1. Introduction

The electronic control system in the automobile is composed of various electronic components, such as sensors and automobile connectors. Due to the high degree of integration and complexity of these electronic components, their failure occurs from time to time, which leads to some functions of the car can not operate normally, such as the car headlights can not be turned on. These functional failures are likely to put the safety of passengers at risk. Therefore, in order to ensure the normal operation of each function of the car, it is very important to analyze the fault efficiently and accurately and determine the reasons for the failure of the parts.

When a car breaks down, how to quickly analyze the fault, locate the fault and confirm the cause of the fault is very important. Failure of any part of the system can cause problems in the operation of the whole system. General failures can lead to performance degradation or failure to start the vehicle, while severe failures can lead to major safety accidents. This requires us in the process of vehicle operation, timely monitor and correct judgment of the running state, as soon as possible to find fault and take corresponding measures to ensure its high performance and high reliability, and improve the efficiency of operation. [1]

One of the most important problems is how to accurately locate and resolve faults. If the fault is not discovered in time, or the fault is incorrectly judged, the consequences will be more serious. Therefore, we can use FMEA and FTA methods to analyze the fault in the process of car operation. These two analysis methods can analyze the fault more effectively and accurately, determine the most basic events leading to the fault, and find the correct solution.

Functional safety also plays an important role in automobiles. Due to the influence of market demand, consumers have higher requirements for the functionality of vehicles, which also leads to a further increase in the complexity of vehicles. Therefore, the functional safety of the vehicle system should also meet the standards and reach a certain level of functional safety requirements, so that the safety and stability of the vehicle can be improved. Based on the above analysis methods, we can locate and analyze faults efficiently and accurately.

In the second part, we will introduce the FMEA analysis method and FTA analysis method, and the use of two methods to analyze the specific steps and requirements of the problem. In the third part, we will cite a specific case of car function failure, analyze it with the above method, and give the failure reason, possible consequences, and solutions to this problem. In the conclusion part, we will summarize the results of the paper and briefly describe the problems to be solved and the solutions. Finally, we will summarize the positive impact of the research results on solving practical problems.

1.1. Related work

FMEA and FTA are widely used in the field of fault analysis.

In [1], the author used FMEA analysis method to analyze the possible failure modes of the Vehicle VCU (Vehicle control unit) system and the impact of component failure. Then based on the ISO26262 functional safety standard, for the system's functional safety problems are further analyzed.

In [2], the author introduced FMEA analysis method and FTA analysis method and used the two methods to solve the fault location and fault analysis of the transmission failure of tracked vehicles, and put forward the method of self-detection fault.

In [3], the author used FMEA analysis method and FTA analysis method to analyze battery safety problems and described detailed methods and steps to determine the most basic causes of failures in the paper.

In [4], the author made a work analysis of the main architecture of VCU based on the requirements of functional safety by using FTA analysis method, and then designed and determined the main architecture of VCU based on the results of functional safety analysis.

In [5], the author used FMEA and FTA methods to analyze the reliability of the vehicle SBW system (Steering-By-Wire System) and calculated the failure rate and importance of the system.

2. FMEA analysis and FTA analysis

2.1. FMEA analysis

By analyzing the failure mode of each component, and then analyzing the impact of each component on the whole system, FMEA analysis can analyze the reliability of the system or determine the cause of failure [2]. It can be used to analyze parts or entire systems and minimize the impact of failures. FMEA is a bottom-up fault analysis method. It can analyze the consequences and damage degree of parts failure and system failure. The failure modes and effects of all parts can be fully considered. At the same time, we can find the parts and failure modes that have a significant impact on the system and analyze their impact degree. FMEA analysis process steps are as follows:

1. List the components.

2. For each component, list all failure modes.

3. For each component/failure mode, list the impact on the next higher level.

4. For each component/failure mode, list the severity of the impact (i.e., the higher failure mode).

2.2. FTA analysis

FTA analysis method is a graphic deductive method [3]. By analyzing the possibility of various factors that cause system faults, it can draw a fault tree to explain the causes of fault events and the logical relationship between these causes and events [4]. And there will be two relationships with “and” and “or”. The purpose is to identify basic faults and determine the cause, impact, and probability of failure. FTA is a top-down fault analysis method [5]. From the perspective of system failure occurrence, the failure of subsystems, parts, and components is analyzed in the reverse process.

3. Vehicle failure analysis and failure solution

3.1. Problem posing

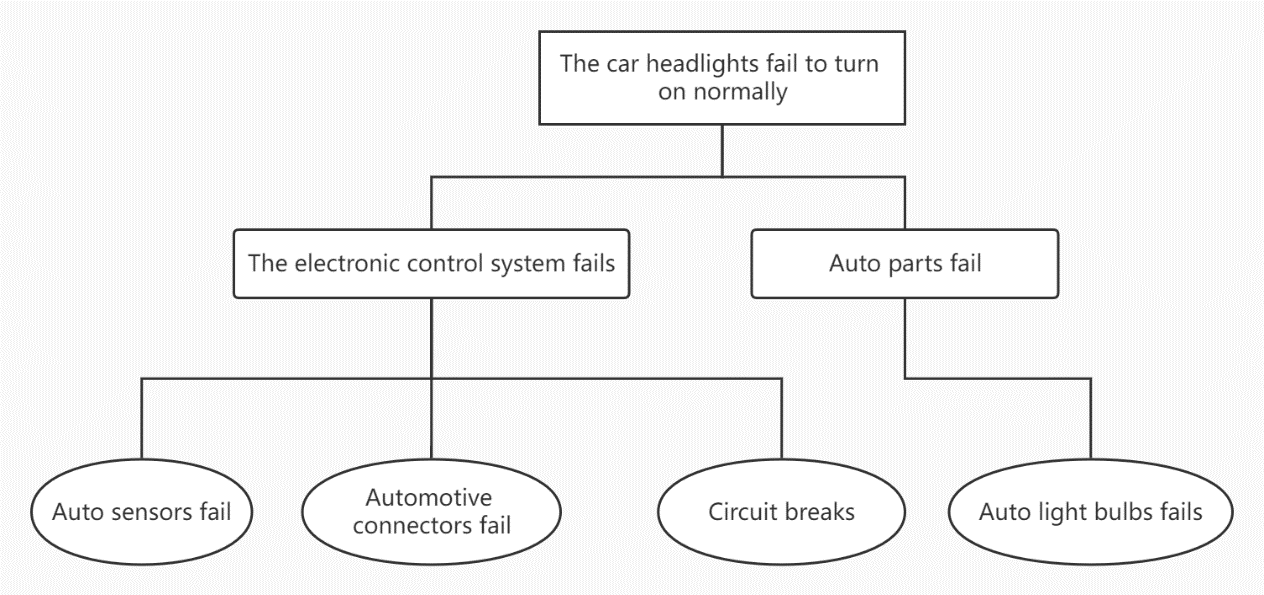

This paper will use a common fault in the process of car use as an example for fault analysis, to demonstrate in detail the application of FTA and FMEA in car fault analysis. The event we analyzed was a car headlight failure. Before using FTA analysis, we should first determine the top-level event. For the problem of car headlight failure, the top-level event can be determined as the failure of car headlights to turn on normally, and then FTA analysis can be used to analyze from top to bottom until the most basic event leading to the failure is analyzed [6].

3.2. Work flow

First, determine the top-level event: the car headlights fail to turn on normally.

|

Figure 1. FTA fault analysis diagram. |

Fig1 shows that the top event we have determined is that the car headlights cannot be turned on normally, so it is written on the top layer of FTA. Through analysis, we can know that when the two reasons for “The electronic control system fails” and “Auto parts fail” occur separately, there will be a fault that the headlights of the car cannot be opened normally. Therefore, the logic door of the first layer is “or”. Then we analyze the “The electronic control system fails”. Its bottom layer is the most basic cause events, they are: (1) “Auto sensor fails”, (2) “Automotive connector fails”, and (3) “Circuit breaks”. The presence of one or more of them together will affect the upper-level event, which is to disable the electronic control system, so the logic gate of the second layer is also “or”.

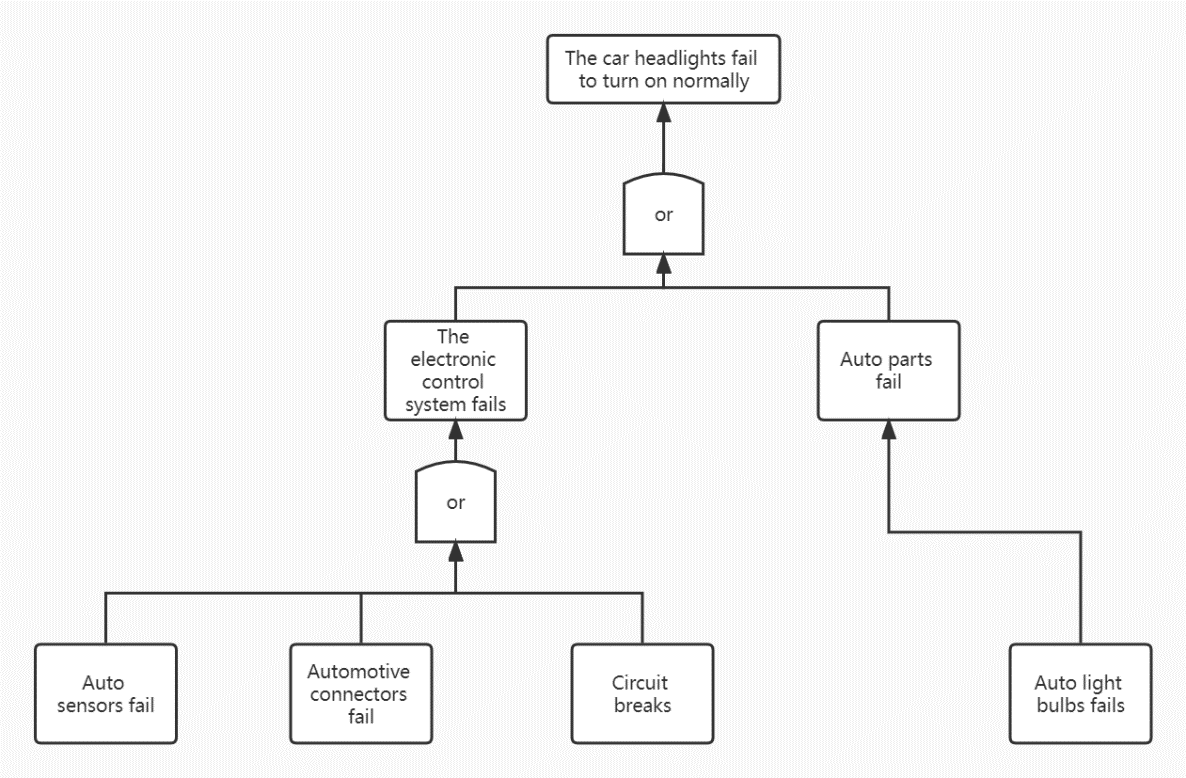

Now the improved FTA fault analysis diagram, including the logic gates section, is shown below in Fig2.

| |

Figure 2. Improved FTA fault analysis diagram. | |

Fault location: Through FTA analysis, the most basic event leading to the failure of the headlights can be obtained, but the specific causes of the failure cannot be determined. Therefore, we can use FMEA analysis method and the bottom-up analysis of the system to determine the most basic cause of failure [7]. The failure of the electronic control system caused by the fault is more common, and the problem is difficult to determine. Below we will do FMEA analysis for the failure of the electronic control system. The result is shown in Fig3.

FMEA analysis begins with identifying failure modes of actual events. For example, in the event “the car headlights fail to turn on normally”, the items to be analyzed are sensors failure, car connectors failure, and circuit break.

For sensors failure, the failure mode is when the sensor cannot work normally. The failure reason is that sensors are damaged and cannot normally receive signals from the external environment, which leads to the failure to determine whether the headlight needs to be turned on. The car’s automatic headlights are not working. At this point, the driver needs to determine whether the current driving environment needs to turn on the headlights. The function of manually turning on the headlights is not affected, so the sensor failure has little impact on safety.

For auto connectors failure, the failure mode is when auto connectors cannot transmit signals because they are damaged or the connection is unstable. At this time, the signal transmission in the system will be affected. The system cannot transmit the signal, so the automatic and manual functions of the headlamp will be affected. If the driver is driving at night, or in the case of poor visibility driving, the car headlights cannot be opened properly for driving safety has a very serious impact. The driver’s vision is affected and he was unable to judge the dangers on the road, which may lead to accidents and failure to ensure safety.

For circuit break, the failure mode is internal circuit open or short circuit, due to circuit damage. In this case, the signal cannot be transmitted and the car headlights cannot be turned on. This may lead to a large current flow in the circuit, cause temperature rise, further damage to other parts of the circuit, and even lead to the possibility of fire. In the case of a circuit break, the automatic and manual functions of headlights will be affected, and then cause the driver’s driving safety problems in the case of poor sight.

3.3. Suggested solutions

When designing the system, we should add the self-detection function of the sensor. The car system should monitor in real-time whether the sensors are working properly. If something goes wrong, the system should prompt the driver to repair or replace the sensor and test it. After replacing the sensors, the car’s automatic headlights should return to normal function.

In the design of the system, the car connector part should be added to the detection circuit function. If the auto connector fails, the detection circuit sends a signal to the system, indicating that the auto connector in the circuit of a specific function fails and should be replaced. After replacement, the car headlights should return to normal function.

When designing the circuit, we should add a protection circuit. When there is a fault in the circuit, it will automatically power off for protection, and send information to the system, indicating that the circuit fault should be repaired. When the circuit is repaired, the car’s headlights function will return to normal.

3.4. Conclusion of functional safety analysis

Safety objective: to prevent the failure of the car headlights to turn on normally.

We have carried out FMEA and FTA analysis for the fault that the car headlights cannot be opened normally. We analyzed the fault accurately, identified the most basic events leading to the fault, and proposed the improvement scheme during the system design. Based on the above analysis and in conjunction with ISO 26262 [8], the proposed system should meet the ASIL B safety requirements.

4. Conclusion

In modern automobiles, a large number of electronic components and intelligent control systems are widely used. These devices ensure the normal operation of the various functions of the car. If one part of the control system fails, the functions of the car will be seriously affected, so it is important to analyze the failure and propose solutions to the problem. We use FMEA and FTA analysis methods to analyze the reasons for the failure of automobile headlights caused by the failure of the automobile electronic circuit system. We determine the most basic events by determining the top-level events and FTA analysis. Then use FMEA method to analyze the failure mode and the severity of the consequences caused by failure. Finally, through the functional safety analysis, we put forward some suggestions for the system design, so that the reliability and security of the system are guaranteed. FTA method and FMEA method are very efficient and accurate for analyzing automobile faults, and this analysis method also provides help for improving the controlling system.

References

[1]. Zhao Yongqiang, Zhao kaicheng, Li Chang and Li Xiang.Development of the safety diagnosis system for VCU of pure electric vehicle, Journal of Physics: Conference Series 1605 (2020) 012033

[2]. ZHANG Yongfeng, ZHOU Renbin, Yang Jiemin, and ZHANG Zheng. Application of FTA-FMEA method in Fault Diagnosis of Tracked Vehicle Advanced Materials Research Vol 940 (2014) pp 112-115

[3]. M. Held ⁎, R. Brönnimann. Safe cell, safe battery? Battery fire investigation using FMEA, FTA, and practical experiments

[4]. Liu Boyu, Li Yanwen. Research on Vehicle Control Unit Based on Functional Safety, 2nd Asia-Pacific Conference on Intelligent Robot Systems 2017

[5]. LIU Zhao. Application of FMEA and FTA Methods to the Reliability Analysis of Steer-by-wire System[J]. Mechanical and Electronic.2009, (9), p.40-43

[6]. IEC 61025, Fault Tree Analysis (FTA), 2006

[7]. IEC 60812, Analysis Techniques for System Reliability - Procedure for Failure Mode and Effects Analysis (FMEA), 2006.

[8]. ISO 26262:2011, “Road vehicles-Functional safety,” International Organization for Standardization, first edition, 2011.

Cite this article

Zhao,Z. (2023). Vehicle fault diagnosis using FTA and FMEA method. Applied and Computational Engineering,6,84-89.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 3rd International Conference on Signal Processing and Machine Learning

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Zhao Yongqiang, Zhao kaicheng, Li Chang and Li Xiang.Development of the safety diagnosis system for VCU of pure electric vehicle, Journal of Physics: Conference Series 1605 (2020) 012033

[2]. ZHANG Yongfeng, ZHOU Renbin, Yang Jiemin, and ZHANG Zheng. Application of FTA-FMEA method in Fault Diagnosis of Tracked Vehicle Advanced Materials Research Vol 940 (2014) pp 112-115

[3]. M. Held ⁎, R. Brönnimann. Safe cell, safe battery? Battery fire investigation using FMEA, FTA, and practical experiments

[4]. Liu Boyu, Li Yanwen. Research on Vehicle Control Unit Based on Functional Safety, 2nd Asia-Pacific Conference on Intelligent Robot Systems 2017

[5]. LIU Zhao. Application of FMEA and FTA Methods to the Reliability Analysis of Steer-by-wire System[J]. Mechanical and Electronic.2009, (9), p.40-43

[6]. IEC 61025, Fault Tree Analysis (FTA), 2006

[7]. IEC 60812, Analysis Techniques for System Reliability - Procedure for Failure Mode and Effects Analysis (FMEA), 2006.

[8]. ISO 26262:2011, “Road vehicles-Functional safety,” International Organization for Standardization, first edition, 2011.