1.Introduction

As an important technology in the medical field, intravenous monitoring equipment provides accurate drug infusion monitoring and patient safety guarantee for medical personnel. Nowadays, many ICU wards require comprehensive and detailed monitoring of patients, severe patients usually need to be given a variety of drugs through intravenous injection, and the need to monitor patients' vital signs and drug response in real time, in addition, for some sterile ICU wards, patients need to change their dressing multiple times, and medical staff will waste a lot of time after disinfection into the ward. Intravenous monitoring equipment can monitor the injection speed and dosage in real time to ensure the safe and effective delivery of drugs to the patient by monitoring the patient's intravenous response and drug infusion in real time [1]. The automatic dressing change system can fully automate the switching of drugs, effectively improve the medical effect, and provide more convenience for medical personnel. Such devices can effectively prevent and timely identify problems during medication, thereby reducing the risk of complications and improving treatment outcomes.

Based on the social investigation and analysis of relevant people in different regions, this study designed a new type of equipment to try to solve the above problems. This paper will discuss the research status, social research and new equipment of automatic dressing changing and monitoring infusion speed control system, in order to explore the development trend and potential of this field.

2.Systematic Literature Survey

2.1.Related Works

At present, there are many kinds of equipment for monitoring the flow rate of intravenous injection, which can be divided into the following categories according to its technical principle: mechanical and intelligent.

Mechanical devices: In the medical field, the ball titrimeter is a more common device. This device controls the drip speed by using ball rolling, which creates less liquid disturbance as the droplets drop, effectively reducing the formation of bubbles and the possibility of other disturbances. Smart devices: These devices use electronic components such as pressure and flow sensors to monitor the pressure and flow during intravenous injection in real time, and combine mechanical, electronic and information technology to monitor and automatically adjust the intravenous flow rate in real time. Here's how smart devices have monitored intravenous devices in the past.

S. sekitoleko et al. used a gravity infusion device to ensure that droplets were dropping into the droplet chamber at a constant rate, and then used photoelectric sensor technology to monitor the flow rate. The sensor unit in the monitoring module contains a reference light source and a photocell with a fixed optical sensing gap between them. When droplets fall into the droplet chamber, they interrupt the beam provided by the light source and modulate the signal provided by the photocell. This modulated frequency is processed by a microprocessor/controller and compared to a preset titration rate for precise flow rate control [2]. Sourabh Suresh Alagundagi et al proposed to use photoelectric system to monitor the intravenous injection process, and added alarm system to conduct a large number of experiments to reduce the risk of other problems in the intravenous injection process [3]. Rehan Tariq Abbasi et al. proposed a new drop count system, which counts drops using light transmitters and light detectors placed on both sides of the drop chamber. By monitoring the number of drops in the drop chamber in real time, the liquid infusion rate can be more easily monitored [4]. Saad ABDULLAH et al. proposed a low-cost BLE based intravenous monitoring and control infusion system, which uses a Bluetooth low power microcontroller, an infrared based drop counting system and a digital servo motor to control the drip rate. The system was connected to an existing intravenous infusion rack, and a LabView graphical user interface was developed. Finally, remote control and monitoring of intravenous infusion were realized [5]. Nicola Giaquinto's team proposed a method of real-time drip monitoring using a computer vision system. They found through comparison that this method of monitoring using cameras is non-invasive and safe, and the cost and size of cameras are constantly decreasing, which can be easily used in smart low-power devices. The use of cameras can also achieve remote monitoring, when the monitoring system sends alarm events, you can quickly check the status of the drip device from a remote location [6, 7]. Andrea Cataldo et al. proposed a monitoring method based on TDR, which monitors the drip rate by directly sensing the change of liquid volume in the bottle. Their team studied the application of different bottles and different TDR probes to the bottle and concluded that this method has good repeatability [8]. Malthar U.Sapatnekar team and Sincy Joseph team have respectively proposed the application of iot to IV drip monitoring systems and designed different applications, among which Sincy Joseph team has proposed the free flow monitoring function for better monitoring of unexpected flow infusion processes. In addition, the Sincy Joseph team has used temperature sensors to monitor liquid temperature during infusion to prevent discomfort due to low temperature during infusion during the winter [9, 10]. Using Auduino and Android, S.Valmurugan enables multiple levels of saline transmission and control in a single-channel iot gateway, where the nurse can receive data from the infusion monitoring device via a central monitor and display it in chart form at the nurse's station. This remote infusion monitoring system can improve the work efficiency of nursing staff, reduce the workload of manual monitoring, and ensure the safety of infusion process [11]. J Ranjani et al. proposed the application of iot to a saline infusion monitoring and control system, in which infrared sensors use infrared radiation to determine the presence or absence of objects, detect the amount of reflected radiation through infrared leds and phototransistors or photodiodes to determine liquid levels, and, The infrared sensor can be connected to the Arduino microcontroller to trigger an alarm or send a notification when the liquid level gets too low [12]. Shizhen Huang and Fusheng Pan designed a robust intravenous infusion monitoring device. Compared with the infusion device using infrared and flowmeter, the intravenous infusion monitoring device designed by Shizhen Huang et al has wider applicability, and can reduce the influence of temperature changes on measured values through correction according to the correction formula. Improve equipment accuracy [13].

2.2.Summary and analysis

Based on the above investigation and research, the results show that the current intravenous monitoring equipment mainly has the following functions: (1) The use of photoelectric system or pressure, flow, temperature sensors to monitor intravenous injection; (2) Use computer vision system to monitor the intravenous injection process; (3) Use the Internet of Things in combination with the above methods for remote monitoring.

3.Social research

Based on the above investigation and research, the results show that the current intravenous monitoring equipment mainly has the following functions: (1) The use of photoelectric system or pressure, flow, temperature sensors to monitor intravenous injection; (2) Use computer vision system to monitor the intravenous injection process; (3) Use the Internet of Things in combination with the above methods for remote monitoring.

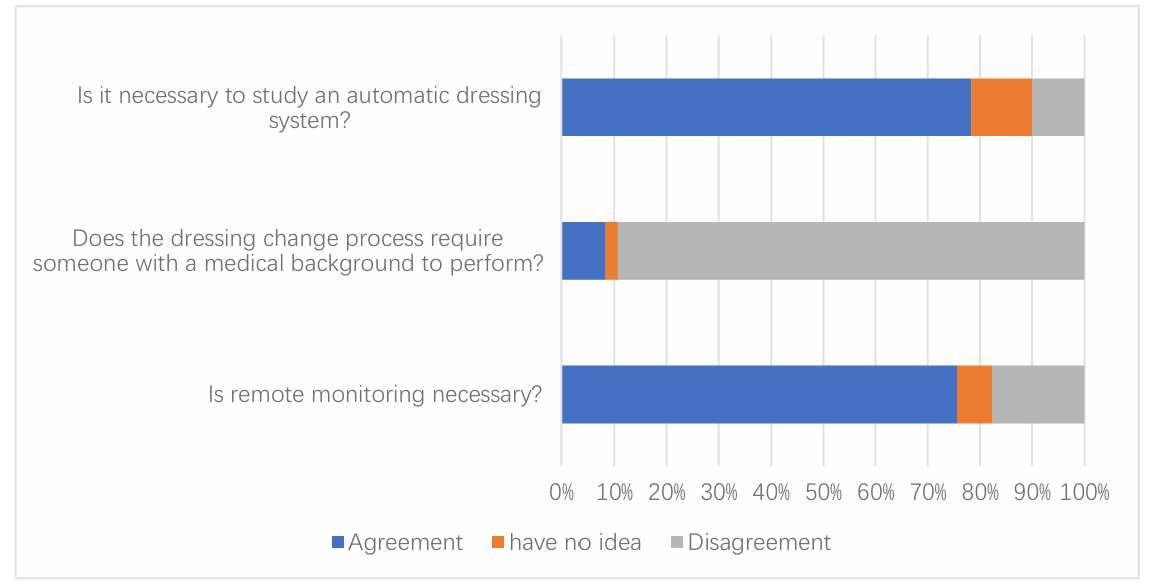

Social research is carried out through systematic and detailed surveys of medical staff, patients and their families in hospitals in different regions. According to the survey data, the following results are obtained: 1. Medical staff agree that remote monitoring is necessary. 2. for the need to inject multiple bottles of medicine to use automatic dressing system, most people agree. 3. Most people believe that the medical basis required for the dressing change process does not need to be high. The social research statistics is shown in figure 1.

Figure 1. Social research statistics (Photo/Picture credit: Original)

4.Solution

Based on the results of social research and the relevant functions of existing intravenous monitoring equipment, the demand for new equipment is put forward. The proposed new device is designed to address the problem identified today by providing healthcare professionals with automated monitoring of intravenous and automatic dressing systems, which add automatic dressing to the function of monitoring the intravenous process and can be monitored remotely from a mobile phone. The main features of the new equipment are as follows:

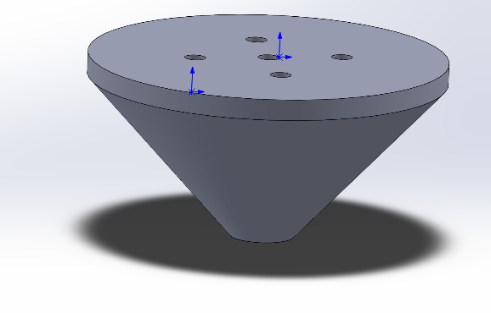

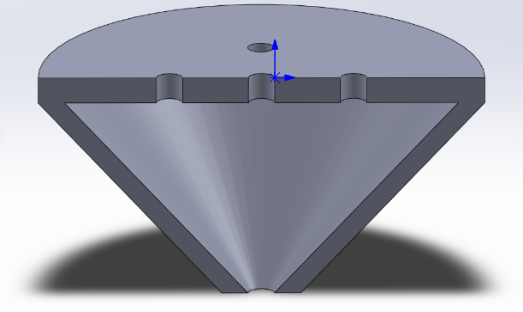

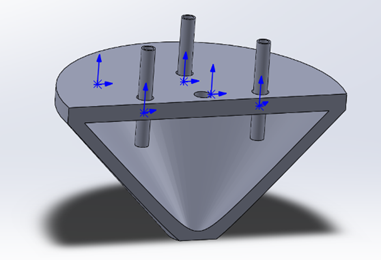

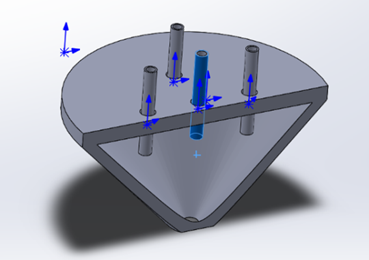

Fig.2 (a) is a simulation of the device used when a patient needs to input multiple drugs using SOLIDWORKS software. Fig.2 (b) shows the planning of this device. The device consists of three parts: a top cover, a channel, and a funnel.

Top cover: It can be adjusted according to the number of drugs entered by the patient. The hole in the middle is the channel corresponding to normal saline, and the hole around it is the channel corresponding to the drug required by the patient. Channel: Hose used to simulate the flow of fluid. The funnel part : collects the needed drugs, which plays a role in reducing bubbles. Method of application: First, all drugs are inserted into the holes around the device according to the sequence of infusion using the channels shown in Fig.2 (c) (simulating a hose flowing through the drugs), and each channel is closed with a one-way valve; The saline solution is then inserted into the middle channel and closed again with a check valve, as shown in Fig.2 (d).

Figure 2. Simulation of the device (Photo/Picture credit: Original)

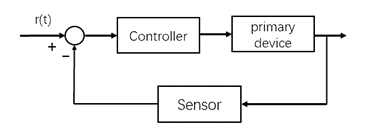

The new equipment is mainly composed of three parts: the sensor part, the controller part and the main equipment part which is shown in figure 3.

Figure 3. Equipment working flow (Photo/Picture credit: Original)

Sensor part: The infrared drop count technology system is used to monitor the flow rate of intravenous drops, and the infrared sensor is fixed in the location where the infusion drug is stored.

Controller part: Control whether to change the medicine through the sensor feedback data, that is, when the liquid level is detected to be very low (about 5% at the bottom of the bottle), the controller will use the check valve to close the channel where the current medicine is located, and then open the corresponding channel of normal saline in the middle.

Main device part: User interface for taking advantage of iot. Medical staff can monitor the operating status of the system in real time through the user interface. When there is an emergency, the user interface will receive an alarm reminder, so as to achieve the purpose of receiving feedback in time.

The new equipment should have the following functions:

Real-time monitoring and regulation: Combined with the Internet of Things technology, the device can monitor the flow rate and drug dosage of intravenous injection in real time to ensure the accuracy and safety of drug delivery. Through remote connection, medical staff can remotely monitor and adjust equipment parameters to avoid problems such as too fast or too slow infusion.

Remote alarm and notification: The application of Internet of Things technology can achieve automatic early warning of equipment failures and abnormal situations. After the device is connected to the Internet of Things, real-time alarms and notifications can be sent to the medical staff, prompting the time of drug dressing change, the exhaustion of medicine liquid, etc., to help timely treatment and avoid interrupting the infusion process.

Data analysis and optimization: iot technologies provide vast amounts of real-time data that can be analyzed and mined to optimize treatment flows and improve patient safety. Through continuous monitoring and analysis of the data, possible problem patterns and treatment abnormalities can be identified and appropriate measures can be taken to improve them. In addition, the collection and analysis of data can also be used for research purposes to drive the development and improvement of medical treatment models.

Remote maintenance and upgrade: After the device is connected to the Internet of Things, the manufacturer can remotely maintain and upgrade the device to repair problems and improve functions in a timely manner to ensure continuous and stable device performance.

The current new equipment has the following problems: 1. The new equipment may have the problem of drug waste: In order to avoid the situation of blood reflux, when the liquid level is detected at about 5% of the bottom of the bottle, the controller will switch the switch to change the drug, resulting in drug waste. 2. The size requirements of the new device have not been accurately designed: the device used in picture 1 when the patient needs to input multiple drugs can replace the top part according to the amount of drugs input by the patient, but the size has not been tested experimentally and needs further study.

5.Conclusion

This paper proposes an intravenous injection monitoring device with automatic dressing change function. The proposed device can be combined with the Internet of Things to realize intelligent monitoring, remote management and data recording of the device, improve the efficiency and safety of medical services, and bring better treatment experience and medical quality. At the same time, this combination can also provide more convenience and support for healthcare staff, reduce human error and improve treatment effectiveness, so that they can focus more on patient care and reduce the workload. However, at present, this device still has some shortcomings, such as the problem of drug waste caused by dressing changes has not yet found a solution.

In the future, the above issues will be simulated and tested in a large amount of data in the clinical environment, and with the continuous development and application of Internet of Things technology, the combination of automatic dressing system and monitoring intravenous injection equipment may be further improved and innovative. For example, artificial intelligence algorithms can be added to optimize the speed and dosage of drug delivery, personalizing the treatment of patients; It is also possible to establish connections between devices to enable collaborative work and data sharing, improving efficiency and coordination across the healthcare system.

References

[1]. Evans K. Diabetic ketoacidosis: update on management. Clinical Medicine, 2019, 19(5): 396.

[2]. Ssekitoleko S, Niyitanga P, Ocheng M, et al. Design of a low-cost electronically controlled gravity-feed infusion set. AFRICON 2015. IEEE, 2015: 1-6.

[3]. Alagundagi S S, Pasala K, Arora M. Opto-electronic system for intravenous infusion monitoring. 2018 10th International Conference on Communication Systems & Networks (COMSNETS). IEEE, 2018: 688-692.

[4]. Abbasi R T, Zahoor A, Junaid L, et al. Automatic Intravenous Drip Drop Counter and Controller. 2023 3rd International Conference on Digital Futures and Transformative Technologies (ICoDT2). IEEE, 2023: 1-5.

[5]. Abdullah S, Kanwal K, Hafid A, et al. Low-cost BLE based intravenous monitoring and control infusion system. 2023 International Conference on Advances in Electronics, Control and Communication Systems (ICAECCS). IEEE, 2023: 1-5.

[6]. Giaquinto N, Scarpetta M, Spadavecchia M, et al. Deep learning-based computer vision for real-time intravenous drip infusion monitoring. IEEE Sensors Journal, 2020, 21(13): 14148-14154.

[7]. Giaquinto N, Scarpetta M, Ragolia M A, et al. Real-time drip infusion monitoring through a computer vision system. 2020 IEEE International Symposium on Medical Measurements and Applications (MeMeA). IEEE, 2020: 1-5.

[8]. Cataldo A, Cannazza G, De Benedetto E, et al. Reproducibility analysis of a TDR-based monitoring system for intravenous drip infusions: Validation of a novel method for flow-rate measurement in IV infusion. 2012 IEEE International Symposium on Medical Measurements and Applications Proceedings. IEEE, 2012: 1-5.

[9]. Joseph S, Francis N, John A, et al. Intravenous drip monitoring system for smart hospital using IoT. 2019 2nd International Conference on Intelligent Computing, Instrumentation and Control Technologies (ICICICT). IEEE, 2019, 1: 835-839.

[10]. Sapatnekar M U, Mainkar P M. Design and Development of IOT Controlled Intravenous Infusion Device. 2022 13th International Conference on Computing Communication and Networking Technologies (ICCCNT). IEEE, 2022: 1-7.

[11]. Velmurugan S, Shanthi G, Raja L, et al. Fully automated single window saline fluid flow control and automatic container changing system. 2021 7th International Conference on Advanced Computing and Communication Systems (ICACCS). IEEE, 2021, 1: 1259-1263.

[12]. Ranjani J, Hariharan S, Jeyashree A, et al. Saline Infusion Monitoring and Control System Using IoT. 2023 International Conference on Distributed Computing and Electrical Circuits and Electronics (ICDCECE). IEEE, 2023: 1-5.

[13]. Huang S, Pan F. Design of robust intravenous infusion monitoring device. 2019 3rd International Conference on Electronic Information Technology and Computer Engineering (EITCE). IEEE, 2019: 1949-1952.

Cite this article

Song,S. (2024). Automatic dressing change and monitoring infusion speed control system. Applied and Computational Engineering,75,217-222.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2nd International Conference on Software Engineering and Machine Learning

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Evans K. Diabetic ketoacidosis: update on management. Clinical Medicine, 2019, 19(5): 396.

[2]. Ssekitoleko S, Niyitanga P, Ocheng M, et al. Design of a low-cost electronically controlled gravity-feed infusion set. AFRICON 2015. IEEE, 2015: 1-6.

[3]. Alagundagi S S, Pasala K, Arora M. Opto-electronic system for intravenous infusion monitoring. 2018 10th International Conference on Communication Systems & Networks (COMSNETS). IEEE, 2018: 688-692.

[4]. Abbasi R T, Zahoor A, Junaid L, et al. Automatic Intravenous Drip Drop Counter and Controller. 2023 3rd International Conference on Digital Futures and Transformative Technologies (ICoDT2). IEEE, 2023: 1-5.

[5]. Abdullah S, Kanwal K, Hafid A, et al. Low-cost BLE based intravenous monitoring and control infusion system. 2023 International Conference on Advances in Electronics, Control and Communication Systems (ICAECCS). IEEE, 2023: 1-5.

[6]. Giaquinto N, Scarpetta M, Spadavecchia M, et al. Deep learning-based computer vision for real-time intravenous drip infusion monitoring. IEEE Sensors Journal, 2020, 21(13): 14148-14154.

[7]. Giaquinto N, Scarpetta M, Ragolia M A, et al. Real-time drip infusion monitoring through a computer vision system. 2020 IEEE International Symposium on Medical Measurements and Applications (MeMeA). IEEE, 2020: 1-5.

[8]. Cataldo A, Cannazza G, De Benedetto E, et al. Reproducibility analysis of a TDR-based monitoring system for intravenous drip infusions: Validation of a novel method for flow-rate measurement in IV infusion. 2012 IEEE International Symposium on Medical Measurements and Applications Proceedings. IEEE, 2012: 1-5.

[9]. Joseph S, Francis N, John A, et al. Intravenous drip monitoring system for smart hospital using IoT. 2019 2nd International Conference on Intelligent Computing, Instrumentation and Control Technologies (ICICICT). IEEE, 2019, 1: 835-839.

[10]. Sapatnekar M U, Mainkar P M. Design and Development of IOT Controlled Intravenous Infusion Device. 2022 13th International Conference on Computing Communication and Networking Technologies (ICCCNT). IEEE, 2022: 1-7.

[11]. Velmurugan S, Shanthi G, Raja L, et al. Fully automated single window saline fluid flow control and automatic container changing system. 2021 7th International Conference on Advanced Computing and Communication Systems (ICACCS). IEEE, 2021, 1: 1259-1263.

[12]. Ranjani J, Hariharan S, Jeyashree A, et al. Saline Infusion Monitoring and Control System Using IoT. 2023 International Conference on Distributed Computing and Electrical Circuits and Electronics (ICDCECE). IEEE, 2023: 1-5.

[13]. Huang S, Pan F. Design of robust intravenous infusion monitoring device. 2019 3rd International Conference on Electronic Information Technology and Computer Engineering (EITCE). IEEE, 2019: 1949-1952.