1. Introduction

Seeding is one of the crucial aspects of agricultural production, high-performance seeding technology and equipment is the basis of modern agricultural production. The seed metering device can be distinguished into large size seed metering device, large and medium seed metering device, small size seed metering device and special crop seed metering device according to the size of different types of seeds [1]. Small size seed crops are heavily dependent on planter's manpower and experience due to its difficulty in seeding and low level of mechanical automation of seed metering device [2]. Therefore, the existing seed metering device for less than 5mm seeds is relatively rare, which has resulted in lower crop yields. The demand for research and development of small size seed metering device is increasing rapidly.

The study of small size seed metering device is highly valued, and the working performance of seed metering device directly affects the seeding quality [3], which determines the quality and yield of the operation. Recently, researchers have carried out extensive research on seed metering devices and precision seeding. The precision seed metering device separates the seeds in a quantitative and organized manner, and forms a stable seed stream falling into the seeding tube to complete the process of precision seeding [4]. Scholars have developed various seed metering devices and tested the operational performance of each equipment by tests, aiming to realize the large-scale mass production of small seed crops. This research adopts bibliometrics [5] and CiteSpace knowledge visualization mapping to analyze the development process of small size seed metering device combining quantitative and qualitative perspectives.

2. Research methods and data

2.1. Research Methods

This research adopts the bibliometric method to search relevant literature from Web of Science (WoS) and China National Knowledge Infrastructure (CNKI), and utilizes Origin and CiteSpace software to visually express the literature data [6].

2.2. Data

To ensure literature quantity and data accuracy, this research sequentially searches the literature.The collected literature is manually screened, and information such as title, abstract, keywords, and article content are browsed in detail. Finally, 212 literature are obtained, of which 168 are from CNKI and 44 are from WoS.

3. Literature trends and research hotspots

This research focuses on analyzing the development trend of the literature and the evolving history of the main keywords, trying to capture the development vein from the quantitative aspect.

3.1. Literature trends

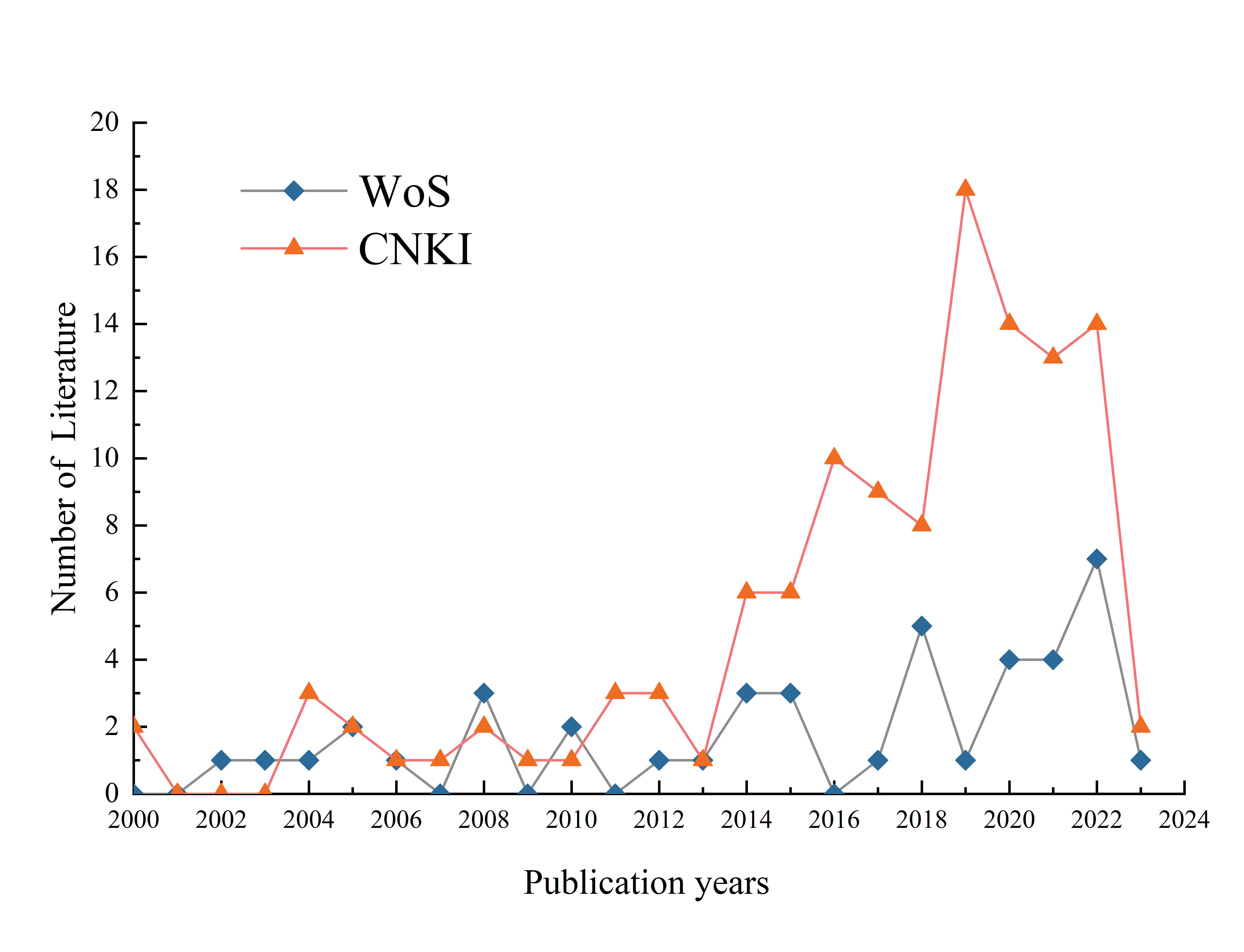

Figure 1. Number of literature related to seeding technology, 2000-2023.

As shown in Figure 1, the CNKI literature shows a slow fluctuating growth trend during 2000-2015, which indicates that at this time, the research is in the preliminary development stage. 2016-2023 shows a rapid growth trend, indicating that with the development and progress of China's agricultural mechanization [7]. The research of small size seed metering device has gradually become a research hotspot. Notably, the number of Chinese literature in 2020-2022 is less than that in 2019 due to the impact of the coronavirus. WoS literature overall shows a fluctuating rising trend, but the number of publications is less than that of CNKI, of which 2022 has the highest number of publications, up to 7, which indicates that small size seed metering devices have gradually attracted agricultural sector's attention.

3.2. Keyword co-occurrence analysis

Keyword co-occurrence network clearly captures how closely the keywords are linked to each other, how they correspond to hot spots and how they have evolved.

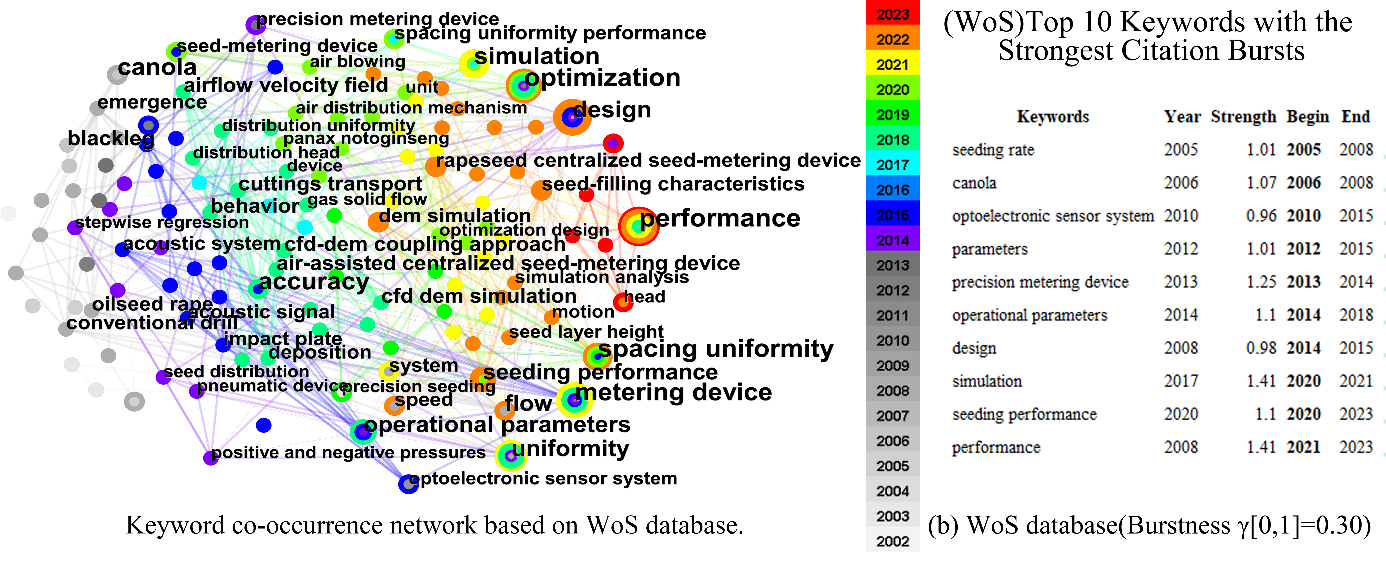

3.2.1. Keywords co-occurrence analysis based on WoS. Import the WoS data into CiteSpace and run the software to acquire Figure 2. The color of each node in the picture means that the publishing time of the literature from 2002-2023. It can be seen that the main keywords are closely linked, while the gray part of Figure 2 is the initial development stage 2002-2013. Because the number of articles published during this period is small and a specific research theme has not yet been formed. The faster development stage 2014-2019 in the blue-green part of Figure 2, has seen an increase in nodes number. Due to the fact that the number of articles have entered the researcher's horizon, at which point a unifying research theme is gradually being seen. The rapid development stage 2020-2023, which are distributed in the green-yellow-orange-red part of Figure 2 on the middle right, indicates the emergence of research focus and unifying themes as the number of articles climbs.

Figure 2. Keyword co-occurrence network based on WoS database.

The number of major keywords shown in initial development stage is less, such as "canola", "emergence", "blackleg", and "oilseed rape". One of the rather significant nodes is "canola", indicating that during the initial development stage "canola", as one of the representatives of small size seeds, was the subject of large numbers of seed metering device studies. The keywords that emerged during the faster development stage are "operational parameters", "precision metering device", "seed-metering device", and "accuracy". The above representative keywords again reflect that with the development of time the research is gradually moving towards the refinement of measurement, simplification of equipment operation, and system intelligence. The keywords that emerged during the rapid development stage are "performance", "optimization", "spacing uniformity", "uniformity", and "simulation". These representative keywords indicate that the content of scientific research in recent years has focused on the simulation, consistency, operability and practical performance of machines[8,9].

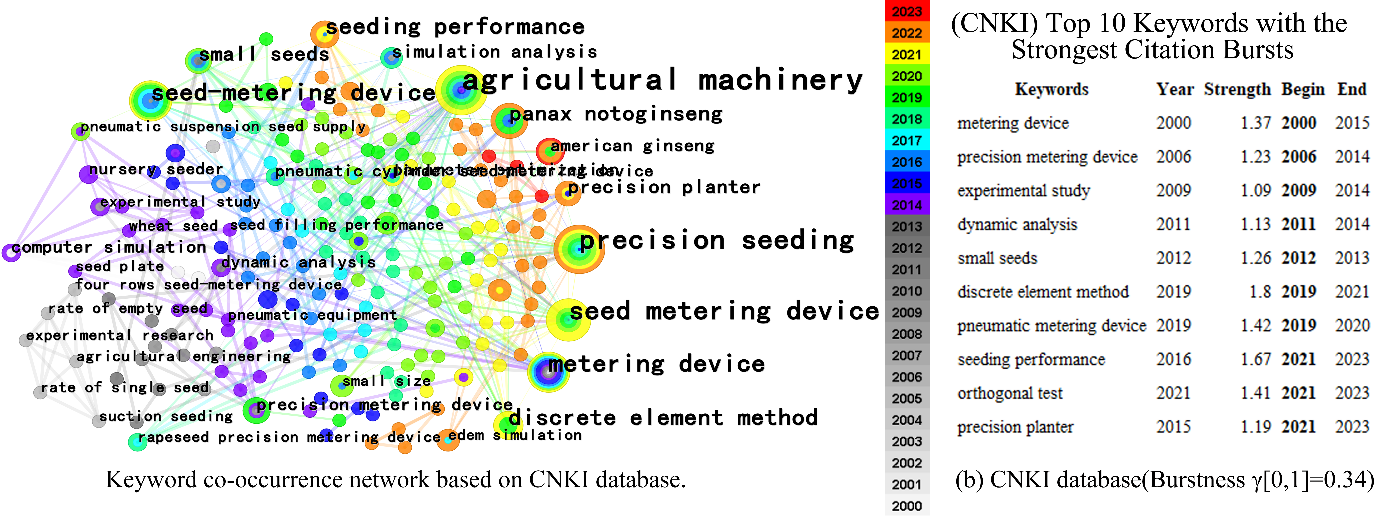

3.2.2. Keyword co-occurrence analysis based on CNKI. As shown in Figure 3, the gray nodes contained in the gray part during 2000-2013 are fewer in number and smaller in diameter. Since 2014, the number of representative keywords within this domain has proliferated, and some representative larger nodes around 2020.

Figure 3. Keyword co-occurrence network based on CNKI database.

The main keywords in the gray part of the lower left corner of Figure 3, for the period 2000-2013, are "four rows seed-metering device", "rate of empty seed", "experimental research", "rate of single seed". It can be found that Chinese scholars mainly focused on the design, experimental and analytical aspects of different seed type metering devices in their early researches. The colored nodes in the right part of Figure 3 are mainly distributed in the period of 2014-2023, and the representative keywords in this period are "precision seeding device ", "seed-metering device", "metering device", "seeding performance", "discrete element method". Based on the research content, the main content in 2021-2023 not only inherited the earlier research topics, but also showed new research content, application of new technologies and methods, research progress in existing fields (review), experimental evaluation of new seeder design, etc.

Throughout the keyword co-occurrence network of WoS and CNKI database(Figure 3), we have found that the research content of Chinese scholars on seed metering device is almost the same as international scholars, focusing on the following aspects, equipment performance evaluation and analysis, equipment experimentation and optimization , new technology and method application and evaluation, and research progress in specific fields.

4. Progress in seed metering devices

4.1. Classification of seed metering devices

As the core component of the seeder, seed metering device is generally divided into two categories based on the different ways of seeding, one is mechanical, the other is pneumatic. The former has advantages such as simple structure and low cost, but affected by the way of seed taking and filling, there are problems such as easy to jam seeds, high absence rate and high seed damage rate [10]. Although the pneumatic seed metering device features a complex mechanical structure and high cost, it is widely used in precision planting because of its advantages such as low seed requirement, high sowing accuracy and fast operation speed. Throughout the relevant literature, the existing common seed metering devices and their advantages, operating principles and other information are shown in Table 1.

Table 1. Comparative analysis of small size seed metering devices.

Seeding method | Seed metering device type | Problems solving | Vantage | Operating principle |

Mechanical | Nest-eye wheel type | Multiple seed shapes and sizes. | Simple structure, high reliability, lower cost, universal applicability | Adjustment of a series of key parameters, such as nest inclination, number, distribution form, horizontal distance of the seed layer adjustment plate and so on, thus seeding. |

Spoon type

| Low seed picking accuracy and high seed damage rate. | Low seed damage rate, high seeding efficiency, simple to make, lower cost. | Seeds are piled up in seed chamber by gravity, inter-seed interaction and joint action of the seed picking spoon, following the rotation of the seeding shaft to drain the seeds. | |

Pneumatic | Nest-eye wheel and pneumatic centralized combined type

| High rate of seed germ damage and low seeding accuracy. | Low seed bud damage, high suitability for small seeds, high seeding accuracy | The seeds are sucked away by cylinder in negative pressure chamber, the excess seeds fall into the seed box, and the remaining seeds are seeded under gravity and positive pressure. |

Ring with hole type pneumatic

| Lack of seeder for single seed. | Low seed size requirements, high seed viability, fast seeding speed. | The seeds are sucked onto the seeding plate under negative pressure and conveyed to the unloading area by seed winding, where they are seeded out by gravity and positive pressure. | |

Ring with hole type double row pneumatic

| Low seeding efficiency and precision. | High-speed precision seeding. | Seeds rotate with the metering plate to the seed-throwing area, and with the cut-off of the negative-pressure airway, they are separated from the inner and outer rings by gravity and centrifugal force, and enter the guide tube, forming a double-row seed flow. | |

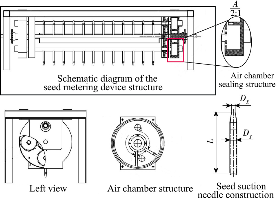

Pneumatic needle type | Mechanized precision seeding is difficult. | High performance and accuracy of seed rowing. | The airflow distribution tube and the suction needle transform the seed mass into even single seeds, and the planetary wheel system seed arranging mechanism ensures a specific trajectory of the suction needle, realizing low speed suction in the suction area and low seed drop in the seed drop area. |

Combining Table 1 and related literature can be seen, contemporary researchers develop seed metering devices often combine the advantages of mechanical and pneumatic, not only to reduce mechanical complexity, cost savings, but also to improve the seeding efficiency, to achieve precision seeding.

4.2. Monitoring system of seed metering devices

The monitoring system of seed metering devices is intended to monitor seeding quality and improve seeding efficiency and crop yields. The monitoring system can directly detect seed absence, reseeding, replanting, and uneven seeding. Monitoring technology upgrading is significant to the intelligent development of seed metering devices.The existing monitoring system of seed metering devices is mainly composed of controllers, sensor detection devices, and automatic reseeding technology [11].

4.2.1. Controller. Controller is equivalent to the "brain" of the seeder monitoring system. Seed metering devices are mostly operated in complex and diverse farming environment, so it is particularly critical to choose the right controller according to different working environment requirements. Most electronic controllers can meet the monitoring needs of the target environment. The current control system used in the controller is mainly divided into microcontroller, PLC and embedded configuration screen three categories, while the advantages and disadvantages of above controllers are shown in Table 2.

Table 2. Comparative analysis of controllers.

Controller Type | Applicable environment | Advantages | Disadvantages |

Microcontroller | Indoor and outdoor conditions with smooth road surfaces | Fast data processing, large data storage, easily accessible. | Unstable, susceptible to interference, high maintenance costs |

PLC | Complex outdoor working conditions | Stable and easily accessible. | Each brand PLC hardware system is incompatible, with closed structure. |

Embedded configuration screen | Greenhouse or indoor conditions | User-friendly and simple functionality. | Single interface and slow updating. |

Microcontroller is the most commonly used and diversified control unit with strong data processing capability and low learning threshold, which is widely used in agricultural machinery control. PLC (Programmable Logic Controller) is widely used in industrial control, and gradually becoming popular in agricultural machinery control. In addition, embedded Linux control system also has a place in agricultural machinery field.

4.2.2. Sensor detection device. Sensor detection device is equivalent to the " sensory " in the monitoring system. During the operation of the seed metering device, it is necessary to instantly monitor seeds quantity, row spacing, absence rate, etc. by sensor detection devices, and transmit the detected actual data to the human-computer interaction interface. Existing sensing detection devices mainly involve mechatronic alarm detection method, machine vision detection method, photoelectric sensing detection method, capacitive sensing detection method, piezoelectric sensing detection method. The advantages and disadvantages of each method are shown in Table 3.

Table 3. Comparative analysis of seed detection methods.

Detection method | Detection principle | Advantage | Disadvantage |

Mechatronic alarm detection method | Detect the state of seed box or seeder operation, if the seed box is empty or the seeder works abnormally, then the alarm goes off. | High compatibility and fault alert. | Can't display the error report. |

Machine vision detection method | The industrial camera can obtain timely and spatial information about the seed drop, and use image processing technology to accurately recognize the seeds and obtain relevant information. | Low seed requirements and detailed data acquisition | High environment requirements, high cost, complex structure, hardly applied to field operation |

Photoelectric sensing detection method | Seed shading emitted light changes the voltage signal, adjusts the voltage signal to a pulse signal, and the controller collects and analyzes the pulse signal. | Low cost, contactless sensing, fast signal response | Lower detection accuracy due to field operating environment. |

Capacitive sensing detection method | Seed delivery works by causing a change in the output capacitance value of the sensor, modeling the relationship between that change and seed quantity, and then detecting the seed. | Stable operation, high reliability, and high resistance to dust contamination. | Low detection accuracy. |

Piezoelectric sensing detection method | The falling seeds collide with the piezoelectric element to change the signal, and the changed signal is converted into a pulse signal that can be used to obtain the falling seed information. | Affordable and accurate for low-frequency seeding detection. | High installation structural requirements and low seeding uniformity. |

The sensor detection device of seed metering device transmits the monitored seed information directly to the human-computer interface, and the results of the device's operation are directly related to seeding operation, and even determine the operation quality. Thus, researchers and agricultural engineers need to select appropriate seed sensing methods and configure appropriate sensor detection devices according to the field environment and operating requirements of each crop.

4.2.3. Automatic reseeding technology. Seed metering devices occasionally have seeding absence during daily operation, which in turn reduces the operation quality. To solve this problem, automatic reseeding technology was born. Automatic reseeding system mostly consists of seeding detection device and variable reseeding device. At present, automatic reseeding technology mainly exists in scientific researches, and has not been applied to actual seed metering device on a large scale, mainly because this technology has not matured yet. On the one hand, it is difficult to accurately obtain the absence index, and on the other hand, it takes a considerable time for the variable reseeding device to receive the absence index and carry out the reseeding work.

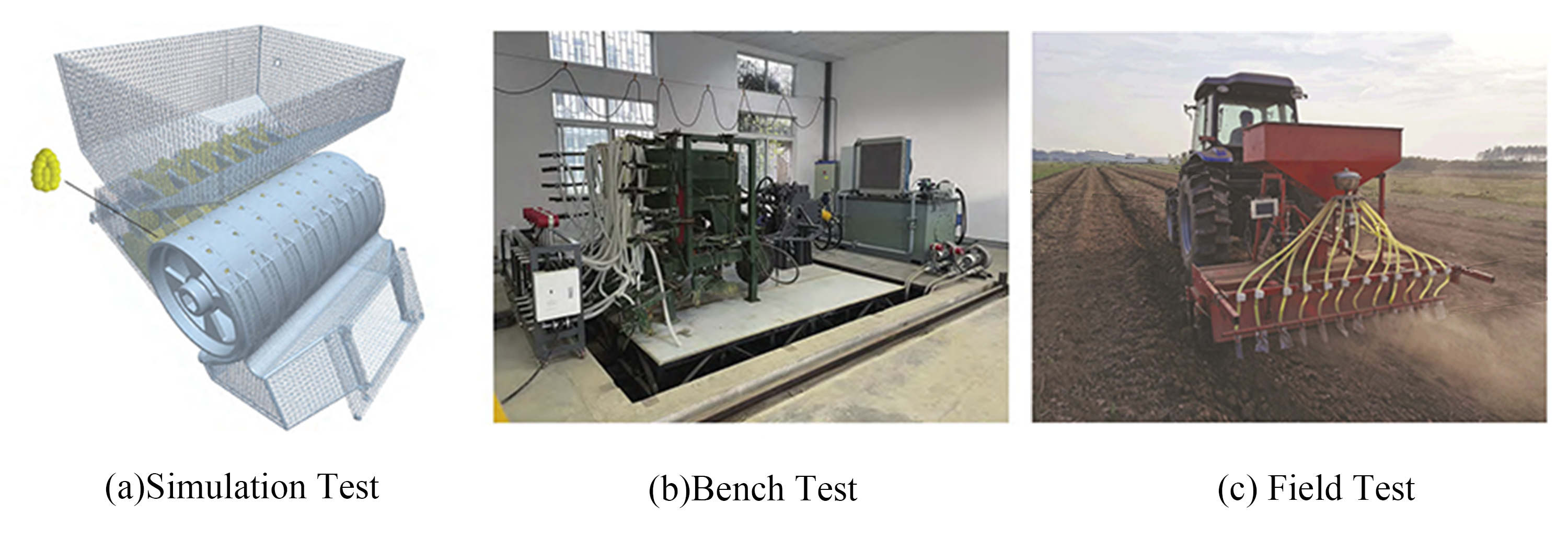

4.3. Seeding test

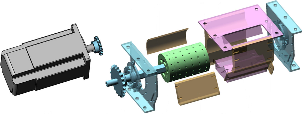

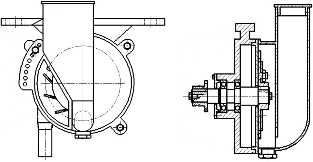

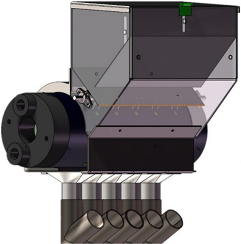

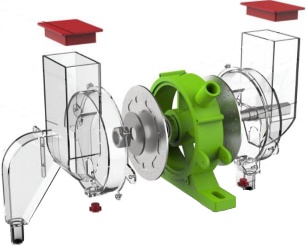

Any seed metering device needs to be tested repeatedly before it is launched into the market to ensure its operational effectiveness and quality. The test methods for seed metering devices mainly include three categories, simulation test, bench test and field test (Figure 4), and each of test methods has its own advantages and disadvantages. Generally speaking, most researchers are combining two test methods to examine the operational effect of seed metering device.

Figure 4. Diagram of seeding test.

4.3.1. Simulation test. The simulation test utilizes computer software to simulate and analyze the seed metering device, which has the advantages of being pre-studyable, not subject to environmental constraints, rich in information, lower cost, and shorter cycle time. Nowadays, researchers are more inclined to simulate a reasonable structure and data parameters through computer simulation software, and then use the bench test or field test to detect the actual operating effect of seed metering devices, as to verify and compare the results of the two tests.

4.3.2. Bench test. Bench test of seed metering device means inputting seeds into homemade bench test equipment to test the performance and reliability by controlling variables, adjusting parameters and structure, and so on. It has the advantages of operability, repeatability and shorter testing process, while the test method can reduce the influence of external environmental factors. According to the operation principle and operation process of the seed metering device to build specific bench test platform, which can further investigate the possible problems in the seeding process, to clarify the role of the key components, to check the quality of the seed metering device operation.

4.3.3. Field test. Although field tests are affected by location, weather, outdoor environment and other factors, and often have problems such as long test period, high cost, and many uncontrollable factors, they can objectively and accurately reflect the performance of seed metering devices. Since seed metering devices usually operate in outdoor environment, field tests are often used as the last test barrier before seed metering devices are released to market.

5. Conclusion

This research analyzes the development history, research hotspots, and research progress of small size seed metering devices from a quantitative perspective based on bibliometric method and CiteSpace software [6]. This research browses the literature in detail, analyzes the current research situation, specifically including the type of seed metering device, seeding monitoring system and the main test methods. The final conclusion is as follows:

1) In terms of the number of literature publications, China has a relatively large number of literature on small size seed metering devices, and the overall research productivity in this field is at a steady developing state, with significant growth potential in China. Overall, the number of international small size seed metering device articles is less than that of China, and it fluctuates greatly and is rather unstable. Both Chinese and international publication trends show fluctuating increases, and both show rapid growth after 2016.

2) It is found that the research on small size seed metering device is broadly focusing on equipment performance evaluation and analysis, equipment experiments and optimization, application and evaluation of new technologies and methods, and specific influence of external conditions on seeding equipment, etc. The optimization and evaluation of specific seeding equipment may become an emerging research hotspots in the future.

3) Small size seed metering devices are mainly divided into mechanical and pneumatic according to different seeding methods. The former has low requirements for seeds suitable for low-speed operation, the latter is widely used in the field of precision planting. There are six types of seed metering devices popular on the market.

4) The monitoring system and test methods as an important way to examine the development of seeder refinement, will continue to promote the development process of small size seed crops in the future.

Author Contributions

Conceptualization, L.Q., A.H. and F.Y.; methodology, L.Q.; software, L.Q.; validation, L.Q. ; formal analysis, L.Q.; data curation, L.Q.; writing—original draft preparation, L.Q.; writing—review and editing, L.Q.; project administration, L.Q. All authors have read and agreed to the published version of the manuscript.

Acknowledgments

We would like to thank the College of Smart Manufacturing Modern Industry, Xinjiang University.

Conflicts of Interest

The authors declare no conflict of interest.

References

[1]. He J, Zhang ZQ, Li HW, Wang QJ. Development of small/medium size no-till and minimum-till seeders in Asia: A review. International Journal of Agricultural and Biological Engineering. Aug 2014;7(4):1-12. doi:10.3965/j.ijabe.20140704.001

[2]. Ding Y, Wang K, Liu X, et al. Research progress of seeding detection technology for medium and smallsize seeds. Transactions of the Chinese Society of Agricultural Engineering. 2021;37(08):30-41(in Chinese).

[3]. Zhao L, Na X. Present Situation of Research And Development of Precision Seed Metering Device. Agricultural Science & Technology and Equipment. 2014;(06):30-31(in Chinese). doi:10.16313/j.cnki.nykjyzb.2014.06.019

[4]. Shi S, Zhang D, Yang L, Cui T, Li K, Yin X. Simulation and verification of seed-filling performance of pneumatic-combined holes maize precision seed-metering device based on EDEM. Transactions of the Chinese Society of Agricultural Engineering. 2015;31(03):62-69(in Chinese).

[5]. Zupic I, Cater T. Bibliometric Methods in Management and Organization. Article. Organizational Research Methods. Jul 2015;18(3):429-472. doi:10.1177/1094428114562629

[6]. Zheng J, Liao Y, Liao Q, Sun M. Trend analysis and prospects of seed metering technologies. Transactions of the Chinese Society of Agricultural Engineering. 2022;38(24):1-13(in Chinese).

[7]. Li G, Li Y, Zhou X. Agricultural Mechanization, Labor Transfer and the Growth of Farmer's Income: A Re-examination of Causality. Chinese Rural Economy. 2018;(11):112-127(in Chinese).

[8]. Karimi H, Navid H, Mahmoudi A. Online laboratory evaluation of seeding-machine application by an acoustic technique. Article. Spanish Journal of Agricultural Research. Mar 2015;13(1)doi:10.5424/sjar/2015131-6050

[9]. Xiahou Y, Zhang P, Wang J, Huang L, Xia H. Simple synthesis of uniformly small gold nanoparticles for sensitivity enhancement in colorimetric detection of Pb2+ by improving nanoparticle reactivity and stability. Article. Journal of Materials Chemistry C. Jan 21 2018;6(3):637-645. doi:10.1039/c7tc04648k

[10]. Qinghui L, Xiulong C, Qingxu Y, Kai S, Wei Q. Design and Experiment of Precision Seeding Device for Hole-drop Planter for Panax notoginseng. Transactions of the Chinese Society for Agricultural Machinery. 2019;50(01):85-95.

[11]. Jin C, Yunqiang L, Wei W, Lu W, Lijing L. Research status and prospects of seeder monitoring system technology. Journal of Chinese Agricultural Mechanization. 2023;44(06):161-167+175. doi:10.13733/j.jcam.issn.2095-5553.2023.06.023

Cite this article

Qiao,L.;Haimudula,A.;Yue,F. (2024). Research progress of small size seed metering devices. Applied and Computational Engineering,65,333-341.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of Urban Intelligence: Machine Learning in Smart City Solutions - CONFSEML 2024

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. He J, Zhang ZQ, Li HW, Wang QJ. Development of small/medium size no-till and minimum-till seeders in Asia: A review. International Journal of Agricultural and Biological Engineering. Aug 2014;7(4):1-12. doi:10.3965/j.ijabe.20140704.001

[2]. Ding Y, Wang K, Liu X, et al. Research progress of seeding detection technology for medium and smallsize seeds. Transactions of the Chinese Society of Agricultural Engineering. 2021;37(08):30-41(in Chinese).

[3]. Zhao L, Na X. Present Situation of Research And Development of Precision Seed Metering Device. Agricultural Science & Technology and Equipment. 2014;(06):30-31(in Chinese). doi:10.16313/j.cnki.nykjyzb.2014.06.019

[4]. Shi S, Zhang D, Yang L, Cui T, Li K, Yin X. Simulation and verification of seed-filling performance of pneumatic-combined holes maize precision seed-metering device based on EDEM. Transactions of the Chinese Society of Agricultural Engineering. 2015;31(03):62-69(in Chinese).

[5]. Zupic I, Cater T. Bibliometric Methods in Management and Organization. Article. Organizational Research Methods. Jul 2015;18(3):429-472. doi:10.1177/1094428114562629

[6]. Zheng J, Liao Y, Liao Q, Sun M. Trend analysis and prospects of seed metering technologies. Transactions of the Chinese Society of Agricultural Engineering. 2022;38(24):1-13(in Chinese).

[7]. Li G, Li Y, Zhou X. Agricultural Mechanization, Labor Transfer and the Growth of Farmer's Income: A Re-examination of Causality. Chinese Rural Economy. 2018;(11):112-127(in Chinese).

[8]. Karimi H, Navid H, Mahmoudi A. Online laboratory evaluation of seeding-machine application by an acoustic technique. Article. Spanish Journal of Agricultural Research. Mar 2015;13(1)doi:10.5424/sjar/2015131-6050

[9]. Xiahou Y, Zhang P, Wang J, Huang L, Xia H. Simple synthesis of uniformly small gold nanoparticles for sensitivity enhancement in colorimetric detection of Pb2+ by improving nanoparticle reactivity and stability. Article. Journal of Materials Chemistry C. Jan 21 2018;6(3):637-645. doi:10.1039/c7tc04648k

[10]. Qinghui L, Xiulong C, Qingxu Y, Kai S, Wei Q. Design and Experiment of Precision Seeding Device for Hole-drop Planter for Panax notoginseng. Transactions of the Chinese Society for Agricultural Machinery. 2019;50(01):85-95.

[11]. Jin C, Yunqiang L, Wei W, Lu W, Lijing L. Research status and prospects of seeder monitoring system technology. Journal of Chinese Agricultural Mechanization. 2023;44(06):161-167+175. doi:10.13733/j.jcam.issn.2095-5553.2023.06.023