1. Introduction

In winter, snow removal in northern China is often carried out by sprinkling deicing salt. After low-temperature freezing and erosion by molten salt water, concrete will peel off and steel bars will rust. Because the weather is too cold, and the ionic solution will also have an impact on the concrete. The material degradation leads to the degradation of its structural performance. This will greatly affect the durability performance of concrete, making it unable to reach the expected service life and creating significant safety hazards. Therefore, the research content of this paper is very meaningful [1-2].

Compared with the first generation of ordinary concrete, the new type of concrete with certain fibers added is more powerful, and scholars are also more concerned about it [3-8]. Concrete with added fibers, which has been studied, is definitely more effective. But adding only one type of fiber has a mediocre effect, and the vast majority of current research is also in this situation. It is obvious that adding different types of fibers can complement each other’s shortcomings and further improve their characteristics. But now few people are studying this direction.

This article studies the salt frost resistance of mixed fiber reinforced concrete by adding carbon fiber and glass fiber in different proportions to concrete. A prediction model for salt frost damage of carbon fiber glass fiber mixed concrete is established, providing guidance and reference for the on-site application of mixed fiber reinforced concrete in severe cold areas. This can provide a theoretical guidance for the practical application of fiber cement in the future. Meanwhile, it will be tailored to different scenarios. Angles with different temperatures, corrosion conditions, salt concentrations, and corrosion durations. Further conduct testing research. And continue the idea of combining experiments with artificial intelligence methods. Continuously improving the research content of this paper.

2. Performance test

2.1. Test materials and proportions

To ensure the quality of the experiment, standard companies produce cement for the selection of cement used in the experiment. Both coarse aggregate and fine stones in the experiment are of high quality. Select Class I fly ash manufactured by Tianjin Thermal Power Plant as the fly ash. The anhydrous sodium sulfate and anhydrous sodium chloride used in the experiment meet the specification requirements.

To ensure the universality of the experiment. Our laboratory first conducted a lengthy, serious, and comprehensive investigation and research on mainstream domestic fiber manufacturers. The system has sorted out 162 fiber manufacturers. They all have national production qualifications. The products produced are highly consistent with the overall product series. So our laboratory conducted a systematic selection from inside. After 6 rounds of 24 rounds of screening. We have compiled a total of 6 types of fiber samples to be used. Corresponding to the 6 manufacturers mentioned above. It has also undergone many comprehensive considerations and trade-offs. Taking into account the technical and economic viability of each fiber. In the end, our laboratory used carbon fibers produced by Jiangsu Boshi Continuous Fiber Co., Ltd. After the same screening criteria, six types of glass fibers have also entered our field of vision. In the end, our laboratory used glass fiber from Hebei Antai Chemical Fiber Co., Ltd. In order to more intuitively and clearly characterize the technical indicators and physical properties of each fiber. Now summarize their main performance. And it is presented in the table 1 below.

Table 1. Performance parameters of fiber

Fiber type | Density /(g·cm-3) | Length /mm | Tensile strength /MPa | Elongation rate /% |

Carbon | 1.8 | 10 | 780~1000 | 2~2.5 |

Glass | 2.6 | 10 | >600 | 2.4-3 |

The designed concrete mix ratio is w (cement): w (water): w (fine aggregate): w (coarse aggregate) =477:194:688:1 032. To ensure the applicability of the experiment. We need to have as many parameters as possible for the testing conditions under different ratio parameters. However, the method of traversal cannot cover all working conditions. Therefore, we set a testing condition every 0.05% interval. Our laboratory conducted experiments on the above content. Representative working conditions will now be organized. This experiment used ordinary concrete (OC) as the control group, kept the concrete mix ratio unchanged, and formed each experimental group by adding fibers with different dosages, named CF** GF**. CF represents concrete doped with carbon fiber, GF represents concrete doped with glass fiber, and the number after the letter represents the fiber content. CF10 represents the addition of carbon fiber concrete with a volume fraction of 0.10%. The mixing ratio parameters of the experimental group are shown in Table 2.

Table 2. Design parameters of concrete mix proportions

Type | Volume fraction /% | Type | Volume fraction /% | ||

Carbon | Glass | Carbon | Glass | ||

OC | 0 | 0 | CF10GF15 | 0.10 | 0.15 |

CF10 | 0.10 | 0 | CF10GF20 | 0.10 | 0.20 |

CF15 | 0.15 | 0 | CF15GF10 | 0.15 | 0.10 |

CF20 | 0.20 | 0 | CF15GF15 | 0.15 | 0.15 |

GF10 | 0 | 0.10 | CF15GF20 | 0.15 | 0.20 |

GF15 | 0 | 0.15 | CF20GF10 | 0.20 | 0.10 |

GF20 | 0 | 0.20 | CF20GF15 | 0.20 | 0.15 |

CF10GF10 | 0.10 | 0.10 | CF20GF20 | 0.20 | 0.20 |

2.2. Test project

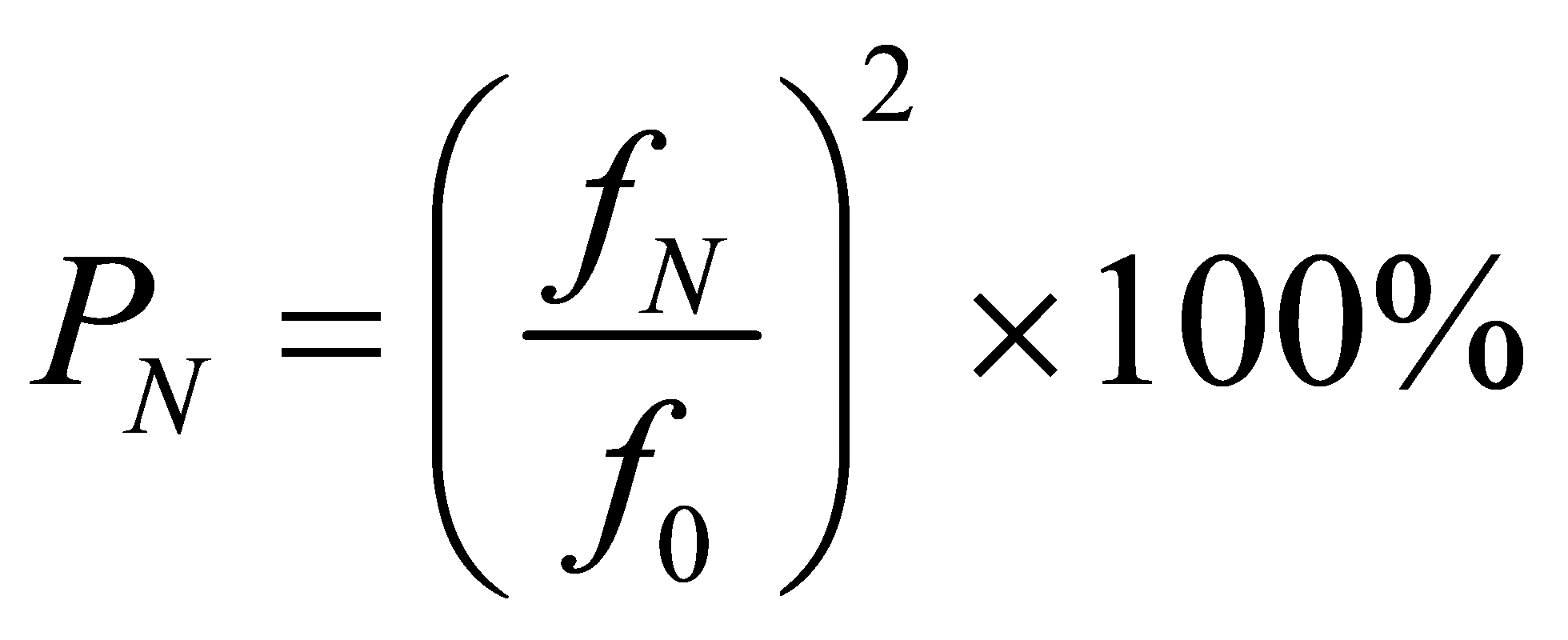

The volume of cement used for testing is 0.20 meters × 0.20 meters × 0.10 meters. A total of 3 pieces were used in the experiment. The chemical reagent used in the experiment is a sodium chloride solution. The duration of the experiment is 48 hours. The mass fraction of sodium chloride solution is 3.5%. When conducting experiments, each experiment should have 25 full freeze-thaw cycles. After thoroughly drying the specimen, weigh the mass of the specimen and calculate its dynamic elastic modulus. The two important indicators for evaluating concrete freeze-thaw damage are the mass loss rate and the relative dynamic modulus of elasticity. After N freeze-thaw cycles. The mass loss rate and relative dynamic modulus of elasticity of concrete are:

\( {W_{N}}=\frac{{m_{0}}-{m_{N}}}{{m_{0}}}×100\% \) | (1) |

is the mass of concrete before freeze-thaw cycles. With a dimension of grams;

is the mass of concrete before freeze-thaw cycles. With a dimension of grams;  is the mass of concrete after N freeze-thaw cycles. With a dimension of grams.

is the mass of concrete after N freeze-thaw cycles. With a dimension of grams.

| (2) |

is the initial transverse fundamental frequency of the concrete before freeze-thaw cycles, with a dimension of Hz;

is the initial transverse fundamental frequency of the concrete before freeze-thaw cycles, with a dimension of Hz;  is the transverse fundamental frequency of the concrete after N freeze-thaw cycles, measured in Hz.

is the transverse fundamental frequency of the concrete after N freeze-thaw cycles, measured in Hz.

3. Test results and Analysis

3.1. Concrete quality loss rate

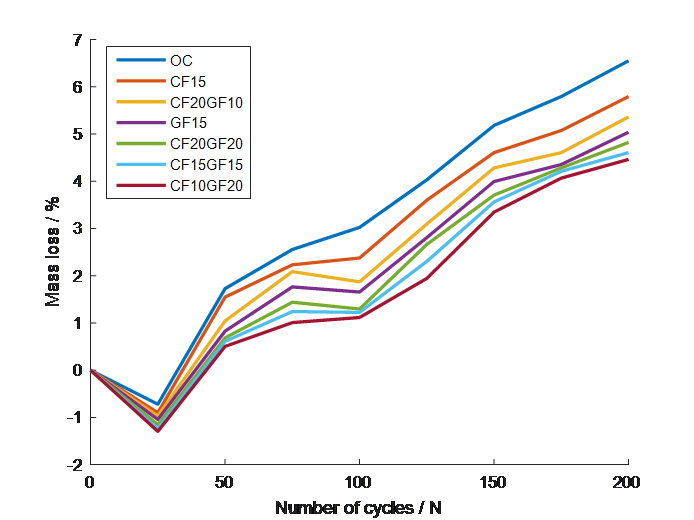

The quality loss rate of OC. And each group of fiber reinforced concrete varies. With the cycles number N. Is shown in Figure 1.

Figure 1. Mass loss rate of concretes

As shown in Figure 1, when N ≤ 25. All curves are in a downward trend. This is due to the presence of micro cracks inside the concrete during the initial stage of the experiment. The traces of cement are becoming increasingly prominent. All the ions in sodium chloride have gone in. The moisture absorbed by cement. The overall quality has improved. When N = 25, the degree of injury becomes even more severe. The mass of sodium chloride solution absorbed by cement is less than the weight of weight loss. When N>125, the degree of injury intensifies on the original basis.

3.2. Concrete elastic loss rate

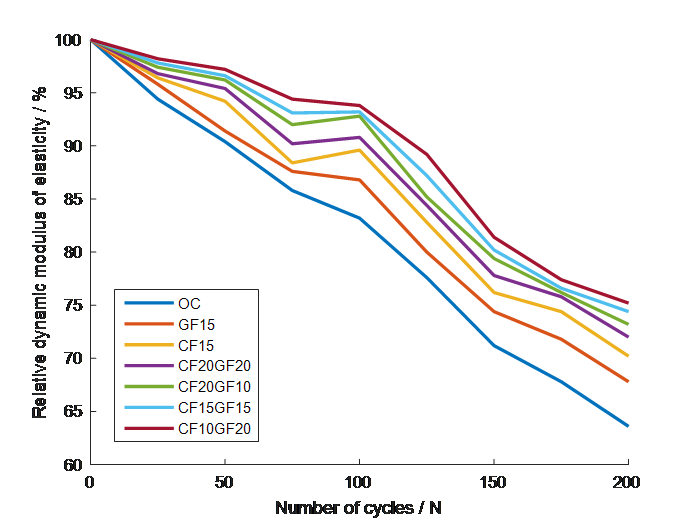

The relative dynamic elastic modulus of OC. And each group of fiber reinforced concrete varies. With the number of freeze-thaw cycles N. Is shown in Figure 2.

Figure 2. Elastic loss rate of concretes

As shown in Figure 2, as the number of freeze-thaw cycles increases, the dynamic elastic modulus of concrete shows a decreasing trend to varying degrees. When N≤75, the dynamic elastic modulus of each group of concrete decreases slowly; When 75

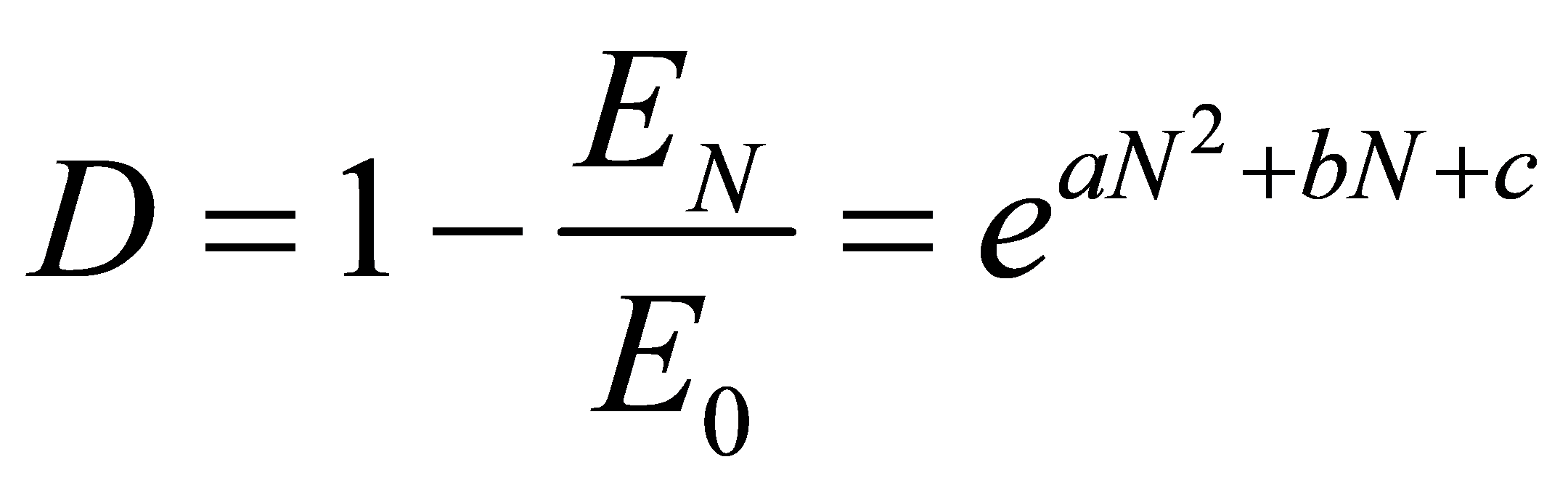

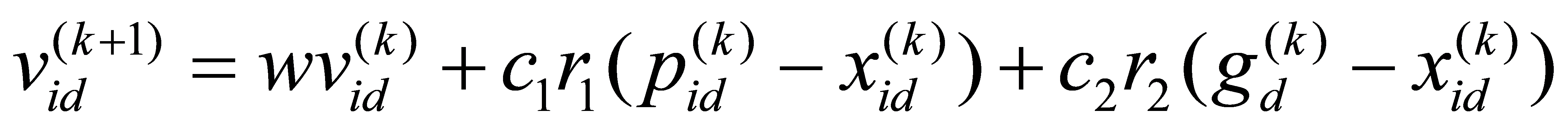

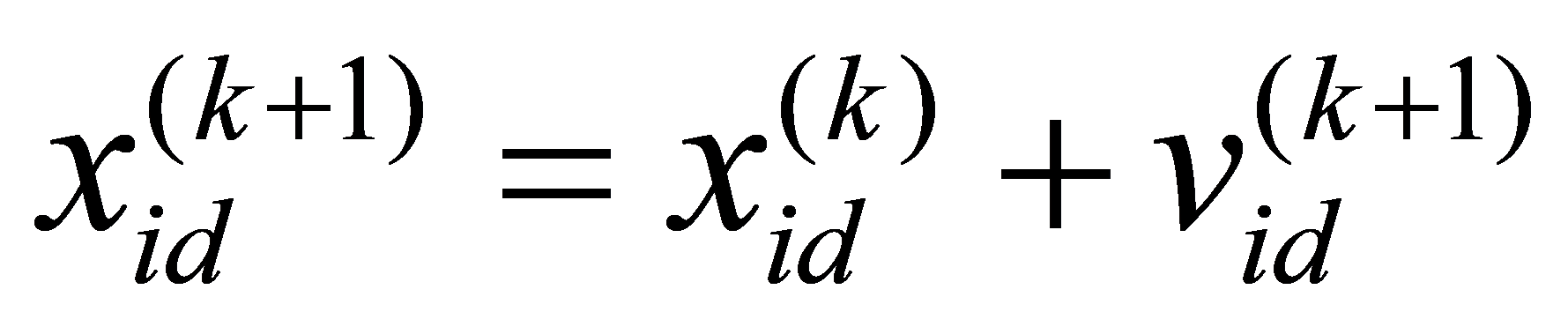

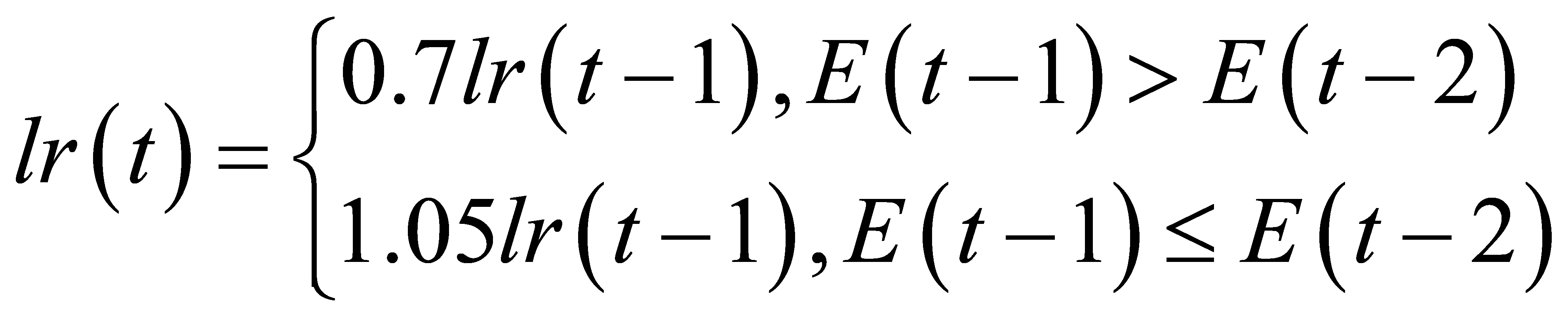

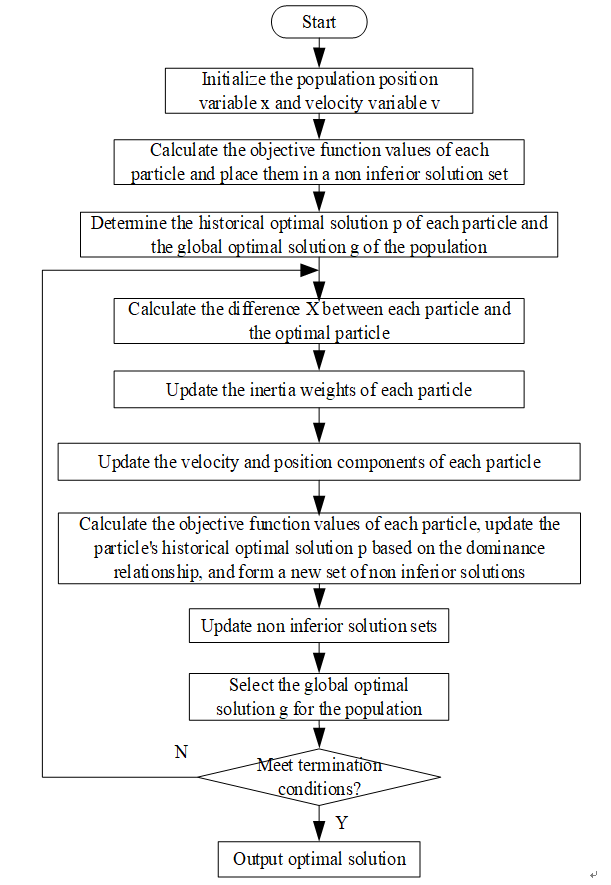

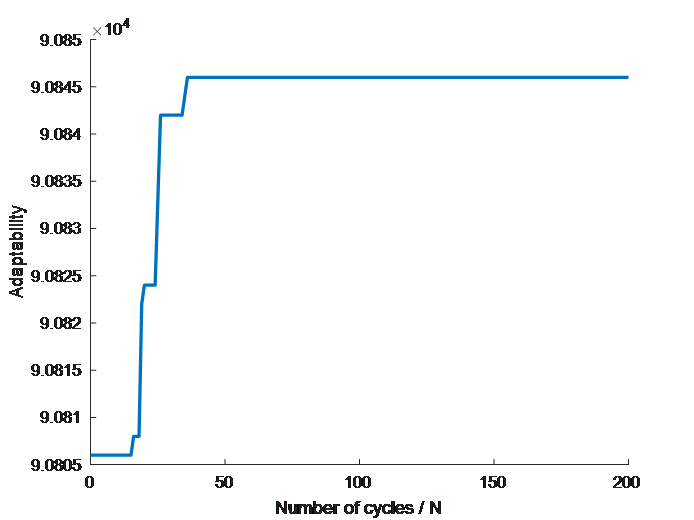

When subjected to 200 freeze-thaw cycles, the relative dynamic elastic modulus of each group of concrete is: OC 4. Performance Prediction 4.1. Freeze thaw damage model To accurately describe the damage caused by cement under freezing and saline conditions. We have consulted literature on temperature and electrolytes. Part of it is to consider the quality loss of cement. Part of it is to consider the cumulative damage caused by freeze-thaw of cement. Here we balance both. Provided a comprehensive definition. For the first type of loss rate. When it is greater than equal to 5%. We position it as causing irreversible structural damage. For the second type of loss rate. When it is greater than equal to 40%. We position it as causing irreversible structural damage. During the process of concrete salt freezing damage, the mass of concrete increases due to the absorption of moisture in the early stages of the test. The modified prediction model for concrete freeze-thaw damage under freeze-thaw cycles and chloride salt coupling is as follows: (3) D represents the cumulative damage of concrete during freeze-thaw cycles, which is dimensionless. E0 is the initial dynamic modulus of elasticity, with a dimension of MPa. EN is the dynamic elastic modulus of the test block after N freeze-thaw cycles, with a dimension of MPa. N is the number of freeze-thaw cycles. a. b and c are the correlation coefficients of fiber content [14]. 4.2. Improved BP neural network prediction method BP neural network is an intelligent sample training method mainly used for optimizing and predicting nonlinear variables, similar to the biological neural response method. When dealing with prediction problems, it does not have high requirements for the original input parameters and has strong data processing capabilities. It mainly calculates the output layer function and inverse error function values of the training samples continuously, and compares and analyzes them with the original parameter requirements until the relevant requirements are met [15-18]. The sample training is stopped and the optimal output result is output. The revised mathematical calculation expression is as follows: (4) (5) The performance improvement of neural network algorithms mainly comes from two aspects. On the one hand, it improves the rationality of the input data of the model, and on the other hand, it improves the model itself, thereby reducing the limitations of algorithm optimization and improving the optimization ability of the algorithm to handle high-dimensional complex data. This article adopts the momentum gradient method with variable step size to improve the learning factor of neural networks, reduce the oscillation of algorithm optimization, and improve the reliability of network training samples. The calculation expression for adjusting the learning factor of neural networks based on variable step size is as follows: (6) On this basis, the momentum term influence factor of the reverse error calculation bias in the neural network training samples is taken into account. The flowchart is shown in Figure 3. Figure 3. Improved BP neural network method flowchart Calculate based on measured data. The convergence curve is shown in Figure 4. From Figure 4, it can be seen that the established prediction model has high accuracy and reliability in predicting the degree of concrete salt frost damage. As can be seen from the figure, the simulation curve with the application of particle swarm optimization algorithm. Its fitting effect is very close to the actual working conditions. In more than ten actual testing conditions. All can correspond to it. The overall trend is consistent with the summarized pattern obtained from the experiment. At the same time, in terms of convergence, it can converge quickly. No divergence occurred. In terms of iteration times, it also maintains overall controllability. The simulation time is fast. Provide guidance for the practical engineering applications. Figure 4. Improved BP neural network method flowchart 5. Conclusion This article proposes a method of adding carbon fiber and glass fiber into cement. This method can improve the frost resistance of cement. A large number of the basic experiments were conducted on the text. Explore the possibilities of various combinations between cement and fibers. The method proposed in this article has been verified to have good accuracy and stability. The research results of this paper have potential applications in many fields in the future. Firstly, the main focus of this paper is on the impact of adding fibers to cement. This paper only studied two types of fibers. One type is carbon fiber. Another type is fiberglass. Further research can be conducted on the types, quantities, proportions, and other aspects of added fibers in the future. For example, carbon fiber, glass fiber, polypropylene fiber, organic synthetic fiber, natural fiber, and so on. This paper is based on experience. Only experiments with a mixing ratio not exceeding 0.2% were conducted. The reason is to balance the economy of cement. But from the scientific research perspective. You can study the addition of various percentages and conduct corresponding tests. In the future, our laboratory will also conduct research on the economy of cement. Find a balance between technical and economic characteristics. Provide a more reasonable solution. This can provide a theoretical guidance for the practical application of fiber cement in the future. Meanwhile, it will be tailored to different scenarios. Angles with different temperatures, corrosion conditions, salt concentrations, and corrosion durations. Further conduct testing research. And continue the idea of combining experiments with artificial intelligence methods. Continuously improving the research content of this paper.

is the inertia weight;

is the inertia weight;  is the velocity of the particle;

is the velocity of the particle;  is the position of the current particle;

is the position of the current particle;  and

and  is the acceleration factor;

is the acceleration factor;  and

and  is the random numbers between B (0,1);

is the random numbers between B (0,1);  is the d-th dimensional component of the optimal position vector for the i-th particle at time k;

is the d-th dimensional component of the optimal position vector for the i-th particle at time k;  is the d-th dimensional component in the optimal position vector of the population at time k.

is the d-th dimensional component in the optimal position vector of the population at time k.

References

[1]. NIU D,SU L,LUO Y,et al.Experimental study on mechanical properties and durability of basalt fiber reinforced coral aggregate concrete[J]. Construction and Building Materials,2020,237:117628.

[2]. NIU D,JIANG L,BAI M,et al.Study of the performance of steel fiber reinforced concrete to water and salt freezing condition[J].Materials and Design,2013,44:267-273.

[3]. NIU D,HUANG D,FU Q.Experimental investigation on compressive strength and chloride permeability of fiber-reinforced concrete with basalt-polypropylene fibers[J].Advances in Structural Engineering, 2019,22(10):2278-2288.

[4]. LI J C,QIAO H X,ZHU F F.Reliability analysis of freeze-thaw damage of fiber concrete based on Miner theory[J].Emerging Materials Research,2019, 8(3):508-515.

[5]. GUO Guangling.Preparation and mechanical properties of steel fiber reinforced concrete[J].Journal of Functional Materials,2020,51(11): 11165-11170.

[6]. GAO Zhen,CAO Peng,SUN Xinjian,et al.Compressive strength analysis and microscopic characterization of basalt fiber reinforced concrete[J]. Journal of Hydroelectric Engineering,2018,37(8):111-120.

[7]. ZHAO Xiaoming,LI Aoyang,QIAO Hongxia,et al.Frost resistance and damage deterioration model of fiber reinforced concrete[J].Bulletin of the Chinese Ceramic Society,2020, 39(10):3196-3202.

[8]. XIE Xiaojie,WANG Yonggui.Study on freeze-thaw resistance of basalt fiber reinforced concrete[J].Concrete,2017(9):108-111.

[9]. JU Yanzhong,XU Libin,WANG Dehong,et al.Study on mechanical properties of hybrid fiber RPC[J].Journal of Basic Science and Engineering,2019,27(6):1381-1389.

[10]. HU X Y,GUO Y,LV J F,et al.The mechanical properties and chloride resistance of concrete reinforced with hybrid polypropylene and basalt fibres[J].Materials,2019,12(15):2371.

[11]. ZENG Zhenhai,LI Chuanxi,KE Lu,et al.Study on mechanical properties and optimum fiber content for basalt/polyacrylonitrile hybrid fiber reinforced concrete[J].Journal of Railway Science and Engineering, 2020,17(10):2549-2557.

[12]. ZHAO Yanru,LIU Fangfang,BAI Jianwen,et al.Experimental salt-freezing resistance of basalt fiber concrete[J].Concrete,2019(8): 68-71.

[13]. NIU Jiangang,ZUO Fuliang,WANG Jialei,et al.Freeze-thaw damage model of plastic-steel fiber reinforced lightweight aggregate concrete[J].Journal of Building Materials,2018, 21(2):235-240.

[14]. WU Hairong,JIN Weiliang,YAN Yongdong,et al.Environmental zonation and life prediction of concrete in frost environments[J].Journal of Zhejiang University(Engineering Science),2012,46(4):650-657.

[15]. ZHAO Yanru, WANG Zhihui, WANG Lei, et al. Grey entropy analysis of macro and micro properties of BFRC after freeze-thaw cycles[J]. Journal of Building Materials, 2019, 22(1): 45-53.

[16]. YANG L Y, XIE H Z, FANG S Z, et al. Experimental study on mechanical properties and damage mechanism of basalt fiber reinforced concrete under uniaxial compression[J]. Structures, 2021, 31: 330-340.

[17]. LIANG Ninghui, YOU Xiufei, CAO Guojun, et al. Strength prediction of mechanical properties of polypropylene fiber reinforced concrete after high temperature based on machine learning[J]. Bulletin of the Chinese Ceramic Society, 2021, 40(2): 455-464.

[18]. ASHRAFIAN A, TAHERI AMIRI M J, REZAIE-BALF M, et al. Prediction of compressive strength and ultrasonic pulse velocity of fiber reinforced concrete incorporating nano silica using heuristic regression methods[J]. Construction and Building Materials, 2018, 190: 479-494.

Cite this article

Xie,Y. (2024). A damage prediction method for building concrete based on improved BP neural network. Applied and Computational Engineering,66,13-20.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2nd International Conference on Functional Materials and Civil Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. NIU D,SU L,LUO Y,et al.Experimental study on mechanical properties and durability of basalt fiber reinforced coral aggregate concrete[J]. Construction and Building Materials,2020,237:117628.

[2]. NIU D,JIANG L,BAI M,et al.Study of the performance of steel fiber reinforced concrete to water and salt freezing condition[J].Materials and Design,2013,44:267-273.

[3]. NIU D,HUANG D,FU Q.Experimental investigation on compressive strength and chloride permeability of fiber-reinforced concrete with basalt-polypropylene fibers[J].Advances in Structural Engineering, 2019,22(10):2278-2288.

[4]. LI J C,QIAO H X,ZHU F F.Reliability analysis of freeze-thaw damage of fiber concrete based on Miner theory[J].Emerging Materials Research,2019, 8(3):508-515.

[5]. GUO Guangling.Preparation and mechanical properties of steel fiber reinforced concrete[J].Journal of Functional Materials,2020,51(11): 11165-11170.

[6]. GAO Zhen,CAO Peng,SUN Xinjian,et al.Compressive strength analysis and microscopic characterization of basalt fiber reinforced concrete[J]. Journal of Hydroelectric Engineering,2018,37(8):111-120.

[7]. ZHAO Xiaoming,LI Aoyang,QIAO Hongxia,et al.Frost resistance and damage deterioration model of fiber reinforced concrete[J].Bulletin of the Chinese Ceramic Society,2020, 39(10):3196-3202.

[8]. XIE Xiaojie,WANG Yonggui.Study on freeze-thaw resistance of basalt fiber reinforced concrete[J].Concrete,2017(9):108-111.

[9]. JU Yanzhong,XU Libin,WANG Dehong,et al.Study on mechanical properties of hybrid fiber RPC[J].Journal of Basic Science and Engineering,2019,27(6):1381-1389.

[10]. HU X Y,GUO Y,LV J F,et al.The mechanical properties and chloride resistance of concrete reinforced with hybrid polypropylene and basalt fibres[J].Materials,2019,12(15):2371.

[11]. ZENG Zhenhai,LI Chuanxi,KE Lu,et al.Study on mechanical properties and optimum fiber content for basalt/polyacrylonitrile hybrid fiber reinforced concrete[J].Journal of Railway Science and Engineering, 2020,17(10):2549-2557.

[12]. ZHAO Yanru,LIU Fangfang,BAI Jianwen,et al.Experimental salt-freezing resistance of basalt fiber concrete[J].Concrete,2019(8): 68-71.

[13]. NIU Jiangang,ZUO Fuliang,WANG Jialei,et al.Freeze-thaw damage model of plastic-steel fiber reinforced lightweight aggregate concrete[J].Journal of Building Materials,2018, 21(2):235-240.

[14]. WU Hairong,JIN Weiliang,YAN Yongdong,et al.Environmental zonation and life prediction of concrete in frost environments[J].Journal of Zhejiang University(Engineering Science),2012,46(4):650-657.

[15]. ZHAO Yanru, WANG Zhihui, WANG Lei, et al. Grey entropy analysis of macro and micro properties of BFRC after freeze-thaw cycles[J]. Journal of Building Materials, 2019, 22(1): 45-53.

[16]. YANG L Y, XIE H Z, FANG S Z, et al. Experimental study on mechanical properties and damage mechanism of basalt fiber reinforced concrete under uniaxial compression[J]. Structures, 2021, 31: 330-340.

[17]. LIANG Ninghui, YOU Xiufei, CAO Guojun, et al. Strength prediction of mechanical properties of polypropylene fiber reinforced concrete after high temperature based on machine learning[J]. Bulletin of the Chinese Ceramic Society, 2021, 40(2): 455-464.

[18]. ASHRAFIAN A, TAHERI AMIRI M J, REZAIE-BALF M, et al. Prediction of compressive strength and ultrasonic pulse velocity of fiber reinforced concrete incorporating nano silica using heuristic regression methods[J]. Construction and Building Materials, 2018, 190: 479-494.