1. Introduction

In the 1940s and 1950s, the Third Industrial Revolution erupted, heralding the dawn of the Information Age with semiconductors, atomic energy, and computer technology as its main representatives. Over the following decades, the value of information gained increasing recognition, becoming a primary asset in society. Information and information technology have transformed the work and lifestyle of every individual, driving rapid economic development and bringing about revolutionary changes to the entire society.

Entering the 21st century, there has been a technological evolution in computing power with advancements in technologies such as cloud computing, big data, and artificial intelligence, as well as a leap in connectivity capabilities represented by all-optical networks, 4G/5G, and Wi-Fi 6. This has raised higher expectations for digital technology. People aspire to go beyond information technology adoption and further achieve digitization, networking, and intelligence, extending the application of digital technology from personal consumption to various industries such as industrial manufacturing, transportation logistics, education, and healthcare. The goal is to accomplish the digital transformation of entire industries and society as a whole. In other words, digital technology is not only meant to enhance consumers' social and entertainment experiences but also to help businesses upgrade manufacturing processes and improve operational efficiency. Additionally, it aims to assist governments in enhancing governance capabilities and optimizing management efficiency, thereby enhancing residents' quality of urban life. The concept of digital twin technology emerges in response to such demands and background of the era. According to the latest research by Markets and Markets, the exploration of digital twin technology has been underway. The digital twin market was valued at $3.8 billion in 2019 and is projected to reach $35.8 billion by 2025 [1]. Digital twins have demonstrated significant potential in various domains, generating widespread interest from both industry and academia. However, the development of digital twins is still in its infancy. There is no standardized definition, implementation framework, or protocol established yet. Therefore, through a comprehensive and in-depth review, the objective of this paper is to:

• Analyzing the research status of digital twin:

• Examining the key technologies required for researching and applying digital twins.

•Providing a comprehensive overview of industrial applications of digital twins across various stages of their lifecycle.

• Suggesting future research directions for digital twins.

• Offering potential solutions to address existing challenges.

2. The development of digital twins

NASA provided the initial detailed definition of digital twins in. Since then, digital twins have become a hot topic in the aerospace industry. In 2014, Michael Grieves published a white paper that further elaborated on the concept. The conceptual model, fulfillment criteria, and use cases of digital twins were extensively discussed in. In 2017, Gartner listed digital twins as one of the top ten strategic technology trends, ranking fifth. They predicted that within three to five years, billions of things would have digital twin representations.

2.1. The origin of digital twins

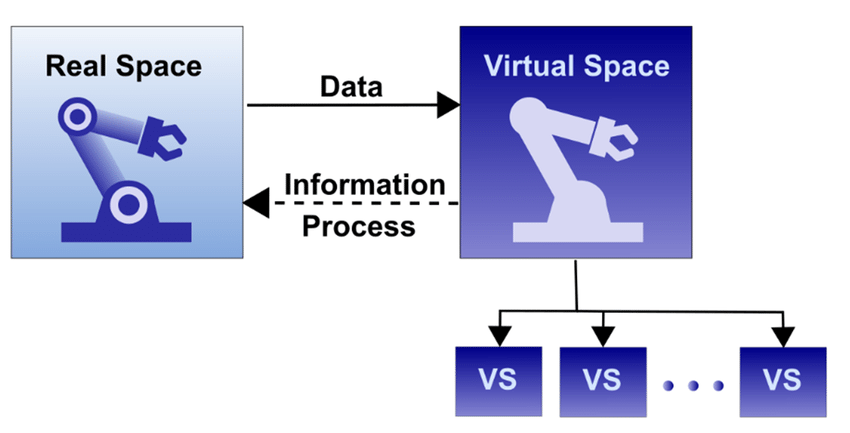

In 2002, The University of Michigan established the Product Lifecycle Management (PLM) Center, where Grieves first introduced the concept model of PLM. The PLM model proposed the concept of "virtual digital representation equivalent to the physical product," introducing the description of real space and virtual space. Additionally, Grieves proposed that the driving premise of this model is that every system consists of two systems: a persistent physical system and a new virtual system that contains all the information of the physical system. This implies the existence of a Mirroring of Systems or Twinning of Systems between the system in the real space and the system in the virtual space, and vice versa. Hence, the digital twin was also referred to as the "Mirror Space Model" in its early stages [2]. Figure 1 shows the Information Mirror Model.

Figure 1. Information mirror model [2].

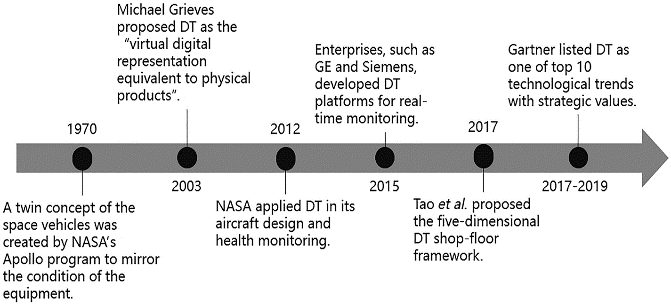

2.2. Stages of digital twin

The development of digital twins has gone through three main stages. The first stage is the period of technological accumulation, prior to the 21st century, where the emergence of 2D drafting tools and simulation technologies became necessary prerequisites for the development of digital twins. The second stage is the period of conceptual development, from 2000 to 2015, where various basic concepts of digital twins were proposed, with the aerospace and military sectors representing key contributors. The third stage is the period of explosive application, where digital twins have been applied in a broader range of industries such as aerospace, industrial, and healthcare, among others [3]. Figure 2 illustrates the different stages of digital twin development.

Figure 2. Digital twin development [3].

2.3. Trend of digital twin

If we liken digital twins to a mirror, they can create a virtual world that is as faithful as the real world, possessing high-fidelity characteristics. However, digital twins also have interoperability, as they map the real physical world and allow for the real-time perception, validation, and prediction of the operating state of physical systems through virtual interaction. They can provide decision optimization recommendations until the system achieves its optimum state. Therefore, digital twins are highly suitable for the development of intelligent manufacturing, aerospace, and smart city sectors, which are currently the main areas of application for digital twins. In the automotive and aircraft manufacturing fields, digital twin technology has become an important tool for optimizing the value chain and innovating entire products. In the energy sector, digital models established by oilfield service operators through the acquisition and analysis of large amounts of well data provide real-time guidance for drilling operations [4].

Digital twins can simulate various aspects of physical objects or processes. They can display blueprints and dimensions of new products, as well as set up revisions to show all sub-components and corresponding links in the consumer's entire supply chain. In all forms, digital twins capture and leverage data from the real world.

3. Application

Digital twin is an innovative concept based on advanced technology that is rapidly gaining prominence across various industries. By combining the physical system or process with its digital representation, digital twin enables real-time simulation, monitoring, and optimization. It finds extensive applications in diverse sectors including manufacturing, energy, healthcare, construction and real estate, urban planning and transportation, and agriculture. Its emergence presents tremendous opportunities for businesses and organizations to enhance efficiency, reduce costs, optimize decision-making, and drive innovation. This article provides a brief overview of the applications of digital twin in different industries, showcasing its potential and impact in various domains.

3.1. In aerospace

In 2010, the National Aeronautics and Space Administration (NASA) of the United States significantly reduced the development cost of spacecraft using digital twin technology. The Boeing 777 aircraft serves as a typical example of early-stage technological development utilizing digital twin technology.

Throughout the entire development process of the Boeing 777, no traditional paper drawings or physical models were used. Instead, the simulation and experimentation of over three million components were entirely reliant on digital twin technology. The use of digital twin technology helped Boeing reduce rework by 50% and effectively shorten the development cycle by 40%. With advancing technology, within the next 1-2 years, over 50% of large-scale factories worldwide are expected to adopt digital twin technology in their production processes, resulting in nearly a 10% increase in production efficiency [5].

Furthermore, in 2010, NASA proposed the goal of achieving the NASA Digital twin by 2027. The report outlined four application scenarios for digital twin technology:

(1) Pre-flight "test flight" for spacecraft: This scenario involves analyzing the impact of different mission parameters and studying and validating corresponding response strategies for various abnormal phenomena.

(2) Real-time monitoring of actual flights with mirrored spacecraft: The digital twin technology is responsible for monitoring payload, temperature, and structural damage status, reflecting the real flight conditions.

(3) Evaluation following faults or damages: When sensors indicate a degradation in structural performance, diagnostic analysis is conducted to identify the causes of anomalies and determine the appropriate measures after failure.

(4) Platform for design modification analysis: Simulating the operational status after the failure of certain components to decide whether design improvements are necessary, thereby avoiding unnecessary modifications and adjustments.

Looking ahead, the development of digital twin technology is predicted to achieve significant milestones. By 2035, digital twin technology is expected to cut aircraft maintenance costs in half and extend the service life level to ten times the current duration [6].

3.2. In smart city

Currently, a digital wave represented by new technologies such as the Internet of Things (IoT), big data, and artificial intelligence (AI) is sweeping across the globe. The physical world and the digital world are forming two parallel and interacting systems. The digital world exists to serve the physical world, while the physical world becomes more efficient and orderly through the digital world. As a result, digital twin technology has emerged and gradually extended from the manufacturing industry to urban spaces, influencing urban planning and construction [7].

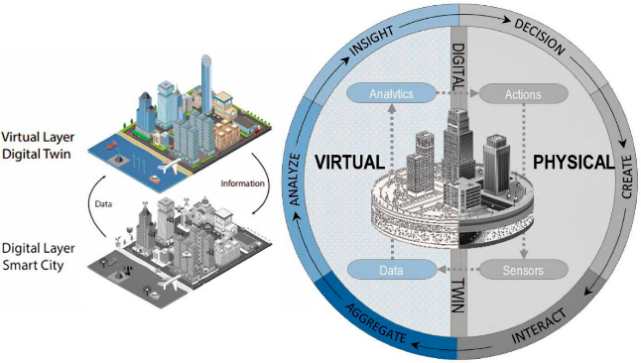

The role of digital twin technology lies in its ability to create a digital city in the digital space that corresponds to and matches the physical city based on an information technology system and a city information spatial model. Through holographic simulation, dynamic monitoring, and real-time diagnosis, it can achieve accurate predictions of the status of physical entities in the urban environment. This further promotes the digitization and virtualization of all elements of the city, the real-time representation and visualization of the entire state, and the intelligent coordination of urban operation and management. Ultimately, it enables the synergistic interaction and parallel operation of the physical city and the digital city. Figure 3 illustrates the implementation path of a digital twin city.

Figure 3. The implementation path of Digital twin cities.

Furthermore, the core value of digital twin technology lies in empowering the new system through the establishment of a highly integrated data closed-loop, generating a comprehensive digital virtual imaging space of the entire city. By utilizing virtualization interaction and modular assembly, a digital twin city is formed, with data-driven decision-making and a seamless integration of the virtual and physical realms. The operation, management, and services of the city will be transformed from the physical to the virtual, where modeling, simulation, evolution, and manipulation can take place in the virtual space. At the same time, the city will also transition from the virtual to the physical by changing and promoting the optimized allocation of urban resource elements in the physical space, opening up new models for smart city construction and governance [8].

This will greatly change the current urban landscape, reshape the city's infrastructure, and ultimately create a new form of urban development that combines the virtual and the real, with interactive twinning (Figure 4) [9].

Figure 4. Digital twin cities [9].

3.3. In industrial manufacturing

In recent years, the industrial machinery sector has gradually focused on independent innovation of high-end equipment and improving product quality. While enhancing market branding awareness, innovative development approaches have been adopted. For example, integrating services into enterprise operations and maintaining professional expertise in specific industrial machinery segments. Additionally, many companies have specialized in the supply of critical components, the development of fundamental processes and materials, providing excellent parts, transmission components, and electromechanical components or systems for industrial machinery and equipment that comply with national and international standards.

Under this development trend, industry stakeholders have had to construct digital models of industrial machinery products in a virtualized and digitized manner. These models incorporate additional attributes to help enterprises improve the efficiency of the industrial chain. This includes rapid proposal generation, validation, decision-making, manufacturing, and assembly.

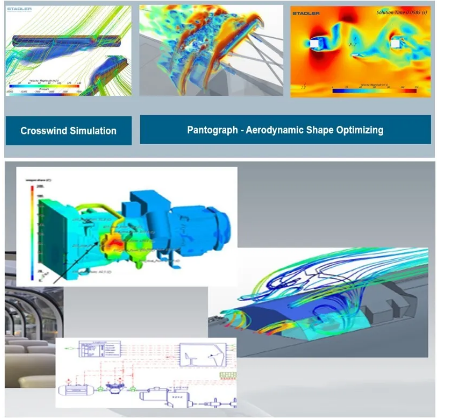

Digital twin technology, utilizing computer technology, computer graphics, and database technologies, enables the complete digitization of models and layout diagrams required in the development of industrial machinery. Various performance aspects of the product are simulated under different operating conditions and physical environments. Moreover, on the virtual digital model, iterative calculations are performed by applying various simulation parameters to assist in design decision-making during product development. This enables the comparison and evaluation of multiple solutions in a short period, facilitating the selection of the most suitable one [10]. Figure 5 depicts the analysis of a digital twin model for a product.

Figure 5. Digital model analysis diagram of the product [10].

4. Development prospects

Large enterprises, due to their decentralized structure and vast quantities of personnel, materials, and assets, can greatly enhance their digital transformation speed, reduce digitalization costs, and mitigate risks by leveraging industrial Internet of Things platforms and the construction of digital twins. Through these initiatives, they can define and implement standardized digital modeling of physical assets, personnel, resources, and the entire enterprise within the corporate group. Digital twin technology not only plays a significant role in areas such as smart cities, smart factories, and aerospace, but also has profound impacts in other sectors [11].

For instance, in the fields of logistics, manufacturing, and supply chain, the use of machine learning and 5G network-enabled digital twin technology enables real-time tracking, monitoring, ordering channels, and optimization of global goods flow. The location and environmental conditions (temperature, humidity, etc.) of goods become visible in real-time. Without human intervention, a "control tower" can command corrective measures such as inventory transfers, adjustments to assembly line processes, and re-routing of containers. In the transition from product sales to product-as-a-service models or sales-as-a-service, connecting digital twins to embedded sensors for financial analysis and forecasting can improve and optimize predictions, pricing, and sales opportunities [12].

5. Conclusion

This article has explored the applications of digital twins in various industries, highlighting their significant role in driving digital transformation and enhancing operational efficiency. Digital twin technology, coupled with the industrial Internet of Things (IoT), has revolutionized industries such as manufacturing, smart cities, aerospace, logistics, and supply chain management.

The adoption of digital twins has led to several key findings. Firstly, in the manufacturing sector, digital twins have facilitated product design, simulation, and optimization, enabling rapid prototyping and reducing time-to-market. Secondly, in the context of smart cities, digital twins have enhanced urban planning, infrastructure management, and resource optimization, leading to improved livability and sustainability. Thirdly, in aerospace and aviation, digital twins have enabled predictive maintenance, reducing downtime and improving safety. Moreover, in logistics and supply chain management, digital twins have enabled real-time tracking, monitoring, and optimization of global goods flow, enhancing operational efficiency and customer satisfaction.

Future research in this field should focus on several key aspects. Firstly, advancing the integration of artificial intelligence (AI) and machine learning (ML) algorithms with digital twins can enable more sophisticated data analysis, decision-making, and predictive capabilities. Secondly, exploring the potential of blockchain technology for secure and transparent data sharing and collaboration among stakeholders in digital twin ecosystems. Lastly, expanding the scope of digital twins to encompass social and environmental factors, enabling holistic and sustainable decision-making in industries and urban environments.

In conclusion, the applications of digital twins have demonstrated their transformative potential across industries. By harnessing the power of virtualization, real-time monitoring, and predictive analytics, digital twins enable organizations to optimize processes, enhance productivity, and drive innovation. With further advancements and interdisciplinary collaborations, digital twins will continue to shape the future of industrial development and urban planning, paving the way for a more connected and intelligent world.

References

[1]. Tao, F.; Zhang, M.; Nee, A.Y.C. Chapter 2—Applications of Digital twin. In Digital twin Driven Smart Manufacturing; Tao, F., Zhang, M., Nee, A.Y.C., Eds.; Academic Press: Cambridge, MA, USA, 2019; pp. 29–62.

[2]. Kritzinger, W.; Karner, M.; Traar, G.; Henjes, J.; Sihn, W. Digital twin in manufacturing: A categorical literature review and classification. IFAC-PapersOnLine 2018, 51, 1016–1022.

[3]. Parrott, A.; Warshaw, L. Industry 4.0 and the Digital twin: Manufacturing Meets its Match; Deloitte University Press: New York, NY, USA, 2017; pp. 1–17.

[4]. Tao, F.; Zhang, M.; Nee, A.Y.C. Chapter 1—Background and Concept of Digital twin. In Digital twin Driven Smart Manufacturing; Tao, F., Zhang, M., Nee, A.Y.C., Eds.; Academic Press: Cambridge, MA, USA, 2019; pp. 3–28.

[5]. MarketsandMarkets. Digital twin Market by Technology, Type (Product, Process, and System), Application (Predictive Maintenance, and Others), Industry (Aerospace & Defense, Automotive & Transportation, Healthcare, and others), and Geography—Global Forecast to 2026; MarketsandMarkets: Pune, India, 2020; p. 177.

[6]. Magomadov, V. The digital twin technology and its role in manufacturing. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Krasnoyarsk, Russia, 16–18 April 2020; p. 032080.

[7]. Grieves, M. Origins of the Digital twin Concept. 2016. Available online: https://www.researchgate.net/publication/307509727_Origins_of_the_Digital_Twin_Concept. (accessed on 25 September 2020)

[8]. Grieves, M.W. Product lifecycle management: The new paradigm for enterprises. Int. J. Prod. Dev. 2005, 2, 71–84.

[9]. Cimino, C.; Negri, E.; Fumagalli, L. Review of digital twin applications in manufacturing. Comput. Ind. 2019, 113, 103130.

[10]. Liu, M.; Fang, S.; Dong, H.; Xu, C. Review of digital twin about concepts, technologies, and industrial applications. J. Manuf. Syst. 2020, 58, 346–361.

[11]. Lu, Y.; Liu, C.; Kevin, I.; Wang, K.; Huang, H.; Xu, X. Digital twin-driven smart manufacturing: Connotation, reference model, applications and research issues. Robot. Comput. Integr. Manuf. 2020, 61, 101837.

[12]. He, B.; Bai, K.-J. Digital twin-based sustainable intelligent manufacturing: A review. Adv. Manuf. 2020, 9, 1–21

Cite this article

Zhang,Z. (2023). Digital twin: Application and prospect. Theoretical and Natural Science,12,220-226.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2023 International Conference on Mathematical Physics and Computational Simulation

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Tao, F.; Zhang, M.; Nee, A.Y.C. Chapter 2—Applications of Digital twin. In Digital twin Driven Smart Manufacturing; Tao, F., Zhang, M., Nee, A.Y.C., Eds.; Academic Press: Cambridge, MA, USA, 2019; pp. 29–62.

[2]. Kritzinger, W.; Karner, M.; Traar, G.; Henjes, J.; Sihn, W. Digital twin in manufacturing: A categorical literature review and classification. IFAC-PapersOnLine 2018, 51, 1016–1022.

[3]. Parrott, A.; Warshaw, L. Industry 4.0 and the Digital twin: Manufacturing Meets its Match; Deloitte University Press: New York, NY, USA, 2017; pp. 1–17.

[4]. Tao, F.; Zhang, M.; Nee, A.Y.C. Chapter 1—Background and Concept of Digital twin. In Digital twin Driven Smart Manufacturing; Tao, F., Zhang, M., Nee, A.Y.C., Eds.; Academic Press: Cambridge, MA, USA, 2019; pp. 3–28.

[5]. MarketsandMarkets. Digital twin Market by Technology, Type (Product, Process, and System), Application (Predictive Maintenance, and Others), Industry (Aerospace & Defense, Automotive & Transportation, Healthcare, and others), and Geography—Global Forecast to 2026; MarketsandMarkets: Pune, India, 2020; p. 177.

[6]. Magomadov, V. The digital twin technology and its role in manufacturing. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Krasnoyarsk, Russia, 16–18 April 2020; p. 032080.

[7]. Grieves, M. Origins of the Digital twin Concept. 2016. Available online: https://www.researchgate.net/publication/307509727_Origins_of_the_Digital_Twin_Concept. (accessed on 25 September 2020)

[8]. Grieves, M.W. Product lifecycle management: The new paradigm for enterprises. Int. J. Prod. Dev. 2005, 2, 71–84.

[9]. Cimino, C.; Negri, E.; Fumagalli, L. Review of digital twin applications in manufacturing. Comput. Ind. 2019, 113, 103130.

[10]. Liu, M.; Fang, S.; Dong, H.; Xu, C. Review of digital twin about concepts, technologies, and industrial applications. J. Manuf. Syst. 2020, 58, 346–361.

[11]. Lu, Y.; Liu, C.; Kevin, I.; Wang, K.; Huang, H.; Xu, X. Digital twin-driven smart manufacturing: Connotation, reference model, applications and research issues. Robot. Comput. Integr. Manuf. 2020, 61, 101837.

[12]. He, B.; Bai, K.-J. Digital twin-based sustainable intelligent manufacturing: A review. Adv. Manuf. 2020, 9, 1–21