, 36: 2849-2856.

[4]. Shen H, Zhang Z, Liu Y, Jiang Z. 2018 Theoretical Analysis of Scramjet propulsion Performance. Gas Physics, 3: 12-19.

[5]. Tai J. 2016 Numerical Study on Three-dimensional CJ Detonation Waves Interacting with Isotropic Turbulence. Science Bulletin (Beijing), 22: 1756-765.

[6]. Li X, Huang H, Liu H, Du J. 2020 Fuel Reactivity Controlled Self-starting and Propulsion Performance of a Scramjet: A Model Investigation. Energy (Oxford), 195: 116920.

[7]. Wang Y, Cheng K, Tang J, Liu X, Bao W. 2020 Analysis of the Maximum Flight Mach Number of Hydrocarbon-fueled Scramjet Engines under the Flight Cruising Constraint and the Combustor Cooling Requirement. Aerospace Science and Technology, 98: 105594.

[8]. McGilvray M, Kirchhartz R, Jazra T. 2010 Comparison of Mach 10 scramjet measurements from different impulse facilities. AIAA Journal, 48(8): 1647-1651.

[9]. Mitani T, Tani K, Miyajima H. 2007 Flow choking by drag and combustion in supersonic engine testing. Journal of Propulsion and Power, 23(6): 1177-1184.

[10]. Amati V C, Bruno D, Simone E. 2008 Exergy Analysis of Hypersonic Propulsion Systems: Performance Comparison of Two Different Scramjet Configurations at Cruise Conditions. Energy (Oxford), 33: 116-29.