1. Introduction

1.1. Silicon

Let’s first talk about what is silicon. Silicon is currently changing people’s conceptions of tiny mechanical devices and components. This flexible material has already completely changed the way we think about electronics [1]. Silicon is an element in the group four of the periodic table. A Swedish chemist Jöns Jacob Berzelius discovered this element in 1824.Silicon is most found in the crust of the Earth, which contains 27.7 percents of the Earth’s crust. Silicon is similar to carbon in many chemical and physical properties, such as they are both in octahedral crystalline structure which is same as the diamond form of carbon. As I said before, silicon is a fundamental material to build Semiconductor industry.

In addition to its traditional use as an electronic material, silicon can also be used as a high-precision, high-strength, high-reliability mechanical material by utilizing the already sophisticated microfabrication technology. This is particularly useful in situations where tiny mechanical components and devices need to be interfaced or integrated with electronics.

Scientists prefer to use germanium to become the material for semiconductor at the beginning. As time goes on, scientists observed that germanium crystal will be destroyed at a high temperature and the maximum voltage can pass through silicon diodes are greater than germanium diodes. Also, the reserve of silicon is second only to oxygen in the Earth crust which is cheaper than the rare metal germanium. The technology to purify silicon is mature, in fact, the purity of silicon can up 99.999 percent and silicon is non-toxic and harmless to human body, so scientists recently prefer to use silicon as the fundamental material in the semiconductor industry. In the semiconductor industry, silicon is used to fabricate the PN junction which play a vital role to build up the transistor. The integrated circuit is connected by the transistor, capacitor, resistor on a thin substrate (usually made by silicon). Microprocessor is one type of integrated circuit, and it can perform billions of operations per second on data. Microprocessors typically contain the central processing unit of a computer.

1.2. Steel

Steel is not a nature element like silicon, it is an alloy which composed by iron, silicon, carbon, phosphorus, sulfur, manganese, and small number of other elements. This alloy leads the second industrial revolution, even up to today steel is still the most widely used material for building the world’s infrastructure and industries, it is used to manufacture everything from sewing needles to oil tankers. Although the major component of steel is iron, iron is soft in pure form.

To solve this problem is to add carbon when converting the iron into steel. The reason for that is because the carbon will deform the structure of iron in micro perspective, so when the dislocation is occurring, the resistive force increase.

However, hardness is not the only reason indicates why steel is commonly used. The key ability for steel is the plasticity and the structure is relatively simple which can efficiently produce massive amount of it. Also due to the plasticity, the steel can easily deform to dynamic shapes which satisfy most of cases.

1.3. History of silicon

The name of silicon derives from the Latin silex or silicis, meaning flint or hard stone. This element is discovered in 1824 by heating chips of potassium in a silica container and then washing away the residual by-products. This element didn’t have a great impact on the first industrial revolution and people always consider it as an unremarkable element until 1940 the invention of PN junction. Six years later, scientists use more than 18000 tubes and massive resistor and capacitor to invent the first electrical computer ENIAC in University of Pennsylvania. This invention leads the third industrial revolution. The first electrical computer occupy 170 square meters and it weighs 30 tons. Obviously, large occupancy area and cannot be moved comes to be the major problem of this first electrical computer so scientist consider integrating these tubes on a little chip so integrated circuit is invented.

Silicon plays an incredibly big role in the invention of integrated circuit. Now a day, integrated circuit already becomes the cornerstone of the information age which is the core philosophy of third industrial revolution.

1.4. History of steel

The development of steel can be traced back approximately 4000 years to the beginning of the Iron Age. When steel was first made it is impossible to state. Perhaps we may venture to say that its manufacture is as old as that of iron. In the pro-duction of wrought iron direct from the ore, the aim was to produce a doughy mass without fusion, and to keep this mass in the hearth and in contact with the fuel for as short a time as possible. If, through some peculiarity in the ore, the iron had to be retained a longer time in the hearth, it took up more or less carbon, and a steely iron, a mass part steel and part iron, or even steel, was produced [2].

By the seventeen centuries, Europe demanded a more versatile structure metal and by the nineteen centuries, huge amount of iron is consumed by expanding railroads and fabricate weapons. The lake of iron leads the metallurgists to find out a solution to iron’s brittleness and inefficient production processes. At that time steel is an unproven structural metal and production of the product is slow and highly costed.

Bulk steel production is implemented by the invention of Bessemer converter in 1855. It gives and effective way to use oxygen to reduce the carbon content in iron which makes a more rigid material than iron. Accordingly, steel becomes the most widely used material during the second industrial revolution.

2. Influence of silicon and steel

2.1. The impact of the silicon to the world.

Since the silicon has been discovered, the main and the most significant usage is to build the semiconductor. Scientists combine trace amount of element in group IIIA to form a p-type semiconductor and combine small amount of element in group VA to form a n-type semiconductor, finally combine these two semiconductors to form PN junction.PN junction almost becomes the basis of modern electronic technology. The unilateral conductivity helps it to construct transistors and diodes and utilize the photovoltaic effects can produce the solar cell. The transistors and diodes can construct the integrated circuit that is utilized to implement the chips in a computer.

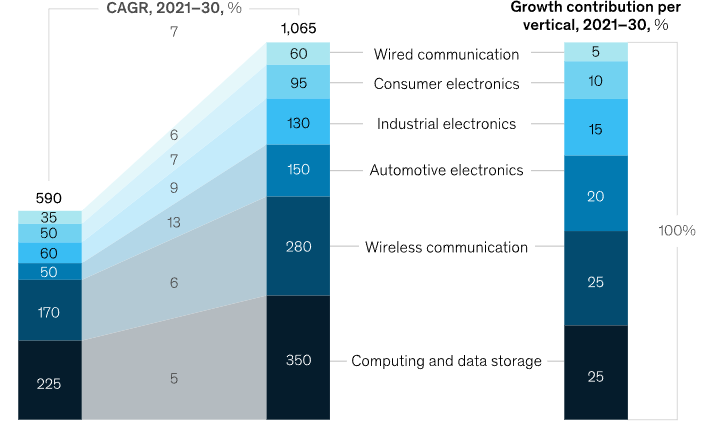

The semiconductor market grew, with sales increasing by more than 20% to almost $600 billion in 2021 as the influence of digitalization on people’s lives and enterprises accelerated. According to a McKinsey estimate based on various macroeconomic hypotheses, the industry’s overall annual growth rate through 2030 may range from 6% to 8%.

The invention of computer greatly facilitates people’s lives, without computer or other high-technology devices, people cannot communicate easily, and internet will not appear human development will not be so rapid. The solar cells also change people’s lives. Solar energy is a renewable energy which will not cause any pollution to damage the environment. According to calculations based on the world’s anticipated energy consumption by 2030, just around 496,805 square kilometers of the surface of the planet to contain solar panels and each solar panel only need work at 20 percent efficiency, can be needed to meet all of the world’s energy needs. Although the amount of material needed would be massive, silicon is the second most common element in the crust of the Earth, therefore it appears doable [3].

In conclusion, silicon is the fundamental material of this information Age also enhances the efficiency in energy production. Additionally, silicon is relatively inexpensive, as there is a large amount of silicon found in crust and the technology for extracting silicon is proficient so people can spend more money on other fields to improve human life. The silicon industry is moving forward well.

Figure 1. Growth of silicon technology [4]

2.2. The impact of steel to the world

The impact of steel on the human is astonishing and remarkable, it can be traced back to the mid nineteen centuries and even now. Although most of the transports are constructed with different material, steel is always one of the basic materials. Additionally, all the buildings no matter it is a skyscraper or just a small residence, you can find the existence of steel. If one day, steel disappear from the Earth the only thing left is a pile of ruins. Steel may not be a complex material that has high scientific research value, but it must be the most commonly used material now a day.

A significant industry in terms of commerce, steel is a vital component of many national economies and is a necessary material for the modern world (Figure 2). It is employed in manufacturing (such as the production of automobiles), the military, and construction. Since 2000, the production of iron and steel, a commodity that is traded worldwide, has tripled, with $2.5 trillion in sales in 2018 [5].

Figure 2. The total amount of steel production about the world [6]

Traditionally, the gross value added from an industry—that is, the difference between the value of intermediate inputs and output—is used to calculate the economic impact of an industry. The number of people employed in the sector is another significant indicator. The direct impact is described in part by these indicators. With a $500 billion gross value added, or 0.7% of the world economy, the steel sector employs little over 6 million people [7].

2.3. Compare the impact between steel and silicon to the society

First of all, these two materials are both made a great contribution to the world and the filed each material takes a dominant position is totally different. The usage of silicon is more to assemble precise stuffs such as Central Processing Unit because the ability of semiconductor which is impossible to reproduce by steel. On the other hand, the silicon is not as hard as steel, and it is brittle so people can’ t use it two build infrastructures. However, in my opinion, compare with the impact of these materials contribute to human, I would say silicon is more significant to society because silicon is hard to replace. Although there are already other materials to construct semiconductors, silicon is still cost-effective because the huge amount of reservation inside Earth.

In conclusion, silicon is difficult to be substituted by other material due to the ability of the semiconductor and it is relatively unexpansive compare with other material to construct semiconductor. Unlike silicon, there is no special feature on steel, so steel is easier to replace by other alloy in the future.

3. Future developments

3.1. Future of silicon technology

Since the concept of semiconductors was proposed, the development has been unexpectedly fast which always obeys Moore’s law. Moore’s Law states that the number of transistors in a microchip doubles every two years. As per the theorem, we can expect our computers to get faster and more functional every two years, all the while costing less. Another aspect of Moore’s Law states that this expansion is exponential. The law is attributed to former Intel CEO and co-founder Gordon Moore [8]. The usage of silicon is not specific to semiconductor it subtly integrated into our lives and becomes an inseparable part now a day. However, there are several new materials have been discovered to replace the application of silicon such as graphene.

A single layer of carbon atoms forming a honeycomb (hexagonal) lattice, or many connected layers of this honeycomb structure make up graphene, a two-dimensional form of crystalline carbon [9]. Physicist Philip R. Wallace proposed the idea of graphene in 1947, but it wasn’t fully understood until 2004. Konstantin Novoselov and Andre Geim, the scientists who extract graphene, were also awarded the Nobel Prize in Physics six years after their discover. The advantage of graphene was significant. Graphite and materials linked to it are widely utilized in battery electrode materials, semiconductor devices, transparent displays, sensors, capacitors, transistors, and other aspects. Graphene research and application development are still in their early stages. Numerous fields, including chemistry, materials science, physics, biology, the environment, and energy, have made significant advancements as a result of the exceptional qualities and prospective applications of graphene materials. The application of graphene has many similarities with silicon, and in many cases is even more effective than silicon. For example, transistors made of graphene can still function steadily at the scale of nearly a single atom because of the tremendous stability of the graphene structure. Graphene transistors can operate at very high frequencies due to the incredibly quick electrons’ reactivity to an external field. In comparison, existing silicon-based transistors lose stability at a scale of roughly 10 nanometers. For instance, IBM declared in February 2010 that it would raise graphene transistors’ working frequency to 100 GHz, which is way higher than silicon transistors’ operating frequency. Also, the storage of graphene can up to 320 million tons which is not a small number, and the production of graphene is relatively affordable and rapid.

Overall, the application of silicon might be replaced by other material in future but not totally because the huge storage of silicon in the Earth crust and skilled purification techniques. However, the limit of silicon is approaching compared to those new material so the impact of silicon to the future society is diminished.

3.2. Future of steel

The demand for steel has increased at a rate of 6% per year since 2000; the Chinese economy’s remarkable growth is largely responsible for this surge, as it currently accounts for 46% of the world’s steel production and consumption—more than double the proportion of the world’s population. With a market value of over $1 trillion, steel is the most popular building material worldwide. It is replacing conventional materials like brick and wood considerably more often than it is being replaced by lighter alternatives like aluminum and plastic. For many applications steel simply has no substitutes [10]. In my opinion, the main reason why steel is impossible to be replaced is because since the history of human using steel are approximately more than 2000 years and with the development of human technology, field and use of steel material application are increasing.

Overall, the impact of steel material to the society is continuous in future. It is the most frequently used material in the world and not suitable for many applications.

4. Conclusion

Both silicon and steel are doing great attribute to the society. It is really hard to compare which one is more influence. The field of these two materials are fit in is totally difference. Steel is more used to build infrastructures and silicon is suitable for precision technology such as semiconductor. However, compare to the fungibility of these materials, I would say steel is more significant to the society.

References

[1]. Proceedings from the topical meeting on “The Limits to Miniaturization,” for optics, electronics, and mechanics at the Swiss Federal Institute of Technology, Lausanne, Switzerland, Oct. 1980.

[2]. Rhys Jenkins Read at the Iron and Steel Institute, Westminster, Nov. 29th, 1922.

[3]. KURT E. PETERSEN, MEMBER, IEEE “Silicon as a Mechanical Material” PROCEEDINGS OF THE IEEE, VOL. 70, NO. 5, MAY 1982 P420

[4]. The semiconductor decade: A trillion-dollar industry | McKinsey

[5]. Zhiyuan Fan and S.Julio Friedmann “Low-carbon production of iron and steel: Technology options, economic assessment, and policy. P829-862 2021

[6]. World steek in figures 2019 https://www.worldsteel.org/en/dam/jcr:96d7a585e6b2-4d63-b9434cd9ab621a91/World%2520Steel%2520in%2520Figures%25202019.pdf

[7]. Blog - Economic impact of the global steel industry - worldsteel.org Eldar Askerov 29 May 2019

[8]. What Is Moore’s Law and Is It Still True? (Investopedia.com)

[9]. Graphene - Properties, Structure, Uses | Britannica

[10]. LAPLACE CONSEL “The Future of steel: How will the industry evolve?” 73rd Session of the OECD Steel Committee Paris, 6-7 December 2012

Cite this article

Ding,W. (2024). Comparative analysis of the impact in societies of silicon technology against that of steel. Applied and Computational Engineering,84,200-205.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 4th International Conference on Materials Chemistry and Environmental Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Proceedings from the topical meeting on “The Limits to Miniaturization,” for optics, electronics, and mechanics at the Swiss Federal Institute of Technology, Lausanne, Switzerland, Oct. 1980.

[2]. Rhys Jenkins Read at the Iron and Steel Institute, Westminster, Nov. 29th, 1922.

[3]. KURT E. PETERSEN, MEMBER, IEEE “Silicon as a Mechanical Material” PROCEEDINGS OF THE IEEE, VOL. 70, NO. 5, MAY 1982 P420

[4]. The semiconductor decade: A trillion-dollar industry | McKinsey

[5]. Zhiyuan Fan and S.Julio Friedmann “Low-carbon production of iron and steel: Technology options, economic assessment, and policy. P829-862 2021

[6]. World steek in figures 2019 https://www.worldsteel.org/en/dam/jcr:96d7a585e6b2-4d63-b9434cd9ab621a91/World%2520Steel%2520in%2520Figures%25202019.pdf

[7]. Blog - Economic impact of the global steel industry - worldsteel.org Eldar Askerov 29 May 2019

[8]. What Is Moore’s Law and Is It Still True? (Investopedia.com)

[9]. Graphene - Properties, Structure, Uses | Britannica

[10]. LAPLACE CONSEL “The Future of steel: How will the industry evolve?” 73rd Session of the OECD Steel Committee Paris, 6-7 December 2012