1. Introduction

Quantum dots (QDs) have emerged as a remarkable class of semiconductor nanocrystals, exhibiting exceptional optical properties that hold immense promise in the realm of optoelectronic advanced materials [1]. These highly efficient photosensitizers have paved the way for a plethora of potential applications ranging from photovoltaic devices to molecular electronics and photocatalysts [2].

Quantum dots are nanoscale semiconductor materials that manifest themselves in spherical forms, typically ranging between 2 and 20 nanometers in diameter. When energized by light or electricity, quantum dots undergo the photoelectric effect, allowing them to emit light of a specific frequency. It is crucial to note that the wavelength of this emitted light directly correlates with the radius of the quantum dot, offering a means to precisely control the wavelength by manipulating the size of these minuscule structures [1, 3, 4].

However, as micro-particle materials, quantum dots often necessitate their integration with other substances to form composite materials that can be employed in practical applications. Unfortunately, the matrix materials conventionally combined with quantum dots primarily entail microscopic metal frameworks or metal nanorods, which have several drawbacks, including exorbitant costs and complex processing methods [5, 6].

In contrast, polymers, renowned for their versatility and vast array of properties, proffer a compelling alternative as composite matrices for quantum dots. These polymeric materials boast remarkable attributes such as excellent mechanical properties, chemical stability, and cost-effectiveness. Consequently, leveraging polymers as a matrix for quantum dot composites presents an outstanding avenue to expand the horizons of research and applications [7].

In this paper, we aim to shed light on the research and application prospects of quantum dot-polymer composites by presenting noteworthy examples from existing studies. By exploring the unique synergies between quantum dots and polymers, we can discern the advantages of this composite approach and elucidate its significance in various domains [8].

Through a meticulous examination of previous research endeavors, we will delve into the diversification of quantum dot-polymer composite materials, elucidating the novel properties and functionalities that arise from this innovative combination. By showcasing the successful integration of quantum dots within polymer matrices, we intend to forge a comprehensive understanding of the vast potential harbored by these composites.

2. Literature Review

For a long time, composite material construction has been increasingly adopted due to the limitations of a single material in performance, as it allows for the integration of multiple material characteristics [9]. Polymer, as a matrix material, has gained widespread usage in various engineering fields owing to its favorable mechanical properties, lower density compared to metals, and ease of processing [8]. Polymer matrix composites can be enhanced with nanoparticles, including quantum dots, which offer exciting possibilities for polymer-quantum dot composites.

This review paper focuses on three specific applications of polymer-quantum dot composites: composite coatings, composite films, and polymer sensors. The remarkable properties of both polymers and quantum dots make them well-suited for these applications, where their synergistic effects can be harnessed [10].

In the realm of lubricants, carbon quantum dots have emerged as significant materials that have captured substantial attention. These cost-effective nanoparticles exhibit exceptional physical properties and chemical stability, enabling them to effectively reduce surface friction and prevent damage to metal components [11]. Simultaneously, polyimide, a commonly utilized polymer coating material, has encountered challenges related to dispersion. Incorporating carbon quantum dots not only addresses this problem but also introduces a novel functional material into the field of functional coatings [12].

Moreover, quantum dots have found wide application in the domain of flexible electronics due to their excellent photoelectric properties. Researchers have successfully utilized quantum dots and polymer films to create flexible thin film structures with carefully designed spatial arrangements, thereby enabling their use as photodetectors [13]. This innovative film material holds great promise for applications in wearable devices, where flexibility and light weight are essential.

The third application discussed in this review paper combines the chemical properties of polymers with the photoelectric properties of quantum dots. Molecular imprinting technology utilizes polymers as core functional materials, enabling specific identification of target molecules. This technology, widely employed in biochemistry and medicine, offers easy synthesis, good chemical stability, and widespread applications. By embedding quantum dots as luminescent markers in molecularly imprinted polymers, improved performance can be achieved compared to traditional luminescent embedding materials [14, 15].

In summary, the use of polymer-quantum dot composites opens up exciting opportunities across various fields. Composite coatings, composite films, and polymer sensors leverage the complementary properties of these two materials, leading to enhanced functionalities. The incorporation of carbon quantum dots in lubricants addresses friction-related challenges, while the integration of quantum dots into flexible thin films creates advanced photodetection capabilities for wearable devices. Additionally, combining quantum dots and polymers in molecularly imprinted polymers enhances their performance in bioscience and medical applications, facilitating improved diagnostics and sensing capabilities. The continuous exploration and advancement of polymer-quantum dot composites hold immense potential in diverse fields, propelling progress and innovation.

3. Methodology

In this review paper, ScienceDirect and Google Scholar were used as data collection platforms to collect secondary data and analyze the research conducted in the field of polymer-quantum dot composites while searching for application information on polymer-quantum dot composites.

The first step in this approach is to identify the data collection platforms - ScienceDirect and Google Scholar. These platforms were chosen because of the wide range of scholarly articles and publications in various subject areas, resulting in a comprehensive review of relevant literature in the field.

The next step is to determine the criteria for selecting research articles from the large amount of available literature. In this study, the selection criteria are based on three main areas: composite film, composite coating and polymer sensor [3, 4, 8]. These areas cover the different construction forms and application areas of polymer quantum dot composites. Description of these areas allows for a systematic review of the literature and a comprehensive analysis of various applications.

During the search process, specific inclusion and exclusion criteria should be used to filter the initial search results. The screening process removes articles not considered or related to the research direction, ensuring that only the most relevant and reliable articles are included in the review.

After a screening process, the selected articles are read in detail, and a series of key information, including research objectives, methods, results and conclusions, are extracted. This information is organized in a systematic way for further analysis and discussion.

Then the topic method is used to analyze the reviewed articles. These topics are derived from the areas identified earlier in the methodology. The analysis includes examining similarities, differences, and emerging patterns in the findings of the selected articles. This method can identify the status quo, trends and gaps in the different fields of application of polymer quantum dot composites.

Finally, this paper gives a comprehensive and comprehensive introduction to the results of the literature review. The Research Methods section explains in detail the steps taken to collect and analyze the data to ensure transparency and reproducibility of the research.

4. Result

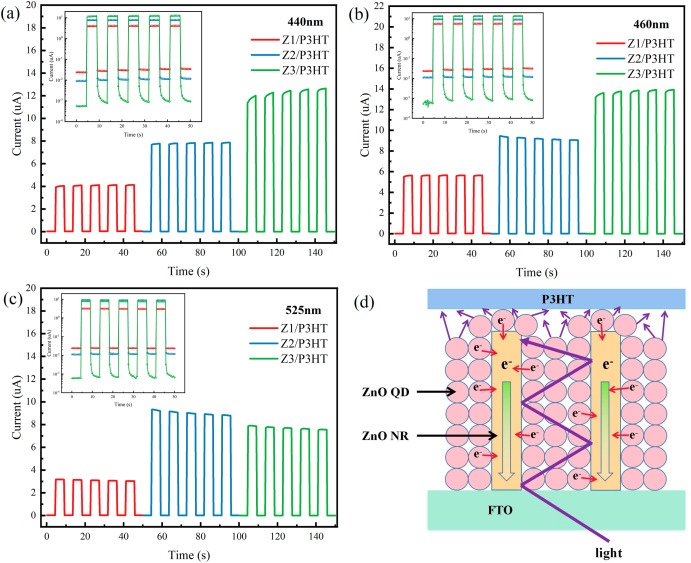

For the ZnO nanorods-ZnO quantum dots-polymer composite film, the surface arrangement of this material made by the spinning coating process is dense and smooth. This material has good optical properties and meets the performance requirements of its intended planning [4].

Figure 1. The logarithmic time curve of a, b and c films of three different specifications under alternating illumination at 440nm, 460nm and 525nm wavelengths, respectively. d Film device working principle diagram under light [4].

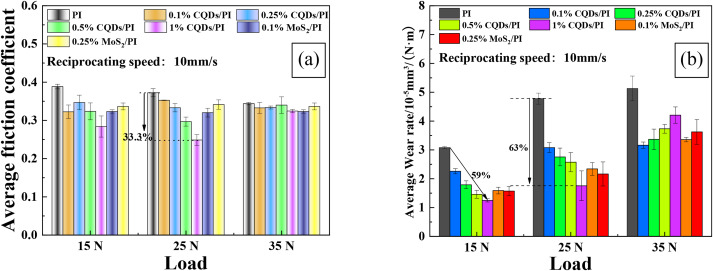

For carbon quantum dot-polyimide composites, this material has excellent thermal stability and mechanical properties. It has good hardness and anti-friction properties. The average friction coefficient of pure polyimide is about 0.37, while the lowest average friction coefficient of 1 wt% CQD/PI is about 0.24, which is about 33.3% lower than that of pure polyimide. Under the same test conditions, the wear rate of pure PI is 4.75×10−5 mm 3/ (Nm), as shown in Figure 2 (b). The PI wear rate, including 1wt%CQD was reduced by 63%. The results show that CQDs play an important role in enhancing the antifriction and wear resistance of PI, including CQDs particles [3].

Figure 2. Performance data under different load conditions. (a) Average friction coefficients; (b) average wear rates [3].

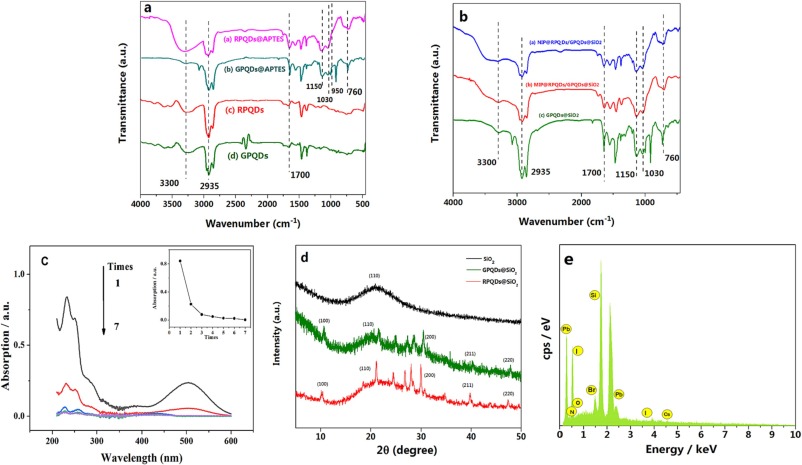

For imprinted polymer sensors, MIPs@RPQDs/GPQDs@SiO2 and NIPs@RPQDs/GPQDs@SiO2 show two fluorescence peaks at 520 nm and 695 nm. When Rhein is added to the MIPs@RPQDs/GPQDs@SiO2 solution, the fluorescence intensity of GPQDs at 520 nm remains unchanged and RPQDs at 695 nm gradually decay. This is because the GPQDs were well wrapped in SiO2 to avoid interaction with the drug, so the fluorescence intensity remains highly stable. However, the surface of MIPs@RPQDs/GPQDs@SiO2 has abundant imprinting cavities, and it can accurately identify Rhein and quench the fluorescence of RPQDs through the interaction of drugs and materials. During this process, the fluorescence color of MIPs@RPQDs/GPQDs@SiO2 changed from red to blue-green. This phenomenon indicates that MIPs@RPQDs/GPQDs@SiO2 plays a crucial role in identifying Rhein. Whether there is Rhein or not can also be judged by observing the change of fluorescence color directly under ultraviolet light. After the template is eluted, the fluorescence intensity of MIPs@RPQDs/GPQDs@SiO2 is restored to the same level as that of NIPs@RPQDs/GPQDs@SiO2. It shows that the eluent selection is effective [14].

Figure 3. The FT-IR spectra of (a) RPQDs, GPQDs, APTES-capped RPQDs, APTES-capped GPQDs and (b) GPQDs@ SiO2, MIPs@RPQDs/GPQDs@SiO2 and NIPs@RPQDs/GPQDs@SiO2. (c) UV absorption spectra of Rhein with different elution times (Insert: absorption of Rhein as a function of elution times). (d) XRD patterns of SiO2, RPQDs@SiO2, and GPQDs@SiO2. (e) EDS spectrum of MIPs@RPQDs/GPQDs@SiO2 [14].

5. Discussion

This paper investigates the potential applications of three quantum dot-polymer composites: carbon quantum dot-polymer lubrication coatings, Zno-polymer composite films, and molecularly imprinted polymers embedded with quantum dots. The results show that these composites have great prospects in mechanical lubrication, flexible optoelectronic devices and molecular imprinting recognition. These materials may attract the attention of chemical and optoelectronics engineers interested in applying quantum dot composites. If they don’t read this article, they may miss the latest cutting-edge advances in quantum dot composites.

Firstly, carbon quantum dot-polymer lubrication coating is an advanced lubrication material with great potential. When carbon quantum dots are added to the polymer matrix, the lubrication performance and wear resistance of the coating are significantly improved, and the friction coefficient and wear rate are reduced. Carbon quantum dots have unique properties such as high surface area, good dispersion and surface chemistry for improved lubrication, helping to reduce friction and wear. These findings make carbon quantum dot-polymer lubrication coatings a promising candidate for a variety of mechanical lubrication applications, including automotive engines, industrial machinery, and micro/nano-electromechanical systems (MEMS/NEMS).

Secondly, Zno-polymer composite films show excellent performance in the development of flexible optoelectronic devices. By combining ZnO nanoparticles with polymers, a composite material with light collection, charge transport and mechanical flexibility was formed. These composite films demonstrate impressive optical and electrical properties, including high optical response, excellent carrier mobility and bendability. Therefore, Zno-polymer composite films can play a role in applications such as flexible solar cells, wearable electronics and displays. In addition, this composite material is compatible with low-cost manufacturing techniques, further increasing the attractiveness of manufacturing large-scale and low-cost optoelectronic devices.

Thirdly, molecularly imprinted polymers embedded with quantum dots are a major breakthrough in the field of molecular imprinting recognition. By embedding quantum dots into molecularly imprinted polymers, the composites have high selectivity and sensitivity to the target molecules. The interaction between the target molecule and the recognition site within the imprinted polymer results in fluorescence quenching or color change, enabling rapid and visual detection. This innovative approach opens up new avenues for molecular imprinting techniques, providing enhanced detection capabilities and reliability. Molecularly imprinted polymers embedded with quantum dots have great potential applications in molecular sensing, environmental monitoring and biomedical diagnostics [15].

In summary, carbon quantum dot-polymer lubrication coatings, Zno-polymer composite films and molecularly imprinted polymers embedded with quantum dots show broad application prospects in mechanical lubrication, flexible optoelectronic devices and molecularly imprinted recognition. These new composites offer improved functionality and performance over single materials, driving progress across multiple industries.

6. Conclusion

In the field of mechanical lubrication, carbon quantum dot-polymer lubrication coatings show extraordinary potential. With its unique composition and properties, this composite material has enhanced lubrication properties, reducing friction and wear in mechanical systems. The integration of carbon quantum dots into the polymer matrix can improve the carrying capacity and reduce energy loss. These advantages have the potential to revolutionize mechanical systems, extending their service life and improving overall efficiency and performance.

In the field of flexible optoelectronic devices, ZnO-polymer composite films show an exciting combination of properties. These films are inherently flexible and transparent due to the incorporation of zinc oxide nanoparticles into the polymer matrix. This remarkable convergence has made possible the development of flexible, lightweight and efficient electronic devices, including wearable technology, flexible displays and solar cells. Harnessing the potential of these composite films opens up huge possibilities for realizing future electronic applications.

In the field of molecular imprinting recognition, quantum dots embedded in molecularly imprinted polymers show extraordinary ability. By embedding quantum dots in polymer structures, these materials provide selective recognition and binding sites for specific target molecules. This molecular imprinting method provides an innovative solution for highly sensitive and specific detection in areas such as biosensing, environmental monitoring and pharmaceutical applications. The integration of quantum dots provides a refined platform for signal amplification and high-affinity binding, which improves the efficiency of molecular recognition.

While these quantum dot polymer composites show great potential, it is critical to understand and address their limitations. One obvious obstacle is the scalability of the manufacturing method. Current technology has effectively reduced production costs, but achieving mass production remains to be tested. To overcome this challenge, future research efforts should focus on improving and optimizing manufacturing processes, and exploring alternative approaches to ensure cost-effectiveness, repeatability, and applicability outside of controlled laboratory environments. By overcoming scalability barriers, these materials can evolve from promising concepts to practical solutions for industrial applications. In addition, the limitations of this study include the dependence of ZnO-polymer films on ZnO nanorods. This material increases the cost and increases the difficulty of large-scale applications [3].

Another notable aspect of this study is its reliance on secondary sources. While a comprehensive analysis of the existing literature provides valuable insights, direct experimental knowledge is essential to a thorough understanding of these composites. The researchers must conduct extensive experimental investigations to validate and reinforce the findings, leading to a more comprehensive assessment of the material’s properties, properties, and potential optimizations.

Carbon quantum dot-polymer lubrication coating, Zno-polymer composite film and quantum dot-embedded molecular imprinting polymer have great application prospects in mechanical lubrication, flexible optoelectronic devices and molecular imprinting recognition, respectively. However, addressing the challenges associated with scalability and the need for direct experimental knowledge is a critical step.

References

[1]. Torres-Torres, C; López-Suárez, A; Can-Uc, B; Rangel-Rojo, R; Tamayo-Rivera, L; Oliver, A (24 July 2015). “Collective optical Kerr effect exhibited by an integrated configuration of silicon quantum dots and gold nanoparticles embedded in ion-implanted silica” Nanotechnology:295701. Bibcode:2015Nanot..26C5701T. doi:10.1088/0957-4484/26/29/295701. ISSN 0957-4484. PMID 26135968. S2CID 45625439.

[2]. Mongin C.; Garakyaraghi S.; Razgoniaeva N.; Zamkov M.; Castellano F.N. (2016). ”Direct observation of triplet energy transfer from semiconductor nanocrystals”. Science. 351 (6271): 369–372.

[3]. Enzhu Hu, Enhao Su, Ayush Subedi, Shusheng Liu, Jianping Wang, Hua Zhong, Kunhong Hu,Investigate on the dry friction tribological behaviors and mechanism of carbon quantum dot/polyimide composites coating,Wear,Volumes 530–531,2023,205048,ISSN 0043-1648,

[4]. Jiawen Zhou, Qian Qiao, Yufei Tan, Cheng Wu, Jiawen Hu, Xiaofeng Qiu, Shengheng Wu, Jian Zheng, Rui Wang, Cunxi Zhang, Xuan Yu, Xiaoming Yu, Zhenhua Li,The improvement of polymer photodetector based on 1D-ZnO nanorod arrays/0D-ZnO quantum dots composite film,Optical Materials,Volume 142,2023,114086,ISSN 0925-3467,

[5]. Xiang-yu ZHANG, Shu-xin LU, Dong-mei HE, Mao-zhou CHAI, Zhuang-zhuang WU, Xiao-hong YAO, Yong-qiang YANG,Antibacterial property of graphene quantum dots-modified TiO2 nanorods on titanium dental implant,Transactions of Nonferrous Metals Society of China,Volume 33, Issue 8,2023,Pages 2395-2405,ISSN 1003-6326,

[6]. Wenbo Lv, Yafang Song, Hebing Pei, Zunli Mo,Synthesis strategies and applications of metal–organic framework-quantum dot (MOF@QD) functional composites,Journal of Industrial and Engineering Chemistry,2023,ISSN 1226-086X,

[7]. Egemen Avcu, Fatih E. Bastan, Mert Guney, Yasemin Yildiran Avcu, Muhammad A. Ur Rehman, Aldo R. Boccaccini,Biodegradable Polymer Matrix Composites Containing Graphene-Related Materials for Antibacterial Applications: A Critical Review,Acta Biomaterialia,Volume 151,2022,Pages 1-44,ISSN 1742-7061,

[8]. Raj Kumar, Kedar Narayan Bairwa, D. Raghurami Reddy,Influence of addition of Al2O3 and SiC on tensile and flexural characteristics of epoxy/glass fiber hybrid polymer composite,Materials Today: Proceedings,2023,ISSN 2214-7853,

[9]. Xiaoqiang Liu, Jiamei Zhang, Rui Yan, Qingyou Zhang, Xiuhua Liu,Preparation of graphene nanoplatelet–titanate nanotube composite and its advantages over the two single components as biosensor immobilization materials,Biosensors and Bioelectronics,Volume 51,2014,Pages 76-81,ISSN 0956-5663,

[10]. Yaohui He, Zhaozhu Zhang, Yanling Wang, Meng Liu, Chaoying Liao, Junya Yuan, Peilong Li, Mingming Yang, Weimin Liu,Synergistic effects of bioprotein decoration and WS2 @Ti3C2 nanohybrids on the interfacial and tribological performance of PPS/PTFE fabric composites,Tribology International,Volume 186,2023,108587,ISSN 0301-679X,

[11]. Raimondas Kreivaitis, Jolanta Treinytė, Artūras Kupčinskas, Milda Gumbytė, Albinas Andriušis,Improving tribological properties of water/glycerol lubricating fluid by the synergy of nanoparticles and protic ionic liquid,Wear,Volumes 534–535,2023,205133,ISSN 0043-1648,

[12]. Junhai Wang, Xinran Li, Yuanyuan Deng, Shihao Chen, Wenfeng Liang, Lixiu Zhang, Xiaoyi Wei, Siyang Gao, Ye Wan,Carbon quantum dots doped with silver as lubricating oil additive for enhancing tribological performance at various temperatures,Applied Surface Science,Volume 599,2022,154029,ISSN 0169-4332,

[13]. Ahlaam T. Nomaan, Anas A. Ahmed, Naser M. Ahmed, M.I. Idris, M.R. Hashim, Marzaini Rashid,ZnO quantum dot based thin films as promising electron transport layer: Influence of surface-to-volume ratio on the photoelectric properties,Ceramics International,Volume 47, Issue 9,2021,Pages 12397-12409,ISSN 0272-8842,

[14]. ]Rongkun Zhu, Zengcheng Du, Mingfang Zhu, Huanru Liang, Shumei Wang, Qing ZhouRui Li, YulanLi, Chaoying Zeng, Wenhao Liu, Qiqing Chen,Molecularly imprinted polymers embedded with double perovskite quantum dots: A ratiometric fluorescence sensor for visible and fluorescent determination of Rhein,Chemical Engineering Journal,Volume 468,2023,143618,ISSN 1385-8947,

[15]. Olof Norrlöw, Magnus Glad, Klaus Mosbach,Acrylic polymer preparations containing recognition sites obtained by imprinting with substrates,Journal of Chromatography A,Volume 299,1984,Pages 29-41,ISSN 0021-9673

Cite this article

Yu,F. (2024). Composition and application prospect of several novel quantum dot-polymer composites. Applied and Computational Engineering,60,6-13.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 4th International Conference on Materials Chemistry and Environmental Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Torres-Torres, C; López-Suárez, A; Can-Uc, B; Rangel-Rojo, R; Tamayo-Rivera, L; Oliver, A (24 July 2015). “Collective optical Kerr effect exhibited by an integrated configuration of silicon quantum dots and gold nanoparticles embedded in ion-implanted silica” Nanotechnology:295701. Bibcode:2015Nanot..26C5701T. doi:10.1088/0957-4484/26/29/295701. ISSN 0957-4484. PMID 26135968. S2CID 45625439.

[2]. Mongin C.; Garakyaraghi S.; Razgoniaeva N.; Zamkov M.; Castellano F.N. (2016). ”Direct observation of triplet energy transfer from semiconductor nanocrystals”. Science. 351 (6271): 369–372.

[3]. Enzhu Hu, Enhao Su, Ayush Subedi, Shusheng Liu, Jianping Wang, Hua Zhong, Kunhong Hu,Investigate on the dry friction tribological behaviors and mechanism of carbon quantum dot/polyimide composites coating,Wear,Volumes 530–531,2023,205048,ISSN 0043-1648,

[4]. Jiawen Zhou, Qian Qiao, Yufei Tan, Cheng Wu, Jiawen Hu, Xiaofeng Qiu, Shengheng Wu, Jian Zheng, Rui Wang, Cunxi Zhang, Xuan Yu, Xiaoming Yu, Zhenhua Li,The improvement of polymer photodetector based on 1D-ZnO nanorod arrays/0D-ZnO quantum dots composite film,Optical Materials,Volume 142,2023,114086,ISSN 0925-3467,

[5]. Xiang-yu ZHANG, Shu-xin LU, Dong-mei HE, Mao-zhou CHAI, Zhuang-zhuang WU, Xiao-hong YAO, Yong-qiang YANG,Antibacterial property of graphene quantum dots-modified TiO2 nanorods on titanium dental implant,Transactions of Nonferrous Metals Society of China,Volume 33, Issue 8,2023,Pages 2395-2405,ISSN 1003-6326,

[6]. Wenbo Lv, Yafang Song, Hebing Pei, Zunli Mo,Synthesis strategies and applications of metal–organic framework-quantum dot (MOF@QD) functional composites,Journal of Industrial and Engineering Chemistry,2023,ISSN 1226-086X,

[7]. Egemen Avcu, Fatih E. Bastan, Mert Guney, Yasemin Yildiran Avcu, Muhammad A. Ur Rehman, Aldo R. Boccaccini,Biodegradable Polymer Matrix Composites Containing Graphene-Related Materials for Antibacterial Applications: A Critical Review,Acta Biomaterialia,Volume 151,2022,Pages 1-44,ISSN 1742-7061,

[8]. Raj Kumar, Kedar Narayan Bairwa, D. Raghurami Reddy,Influence of addition of Al2O3 and SiC on tensile and flexural characteristics of epoxy/glass fiber hybrid polymer composite,Materials Today: Proceedings,2023,ISSN 2214-7853,

[9]. Xiaoqiang Liu, Jiamei Zhang, Rui Yan, Qingyou Zhang, Xiuhua Liu,Preparation of graphene nanoplatelet–titanate nanotube composite and its advantages over the two single components as biosensor immobilization materials,Biosensors and Bioelectronics,Volume 51,2014,Pages 76-81,ISSN 0956-5663,

[10]. Yaohui He, Zhaozhu Zhang, Yanling Wang, Meng Liu, Chaoying Liao, Junya Yuan, Peilong Li, Mingming Yang, Weimin Liu,Synergistic effects of bioprotein decoration and WS2 @Ti3C2 nanohybrids on the interfacial and tribological performance of PPS/PTFE fabric composites,Tribology International,Volume 186,2023,108587,ISSN 0301-679X,

[11]. Raimondas Kreivaitis, Jolanta Treinytė, Artūras Kupčinskas, Milda Gumbytė, Albinas Andriušis,Improving tribological properties of water/glycerol lubricating fluid by the synergy of nanoparticles and protic ionic liquid,Wear,Volumes 534–535,2023,205133,ISSN 0043-1648,

[12]. Junhai Wang, Xinran Li, Yuanyuan Deng, Shihao Chen, Wenfeng Liang, Lixiu Zhang, Xiaoyi Wei, Siyang Gao, Ye Wan,Carbon quantum dots doped with silver as lubricating oil additive for enhancing tribological performance at various temperatures,Applied Surface Science,Volume 599,2022,154029,ISSN 0169-4332,

[13]. Ahlaam T. Nomaan, Anas A. Ahmed, Naser M. Ahmed, M.I. Idris, M.R. Hashim, Marzaini Rashid,ZnO quantum dot based thin films as promising electron transport layer: Influence of surface-to-volume ratio on the photoelectric properties,Ceramics International,Volume 47, Issue 9,2021,Pages 12397-12409,ISSN 0272-8842,

[14]. ]Rongkun Zhu, Zengcheng Du, Mingfang Zhu, Huanru Liang, Shumei Wang, Qing ZhouRui Li, YulanLi, Chaoying Zeng, Wenhao Liu, Qiqing Chen,Molecularly imprinted polymers embedded with double perovskite quantum dots: A ratiometric fluorescence sensor for visible and fluorescent determination of Rhein,Chemical Engineering Journal,Volume 468,2023,143618,ISSN 1385-8947,

[15]. Olof Norrlöw, Magnus Glad, Klaus Mosbach,Acrylic polymer preparations containing recognition sites obtained by imprinting with substrates,Journal of Chromatography A,Volume 299,1984,Pages 29-41,ISSN 0021-9673