1.Introduction

From ancient times, people have kept working hard to find or create intensive and durable materials for different application purposes. In the past century, high-strength materials, such as alloys and composite materials, satisfied most of the application requirements by their firmness. However, as time passes, these traditional materials are facing the aging problem. Small cracks, maybe caused by pressure, temperature change or any other unpredictable factors, will rapidly expand to cause irreversible damages and eventually limit materials life [1-2]. The ancient Roman Empire makes its presence for more than 2000 years with many buildings still standing. Roman concrete with self-healing properties was used in the majority of their construction projects by 200 B.C.E. Roman concrete consisted of a mixture of lime, rock fragments volcanic ash and water. In 128 A.D., Italian researchers from Havard University found that Roman concrete was structure-enhancing [3]. In the 1980s, scientists started to study self-healing materials and try to synthesize them [1]. Scientists are inspired by the natural ability of biological tissue to self-repair, such as muscles, which contain self-healing and adhesive tissues, or blood platelets which can heal wounds on human skin after injuries. In 1993, scientists successfully synthesized a hollow tube with self-healing agents fibred inside, which was the first display of self-healing polymers. An ideal self-healing material is supposed to automatically, without any external action, recover its characteristics and integrity in a minimum amount of time necessary after suffering damage and repeating this countless times [4].

This review has summarized the recent research progress in self-healing materials used in wearable devices with mechanisms and applications. Moreover, the relationship between the materials design and device performance for self-healing properties is discussed. Finally, the review has explored the primary challenges and outlook in this promising field.

2.Introduction to Self-healing Polymers

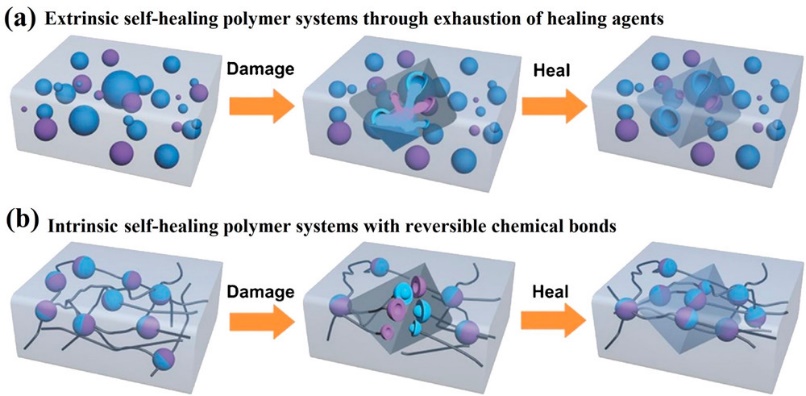

Self-healing polymers are divided into two major distinct systems: extrinsic and intrinsic self-healing polymers. (see Figure 1). Extrinsic self-healing materials contain capsules or microtubes. Spaces caused by injuries can be filled with backup materials which have been inserted. Intrinsic self-healing materials utilize the characteristics of atoms. To store more energy, the atoms tend to stay bonded, so the material will gradually fix itself after injuries [5]. Intrinsic self-healing materials rely on reversible chemical bonds throughout the piece to refill cracks.

(a)

(b)

Figure 1: Extrinsic(a) and Intrinsic(b) Self-Healing Polymer Systems [6]

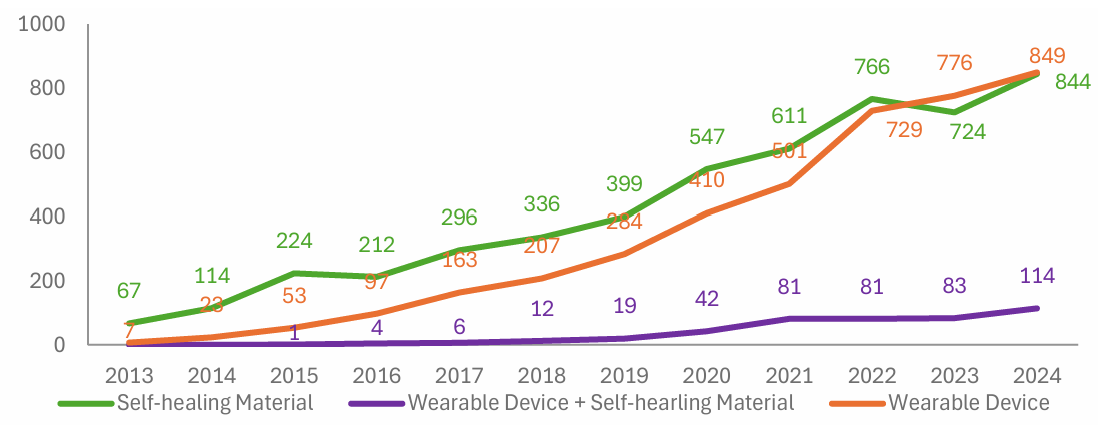

Since the 21st century, materials with self-healing ability have attracted increasing interest due to their vast prospects in the fields of medical practice, health care and electronic uses [2,7]. Figure 2 shows the number of publications at ScienceDirect has increased dramatically in the past decade. Research for both self-healing materials and wearable devices shows similar trends in the past 12 years. In the past 3-4 years, the number of publications for two topics was getting closer. Meanwhile, the publication number for wearable devices using self-healing material was notably increased significantly. Self-healing materials play an essential role in the field of wearable devices with numerous stunning applications such as flexible sensors and E-skin. It is becoming increasingly important both academically and industrially for innovative wearable devices.

Figure 2: Publications for Self-healing Material and Wearable Device at ScienceDirect [8]

3.Recent Advances of Self-healing Materials Applied in Wearable Devices

Scientists want to incorporate self-healing properties of polymers in wearable devices in multiple fields of chemical, mechanical and electronical research, as e-skin required. Three research progresses across and beyond disciplines are shared. For sure, there are many other research fields to be explored.

3.1.PBS+Ecoflex (or PDMS) Crosslinked Network

Since the irreversible environmental damages caused by undegradable plastic abuse, scientists have been studying substitutions degradable and easy to be produced. A series of organic degradable materials were developed and originated from renewable resources [9]. Poly (butylene succinate) (PBS), or poly (tetramethylene succinate) was one of the synthetic bioplastics. The invention achieved its environmentally-friendly purpose, as ingredients can be extracted from renewable resources. The networked shape of PBS gives its property of heat insulation, thus implying that PBS will rapidly form a core-shell structure, when being burnt in order to protect materials inside [5].

However, in order to reach other good properties, PBS had lost its mechanical strength to some extent. Scientists found that combining PBS to other materials is a good approach to not only prevent the problem of mechanical strength but also enable them to add new properties of the material [10]. Ecoflex was then found. Since ecoflex proved a great ability of self-healing, it should have a great potential of combination to other materials. Scientists synthesized PBS-Ecoflex complexes. The combination of PBS and Ecoflex brings a brand new multifunctional self-healing, stretchable, deformable, biocompatible, transparent, and self-adhesive [3,7]. Complex matrix structure results in multiple attributions. It can be self-repaired in 30 seconds at room temperature, while previous studies need days, and sometimes it’s inconvenient due to the requirement of high temperatures. The PBS-Ecoflex complex has extraordinary stretchability of over 500%, as well as other advantages of good thermal stability and transparency. Unlike other crosslink networks, PBS and Ecoflex complex polymers will not easily slide over each other and thus can maintain the shape for a long period, for permanent wearers, avoiding structural instability.

The two networks separate networks in the whole structure crosslinked together and form interactive forces, such as hydrogen bonds, between molecules. (Some other kinds of networks, or polymers, tend to perform redox reactions for self-healing [11].) As a result, when facing stretches, it is beneficial because the space between the two networks is larger, and the material is less likely to be damaged. And because of the crosslink structure, the molecules are bonded extremely tightly. Damages hurt less in those tightly bonded materials, as the bond energy is higher and the bonds are less likely to be broken.

Poly(dimethyl)siloxane (PDMS) is similar to EcoFlex, renowned for its biocompatibility [12]. Nowadays it is used in wearable devices and other medical circumstances. Recent progress in specialized PDMS is discovering its potential and expanding its contexts of use.

The crosslink network structures are good choices for improving materials’ endurance, which is what E-skins require. E-skins are a very good example of human-device interaction, as it was widely used in wearable devices as the layer of slightly adhesive material between human skin and sensors. E-skins were inspired by human skins, which also have self-healing abilities. E-skins were mainly designed to mimic human skin [13]. E-skins mainly focuses on the change of pressure of current. The sensors were wrapped with biodegradable, stretchable, and self-healing materials [14]. In order to perfectly reach the goal of fitting well with human skin, all of the parts of the device (including the sensors and the outside coats) should be self-healing, even self-adhesive. Parts contain uses of microelectronics, requiring newly developed or future techniques. Scientists are also focusing on combining different self-healing materials in order to reach a ‘perfect self-healing’ because nowadays research mostly discusses specific types of materials.

In e-skins, PDMS is often used in stretchable insulators. Although it requires the device to run at a high voltage, some other inorganic substrates can fix the problem [13]. PDMS polymers were supposed to mix with EGaln droplets. Once there is a crack, the droplets will be released and broken circuits will be repaired. The conductivity of the network-droplet combination shows a 108 times self-healing ability once being activated [15]. Future studies can be focused on how to mass-produce this kind of material. Besides, the self-healing property of Ecoflex and PDMS will possibly cause the material to be too dense, thus decreasing the sensitivity. This can also be a research orientation. Additionally, the leakage problem is important.

3.2.Cellulose Complexes

Throughout the history of materials, cellulose has always been a good example in any situation of needs, for its good biocompatibility, renewability, and mechanical strength [16]. Parallel-arranged chains can efficiently distribute horizontal forces, thus mitigating the forces and minimizing potential damages caused by especially pulling forces. Also, some kinds of cellulose are easy to expand by mass production, as a result of the material’s repetitive structures.

For the reasons above, cellulose-based materials show ideal properties when combined with other materials. Cellulose-based materials often contain a backbone made by other materials and nanocellulose (including cellulose nanofibers (CNFs), cellulose nanocrystals (CNCs), etc.). Similar to PBS and Ecoflex crosslink systems, cellulose, and backbone materials also play complementary roles in the whole complex, in which the two structures are tightly fixed together by both covalent and non-covalent bonds. Various combinations of nanocellulose, backbone materials, and other additional create diverse properties. Minor fluctuations may occur as a result of different synthesis processes, as people need various kinds of sensors to track their health.

There are a large number of hydrogels made of nanocelluloses. Hydrogels were often used as organic adhesives or capsule coats due to their good adhesivity and self-healing properties. So, hydrogels can be also found on flexible sensors. Cellulose is an ideal material for flexible sensors. It is UV proofed, which means patients wearing them don’t need to take it off when it’s too hot, and it won’t break). A number of the hydrogels could even reach 2108% fracture strain, a high increase compared to other previous hydrogels [17].

In order to create a self-healing, stretchable, well-biocompatible structure, some researchers choose to use lignin as a rather stable option. With the assistance of sodium lignosulfate (24) and Fe3+, this flexible carbon sensor is able to heal by itself by 91.76% in 2 hours [17]. This kind of hydrogel can tightly stick to the elders’ rough skin, and it is particularly suitable for elderly health and sleep management [17].

Recently, scientists have been studying how to 3D print self-healing polymers. This method enables the non-professionals to understand what self-healing material is, visually and clearly [18]. Inspired by the human body, scientists also developed fast-adapting mechanoreceptors (FA) and slow-adapting mechanoreceptors (SA) [19]. The textile-based tactile sensors are able to easily distinguish different body parts. Not only does it enable doctors to monitor patients’ lives so that they can remind patients to do activities on time or eat healthier, but it can also serve as a gigantic database, in which Artificial Intelligence learns [20]. AI may link to soft robotics, which can express the actions of a human-like robot based on data that AI just studied. In fact, the application of different kinds of self-healing materials tends to be so similar, but there are still slight differences. Besides soft robotics, most of the biological soft tissues can be made, including muscles, cartilage, etc. Their various properties could be determined by the concentration and alignment of CNF and CNC [17]. When to athletes, the flexible sensors made of cellulose offer a real-time recording of several indices of their body, such as sweat, frequency of breathing, etc., so that athletes and coaches can better make training plans [16]. Research has also shown that E-skin made by cellulose chains can also transmit private words underwater [21]. Wearable devices require long-time wearing, so the material aging problem is significantly important. There is a lack of research on endurance problems yet. And, even the self-healing materials occurring in nature, are time-requiring and money-requiring to be distracted. Scientists can be more focused on a cheaper way of synthesizing those practical self-healing materials. Even if it is 3D printing, it is still indispensable to ensure the mechanical strength of the materials.

3.3.Rubber Self-healing Materials

Rubber has always been renowned as a high-stretchability material. People even plant special trees to collect rubber, for a variety of reasons. Recently, scientists successfully synthesized flexible sensors using maleic acid-grafted natural rubber. The rubber formed a basic matrix along with other polymers such as polyaniline and phytic acids, as crosslinking agents. Linearity of the matrix ensures that motion-recording electrical signals can be precisely transported, starting from the flexible sensors and finally forming a 3D mimic graph of the motions of the wearer [22]. Some can reach an accuracy of 98.43% [23]. Compared to natural rubber, synthetic rubbers can be easier to obtain (as it’s can be produced by factories all around the globe, and there is no climate restriction), more widely used (including flexible electronics, various healthcare devices, adhesives, etc.) and there are no seasonal or environmental restrictions [24]. Synthetic rubber may contain different properties with a combination of other materials. Similar to other self-healing polymers, they often form irreversible covalent bonds. For example, the addition of thiourea-based polymer polyether thiourea ethylene glycol (PTUEG) in natural rubber and epoxidized natural rubber leads to extra β-hydroxyl ring-opening reaction, creating more hydrogen bonding and dynamic covalent motif [25]. Its good thermal mechanism, stability, and longevity provide a great potential for application in wearable devices. Scientists developed a kind of complex using 4,4’-methylenebis and isophorone bisurea units. There is a specialized dielectric layer, making the material maintain the same mechanical properties under wet conditions like possible sweats [26]. Most self-healing materials are biodegradable. This seems a good property, as it does positively contribute to the environment, however, this is not beneficial when compared to wearable devices. Wearable devices require materials to be long-lasting. Therefore, SR polymers combined with self-healing synthetic nitrile-based rubber become a good choice to expand the life of the products, along with heating the product for ruggedization [24].

4.Conclusion

This review discusses the recent progress of self-healing polymers applied in wearable devices including mechanical theories, pragmatic applications and potential challenges as well as future potential types of applications. So far, the most prevalent solution is to create multi-material matrices, strengthen the material, and sometimes perform extra properties. Future developments might mainly focus on practices of self-healing wearable devices in real life. It may bring a considerable number of unmet needs, such as the feasibility of mass production and the circumstances of wearing devices on joints. Scientists can also focus on the thermal mechanics and aging issues of self-healing materials. For sure, there is a long way to go from labs to life. The related research work is still in the initial stage due to the challenges in developing pragmatic applications and industrializing them in a dynamic market to meet the tremendous needs for people wearing smart devices. This review is not yet able to comprehensively discuss those challenges. There are so many unknown fields that need multi-discipline knowledge and in-depth collaboration among scientists.

References

[1]. Canali, S., Schiaffonati, V., & Aliverti, A. (2022). Challenges and recommendations for wearable devices in digital health: Data quality, interoperability, health equity, fairness. PLOS digital health, 1(10), e0000104. https://doi.org/10.1371/journal.pdig.0000104

[2]. Moshuqi Zhu, Jian Liu, Lihui Gan, Minnan Long. Research progress in bio-based self-healing materials. European Polymer Journal, Volume 129, 2020, 109651, ISSN 0014-3057 https://doi.org/10.1016/j.eurpolymj.2020.109651.

[3]. Linda M. Seymour et al. Hot mixing: Mechanistic insights into the durability of ancient Roman concrete.Sci. Adv.9, eadd1602(2023).DOI:10.1126/sciadv.add1602

[4]. Jomon Joy, Elssa George, S. Anas, Sabu Thomas, Chapter 17 - Applications of self-healing polymeric systems, Editor(s): Sabu Thomas, Anu Surendran, Self-Healing Polymer-Based Systems, Elsevier, 2020, Pages 495-513, ISBN 9780128184509, https://doi.org/10.1016/B978-0-12-818450-9.00016-7.

[5]. Ze Ping Zhang, Min Zhi Rong, Ming Qiu Zhang, Polymer engineering based on reversible covalent chemistry: A promising innovative pathway towards new materials and new functionalities, Progress in Polymer Science, Volume 80, 2018, Pages 39-93, ISSN 0079-6700, https://doi.org/10.1016/j.progpolymsci.2018.03.002.

[6]. Yue H., Wang Z., Zhen Y. (2022) Recent Advances of Self-Healing Electronic Materials Applied in Organic Field-Effect Transistors. ACS Omega. https://doi.org/10.1021/acsomega.2c00580

[7]. Nan Wen, Tingting Song, Zhuohan Ji, Dawei Jiang, Zijian Wu, Ying Wang, Zhanhu Guo, Recent advancements in self-healing materials: Mechanicals, performances and features, Reactive and Functional Polymers, Volume 168, 2021, 105041, ISSN 1381-5148, https://doi.org/10.1016/j.reactfunctpolym.2021.105041.

[8]. (2024) https://www.sciencedirect.com [Access date: Sep 16th, 2024]

[9]. Rubaya Yeasmin, Seung-Ik Han, Le Thai Duy, Byungmin Ahn, Hyungtak Seo, A Skin-like Self-healing and stretchable substrate for wearable electronics, Chemical Engineering Journal, Volume 455, 2023, 140543, ISSN 1385-8947, https://doi.org/10.1016/j.cej.2022.140543.

[10]. Massimiliano Barletta, Clizia Aversa, Muhammad Ayyoob, Annamaria Gisario, Kotiba Hamad, Mehrshad Mehrpouya, Henri Vahabi, Poly(butylene succinate) (PBS): Materials, processing, and industrial applications, Progress in Polymer Science, Volume 132, 2022, 101579, ISSN 0079-6700, https://doi.org/10.1016/j.progpolymsci.2022.101579.

[11]. Nat Commun. 2011 Oct 25; 2: 511. Published online 2011 Oct 25. doi: 10.1038/ncomms1521

[12]. Marc P. Wolf, Georgette B. Salieb-Beugelaar, Patrick Hunziker, PDMS with designer functionalities - Properties, modifications strategies, and applications, Progress in Polymer Science, Volume 83, 2018, Pages 97-134, ISSN 0079-6700, https://doi.org/10.1016/j.progpolymsci.2018.06.001.

[13]. Jun Chang Yang, Jaewan Mun, Se Young Kwon, Seongjun Park, Zhenan Bao, Steve Park, Electronic Skin: Recent Progress and Future Prospects for Skin-Attachable Devices for Health Monitoring, Robotics, and Prosthetics, Advanced Materials, Volume 31, 2019, https://doi.org/10.1002/adma.201904765

[14]. Guozhen Shen, Recent advances of flexible sensors for biomedical applications, Progress in Natural Science: Materials International, Volume 31, Issue 6, 2021, Pages 872-882, ISSN 1002-0071, https://doi.org/10.1016/j.pnsc.2021.10.005.

[15]. Nyamjargal Ochirkhuyag, Yuji Isano, Kota Inoue, Hiroki Ota, Biphasic liquid metal mixtures in stretchable and flexible applications, Sensors and Diagnostics, Volume 2, Issue 2, 2023, Pages 290-306, ISSN 2635-0998, https://doi.org/10.1039/d2sd00214k.

[16]. Yichi Liu, Feijie Wang, Zihan Hu, Mengdi Li, Shiqiang Ouyang, Yiting Wu, Suyang Wang, Zhihua Li, Jing Qian, Liqiang Wang, Shufeng Ma, Applications of cellulose-based flexible self-healing sensors for human health monitoring, Nano Energy, Volume 127, 2024, 109790, ISSN 2211-2855, https://doi.org/10.1016/j.nanoen.2024.109790.

[17]. Rafi Ullah, Luqman Ali Shah, Muhammad Tahir Khan, Cellulose nanocrystals boosted hydrophobically associated self-healable conductive hydrogels for the application of strain sensors and electronic devices, International Journal of Biological Macromolecules, Volume 260, Part 1, 2024, 129376, ISSN 0141-8130, https://doi.org/10.1016/j.ijbiomac.2024.129376.

[18]. Juan Wang, Peng Du, Yu-I Hsu, Hiroshi Uyama, Rapid preparation of dynamic-crosslinked nanocomposite hydrogel sensors with efficiency self-healing and adhesion properties for elderly health and sleep management, Chemical Engineering Journal, Volume 480, 2024, 148324, ISSN 1385-8947, https://doi.org/10.1016/j.cej.2023.148324.

[19]. Yaokun Pang, Xianchen Xu, Shoue Chen, Yuhui Fang, Xiaodong Shi, Yiming Deng, Zhong-Lin Wang, Changyong Cao, Skin-inspired textile-based tactile sensors enable multifunctional sensing of wearables and soft robots, Nano Energy, Volume 96, 2022, 107137, ISSN 2211-2855, https://doi.org/10.1016/j.nanoen.2022.107137.

[20]. Babak Mikaeeli Kangarshahi, Seyed Morteza Naghib, Gelareh Mikaeeli Kangarshahi, M.R. Mozafari, Bioprinting of self-healing materials and nanostructures for biomedical applications: Recent advances and progresses on fabrication and characterization techniques, Bioprinting, Volume 38, 2024, e00335, ISSN 2405-8866, https://doi.org/10.1016/j.bprint.2024.e00335.

[21]. Zhenxing Wang, Zijing Zhou, Sijie Wang, Xiaomin Yao, Xuewen Han, Wentao Cao, Junwen Pu, An anti-freezing and strong wood-derived hydrogel for high-performance electronic skin and wearable sensing, Composites Part B: Engineering, Volume 239, 2022, 109954, ISSN 1359-8368, https://doi.org/10.1016/j.compositesb.2022.109954.

[22]. Zhenxing Wang, Zijing Zhou, Sijie Wang, Xiaomin Yao, Xuewen Han, Wentao Cao, Junwen Pu, An anti-freezing and strong wood-derived hydrogel for high-performance electronic skin and wearable sensing, Composites Part B: Engineering, Volume 239, 2022, 109954, ISSN 1359-8368, https://doi.org/10.1016/j.compositesb.2022.109954.

[23]. Jinsui Xu, Boyi Xu, Hao Zhan, Zhijie Xie, Zhen Tian, Yifan Lu, Zheping Wang, Honghao Yue, Fei Yang, A soft robotic system imitating the multimodal sensory mechanism of human fingers for intelligent grasping and recognition, Nano Energy, Volume 130, 2024, 110120, ISSN 2211-2855, https://doi.org/10.1016/j.nanoen.2024.110120.

[24]. D.Y.S. Low, J. Supramaniam, W.D. Leong, A. Soottitantawat, T. Charinpanitkul, W. Tanthapanichakoon, S. Manickam, K.W. Tan, B.H. Goh, S.Y. Tang, Self-healing synthetic rubber composites: a review of recent progress and future directions towards sustainability, Materials Today Sustainability, Volume 24, 2023, 100545, ISSN 2589-2347, https://doi.org/10.1016/j.mtsust.2023.100545.

[25]. Afreen Shagufta, Lei Wang, Senbiao Fang, Qingshan Kong, Haibo Zhang, Endowing rubber with intrinsic self-healing properties using thiourea-based polymer††Electronic supplementary information (ESI) available. See DOI: https://doi.org/10.1039/d4ra03808h, RSC Advances, Volume 14, Issue 36, 2024, Pages 26198-26207, ISSN 2046-2069, https://doi.org/10.1039/d4ra03808h.

[26]. Zhe Wang, Yuetao Liu, Dejin Zhang, Chuanhui Gao, Yumin Wu, Mussel-inspired self-healing PDMS/AgNPs conductive elastomer with tunable mechanical properties and efficient antibacterial performances for wearable sensor, Composites Part B: Engineering, Volume 224, 2021, 109213, ISSN 1359-8368, https://doi.org/10.1016/j.compositesb.2021.109213.

Cite this article

Sun,Y. (2025). Analysis of Recent Advances of Self-healing Materials Applied in Wearable Devices. Applied and Computational Engineering,136,15-21.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 5th International Conference on Materials Chemistry and Environmental Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Canali, S., Schiaffonati, V., & Aliverti, A. (2022). Challenges and recommendations for wearable devices in digital health: Data quality, interoperability, health equity, fairness. PLOS digital health, 1(10), e0000104. https://doi.org/10.1371/journal.pdig.0000104

[2]. Moshuqi Zhu, Jian Liu, Lihui Gan, Minnan Long. Research progress in bio-based self-healing materials. European Polymer Journal, Volume 129, 2020, 109651, ISSN 0014-3057 https://doi.org/10.1016/j.eurpolymj.2020.109651.

[3]. Linda M. Seymour et al. Hot mixing: Mechanistic insights into the durability of ancient Roman concrete.Sci. Adv.9, eadd1602(2023).DOI:10.1126/sciadv.add1602

[4]. Jomon Joy, Elssa George, S. Anas, Sabu Thomas, Chapter 17 - Applications of self-healing polymeric systems, Editor(s): Sabu Thomas, Anu Surendran, Self-Healing Polymer-Based Systems, Elsevier, 2020, Pages 495-513, ISBN 9780128184509, https://doi.org/10.1016/B978-0-12-818450-9.00016-7.

[5]. Ze Ping Zhang, Min Zhi Rong, Ming Qiu Zhang, Polymer engineering based on reversible covalent chemistry: A promising innovative pathway towards new materials and new functionalities, Progress in Polymer Science, Volume 80, 2018, Pages 39-93, ISSN 0079-6700, https://doi.org/10.1016/j.progpolymsci.2018.03.002.

[6]. Yue H., Wang Z., Zhen Y. (2022) Recent Advances of Self-Healing Electronic Materials Applied in Organic Field-Effect Transistors. ACS Omega. https://doi.org/10.1021/acsomega.2c00580

[7]. Nan Wen, Tingting Song, Zhuohan Ji, Dawei Jiang, Zijian Wu, Ying Wang, Zhanhu Guo, Recent advancements in self-healing materials: Mechanicals, performances and features, Reactive and Functional Polymers, Volume 168, 2021, 105041, ISSN 1381-5148, https://doi.org/10.1016/j.reactfunctpolym.2021.105041.

[8]. (2024) https://www.sciencedirect.com [Access date: Sep 16th, 2024]

[9]. Rubaya Yeasmin, Seung-Ik Han, Le Thai Duy, Byungmin Ahn, Hyungtak Seo, A Skin-like Self-healing and stretchable substrate for wearable electronics, Chemical Engineering Journal, Volume 455, 2023, 140543, ISSN 1385-8947, https://doi.org/10.1016/j.cej.2022.140543.

[10]. Massimiliano Barletta, Clizia Aversa, Muhammad Ayyoob, Annamaria Gisario, Kotiba Hamad, Mehrshad Mehrpouya, Henri Vahabi, Poly(butylene succinate) (PBS): Materials, processing, and industrial applications, Progress in Polymer Science, Volume 132, 2022, 101579, ISSN 0079-6700, https://doi.org/10.1016/j.progpolymsci.2022.101579.

[11]. Nat Commun. 2011 Oct 25; 2: 511. Published online 2011 Oct 25. doi: 10.1038/ncomms1521

[12]. Marc P. Wolf, Georgette B. Salieb-Beugelaar, Patrick Hunziker, PDMS with designer functionalities - Properties, modifications strategies, and applications, Progress in Polymer Science, Volume 83, 2018, Pages 97-134, ISSN 0079-6700, https://doi.org/10.1016/j.progpolymsci.2018.06.001.

[13]. Jun Chang Yang, Jaewan Mun, Se Young Kwon, Seongjun Park, Zhenan Bao, Steve Park, Electronic Skin: Recent Progress and Future Prospects for Skin-Attachable Devices for Health Monitoring, Robotics, and Prosthetics, Advanced Materials, Volume 31, 2019, https://doi.org/10.1002/adma.201904765

[14]. Guozhen Shen, Recent advances of flexible sensors for biomedical applications, Progress in Natural Science: Materials International, Volume 31, Issue 6, 2021, Pages 872-882, ISSN 1002-0071, https://doi.org/10.1016/j.pnsc.2021.10.005.

[15]. Nyamjargal Ochirkhuyag, Yuji Isano, Kota Inoue, Hiroki Ota, Biphasic liquid metal mixtures in stretchable and flexible applications, Sensors and Diagnostics, Volume 2, Issue 2, 2023, Pages 290-306, ISSN 2635-0998, https://doi.org/10.1039/d2sd00214k.

[16]. Yichi Liu, Feijie Wang, Zihan Hu, Mengdi Li, Shiqiang Ouyang, Yiting Wu, Suyang Wang, Zhihua Li, Jing Qian, Liqiang Wang, Shufeng Ma, Applications of cellulose-based flexible self-healing sensors for human health monitoring, Nano Energy, Volume 127, 2024, 109790, ISSN 2211-2855, https://doi.org/10.1016/j.nanoen.2024.109790.

[17]. Rafi Ullah, Luqman Ali Shah, Muhammad Tahir Khan, Cellulose nanocrystals boosted hydrophobically associated self-healable conductive hydrogels for the application of strain sensors and electronic devices, International Journal of Biological Macromolecules, Volume 260, Part 1, 2024, 129376, ISSN 0141-8130, https://doi.org/10.1016/j.ijbiomac.2024.129376.

[18]. Juan Wang, Peng Du, Yu-I Hsu, Hiroshi Uyama, Rapid preparation of dynamic-crosslinked nanocomposite hydrogel sensors with efficiency self-healing and adhesion properties for elderly health and sleep management, Chemical Engineering Journal, Volume 480, 2024, 148324, ISSN 1385-8947, https://doi.org/10.1016/j.cej.2023.148324.

[19]. Yaokun Pang, Xianchen Xu, Shoue Chen, Yuhui Fang, Xiaodong Shi, Yiming Deng, Zhong-Lin Wang, Changyong Cao, Skin-inspired textile-based tactile sensors enable multifunctional sensing of wearables and soft robots, Nano Energy, Volume 96, 2022, 107137, ISSN 2211-2855, https://doi.org/10.1016/j.nanoen.2022.107137.

[20]. Babak Mikaeeli Kangarshahi, Seyed Morteza Naghib, Gelareh Mikaeeli Kangarshahi, M.R. Mozafari, Bioprinting of self-healing materials and nanostructures for biomedical applications: Recent advances and progresses on fabrication and characterization techniques, Bioprinting, Volume 38, 2024, e00335, ISSN 2405-8866, https://doi.org/10.1016/j.bprint.2024.e00335.

[21]. Zhenxing Wang, Zijing Zhou, Sijie Wang, Xiaomin Yao, Xuewen Han, Wentao Cao, Junwen Pu, An anti-freezing and strong wood-derived hydrogel for high-performance electronic skin and wearable sensing, Composites Part B: Engineering, Volume 239, 2022, 109954, ISSN 1359-8368, https://doi.org/10.1016/j.compositesb.2022.109954.

[22]. Zhenxing Wang, Zijing Zhou, Sijie Wang, Xiaomin Yao, Xuewen Han, Wentao Cao, Junwen Pu, An anti-freezing and strong wood-derived hydrogel for high-performance electronic skin and wearable sensing, Composites Part B: Engineering, Volume 239, 2022, 109954, ISSN 1359-8368, https://doi.org/10.1016/j.compositesb.2022.109954.

[23]. Jinsui Xu, Boyi Xu, Hao Zhan, Zhijie Xie, Zhen Tian, Yifan Lu, Zheping Wang, Honghao Yue, Fei Yang, A soft robotic system imitating the multimodal sensory mechanism of human fingers for intelligent grasping and recognition, Nano Energy, Volume 130, 2024, 110120, ISSN 2211-2855, https://doi.org/10.1016/j.nanoen.2024.110120.

[24]. D.Y.S. Low, J. Supramaniam, W.D. Leong, A. Soottitantawat, T. Charinpanitkul, W. Tanthapanichakoon, S. Manickam, K.W. Tan, B.H. Goh, S.Y. Tang, Self-healing synthetic rubber composites: a review of recent progress and future directions towards sustainability, Materials Today Sustainability, Volume 24, 2023, 100545, ISSN 2589-2347, https://doi.org/10.1016/j.mtsust.2023.100545.

[25]. Afreen Shagufta, Lei Wang, Senbiao Fang, Qingshan Kong, Haibo Zhang, Endowing rubber with intrinsic self-healing properties using thiourea-based polymer††Electronic supplementary information (ESI) available. See DOI: https://doi.org/10.1039/d4ra03808h, RSC Advances, Volume 14, Issue 36, 2024, Pages 26198-26207, ISSN 2046-2069, https://doi.org/10.1039/d4ra03808h.

[26]. Zhe Wang, Yuetao Liu, Dejin Zhang, Chuanhui Gao, Yumin Wu, Mussel-inspired self-healing PDMS/AgNPs conductive elastomer with tunable mechanical properties and efficient antibacterial performances for wearable sensor, Composites Part B: Engineering, Volume 224, 2021, 109213, ISSN 1359-8368, https://doi.org/10.1016/j.compositesb.2021.109213.