1. Introduction

In recent years, with the rapid development of automotive technology, modern automobiles have evolved beyond mere mechanical devices, becoming intelligent, digitized, and interconnected. People's expectations of cars have transformed from simple transportation tools to lifestyle-changing vehicles. Automotive intelligent control systems have become a crucial means to achieve this goal, aiming for high levels of safety, efficiency, and convenience, all of which are competitive objectives for automotive brands [1]. In this context, FPGA technology has emerged as an increasingly vital technology in the field of automotive intelligent control. Due to its characteristics such as high performance, low latency, reconfigurability, and hardware acceleration, FPGA has become the ideal choice to meet these evolving demands.

In this study, the authors embark on an exploration of the theoretical underpinnings of FPGA applications within the realm of automotive intelligent control. FPGA, characterized as an integrated circuit device, offers the capability to implement a diverse array of digital circuit functionalities through user programming. It is particularly well-suited for purposes such as prototype development, expedited design iterations, and research validation.

Automotive intelligent control, as the overarching objective, seeks to leverage advanced computing and sensor technologies to enhance the safety, efficiency, convenience, and driving experience of vehicles. This endeavor integrates an amalgamation of both hardware and software systems, with FPGA aligning seamlessly with the developmental requisites of automotive intelligent control.

The subsequent sections of this study delve into a comprehensive analysis of the technical prerequisites necessary for realizing control functionalities. These encompass embedded systems development, data fusion and perception, control algorithms, artificial intelligence, and machine learning. Subsequently, the authors categorize FPGA applications within the domain of automotive intelligent control into three primary classifications: FPGA applications dedicated to autonomous driving image processing, FPGA applications facilitating the implementation of automotive control functions, and FPGA applications tailored for automotive electronic design. Within each of these categories, the authors extrapolate overarching principles and patterns through the meticulous examination of illustrative case studies.

In summation, this study culminates by elucidating the challenges confronting FPGA deployment within the purview of automotive intelligent control and offering insights into prospective avenues for future development within this domain. This research has revealed that the application of FPGA in the field of automotive intelligent control contributes significantly to enhancing the intelligence, safety, and performance efficiency of vehicles. These factors underscore the significance of FPGA in the domain of automotive intelligent control.

2. Theoretical foundation

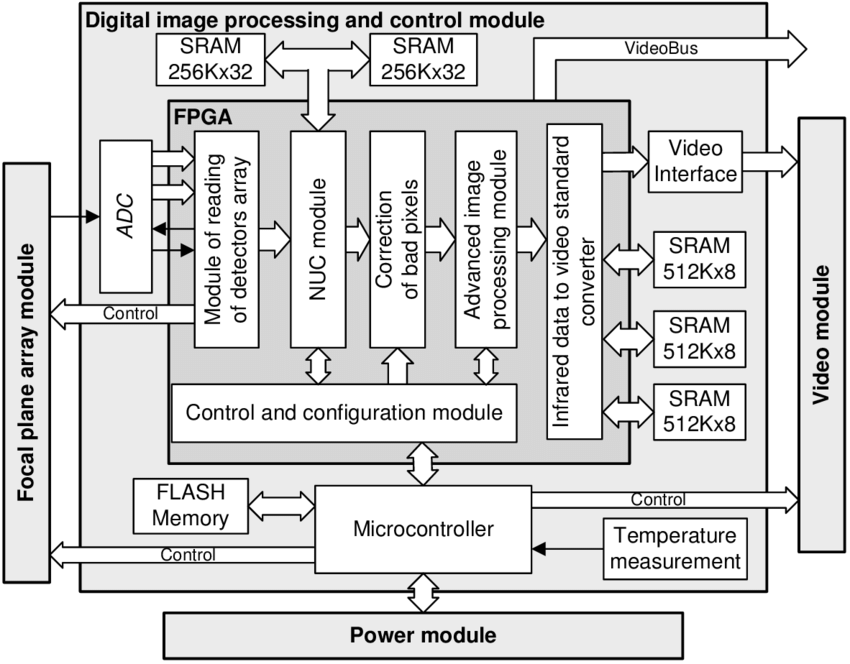

FPGA is an integrated circuit device that can implement various digital circuit functionalities through user programming. It consists of a multitude of logic gates, storage units, and programmable interconnect resources. Logic blocks, including logic gates, flip-flops, and other logic elements, are used to perform digital logic operations. Programmable memory blocks are utilized for data storage or distributed memory implementation. Clock management resources control the timing circuits to ensure the synchronization of different components. Global interconnect resources are employed to connect logic blocks and memory blocks, as well as interface with input/output pins. Users can program these resources according to their specific needs, thereby creating custom digital circuits. An example of different modules and functions in FPGA is shown in figure 1 [2].

Figure 1. An example of different modules and functions in FPGA [2].

FPGAs are commonly used in rapid prototyping, digital signal processing, image processing, communication applications, encryption algorithms, and embedded systems, among other fields. The primary advantages of FPGAs include flexibility and reconfigurability. Unlike Application-Specific Integrated Circuits (ASICs), FPGAs can be reprogrammed multiple times as needed, making them well-suited for prototype development, rapid design, and research validation. They are also frequently employed in digital signal processing, communications, embedded systems, and encryption algorithm applications.

Automotive intelligent control is a complex technological field aimed at leveraging advanced computing and sensor technologies to enhance the safety, efficiency, convenience, and driving experience of vehicles. It integrates multiple hardware and software systems with the goal of enabling vehicles to perceive their surrounding environment, make autonomous decisions, and engage in real-time communication with drivers, other vehicles, and traffic infrastructure [3]. Key aspects of automotive intelligent control encompass environmental perception and sensor fusion, decision-making and control algorithms, autonomous driving technology, human-machine interfaces, communication technologies, and data security and privacy protection. Automotive intelligent control represents a comprehensive technological framework that amalgamates perception, decision-making, control, communication, and user experience to realize a safer, more efficient, and convenient automotive transportation system.

3. Technological requirements for achieving primary functionalities

In the field of automotive intelligent control, FPGA (Field-Programmable Gate Array) plays a crucial role and is closely intertwined with various aspects of automotive intelligence. FPGA is a powerful tool known for its capabilities in high performance, low latency, reconfigurability, and hardware acceleration. It offers flexibility and performance when dealing with complex control and perception tasks. Here are key connections between FPGA and automotive intelligent control in multiple domains:

Embedded System Development: FPGA is commonly employed as a part of embedded systems to implement specific digital logic and control functions. In the realm of automotive intelligent control, developers utilize FPGA for real-time control tasks such as engine management, sensor data processing, and decision-making [4].

Sensor Technology: FPGA is utilized for processing and integrating data from various sensors. For example, data from cameras and LiDAR sensors on vehicles can be transmitted to FPGA, where algorithms perform data fusion and perception tasks efficiently, enabling a comprehensive understanding of the vehicle's surroundings.

Control Algorithms: FPGA can be employed to implement high-performance control algorithms, including vehicle stability control, brake systems, and cruise control. Its hardware acceleration capabilities facilitate low-latency and highly reliable control feedback.

Artificial Intelligence and Machine Learning: FPGA is also used to accelerate the inference process of machine learning and deep learning models. This is particularly critical in autonomous driving systems, where FPGA's parallel computing capabilities support real-time decision-making and perception tasks.

Communication Technology: FPGA is capable of handling data communication between vehicles (V2V) and between vehicles and infrastructure (V2I). It can efficiently process data and support communication protocols, enabling vehicles to collaborate and interact with traffic infrastructure [5].

Software Security and Data Privacy: FPGA is employed to implement hardware security features, aiding in protecting automotive intelligent control systems from potential attacks. Additionally, FPGA can be used for data encryption and privacy protection, ensuring the security of transmitted and stored data.

4. Application scenario analysis

4.1. Applications in Autonomous Driving and Image Processing Category

Autonomous driving refers to a technology and system that enables vehicles to navigate and make decisions autonomously without human driver intervention.

The core of this paper lies in deploying the Model Predictive Control (MPC) algorithm on FPGA and demonstrating its effectiveness through experiments. This approach significantly simplifies the complexity of algorithm implementation on FPGA and accelerates the execution of MPC solutions [6].

Specifically, the paper introduces a design method based on ZYNQ (Zynq-7000 All Programmable SoC), which combines hardware and software to integrate the MPC algorithm into FPGA. Compared to standalone FPGAs, ZYNQ combines the high-performance computing capabilities of FPGAs with the resource allocation capabilities of CPUs, providing researchers with greater flexibility when dealing with algorithms.

The conclusion of the paper is that this new method provides an efficient algorithm deployment approach for the next generation of FPGA hardware and lays the foundation for practical vehicle experiments using ZYNQ. This comprehensive approach reduces the complexity of algorithm implementation on FPGA and accelerates the implementation of MPC solutions [6].

In the field of autonomous driving, MPC can be applied to various aspects such as trajectory tracking, vehicle speed control, and path planning, enabling precise control and optimization of autonomous vehicles. Therefore, MPC holds significant application value in the autonomous driving field, enhancing the safety, stability, and ride comfort of autonomous vehicles [7].

The paper proposes an algorithm deployment approach based on a CPU+FPGA architecture. By deploying the algorithm on FPGA, it achieves hardware-accelerated solutions for Model Predictive Control (MPC). Simultaneously, it leverages the flexibility and generality of the CPU to coordinate resource allocation and data transfer tasks on FPGA [8].

Experimental results indicate that this method significantly improves the solving speed and real-time performance of MPC algorithms while maintaining high levels of control accuracy and stability. Specifically, compared to traditional CPU-based solving methods, this approach reduces solving time to approximately one-tenth of the original time while preserving high control accuracy and stability [8]. This demonstrates that FPGA acceleration holds high practicality and feasibility in addressing challenges related to autonomous driving MPC, providing a new avenue and method for algorithm optimization in the autonomous driving field.

4.2. Applications in Automotive Control Function Implementation Category

FPGA plays a crucial role in various aspects of automotive control function implementation, bringing performance enhancements to automotive mechanical control systems and automotive electronic control systems.

The vehicle braking system is the most crucial safety device in an automobile. It is a mechanism designed to apply a certain amount of force, primarily to the wheels, in response to external factors, mainly the road surface, to impose a certain degree of mandatory braking. The purpose of the vehicle braking system is to enable the moving vehicle to decelerate or even come to a complete stop as per the driver's commands. It also ensures that a stationary vehicle remains stable under various road conditions, including on inclines, and maintains a stable speed for vehicles traveling downhill [9].

FPGA technology has matured over time and offers advantages such as stability, high operating speed, low cost, and reliability. It not only addresses the issues associated with custom circuits but also overcomes the limitations of traditional programmable devices with limited gate counts. It has a promising future, effectively meeting the demands of future markets.

The study verified that when commands for right turns, left turns, reverse, or braking are issued, the FPGA system effectively simulates the corresponding car tail light on/off patterns using the LEDs on the development board [9]. This design not only meets the project requirements but also utilizes the FPGA system for car tail light control.

4.3. Applications in Automotive Control Function Implementation Category

FPGA in the automotive electronics design process can assist the car's reversing camera, GPS (Global Positioning System) navigation and positioning, internal camera, and other functions, in the design process of the system, the processor, memory and so on will be integrated into the programmable components, thus gradually forming the programmable components. In the process of system design, processor, memory, etc. will be integrated into programmable components, thus gradually forming a system that can be programmed [10]

By incorporating Cyclone series FPGA system devices into the system design, a multifunctional automotive electronic system has been constructed. This system includes features such as fingerprint recognition, password locking, GSM (Global System for Mobile Communications) communication, GPS navigation, automatic anti-theft alarm, cameras, in-car audio and video, USB (Universal Serial Bus) transmission, and more. It also reserves a CAN (Controller Area Network) control interface for future system functionality expansion. This system utilizes programmable system technology to integrate multiple modules into one, forming a programmable system-on-chip [11].

The provided passage discusses how to improve the design process of automotive ASICs through FPGA-based prototype verification, aiming to enhance design reliability, reduce the risk of re-submissions, and lower development costs. It introduces an enhanced automotive ASIC development workflow, including a hardware prototype verification step based on FPGA [12].

By incorporating FPGA prototype verification into the design process, the entire design, including various operating conditions within automotive modules, can be tested in real-time. This helps in identifying issues before submitting the design for production. While this approach has limitations in verifying analog functional aspects and meeting qualification requirements, it significantly reduces the risk associated with submitting designs in automotive ASIC development [13].

In summary, the FPGA prototype verification design process holds great significance in automotive ASIC application development. It improves design reliability, shortens development time, reduces the risk of multiple re-submissions, and enhances cost-effectiveness. The article underscores the advantages and importance of this workflow [14].

FPGA plays the following roles in the development of mixed-signal integrated circuits (ASICs) for automobiles, and it offers the following advantages compared to traditional methods:

Hardware Prototype Verification: FPGA is used to create hardware prototypes, allowing the entire ASIC design to run and be tested within actual automotive modules. This helps in identifying design issues and performance bottlenecks, enabling early detection and resolution of potential problems, which is not possible with traditional methods that rely on post-design verification.

Reduced Submission Risk: Traditional ASIC design processes carry a high submission risk because there is no opportunity to test the performance of the entire system under real operating conditions during the initial submission. FPGA prototype verification reduces submission risk by enabling comprehensive testing and validation before the final submission.

Accelerated Development Time: FPGA prototypes can be built and verified more quickly, significantly shortening the overall design process compared to traditional methods.

Mitigation of Multiple Submission Risks: FPGA prototype verification helps reduce the need for multiple submissions. Traditional methods may require multiple submissions, with each submission requiring waiting time at the manufacturing facility, while FPGA prototype verification can circumvent such delays.

Easier Design Changes: Implementing design changes is relatively straightforward within an FPGA, allowing for the early identification and correction of design issues.

In summary, FPGA's role in automotive ASIC development is to enhance design reliability, reduce submission risks, accelerate development time, mitigate the risk of multiple submissions, and facilitate easier design changes through hardware prototype verification. These advantages contribute to improved efficiency and success rates in automotive ASIC development.

Footnotes should be avoided whenever possible. If required they should be used only for brief notes that do not fit conveniently into the text.

5. Conclusion

The research has revealed numerous applications of FPGA in the field of automotive intelligent control, aligning with the developmental requirements of this domain. FPGA finds extensive use in various domains, including automatic driving image processing, automotive control function implementation, and automotive electronic design, offering high convenience, efficiency, and a user-friendly development environment. In recent years, the author has observed widespread utilization of FPGA in image processing, automotive electronic circuit control, and even mechanical electronic braking and taillight control.

However, this paper have identified several challenges in the application of FPGA in the field of automotive intelligent control. The automotive intelligent control system itself is highly complex, involving the processing of vast amounts of sensor data and the implementation of advanced control algorithms and decision logic. Mapping these functions onto FPGA platforms necessitates addressing issues related to complexity and extensive optimization. Additionally, FPGAs have finite resources, including logic units, storage units, and clock resources, posing challenges in efficiently utilizing resources within automotive control systems. Furthermore, there are challenges related to real-time processing and issues concerning hardware-software co-design that are not easily resolved. Nevertheless, it is noteworthy that FPGA technology is rapidly gaining momentum in the domain of automotive intelligent control, offering capabilities that other devices may not provide. In the future, it may play an increasingly transformative role in various aspects of the automotive industry, from development to application, potentially offering new lifestyles and experiences to individuals.

References

[1]. Shreejith S, Fahmy S A. Extensible FlexRay communication controller for FPGA-based automotive systems. IEEE transactions on vehicular technology, 2014, 64(2): 453-465.

[2]. Cho K, Kim J, Choi D Y, et al. An FPGA-based ECU for remote reconfiguration in automotive systems. Micromachines, 2021, 12(11): 1309.

[3]. Omran A H, Abid Y M, Mahdi M S, et al. Design of intelligent controller to minimize the power consumption in smart city based on FPGA. Solid State Technology, 2020, 63(6): 9120-9136.

[4]. Saravanan S. Smart Automotive Systems Supported by Configurable FPGA, IoT, and Artificial Intelligence Techniques. FPGA Algorithms and Applications for the Internet of Things. IGI Global, 2020: 108-132.

[5]. Du B, Sterpone L. An FPGA-based testing platform for the validation of automotive powertrain ECU. 2016 IFIP/IEEE International Conference on Very Large Scale Integration (VLSI-SoC). IEEE, 2016: 1-7.

[6]. Chen Yifei, Yu Chunlei, Zheng Shiliang et al. Real-time point Cloud target Detection of autonomous vehicle based on FPGA hardware and Software Collaborative optimization. China Society of Automotive Engineers. Proceedings of the 2021 Annual Meeting of China Society of Automotive Engineers. 2021, 202: 44-51.

[7]. Li Yunfei. FPGA Accelerated Solution Method for Model Predictive Control for Autonomous Driving. Chongqing University,2020.

[8]. Li Y, Li S E, Jia X, et al. FPGA accelerated model predictive control for autonomous driving. Journal of Intelligent and Connected Vehicles, 2022, 5(2): 63-71.

[9]. Tian Hongsheng. Research on Automotive electro-mechanical Brake Control System based on FPGA/SOPC technology. Jiangsu University,2010

[10]. Ma Ming. Research on Automotive Electronic Design based on FPGA. Electronic Production, 2020, (10): 15-17

[11]. Ren Kexin, Wang Ying. Design of Automobile taillight Control Circuit based on FPGA. Information and Computer (Theoretical Edition), 2021, 33(02): 90-91

[12]. Gong F, Vaidya M, Kora R, et al. A FPGA based prototype verification in automotive mixed signal integrated circuit development. 2013 IEEE 56th International Midwest Symposium on Circuits and Systems (MWSCAS). IEEE, 2013: 1200-1203.

[13]. Bi L, Wei X, Sun Z. A high-voltage safety protection method for electric vehicle based on FPGA. 2006 IEEE International Conference on Vehicular Electronics and Safety. IEEE, 2006: 26-31.

[14]. Liang Wenyuan, Yi Chen. Application of FPGA in Electric vehicle Motor Controller. Mechanical and Electrical Engineering Technology, 2019, 49(11): 231-232+242.

Cite this article

Liu,D. (2024). The efficient application analysis of FPGA in automotive intelligent control. Applied and Computational Engineering,54,57-63.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 4th International Conference on Signal Processing and Machine Learning

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Shreejith S, Fahmy S A. Extensible FlexRay communication controller for FPGA-based automotive systems. IEEE transactions on vehicular technology, 2014, 64(2): 453-465.

[2]. Cho K, Kim J, Choi D Y, et al. An FPGA-based ECU for remote reconfiguration in automotive systems. Micromachines, 2021, 12(11): 1309.

[3]. Omran A H, Abid Y M, Mahdi M S, et al. Design of intelligent controller to minimize the power consumption in smart city based on FPGA. Solid State Technology, 2020, 63(6): 9120-9136.

[4]. Saravanan S. Smart Automotive Systems Supported by Configurable FPGA, IoT, and Artificial Intelligence Techniques. FPGA Algorithms and Applications for the Internet of Things. IGI Global, 2020: 108-132.

[5]. Du B, Sterpone L. An FPGA-based testing platform for the validation of automotive powertrain ECU. 2016 IFIP/IEEE International Conference on Very Large Scale Integration (VLSI-SoC). IEEE, 2016: 1-7.

[6]. Chen Yifei, Yu Chunlei, Zheng Shiliang et al. Real-time point Cloud target Detection of autonomous vehicle based on FPGA hardware and Software Collaborative optimization. China Society of Automotive Engineers. Proceedings of the 2021 Annual Meeting of China Society of Automotive Engineers. 2021, 202: 44-51.

[7]. Li Yunfei. FPGA Accelerated Solution Method for Model Predictive Control for Autonomous Driving. Chongqing University,2020.

[8]. Li Y, Li S E, Jia X, et al. FPGA accelerated model predictive control for autonomous driving. Journal of Intelligent and Connected Vehicles, 2022, 5(2): 63-71.

[9]. Tian Hongsheng. Research on Automotive electro-mechanical Brake Control System based on FPGA/SOPC technology. Jiangsu University,2010

[10]. Ma Ming. Research on Automotive Electronic Design based on FPGA. Electronic Production, 2020, (10): 15-17

[11]. Ren Kexin, Wang Ying. Design of Automobile taillight Control Circuit based on FPGA. Information and Computer (Theoretical Edition), 2021, 33(02): 90-91

[12]. Gong F, Vaidya M, Kora R, et al. A FPGA based prototype verification in automotive mixed signal integrated circuit development. 2013 IEEE 56th International Midwest Symposium on Circuits and Systems (MWSCAS). IEEE, 2013: 1200-1203.

[13]. Bi L, Wei X, Sun Z. A high-voltage safety protection method for electric vehicle based on FPGA. 2006 IEEE International Conference on Vehicular Electronics and Safety. IEEE, 2006: 26-31.

[14]. Liang Wenyuan, Yi Chen. Application of FPGA in Electric vehicle Motor Controller. Mechanical and Electrical Engineering Technology, 2019, 49(11): 231-232+242.