1. Introduction

The construction industry is closely linked to people’s daily lives as an integral component of economic advancement on a national level. Residential properties, shopping centres, and libraries meet people’s basic requirements while providing areas for education and entertainment. Especially with the innovation of technology and the development of construction methods, people have higher requirements for the functions and quality of buildings. However, the traditional construction industry is resulting in alarming levels of pollution due to the growing number of buildings. For instance, reflective materials such as glass used in buildings can cause light pollution in cities, and ventilation systems in some buildings emit polluting gases. In this way, people are becoming more environmentally aware, and problems such as resource shortage and climate pollution in the construction industry need to be resolved. Consequently, sustainable construction is proposed, and several sustainable construction materials are utilised worldwide.

Sustainable construction refers to architectural practice with more responsible behaviour, which utilises the characteristics of sustainable development to create buildings with a positive impact [1]. More and more studies are indicating that the implementation of sustainable construction reduces environmental energy consumption and protects occupants’ lives. Sustainable construction includes the ecological and environmental influence of construction resources, such as the carbon emission of the building’s construction. Following this trend, using sustainable construction materials is becoming a popular trend in the construction industry.

Sustainable construction materials are cost-effective, usable construction materials that help improve the energy efficiency of buildings [2]. These materials are widely used in the construction industry due to their environmentally friendly, resource-saving, and economically efficient characteristics. For construction materials, durability is an essential consideration for sustainability. Sustainable construction materials are more resource-efficient in selecting and using raw materials, focusing on renewable materials or recycled waste. In addition, new materials technologies provide challenging opportunities for sustainable construction design. High-quality building materials can be produced with the help of biomaterials and biocomposites. This study will present and analyse four sustainable construction materials widely used in the current construction industry: polyester polymer concrete, cement stabilised rammed earth, geopolymer-bamboo composite, and steel slay.

2. Properties and application of different sustainable materials

2.1. Polymer concrete

Concrete is a common material used in the construction industry. Its raw materials are easy to access and processed, so it has become popular in the construction industry. The main raw materials of traditional concrete include water, cement, sand and aggregates, and cement is the main binder.

With the development of modern industry, polymer materials have been developed and are used in various industries. It is a new emerging sustainable concrete, which is used as a sustainable material to replace the role of traditional concrete as a binder. Utilising polymeric monomers as a binder for the aggregate, it is a composite material made up of a monomer or aggregate polymer [3]. It has been shown that the ideal weight ratio for polymer to aggregate in polymer concrete is between 1:7 and 1:12 [4]. Compared to traditional concrete, the microstructure of polymer concrete leads to lower permeability [5] . Consequently, polymer concrete is known for its high durability, which makes it a valuable material. Even when exposed to harsh environments, polymer concrete has a service life of 20 years [6]. Polymer concrete needs to increase the contact area of the concrete by filling the gaps with smaller aggregates [3]. This is the result of the high cost and low content of binders in polymer concrete. Moreover, the addition of fly ash to polymer concrete can also enhance the compressive strength [3].

Polymers are widely used in modern industries such as construction, automotive, and aerospace. Polymer concrete provides better performance and durability, meeting specific building requirements. Due to its high tensile strength, polymer concrete is often used for underground utilities, bridge deck coverings, and abandoned sewers [5]. It will reduce the carbon footprint and contributes to the sustainable development in the construction industry. For best results, polymer concrete should be cured at room temperature before handling and on-site use [3]. In terms of economic efficiency, for the same volumes, the price of polymer is higher than that of ordinary concrete. However, when compared on the basis of strength and service life, polymer concrete is less expensive. In addition, polymer concrete is acid-resistant and can be used to make pipes for transporting a variety of chemicals [6]. Figure 1 shows a site diagram of a polymer concrete application.

Figure 1. Application of Polymer Concrete [7].

2.2. Cement Stabilized Rammed Earth

The construction industry heavily depends on natural resources, such as water, timber, soil, and so on. The increasing demand for buildings and constructions around the world has caused a shortage of resources and increased construction materials prices. A new material, cement-stabilized rammed earth, is used in construction to reduce energy consumption and carbon emissions. Rammed earth construction uses recycled materials and attempts have been made to add stabilisers like cement to increase its strength [8]. Rammed earth structures can be categorised as stabilised or unstabilised rammed earth. Cement-stabilised rammed earth is made by mixing cement and soil at optimum moisture and moulding it to achieve sufficient strength [9].

The structure characteristics of cement-stabilized rammed earth are related to geographical conditions. These properties will further make a significant influence on its application. Rammed earth is a mixture of sand, gravel, clay and silt that can be improved by some chemical stabilisers [10]. Many studies have suggested that the addition of cement can improve the stability of rammed earth and is suitable for use in wall constructions [11]. The stability of the wall is an important factor in the structure of rammed earth, and its construction will impact the quality of a building. On the other side, architects usually use materials such as lime, mortar, etc. on the surface of cement-stabilised rammed earth and apply suitable paints to increase durability [10]. Moreover, environmental cement-stabilized rammed earth can be used near the construction site, and the materials can be recycled after dismantling. Thus, it has become a popular choice in the construction industry.

Many countries are focusing more on sustainable development of the construction industry, so the characteristics of cement-stabilized rammed earth such as low energy consumption and strength of use are also welcomed by many countries. They take into account the local soil characteristics while using cement-stabilized rammed earth, which helps reduce the cost of transporting materials. Being tested by a number of universities, cement-stabilised rammed earth has been used as a wall material for single-storey houses in several house construction projects in Sri Lanka [11]. The Meditation Centre, as a pilot project in Sri Lanka, uses cement-stabilised rammed earth as the material for the building walls, which have a construction thickness of 200 mm. Figure 2 is the diagram of the meditation centre with cement-stabilized rammed earth walls. Besides, the architects also extracted clay and laterite from the building site and used this material in the retaining wall of the half-storey residential project, as shown in figure 3. In practical application, attention should be paid to the ratio of cement to ensure the construction quality and curing effect. Cement-stabilised rammed earth has a wide range of applications in civil engineering and is constantly evolving and improving in terms of environmental friendliness and performance. As society's focus on sustainability continues to grow, more innovative soil improvement techniques may emerge in the future to meet the needs of different engineering projects.

Figure 2. Meditation Centre with Cement-stabilized Rammed Earth Walls [10].

Figure 3. Cement-stabilised Rammed Earth in Half-storey Residential Project [10].

2.3. Geopolymer- Bamboo Composite

Geopolymer is considered to be one of the most promising new natural composites of the 21st century. Nowadays, the civil engineering or construction industry in many countries is using traditional construction materials like common concrete and steel. These materials are not only high in cost and low in performance but also produce hazardous substances that indirectly harm the environment and people’s physical and mental health. Consequently, the exaction of useful components from organic materials or the recycling of waste is gradually becoming the main source of sustainable construction materials. The geopolymer itself is a low-carbon and environmentally sustainable material, which is obtained by polycondensation of aluminosilicate solids [12].

Geopolymers usually refer to alkali metal aluminosilicate products synthesised by reacting with alkali metal hydroxides or alkali metal silicate solutions, which have the same function as conventional concrete binders [13]. Concrete used in most constructions is mixed with Ordinary Portland Cement (known as OPC) binder. Since limestone is one of the main components of OPC, burning it creates high gas emissions and consumes significant energy [14]. Depending on the raw materials and processing site, geopolymers also show various properties such as low shrinkage, fire resistance, and acid resistance [13]. This kind of material is a new development in recent years, and many studies have shown that concrete containing geopolymers emits approximately 9% less carbon dioxide than concrete with OPC binders [14]. Accordingly, it has been widely used as a building material to replace OPC in many construction projects due to its superior performance.

However, more and more research has suggested that geopolymers should have an optimised structure with higher resistance to completely replace the role of cement. Many previous studies have indicated that the addition of natural fibres, such as bamboo fibres, to geopolymers could help increase flexural strength and reduce compressive strength by 50% [15]. Figure 4 is a picture of mechanically extracted bamboo fibre. Bamboo fibre is a biodegradable material which absorbs and produces three times more carbon dioxide than other plants, enhancing the sustainability of geopolymers [12]. Bamboo is known to be a fast-growing, high-yielding renewable resource that also reduces the cost of producing materials. Especially in the Brazilian Amazon, composite materials made from bamboo fibres and geopolymers are frequently used. Studies have proposed that adding bamboo fibres to geopolymers boosts flexural strength by 3.5 times while also providing good durability and resistance to acid exposure. Therefore, geopolymers and natural fibre-reinforced composites as the best potential alternatives to OPC.

Figure 4. Mechanically Extracted Bamboo Fibres [12].

Due to the properties of bamboo fibre geopolymers, this material is widely used in various fields. In the construction industry, it is commonly used to make building materials such as bamboo fibre concrete, bamboo fibre reinforced wall panels and bamboo fibre floor tiles [16]. These materials offer high strength and durability while reducing the reliance on traditional wood in buildings.

2.4. Steel Slag

Steel slag is the waste product from the metallurgy of steel bars. With the increasing number of steel production, the amount of steel slag has been increased as well. Actually, steel slag is not well recycled in many countries, with utilisation rates generally below 50% [17]. It has proposed that steel slag contributes to sustainable materials through efficient recycling and utilisation.

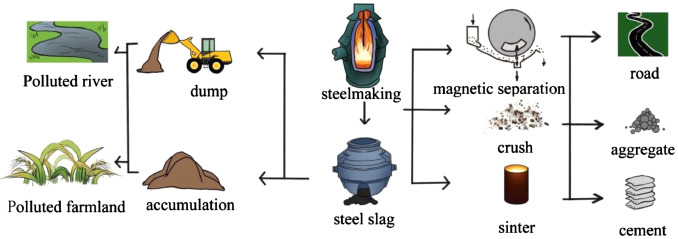

Untreated steel slag has leaching of heavy metals such as lead, mercury and chromium, which will cause serious environmental pollution if used directly or dumped [17]. In the recycling and utilisation process of steel slag, appropriate measures and technologies should be taken to ensure safe and environmentally friendly materials production. Steel slag is pre-treated by crushing, screening, and splitting and then used to produce concrete for construction [17]. Figure 5 is a flow chart of steel slag production and treatment. It is used in concrete to enhances strength while also reducing industrial waste generation. Steel slag is hard, abrasion-resistant and sticky, making it suitable for use in road and water construction. Steel slag has another special characteristic of water absorption. When mixed with superplasticiser, concrete containing steel slag exhibits good use characteristics [18]. Steel slag can be stabilised and repurposed for constructing pre-concrete, floor tiles, etc., reducing the need for water and clay. However, it should be noted that steel slag will only show higher strength than pure cement concrete at a later stage under the condition of constant compressive strength at 28 days [19].

Figure 5. Steel Slag Production and Treatment [18].

The utilisation of steel slag not only plays a positive role in waste disposal but also provides resources for the sustainable development of the construction industry. It can replace traditional building materials and can be applied in cement and concrete to reduce environmental pollution. Compared with ordinary steel slag, the treated steel slag has more superior performance. Stabilised steel slag can be used in green building materials to make cementitious materials for concrete, aggregates, and artificial corals [17].

3. Conclusion

Sustainable construction materials are an important component of both the construction industry and environmental sustainability. As concerns about environmental impacts and resource scarcity have increased, the construction industry has adopted a range of measures to promote the development of sustainable construction materials. Concrete is widely used in constructions and the addition of such materials to polymer concrete reduces the carbon footprint of concrete. This also reduces the construction industry's reliance on traditional energy sources. Cement-stabilised rammed earth makes good use of recycled building materials and helps to reduce generating wastes. Moreover, the emergence of cement to rammed earth strengthens the structure of such buildings and is therefore used in many construction projects. After suitable treatment, steel slag has high mechanical properties and durability. As an industrial waste, steel slag can also be used to reinforce and strengthen foundations, reducing the construction cost of buildings. In addition, biomaterials are increasingly used in environmentally friendly construction materials for various purposes. The addition of bamboo fibre geopolymers improve the availability of concrete and reduce its adverse environmentally impact. Consequently, the use of such materials can reduce the construction industry's dependence on natural resources and improve the energy efficiency and comfort of buildings.

Future developments in sustainable building materials will place greater emphasis on reducing carbon footprints. This may include the adoption of more sustainable building materials or the recycling of construction waste to reduce the carbon emissions generated in the construction process. These sustainable building materials has significant potential to improve the environmental performance of the construction industry and reduce reliance on finite resources. However, challenges in terms of cost, technology, supply chain and awareness need to be overcome in order to fully realise this potential. Over time, sustainable building materials will play an even more important role in the construction industry, driving more building projects in a more sustainable direction.

References

[1]. Miyatake Y 1996 Technology development and sustainable construction J. Manag. Eng. 12(4) 23–7

[2]. Danso H 2018 Identification of Key Indicators for sustainable construction materials Adv. Mater. Sci. Eng. 1–7

[3]. Bedi R, Chandra R and Singh S P 2013 Mechanical properties of polymer concrete J. Compos. 1-13

[4]. Abdel-Fattah H, El-Hawary M M 1999 Flexural behavior of polymer concrete Constr. Build. Mater. 13(5) 253–62

[5]. Dehghani Najvani M A, Heras Murcia D, Soliman E and Reda Taha MM 2023 Early-age strength and failure characteristics of 3D printable polymer concrete Constr. Build. Mater. 394 132119

[6]. Kiruthika C, Lavanya Prabha S and Neelamegam M 2021 Different aspects of polyester polymer concrete for sustainable construction Mater. Today Proc. 43 1622–1625

[7]. adtrak.admin 2022 EasyMix Concrete UK Ltd. What is Polymer Concrete? Available from: https://www.easymixconcrete.com/news/what-is-polymer-concrete/

[8]. Venkatarama Reddy B V and Prasanna Kumar P 2010 Embodied energy in cement stabilised rammed earth walls Energy. Build. 42(3) 380–385

[9]. Zhang X and Nowamooz H 2023 Chemo-thermo-hydro-mechanical behavior of a cement-stabilized rammed earth wall in interaction with the environment and underground soil Eng Struct. 293:116638

[10]. Kariyawasam K and Jayasinghe C 2016 Cement stabilized rammed earth as a sustainable construction material Constr. Build. Mater. 15(105) 519–527

[11]. Jayasinghe C, Kamaladasa N 2007 Compressive strength characteristics of cement stabilized rammed earth walls Constr. Build. Mater. 21(11) 1971–1976

[12]. Sá Ribeiro R A, Sá Ribeiro M G, Sankar K and Kriven W M2016 Geopolymer-bamboo composite – A novel sustainable construction material Constr. Build. Mater. 123 501–507

[13]. Duxson P, Fernández-Jiménez A, Provis J L, Lukey G C, Palomo A and Van Deventer J S J 2007 Geopolymer technology: the current state of the art J. Mater. Sci. 42(9) 2917–2933

[14]. Turner L K and Collins F G 2013 Carbon dioxide equivalent (CO2-e) emissions: A comparison between geopolymer and OPC cement concrete Constr. Build. Mater. 43 125–130

[15]. Riofrio A, Cornejo M and Baykara H 2022 Environmental performance of bamboo fibers and sugarcane bagasse reinforced metakaolin-based geopolymers Case Stud. Constr. Mater. 17 1-13

[16]. Kumar V P and Vasugi V 2020 Bamboo materials in cement, geopolymer and reinforced concrete as sustainable solutions for better tomorrow IOP Conf. Ser. Earth. Environ. Sci. 573(1) 012036

[17]. Song Q, Guo M Z, Wang L and Ling T C 2021 Use of steel slag as sustainable construction materials: A review of accelerated carbonation treatment Resour. Conserv. Recycl. 173 105740

[18]. Yüksel İ 2017 A review of steel slag usage in construction industry for sustainable development Environ. Dev. Sustain. 19(2) 369–384

[19]. Wang Q, Yan P, Yang J and Zhang B 2013 Influence of steel slag on mechanical properties and durability of concrete Constr. Build. Mater. 47 1414–1420

Cite this article

Yu,X. (2024). Research on the sustainable materials in building construction. Applied and Computational Engineering,60,119-125.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 4th International Conference on Materials Chemistry and Environmental Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Miyatake Y 1996 Technology development and sustainable construction J. Manag. Eng. 12(4) 23–7

[2]. Danso H 2018 Identification of Key Indicators for sustainable construction materials Adv. Mater. Sci. Eng. 1–7

[3]. Bedi R, Chandra R and Singh S P 2013 Mechanical properties of polymer concrete J. Compos. 1-13

[4]. Abdel-Fattah H, El-Hawary M M 1999 Flexural behavior of polymer concrete Constr. Build. Mater. 13(5) 253–62

[5]. Dehghani Najvani M A, Heras Murcia D, Soliman E and Reda Taha MM 2023 Early-age strength and failure characteristics of 3D printable polymer concrete Constr. Build. Mater. 394 132119

[6]. Kiruthika C, Lavanya Prabha S and Neelamegam M 2021 Different aspects of polyester polymer concrete for sustainable construction Mater. Today Proc. 43 1622–1625

[7]. adtrak.admin 2022 EasyMix Concrete UK Ltd. What is Polymer Concrete? Available from: https://www.easymixconcrete.com/news/what-is-polymer-concrete/

[8]. Venkatarama Reddy B V and Prasanna Kumar P 2010 Embodied energy in cement stabilised rammed earth walls Energy. Build. 42(3) 380–385

[9]. Zhang X and Nowamooz H 2023 Chemo-thermo-hydro-mechanical behavior of a cement-stabilized rammed earth wall in interaction with the environment and underground soil Eng Struct. 293:116638

[10]. Kariyawasam K and Jayasinghe C 2016 Cement stabilized rammed earth as a sustainable construction material Constr. Build. Mater. 15(105) 519–527

[11]. Jayasinghe C, Kamaladasa N 2007 Compressive strength characteristics of cement stabilized rammed earth walls Constr. Build. Mater. 21(11) 1971–1976

[12]. Sá Ribeiro R A, Sá Ribeiro M G, Sankar K and Kriven W M2016 Geopolymer-bamboo composite – A novel sustainable construction material Constr. Build. Mater. 123 501–507

[13]. Duxson P, Fernández-Jiménez A, Provis J L, Lukey G C, Palomo A and Van Deventer J S J 2007 Geopolymer technology: the current state of the art J. Mater. Sci. 42(9) 2917–2933

[14]. Turner L K and Collins F G 2013 Carbon dioxide equivalent (CO2-e) emissions: A comparison between geopolymer and OPC cement concrete Constr. Build. Mater. 43 125–130

[15]. Riofrio A, Cornejo M and Baykara H 2022 Environmental performance of bamboo fibers and sugarcane bagasse reinforced metakaolin-based geopolymers Case Stud. Constr. Mater. 17 1-13

[16]. Kumar V P and Vasugi V 2020 Bamboo materials in cement, geopolymer and reinforced concrete as sustainable solutions for better tomorrow IOP Conf. Ser. Earth. Environ. Sci. 573(1) 012036

[17]. Song Q, Guo M Z, Wang L and Ling T C 2021 Use of steel slag as sustainable construction materials: A review of accelerated carbonation treatment Resour. Conserv. Recycl. 173 105740

[18]. Yüksel İ 2017 A review of steel slag usage in construction industry for sustainable development Environ. Dev. Sustain. 19(2) 369–384

[19]. Wang Q, Yan P, Yang J and Zhang B 2013 Influence of steel slag on mechanical properties and durability of concrete Constr. Build. Mater. 47 1414–1420