1. Introduction

Currently, the global warming crisis is intensifying, leading to various severe meteorological issues. In response to the growing demand for environmental protection, China has actively promoted the development of new and renewable energy technologies, including nuclear power, wind power, solar power, and biomass power generation. However, due to China's energy situation of being "relatively rich in coal, lacking in oil, and scarce in natural gas," along with the advantages of coal-fired power in terms of safety, cost-effectiveness, and stability, coal-fired power generation continues to dominate electricity production. [1] The growing energy demand and the desire to reduce greenhouse gas emissions have continuously driven the development of next-generation coal-fired power technologies. Several clean coal power generation technologies, such as Pressurized Fluidized Bed Combustion (PFBC) and Integrated Gasification Combined Cycle (IGCC), are still in the experimental or demonstration stages. [2] However, the development and application of ultra-supercritical (USC) units have matured. Therefore, vigorously promoting large-capacity, high-parameter USC power plants is a key approach to achieving the "dual carbon" targets and improving power generation efficiency. The steam temperature of advanced supercritical (or ultra-supercritical) has reached 580–600℃ in 1990s, and numerous 600℃ ultra-supercritical units have since been successfully put into commercial operation. To further enhance the net efficiency of coal-fired power plants, the development of 700℃ USC boilers is required to increase the main steam and reheat steam temperatures to 700℃ or higher. Compared to the 600℃ units, the main steam pressure in 700℃ units increases from 27 MPa to over 35 MPa, reducing turbine heat consumption by 7.04%. This ultimately boosts unit thermal efficiency from 43% to over 46%, and reduces coal consumption from 284 g/kWh to 210 g/kWh. [3]The goal of improving power generation efficiency and reducing pollutant emissions can thus be achieved. The power generation efficiency of the 700℃ USC units is expected to exceed 46%, possibly reaching around 50%, with coal consumption reduced to 210 g/kWh—a decrease of approximately 70 g compared to the 600℃ units, while CO2 emissions are also reduced by 14%. However, current research indicates that ferritic and martensitic steels used for boiler applications lack sufficient high-temperature strength, corrosion resistance, and oxidation resistance at temperatures above 700℃, making high-temperature alloy materials for ultra-supercritical units a bottleneck in the development of these advanced power generation systems. Several developed countries began researching 700℃ ultra-supercritical units around the 1990s. Their studies revealed that only a few nickel-based alloys, such as Nimonic 105, Haynes 282, and Waspaloy, meet the requirements for a creep strength of over 100 MPa at 760℃ for 100,000 hours. [4]

Nickel-based alloys are essentially based on Ni-Cr or Ni-Cr-Co base. Cr is added to high-temperature alloys as a crucial element for oxidation and corrosion resistance. Nickel-based alloys containing chromium exhibit superior oxidation and coal ash resistance compared to iron-based heat-resistant steels. This is because, in nickel-based alloys, chromium can form a stable α-Cr2O3 film at 300℃–900℃, providing a protective effect. Since Cr2O3 tends to volatilize at temperatures above 1000℃, the operating temperature of Ni-Cr-based alloys should be below 1000℃. Moreover, nickel-based alloys exhibit good microstructural stability after prolonged aging above 600℃, allowing them to dissolve a considerable amount of alloying elements. Additionally, as alloy strengthening relies on the formation of the γ' phase, nickel-based alloys demonstrate higher high-temperature strength than conventional alloys. Therefore, the study of characterization and improvement methods for nickel-based alloys is of critical importance.[5] However, research on modification methods for nickel-based alloys remains insufficient.

This work summarizes specific approaches and characterization methods for enhancing nickel-based alloys under ultra-supercritical (USC) high-temperature conditions. Modifications achieved through high-entropy alloying and oxide dispersion strengthening techniques are introduced, focusing on the mechanisms and recent advancements in these areas. Additionally, common methods for morphology and elemental characterization of nickel-based alloys, as well as techniques for assessing their mechanical properties, are reviewed. We hope this work would seek to guide future research efforts, ultimately advancing energy efficiency and reducing consumption in USC power generation systems.

2. Modification method of nickel-based alloy materials

The main modification methods currently include the following: a. Achieving high-entropy alloying through multi-component alloy design significantly enhances the creep resistance and thermal stability of the alloy.; b. By employing ODS technology, the introduction of nano-oxide particles significantly improves the mechanical properties of materials at high temperatures. These diversified alloy design and strengthening techniques offer new insights for optimizing material performance in high-temperature environments, further advancing the research and application of materials for ultra-supercritical units.

2.1. High-Entropy Alloying

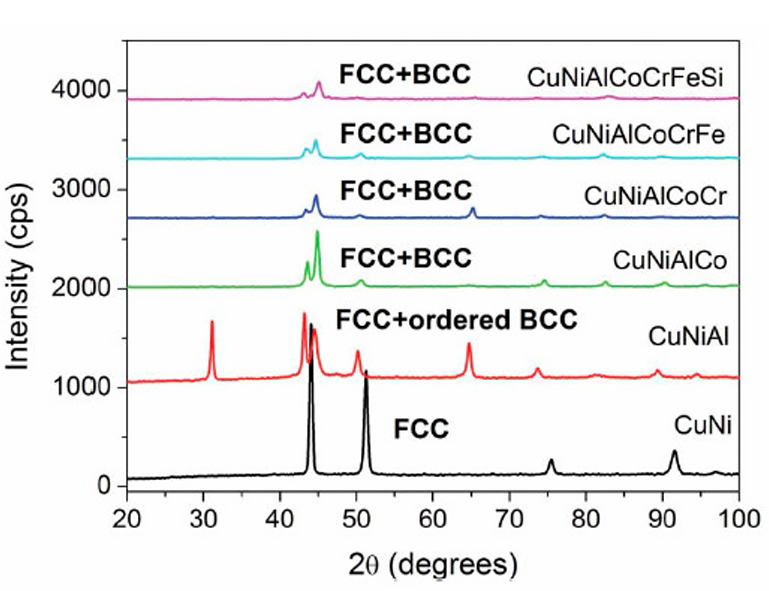

High entropy alloys (HEAs) are alloys composed of five or more elements, where the atomic ratios are nearly equal, leading to a higher mixing entropy. In 1995, Taiwanese scholar J.W. Yeh first proposed the concept of multi-principal element high entropy alloys, challenging the traditional alloy design concept. In 2004, he published a seminal paper on Cu-Co-Ni-Cr-Al-Fe-Ti-V alloys with multiprincipal metallic elements. [6]In thermodynamics, entropy is a measure of disorder in a system. The greater the disorder, the higher the entropy. As shown in Fig. 1, with an increasing number of alloy components, the phase structure transitions from a binary FCC structure to a multi-component FCC+BCC dual-phase structure, becoming more holistic and stable overall.

Figure 1: Relationship between alloy phase structure and its composition.[7]

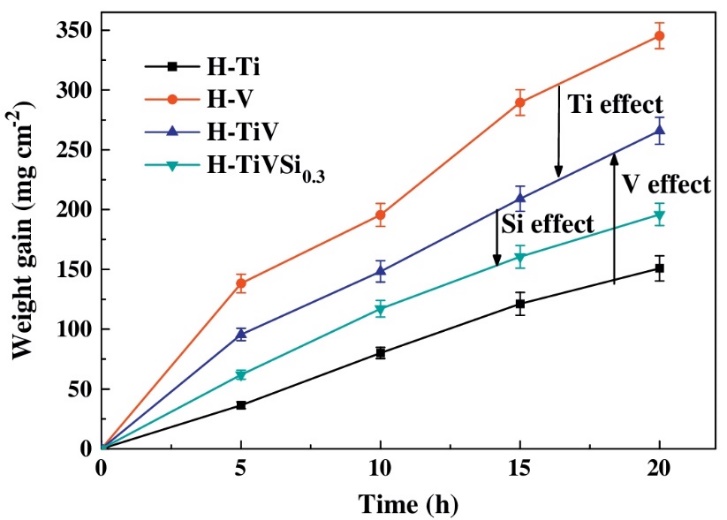

Nowadays, elements commonly incorporated into HEAs primarily include metals from the third period such as Mg and Al, fourth period metals like Ti, V, Cr, Mn, Fe, Co, Ni, Cu, and Zn, as well as elements from the fifth period like Zr, Nb, Mo, and Sn, and sixth-period metals such as Hf, Ta, W, and Pb. Additionally, metalloids such as Si and B are sometimes included. Due to the combined effects of high entropy, lattice distortion, sluggish diffusion, and the "cocktail effect," HEAs exhibit superior properties such as high strength, hardness, wear resistance, oxidation resistance, and corrosion resistance—characteristics that are difficult to achieve simultaneously in traditional alloys. Adding elements like Ti, Si, Cr, and Al to Ni-based alloys has been shown to significantly enhance their oxidation resistance. Related research shows the effects of Ti, V, and Si on the oxidation behavior of these alloys. [8] As shown in Fig. 2, Ti and Si enhance oxidation resistance, while V has a detrimental effect. What’s more, Senkov O N et al.’study shows that quaternary MoNbTaW and quinary MoNbTaVW alloys have melting points as high as 2600°C, which exceed the melting points of any of their individual constituent elements. Hence, adding elements like Mo, V, and Nb to Ni-based alloys can elevate their melting points and improve high-temperature performance.[9]

Figure 2: The isothermal oxidation curves for the HEAs at 1300 °C, showing the effects of Ti, V and Si addition [8]

In addition, high-entropy alloy coatings are also a viable approach. Liu L et al. successfully produced a FeCoNiCrMo HEA coating on 15CrMo boiler tubes. The oxidation rate constant of Ni-based alloys with the HEA coating in the steady-state stage was determined to be 2.45×10-5, showing a two-order magnitude reduction compared to conventional Ni-based superalloys. [10]

HEAs exhibit excellent hardness, corrosion resistance, and high-temperature performance, particularly under harsh conditions such as strong acidic environments and high temperatures. However, their corrosion resistance decreases significantly at elevated temperatures in molten salt environments. Additionally, theoretical research on HEAs remains underdeveloped, leading to a degree of experimental uncertainty in composition design. Incorporating high-entropy elements directly into Ni-based alloys may result in compositional inhomogeneity, and when used as coatings, issues like micro-cracks and internal stress may affect structural stability and service life. Therefore, further optimization is necessary for practical applications.

2.2. oxide dispersion strengthening (ODS)

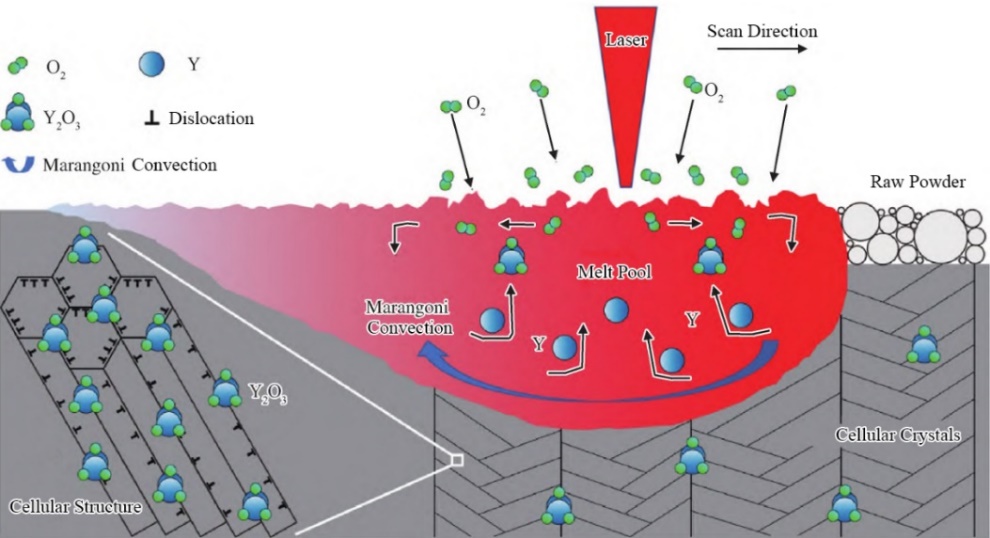

Research on oxide dispersion strengthening (ODS) technology began in the early 20th century, initially using traditional powder metallurgy processes to prepare oxide dispersion strengthened tungsten. Grain boundary strengthening, solid solution strengthening, dislocation strengthening, and second-phase strengthening are the main strengthening mechanisms of ODS high-temperature alloys. ODS high-temperature alloys improve their mechanical properties by introducing nano-sized inert particles with high thermal and chemical stability (e.g., ThO2, Y2O3, and Al2O3), which are dispersed throughout the matrix and hinder dislocation and grain boundary movement. Related research finds that ODS steel remains stable even at 1150°C, while the oxides in ODS steel also maintain excellent stability. [11]ODS high-temperature alloys are primarily categorized into two types: iron-based and nickel-based. Nickel-based ODS alloys can further be classified into two subtypes: one with a Ni or Ni-Cr matrix with low Al and Ti content, and the other with increased Al and Ti content, along with added W, Mo, Ta, and other elements that stabilize the γ' phase, enabling co-strengthening from both the γ' phase and the nano-oxides. [12] Y2O3 is the most commonly used dispersoid in ODS alloy production. Additionally, other dispersoids (e.g., ZrO2, HfO2, La2O3, Ce2O3, Al2O3, MgO, V2O3, and YH2) have gradually been used by researchers to produce different oxide dispersion-strengthened high-temperature alloys. Fig. 3. illustrates the in-situ formation process of Y2O3 particles within an ODS Nickel-based alloy produced via Laser Powder Bed Fusion (LPBF). The ODS nickel-based alloy, synthesized through LPBF in situ, demonstrates exceptional high-temperature mechanical properties. This process offers a novel approach to developing alloys with oxide dispersion strengthening through additive manufacturing.

Figure 3: Schematic diagram of in-situ formation for Y2O3 particles in ODS Nickel-based alloy prepared by LPBF[13]

Nickel-based ODS high-temperature alloys exhibit outstanding properties at high temperatures, including superior strength, creep resistance, oxidation resistance, and mechanical strength. Therefore, oxide dispersion strengthening technology may enhance the application of nickel-based alloys in ultra-supercritical high-temperature environments. Tang Q et al.’s search have shown that trace additions of elements such as Ti, Mg, Zr, Ca, and Hf can refine particles and reduce segregation. In the future, modifying the types, ratios, and trace elements added to nickel-based alloys may further improve their performance. [14]

However, the formation and evolution of nano-oxides are exceptionally complex, often resulting in the inclusion or formation of impurities during the preparation of nickel-based alloys, which can affect the overall performance of the alloy. Additionally, compared to the nano-oxide particles in ODS iron-based alloys, the oxide particles in nickel-based ODS high-temperature alloys are much coarser. Further research is needed on reducing oxide particle size and inhibiting grain boundary sliding and migration at high temperatures. [15]

3. Characterization Methods

3.1. Morphology and Elemental Characterization

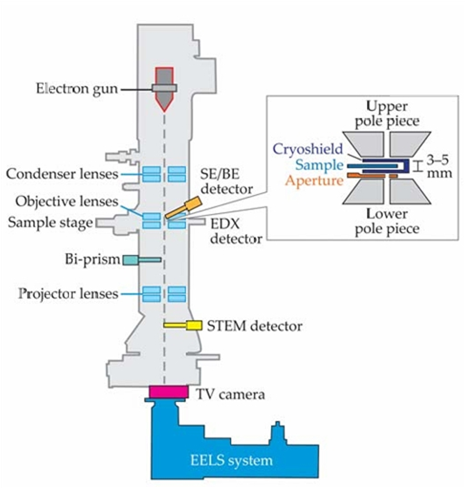

Transmission electron microscopy (TEM) is a critical tool for characterizing the microstructure of materials, primarily used for morphology and elemental characterization. On June 4, 1931, Knoll and Ruska first reported the successful development of the world's first transmission electron microscope (TEM). TEM uses a focused electron beam with an extremely short wavelength as the illumination source. It employs thin film samples (101-103 nm) that are transparent to the electron beam. The transmitted electrons form the imaging signal, and the image is magnified using electromagnetic lenses, resulting in high resolution and magnification. The resolution of TEM is typically 0.1~0.2 nm, with magnifications up to one million times. The TEM is mainly composed of three basic parts: the electron optics system, the vacuum control system, and the power supply system. [16]

The basic structure of the TEM is shown in Fig. 4, which illustrates its system of an electron gun, lenses, sample stage, and detectors. Dedicated detectors collect various signals for diffraction and imaging (STEM detector for scanning transmission electron microscopy mode), energy-dispersive X-ray spectroscopy (EDX), secondary and backscattered electron measurements (SE/BE), off-axis electron holography (bi-prism), and electron energy-loss spectroscopy (EELS). The inset is a close-up of the objective lens, which typically has upper and lower pole pieces. The sample area, objective aperture, and a contamination-reducing cryoshield are all located in the gap between the two pole pieces. [17]

Figure 4: A schematic of a typical transmission electron microscope[17]

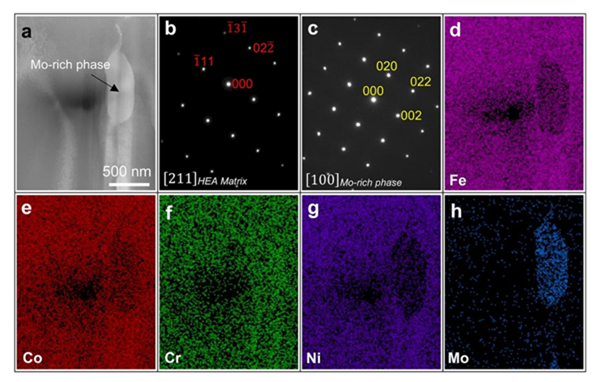

For instance, Darius Tytko et al. investigate the microstructural evolution of a Ni-based superalloy (617B) was studied at 700°C using TEM, revealing that the grain boundaries of this alloy exhibited a serrated appearance and were decorated with M23C6 particles.[18] Similarly, Kong Qingping et al. used transmission electron microscopy (thin-film technique) to directly observe the dislocation structures of Ni80Cr20Ti alloy after creep deformation. This method has proven highly effective in revealing the microscopic creep processes. Additionally, as shown in Fig. 5, Liu L et al. used bright-field transmission electron microscopy (TEM) to observe the presence of a Mo-rich phase along grain boundaries in the FeCoNiCrMo high-entropy alloy coating after 500 hours of oxidation at 900℃ (a). The electron diffraction patterns were collected for both the Mo-rich phase (b) and the interior grain of the high-entropy alloy coating (c). Additionally, elemental distribution maps were obtained through energy-dispersive X-ray spectroscopy (EDS) analysis (d-h).[10]

Figure 5: The TEM characterization results of the FeCoNiCrMo high-entropy alloy [10]

Traditional research on the microstructural evolution, deformation, and strengthening mechanisms of Ni-based superalloys has primarily used post-TEM analysis, but its limitations, such as low sampling rates and inability to capture dynamic processes, are evident. With advancements in in-situ high-temperature mechanical TEM techniques, methods like high-temperature, mechanical, and combined high-temperature + mechanical in-situ TEM now enable real-time observation of microstructures under high-temperature conditions. Next-generation ultra-supercritical power plants aim to operate Ni-based superalloys at 700-720 ℃ and steam pressures up to 393 bar to enhance efficiency.[19] In-situ TEM experiments offer direct observation of dynamic microscale processes, allowing precise tracking of microstructural evolution and underlying mechanisms. The rapid development of electron microscopy has also led to innovations like STEM, UTEM, Cryo-TEM, in-situ TEM, and spherical aberration-corrected TEM, significantly expanding the capabilities and applications of TEM technology. [20]

3.2. Mechanical Properties Characterization

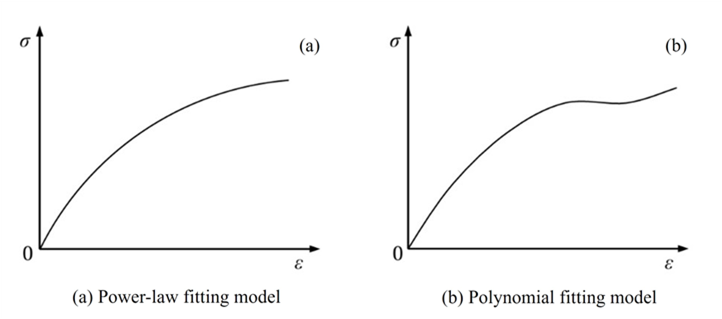

The stress-strain curve is a fundamental tool for evaluating the mechanical behavior of metallic materials, illustrating the relationship between stress and strain during loading. Typically, quasi-static standard tensile tests are used to measure the stress-strain curves of metals. In these curves, the horizontal axis represents strain, indicating the degree of deformation per unit length, while the vertical axis represents stress, denoting the force per unit area. The shape of the stress-strain curve is closely tied to the properties of the metal; analyzing its features allows for the determination of a material's elasticity, plasticity, and fracture behavior.[21] From the curve, we can also calculate the yield strength and examine the material’s behavior under stress, which is crucial for assessing the effectiveness of modifications in nickel-based alloys.Given the increasingly widespread application of metallic materials in high-temperature environments, and particularly in ultra-supercritical conditions characterized by high pressure, it is essential to understand that metals exhibit distinct mechanical properties at elevated temperatures compared to ambient conditions. Therefore, investigating the mechanisms that control yield strength under high-temperature and high-pressure conditions, as well as the temperature dependence of these properties, is of theoretical and engineering significance for elucidating the underlying physical mechanisms and evolutionary patterns. [22] For practical engineering applications, the stress-strain relationship of a material is often expressed in a functional form: \( \bar{σ }= F( \bar{ε }) \) . In practice, experimental data is commonly fitted using appropriate functional equations to obtain regression models, as demonstrated in Fig. 6, which shows two typical fitting models:

Figure 6: Simplified models of stress-strain curves [23]

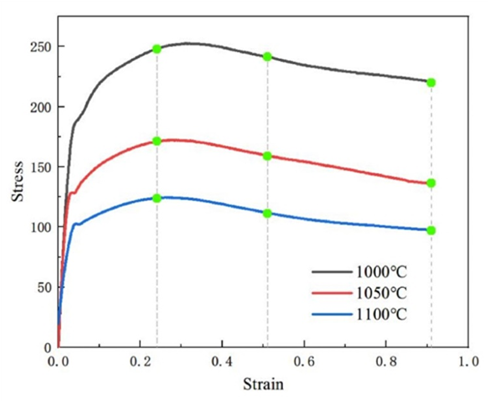

For instance, Ren Shuai plotted the stress-strain curves for A2 nickel-based powder metallurgy superalloy and GH141 nickel-based superalloy, revealing the effects of temperature and strain rate on their hot deformation behavior and predicting stress-strain curves under different deformation conditions.[24] Similarly, Huang F et al. demonstrated through stress-strain curves that the competition between work hardening and softening, driven by dynamic recovery and dynamic recrystallization, influences stress variations and microstructure evolution under various deformation conditions in nickel-based alloys, as shown in Fig. 7.[25]

Traditional stress-strain curves are limited to measuring in-plane deformation of flat objects. The Digital Image Correlation method, developed by Pan Bing et al., enables three-dimensional, full-field, non-contact, and high-precision measurement of objects. This technology provides a comprehensive representation of the stress-strain behavior of nickel-based alloys in ultra-supercritical high-temperature environments.[26] Studies indicate that creep performance is a critical factor for nickel-based alloys used in ultra-supercritical power units. While stress-strain curves typically measure the instantaneous mechanical properties over a short period, high-temperature creep tests focus on time-dependent plastic deformation under prolonged high-temperature stress. Through creep testing, the deformation rate, creep rupture, and long-term strength characteristics of the alloy under sustained high temperatures can be analyzed. Mechanical characterization of the alloys may also include microhardness and Brinell hardness testing to determine hardness, tensile testing to measure tensile strength, and impact and high-temperature endurance testing to assess strength. These comprehensive mechanical characterization techniques provide detailed information about the alloy’s performance under extreme conditions, enabling an accurate assessment of the effects of alloy modifications and guiding optimization of alloy composition and heat treatment processes.

Figure 7: The stress-strain curves at different temperatures [25]

4. Conclusions

In this paper, we discussed various contemporary modification techniques and characterization methods, including high-entropy alloying (HEAs) and oxide dispersion strengthening (ODS). Researchers can now observe the entire process of alloy behavior at elevated temperatures, rather than just instantaneous phenomena. Transmission electron microscopy (TEM) has revealed precipitates at grain boundaries in nickel-based alloys and their influence on the mechanical properties of the alloys, paving the way for microstructural optimization. In addition, utilizing mechanical characterization methods such as stress-strain curves, hardness testing, and high-temperature endurance testing enables the evaluation of alloy performance under varying conditions. Detailed analyses of the performance of nickel-based alloys under ultra-supercritical conditions using these characterization techniques are crucial for further advancements.

Future research should focus on the following areas: 1. optimization of material composition. Introducing new alloying elements or adjusting the proportions of existing ones to enhance high-temperature stability and creep resistance, particularly improving performance at temperatures exceeding 700°C. 2. precision control of nanostructures. Advancements in high-resolution electron microscopy and atom probe technologies will enable more accurate characterization of the nanostructures and defect evolution in nickel-based alloys, facilitating deeper material optimization. 3. long-term service performance studies. Conducting long-term aging experiments and creep tests under actual operating conditions of ultra-supercritical units to gain insights into the performance changes and failure mechanisms of materials during extended high-temperature service. Moreover, the processing methods of the alloys play a crucial role in determining their properties. For instance, solution treatment processes can significantly enhance the tensile and yield strengths of the materials.

References

[1]. Lin Fusheng ,Xie Xishan ,Zhao Shuangqun ,et al. Selection of Superalloys for Superheater Tubes of Domestic 700 ℃ A-USC Boilers [J]. Journal of Chinese Society of Power Engineering,2011,31(12):960-968.

[2]. Ding Jianbo ,Zhou Guangli ,Liu Zhibao ,et al. Research on joint technology of new energy and thermal power [J]. China Energy and Environmental Protection,2024,46(02):184-190+197.

[3]. Tian Zhihao. Research on Microstructure and Property of 617B Alloy Used For 700℃ USC Boiler [D]. Shanghai Jiao Tong University,2020.

[4]. Li Yao ,Yang Xiaobing ,Xiao Zhangyu ,et al. Research on Casting Technology of Ultra-supercritical Nickel-based High-temperature Alloy Ultra-high Pressure Inner Cylinder at 650℃[J]. Heavy Casting and Forging,2024,(01):1-6.

[5]. Zhou Gangbao. Experimental Study on High-temperature Low Cycle Fatigue Performance of Inconel 617 and C-HRA-2 Alloys for Advanced Ultra-supercritical Units [D]. North China Electric Power University (Beijing),2022.

[6]. Yeh J W , Lin S J , Chin T S ,et al.Formation of simple crystal structures in Cu-Co-Ni-Cr-Al-Fe-Ti-V alloys with multiprincipal metallic elements[J].Metallurgical & Materials Transactions A, 2004, 35(8):2533-2536.

[7]. Wang Z, Zhang S. Research and application progress of high-entropy alloys[J]. Coatings, 2023, 13(11): 1916.

[8]. S. Q ,Zhang,CM,et al.Microstructure and oxidation behavior of new refractory high entropy alloys[J].Journal of Alloys & Compounds An Interdisciplinary Journal of Materials Science & Solid State Chemistry & Physics, 2014.

[9]. Senkov O N, Wilks G B, Miracle D B, et al. Refractory high-entropy alloys[.Intermetallics,2010,18(9):1758-1765

[10]. Liu L, Zhang J, Zhai C, et al. Addressing challenges in high-temperature oxidation of ultra-supercritical boiler tubes via FeCoNiCrMo high-entropy alloy coatings[J]. Surface and Coatings Technology, 2024, 477: 130351.

[11]. Yan Peiyun. Effects of Hf Addition on the Thermal Stability of FeCrAl ODS Steels [D]. Tianjin University,2017.

[12]. Liu Guangzu, Tian Yun, Shan Bingquan. Oxide dispersion strengthened superalloys. Powder Metallurgy Technology, 2001, 19(1): 20-23.

[13]. Zhao Ding-guo ,Li Yue ,Liu Yan ,et al. Research progress for manufacturing technology of advanced oxide dispersion strengthened steel [J]. China Metallurgy,2023,33(03):1-16.

[14]. Tang Q, Hoshino T, Ukai S, et al. Refinement of oxide particles by addition of Hf in Ni-0.5 mass% Al-1 mass% Y2O3 alloys[J]. Materials transactions, 2010, 51(11): 2019-2024.

[15]. He Wuqiang.Preparation,Microstructure and Property of Oxide Dispersion Strengthened Nickel-based Superalloys [D]. Central South University,2022.

[16]. Zhang Baolin ,Yi Nan ,Zhu Rongying ,et al . Analysis of transmission electron microscope and scanning electron microscope [J]. Wireless Internet Technology, 2016(23):2.

[17]. Zhu Y, Dürr H. The future of electron microscopy[J]. Physics Today, 2015, 68(4): 32-38.

[18]. Tytko D, Choi P P, Klöwer J, et al. Microstructural evolution of a Ni-based superalloy (617B) at 700 C studied by electron microscopy and atom probe tomography[J]. Acta materialia, 2012, 60(4): 1731-1740.

[19]. Viswanathan R, Gandy D, Coleman K. Proc of the 5th EPRI. ASM International; 2008.

[20]. Dong Quanlin ,Jiang Yueling ,Wang Jiujiu ,et al . A brief review on the history of the development of transmission electron microscope [J]. Journal of Chinese Electron Microscopy Society,2022,41(06):685-688.

[21]. Wang Lu. Effects of Particle Size and Mixture of Particle Types on Stress-strain Curve of Particle Reinforced Iron Matrix Composite Using Molecular Dynamic Simulation [D]. Northeastern University,2016.

[22]. Li Weiguo, Shao Jiaxing, Kou Haibo, et al. Research Progress on the Theoretical Characterization Methods for the High-temperature Mechanical Properties of Materials [J]. Chinese Journal of Solid Mechanics, 2017, 38(2):31.

[23]. Li Li. Research on Forming Limit of Aluminum Alloy Sheets Based on Different Stress-strain Curve Models [J].[2024-10-14].

[24]. Ren Shuai. Hot Deformation Behavior and Microstructure Evolution of Nickel-based Superalloys during Hot Deformation [D]. Yantai University, 2022.

[25]. Huang F , Song Y , Li Y ,et al. Microstructure evolution of high-temperature deformation behavior of nickel based alloys for advanced ultra-supercritical applications[J].Materials Chemistry and Physics, 2024, 314.

[26]. Pan Bing, Xie Huimin, Li Yanjie. Three-dimensional Digital Image Correlation Method for Shape and Deformation Measurement of an Object Surface [J]. Journal of Experimental Mechanics, 2007, 22(6):555-567.

Cite this article

Bao,Z. (2025). Modification and Characterization for Nickel-Based Alloys used in Ultra-Supercritical Units. Applied and Computational Engineering,130,159-168.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 5th International Conference on Materials Chemistry and Environmental Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Lin Fusheng ,Xie Xishan ,Zhao Shuangqun ,et al. Selection of Superalloys for Superheater Tubes of Domestic 700 ℃ A-USC Boilers [J]. Journal of Chinese Society of Power Engineering,2011,31(12):960-968.

[2]. Ding Jianbo ,Zhou Guangli ,Liu Zhibao ,et al. Research on joint technology of new energy and thermal power [J]. China Energy and Environmental Protection,2024,46(02):184-190+197.

[3]. Tian Zhihao. Research on Microstructure and Property of 617B Alloy Used For 700℃ USC Boiler [D]. Shanghai Jiao Tong University,2020.

[4]. Li Yao ,Yang Xiaobing ,Xiao Zhangyu ,et al. Research on Casting Technology of Ultra-supercritical Nickel-based High-temperature Alloy Ultra-high Pressure Inner Cylinder at 650℃[J]. Heavy Casting and Forging,2024,(01):1-6.

[5]. Zhou Gangbao. Experimental Study on High-temperature Low Cycle Fatigue Performance of Inconel 617 and C-HRA-2 Alloys for Advanced Ultra-supercritical Units [D]. North China Electric Power University (Beijing),2022.

[6]. Yeh J W , Lin S J , Chin T S ,et al.Formation of simple crystal structures in Cu-Co-Ni-Cr-Al-Fe-Ti-V alloys with multiprincipal metallic elements[J].Metallurgical & Materials Transactions A, 2004, 35(8):2533-2536.

[7]. Wang Z, Zhang S. Research and application progress of high-entropy alloys[J]. Coatings, 2023, 13(11): 1916.

[8]. S. Q ,Zhang,CM,et al.Microstructure and oxidation behavior of new refractory high entropy alloys[J].Journal of Alloys & Compounds An Interdisciplinary Journal of Materials Science & Solid State Chemistry & Physics, 2014.

[9]. Senkov O N, Wilks G B, Miracle D B, et al. Refractory high-entropy alloys[.Intermetallics,2010,18(9):1758-1765

[10]. Liu L, Zhang J, Zhai C, et al. Addressing challenges in high-temperature oxidation of ultra-supercritical boiler tubes via FeCoNiCrMo high-entropy alloy coatings[J]. Surface and Coatings Technology, 2024, 477: 130351.

[11]. Yan Peiyun. Effects of Hf Addition on the Thermal Stability of FeCrAl ODS Steels [D]. Tianjin University,2017.

[12]. Liu Guangzu, Tian Yun, Shan Bingquan. Oxide dispersion strengthened superalloys. Powder Metallurgy Technology, 2001, 19(1): 20-23.

[13]. Zhao Ding-guo ,Li Yue ,Liu Yan ,et al. Research progress for manufacturing technology of advanced oxide dispersion strengthened steel [J]. China Metallurgy,2023,33(03):1-16.

[14]. Tang Q, Hoshino T, Ukai S, et al. Refinement of oxide particles by addition of Hf in Ni-0.5 mass% Al-1 mass% Y2O3 alloys[J]. Materials transactions, 2010, 51(11): 2019-2024.

[15]. He Wuqiang.Preparation,Microstructure and Property of Oxide Dispersion Strengthened Nickel-based Superalloys [D]. Central South University,2022.

[16]. Zhang Baolin ,Yi Nan ,Zhu Rongying ,et al . Analysis of transmission electron microscope and scanning electron microscope [J]. Wireless Internet Technology, 2016(23):2.

[17]. Zhu Y, Dürr H. The future of electron microscopy[J]. Physics Today, 2015, 68(4): 32-38.

[18]. Tytko D, Choi P P, Klöwer J, et al. Microstructural evolution of a Ni-based superalloy (617B) at 700 C studied by electron microscopy and atom probe tomography[J]. Acta materialia, 2012, 60(4): 1731-1740.

[19]. Viswanathan R, Gandy D, Coleman K. Proc of the 5th EPRI. ASM International; 2008.

[20]. Dong Quanlin ,Jiang Yueling ,Wang Jiujiu ,et al . A brief review on the history of the development of transmission electron microscope [J]. Journal of Chinese Electron Microscopy Society,2022,41(06):685-688.

[21]. Wang Lu. Effects of Particle Size and Mixture of Particle Types on Stress-strain Curve of Particle Reinforced Iron Matrix Composite Using Molecular Dynamic Simulation [D]. Northeastern University,2016.

[22]. Li Weiguo, Shao Jiaxing, Kou Haibo, et al. Research Progress on the Theoretical Characterization Methods for the High-temperature Mechanical Properties of Materials [J]. Chinese Journal of Solid Mechanics, 2017, 38(2):31.

[23]. Li Li. Research on Forming Limit of Aluminum Alloy Sheets Based on Different Stress-strain Curve Models [J].[2024-10-14].

[24]. Ren Shuai. Hot Deformation Behavior and Microstructure Evolution of Nickel-based Superalloys during Hot Deformation [D]. Yantai University, 2022.

[25]. Huang F , Song Y , Li Y ,et al. Microstructure evolution of high-temperature deformation behavior of nickel based alloys for advanced ultra-supercritical applications[J].Materials Chemistry and Physics, 2024, 314.

[26]. Pan Bing, Xie Huimin, Li Yanjie. Three-dimensional Digital Image Correlation Method for Shape and Deformation Measurement of an Object Surface [J]. Journal of Experimental Mechanics, 2007, 22(6):555-567.