1. Introduction

The global warming and the rise in Earth's surface temperature have attracted widespread attention from governments and scientists around the world [1]. Scientists have also noticed that the rise in Earth's surface temperature, although a slow phenomenon, is continuous and its long-term accumulation will be quite significant. Moreover, human activities are becoming more frequent, exacerbating the harm of global warming and bringing many adverse effects on the ecosystem. Statistics show that the economic losses caused by global climate change and related extreme events have increased by 10 times in the past 40 years [2]. Since the Industrial Revolution, the Earth's climate has become increasingly hot, and this trend is intensifying. In the past century, global temperatures have begun to warm up significantly, and the six warmest years have all occurred after the 1980s .

Regarding the future trend of climate change, it is widely believed that the global climate will continue to warm. The Intergovernmental Panel on Climate Change (IPCC) said in a report that by 2025, the global surface temperature will rise by 1°C, and the global average temperature may rise by 1.4~4.8°C in the next 100 years, with the rate of global warming faster than the past 100 years . The results of climate model predictions suggest that by the end of the 21st century, China's average annual temperature may increase by 3~4°C [2]. There are a large number of biomass waste energy such as straw, garbage and domestic sewage in rural area of China. The population density and load density are relatively low, which provides rich space resources for roof photovoltaic and decentralized wind power [3]. How to promote the energy conversion of rural biomass resources and establish a clean and efficient function mode with multi-energy coupling among biomass energy, wind power and photovoltaic power has become an urgent issue [4]. The main way to deal with this challenge is to abandon carbon in the energy field and develop renewable energy, such as photovoltaics, wind power, hydropower, geothermal, biomass, etc. Biomass is one of the earliest forms of energy used by humans, and as a renewable and clean energy source, Biomass energy has become China's fourth largest energy system, following coal, oil, and natural gas, which are traditional fossil fuels [5]. It accounts for about 10.0% of the world's energy consumption [6]. Biomass energy is not only the fourth largest primary energy source on Earth but also the only storable renewable energy source currently available. Approximately two-thirds of biomass resources consist of agricultural and forestry residues. The main biomass is wheat and rice straw as agriculture is the main occupation of rural people. Both food crops and cash crops are grown in the state. The main cash crops include groundnut, cotton, sugarcane, turmeric, and tobacco [7]. As one of the world's major agricultural countries, China has a diverse and abundant biomass resource base. According to statistics, the total annual output of crops that can be utilized in China is about 5.0×10^8 tons, equivalent to 3.1×10^8 tons of standard coal [8]. One of the carbon-containing renewable energy sources discovered on Earth is biomass, which serves as a direct alternative fuel to traditional carbon-based mineral energy [9].

According to the definition of the International Energy Agency, biomass is any organic matter from biological sources and is renewable, including terrestrial or aquatic plant materials, animal products and manure, food processing and forestry by-products, and urban waste. Biomass resources include organic waste used for energy, agricultural and forestry biomass, and various biomass resources planted on marginal lands. The total volume of existing biomass resources is equivalent to 540 million tons of standard coal, of which 280 million tons can be used for energy. With the increase of organic waste and the development of marginal land, Forests, agriculture, and wastes are the three major sources from which, huge amount of biomass feedstock is generated [7]. By 2050, China's biomass resources will reach 1.4 million tons, and the potential of bioenergy as a clean energy source is equivalent to 270 million tons of standard coal. The use of biomass energy can reduce dependence on fossil resources and greenhouse gas emissions, and improve fuel supply security. In the 1970s, Nordic countries began to explore biomass energy such as ethanol [10].In 1993, Japan restarted the "Sunshine Project" to develop renewable energy. In 2000, the European Union formulated the "European Policy for Energy Supply Security" to encourage the development of biomass fuels [11]. In 2013, India proposed to double unconventional energy. According to the "China Renewable Energy Development Strategy Research Report" by the Chinese Academy of Engineering, China's annual exploitation of clean energy, including solar energy, is equivalent to 2.148 billion tons of standard coal. Among them, biomass energy accounts for 54.5%, which is 2.0 times that of hydropower and 3.5 times that of wind power, making it China's most promising renewable energy [12]. The 2021 global bioenergy statistics provided by the World Bioenergy Association (WBA) show that Europe is the world leader in biomass power plant heat production, accounting for 88% of the global share. In 2019, the world produced 159 billion liters of biofuels, with the Americas accounting for the main position, producing 70% of the world's biofuels, and Europe accounting for 15%. In 2019, the world produced 62.3 billion cubic meters of biogas, equivalent to 1.43 EJ of energy content. The ways of utilizing biomass energy include: combustion, biogas utilization, pyrolysis gasification, etc.

Although the technology of biomass energy utilization has developed rapidly, there are still some bottleneck issues, including efficiency and cost.

In terms of raw material supply, biomass has dispersion, usually scattered in vast rural areas and different industries, with high collection and transportation costs. For example, crop straw is often distributed in various fields, and collecting it requires a lot of manpower, material resources, and time. It also has seasonality for many biomass resources are produced seasonally, such as crop straw in specific harvest seasons, leading to unstable raw material supply, which is difficult to meet continuous production needs. There may also be quality difference issues. The quality of biomass from different sources varies greatly, such as water content, ash content, calorific value, etc., which poses higher requirements for processing and utilization technology.

On the technical level, the conversion efficiency of current biomass energy utilization technology is relatively low, for example, in the biomass gasification process, the calorific value and yield of the gas need to be improved. In biodiesel production, the conversion rate of the ester exchange reaction and product quality also need further optimization.

Some new types of biomass energy utilization technologies are still in the research and development or demonstration stage, with insufficient technical maturity, and there are reliability and stability issues. For example, some biomass pyrolysis technologies may face equipment failure and process instability when applied on a large scale.

Biomass energy utilization requires special equipment and facilities, and the investment of these devices is high, which is a significant burden for some small and medium-sized enterprises and rural areas. For example, building a biomass gasification power station requires a large amount of capital investment, including gasification equipment, power generation equipment, gas storage facilities, etc.

This paper analyzes the status of biomass energy technology, the main utilization methods, the problems faced, and possible solutions, and predicts the future development direction of the technology.

2. Combustion

2.1. Principle

Heating values often used as a principal indicator of the energy that specific biomass contains. Heating value is the amount of heat generated when a substance undergoes complete combustion and is also called the heat of combustion. Biomass comprises of organic substances, composed mostly of carbon, hydrogen and oxygen and when it is completely combusted, it produces water and carbon dioxide. The generated water and water vapors contain much latent heat that is given off upon condensation. The heating value, which includes latent heat is the high heating value (HHV), while that from which latent heat is subtracted is the lower heating value (LHV) [7].

\( {C_{6}}{H_{10}}{O_{5}}+6{O_{2}} →6{CO_{2}}+5 {H_{2}}O+heat \) (1)

The combustion reaction of hemicellulose is similar to that of cellulose, also reacting with oxygen to produce carbon dioxide, water, and heat.

Lignin is a complex high molecular compound, and its combustion reaction is more complex, but overall, it also reacts with oxygen to produce carbon dioxide, water, and heat.

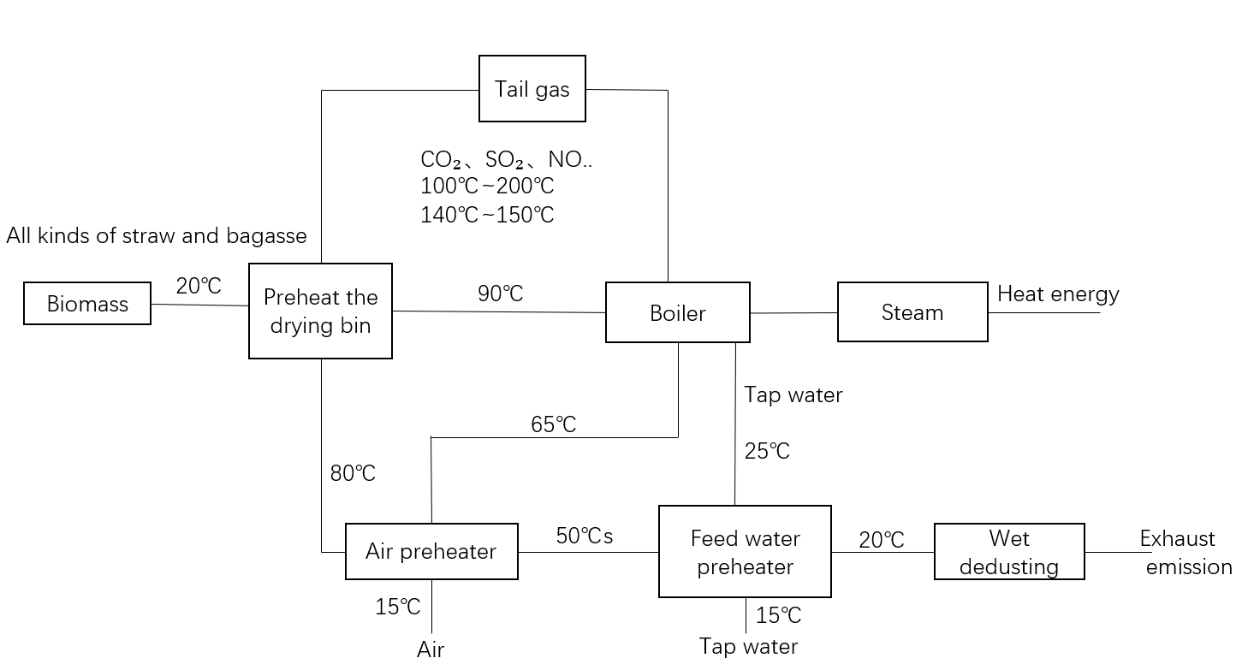

The process of biomass combustion is shown in Figure 1. Biomass raw materials enter the combustion furnace through the feeding system and react with oxygen provided by the combustion air system to release heat. The waste heat recovery system recovers the waste heat generated by combustion for power generation and heating. The flue gas treatment system treats the flue gas produced by combustion to remove pollutants and finally emits it through the chimney.

Figure 1: Process of biomass combustion

In summary, biomass combustion is an effective way to convert biomass into thermal energy, and its principle is to release heat by burning the organic matter in biomass. The design and operation of the biomass combustion system need to consider factors such as the characteristics of biomass, combustion conditions, waste heat recovery, and flue gas treatment to achieve efficient and environmentally friendly energy utilization.

2.2. Development Degree

Globally, to address energy shortages and environmental pollution, biomass energy power generation has received widespread attention, and biomass combustion power generation is an important part of it. According to relevant data, the global biomass energy installation capacity was 61.8GW in 2009, reaching 117.8 GW by 2018, with a compound annual growth rate of 7.43 %.

Germany is a pioneer country in the development of renewable energy and has made significant progress in the field of biomass combustion. The government strongly supports energy transformation and has formulated relevant energy laws and policies to provide legal and policy guarantees for biomass power generation. For example, the municipal company's biomass power plant in Magdeburg, eastern Germany, uses the energy from waste wood to power 4,000 households and heat 6,000 households daily. In 2021, Germany's total electricity generation from waste was about 5.7 billion kilowatt-hours.

Although China's biomass energy power generation started later than Europe and America, it has developed rapidly. The National Energy Administration pointed out that in 2019, biomass power generation added 4.73 million kilowatts of installed capacity, with a total installed capacity reaching 22.54 million kilowatts, and the annual biomass power generation was 111.1 billion kilowatt-hours; by the end of 2020, biomass power generation added 5.43 million kilowatts of installed capacity, with a total installed capacity reaching 29.52 million kilowatts, and the annual biomass power generation was 132.6 billion kilowatt-hours; by 2022, China's biomass power generation reached 182.4 billion kilowatt-hours, a year-on-year increase of 11.4%, ranking first in the world .

2.3. Problems

2.3.1. Cost

To carry out effective biomass pretreatment, special equipment is usually required, such as crushers, dryers, and compression molding machines. The purchase and installation of these devices require a significant financial investment. For example, a medium-sized biomass crushing and drying equipment may require an investment of several hundred thousand to millions of yuan.

The operation of pretreatment equipment consumes energy, such as electricity and fuel, and requires manual maintenance and management. These operating costs will increase the overall cost of biomass combustion. For example, drying biomass requires a lot of thermal energy, and the operation of crushers requires electricity, which will increase costs.

If biomass needs to be concentrated for pretreatment and then transported to the combustion site, transportation costs will also become a constraining factor. Especially for dispersed biomass resources, when the transportation distance is far, transportation costs may be very high.

At present, there are many methods for biomass pretreatment, such as crushing, drying, compression molding, and carbonization. Different pretreatment methods are suitable for different types of biomasses and combustion equipment. Choosing the right pretreatment process requires considering multiple factors, such as the characteristics of biomass, the requirements of combustion equipment, and costs. This increases the complexity of technology selection.

The reliability of pretreatment equipment is also a constraining factor. Due to the characteristics of biomass, such as hardness and humidity, it may cause wear and corrosion to the equipment, reducing the reliability and service life of the equipment.

2.3.2. Environmental Impact

Biomass pretreatment processes may produce some pollutants, such as dust, exhaust gases, and wastewater. If these pollutants are not effectively treated, they will pollute the environment. For example, biomass drying processes will produce exhaust gases, which may contain some volatile organic compounds. If they are emitted directly without treatment, they will pollute the atmospheric environment.

The pretreatment process itself consumes energy, and if the energy consumption is too large, it will reduce the overall energy efficiency of biomass combustion. For example, drying biomass requires a lot of thermal energy, and if traditional energy is used for drying, it may lead to energy waste.

Pretreatment processes will produce some waste, such as slag and wastewater. The treatment of these wastes also needs to be considered, otherwise, it will pollute the environment. For example, biomass carbonization processes will produce slag, and if it cannot be reasonably treated, it will occupy land resources and even pollute soil and groundwater.

3. Anaerobic digestion

3.1. Principle

The anaerobic digestion process of biomass waste mainly includes the following stages.

3.1.1. Hydrolysis Stage

In the hydrolysis stage, complex organic substances, such as polysaccharides, proteins, and fats, are decomposed into small, water-soluble substances under the action of hydrolytic enzymes secreted by fermentative bacteria. The hydrolysis stage is the first step of anaerobic digestion and is also the rate-limiting step because the hydrolysis rate of large molecular organic substances is relatively slow, which limits the rate of the entire anaerobic digestion.

3.1.2. Acidification Stage

In the acidification stage, the small molecular substances produced in the hydrolysis stage are further decomposed and transformed under the action of acid-producing bacteria. For example, amino acids deaminate to produce ammonia and organic acids, and monosaccharides ferment to produce various organic acids such as propionic acid, butyric acid, lactic acid, etc., alcohols, carbon dioxide, hydrogen, and a small amount of ammonia. In this stage, due to the continuous production and accumulation of organic acids, the pH value of the fermentation liquid will drop to below 6. However, subsequently, due to the decomposition of organic acids and nitrogen-containing compounds, substances such as carbonates and ammonia are produced, which gradually reduce the acidity of the fermentation liquid, and the pH value rises to around 6.6-6.8.

3.1.3. Methanation Stage

In this stage, methanogenic bacteria use substances such as acetic acid, hydrogen, and carbon dioxide produced in the previous stage to convert them into methane and carbon dioxide. Methanogenic bacteria are a special type of archaea that have strict requirements for environmental conditions such as temperature, pH value, redox potential, etc., slow growth rates, and long generation times. The conversion process mainly has two ways, one is to use acetic acid as a substrate to produce methane through decarboxylation reactions and the other is to use hydrogen and carbon dioxide to produce methane through reduction reactions.

It is generally believed that about 70% of methane in anaerobic biological treatment processes comes from the decomposition of acetic acid, and the rest comes from hydrogen and carbon dioxide.

3.2. Main Technical Parameters of Anaerobic Digestion

3.2.1. Temperature

Anaerobic digestion can be divided into mesophilic and thermophilic anaerobic digestion according to the operating temperature. Thermophilic anaerobic digestion usually has a temperature between 50°C and 60°C. This higher temperature can accelerate the metabolic activities of microorganisms, thereby increasing the decomposition speed of organic matter. Mesophilic anaerobic digestion usually has a temperature around 30°C - 40°C. This temperature range is relatively mild and also has a good promotion for the growth and metabolic activities of microorganisms, but the speed is relatively slower than thermophilic anaerobic digestion.

3.2.2. Microbial Community

Thermophilic anaerobic digestion is suitable for the growth of thermophilic bacteria. Mesophilic anaerobic digestion is mainly dominated by mesophilic bacteria. Mesophilic bacteria grow well in mesophilic conditions and have certain adaptability to temperature changes. The growth rate and metabolic activity of mesophilic bacteria are slightly lower than thermophilic bacteria, but they can effectively decompose organic matter under stable environmental conditions.

3.2.3. Digestion Efficiency

During thermophilic anaerobic digestion, due to the high temperature, the metabolic activities of microorganisms are vigorous, and the decomposition speed of organic matter is relatively fast, resulting in relatively high digestion efficiency. It requires more energy consumption to maintain the temperature. Mesophilic anaerobic digestion has a relatively slow digestion speed and requires a longer residence time to achieve an organic matter removal rate and biogas production comparable to thermophilic anaerobic digestion. The operation cost of mesophilic conditions is relatively low, and the demand for energy is also less.

3.2.4. Stability

Thermophilic anaerobic digestion is sensitive to temperature fluctuations, and once the temperature changes significantly, it may affect the growth and metabolic activities of microorganisms, leading to instability in the digestion process. It requires precise temperature control and monitoring systems to ensure the stable progress of the digestion process. Mesophilic anaerobic digestion has relatively strong adaptability to temperature in mesophilic bacteria, and the digestion process is relatively stable. Within a certain temperature range, mesophilic anaerobic digestion can better withstand temperature fluctuations, and the requirements for operating conditions are relatively low.

3.2.5. Application Scenarios

Thermophilic anaerobic digestion is suitable for treating high-concentration organic wastewater and waste, such as food processing wastewater and livestock and poultry manure. It is more suitable for occasions that require rapid processing and high biogas production. However, due to the high cost of equipment and operation, it is usually chosen when economic conditions permit. Mesophilic anaerobic digestion is widely used in the treatment of sludge. It is more suitable for occasions with large processing volume and low operating cost requirements. In some developing countries and regions, mesophilic anaerobic digestion is widely applied due to its mature technology and low cost.

3.2.6. Concentration of Feedstock in the Reactor

High-solid anaerobic digestion has a high solid content in the feed, generally as 20% - 40% or even higher. It can handle high-concentration organic solid waste. Conventional anaerobic digestion has a relatively low solid content in the feed, usually below 10%. It is mainly suitable for treating low-concentration organic wastewater and sludge.

3.3. Reactor Types

High-solid anaerobic digestion often uses dry fermentation reactors, such as garage-style reactors and plug-flow reactors. These reactors are usually designed to consider issues such as material stirring, mass transfer, and heat transfer to ensure uniformity and efficiency of the reaction. Conventional anaerobic digestion uses fully mixed reactors (CSTR) and upflow anaerobic sludge bed reactors (UASB). The structure of the reactor is relatively simple and can adapt well to the treatment of low-solid content materials.

3.4. Digestion Efficiency

High-solid anaerobic digestion, due to the high concentration of materials, has a large amount of organic matter per unit volume. However, by reasonable reactor design and optimization of operating parameters, digestion efficiency can be improved.

Conventional anaerobic digestion has a low material concentration, and mass transfer and heat transfer are relatively easy. Microorganisms can fully contact with substrates, and digestion efficiency is relatively high. However, treating the same amount of organic matter requires a larger reactor volume, occupying a larger area.

3.5. Utilization of Anaerobic Digestion Products

Biogas which is a mixture of CO2 and CH4 can be purified to obtain CH4 with a purity of over 97%, which can be used as biogas and replace petroleum natural gas. Biogas can be used as a carbon source in wastewater plants or made into liquid fertilizer for agriculture; ammonium bicarbonate can also be extracted as fertilizer; biogas residue can be used as a soil conditioner.

3.6. Problems

In terms of raw material quality, different biomass raw materials have different biogas production potentials. For example, crops with high cellulose and hemicellulose content, such as crop straw and livestock manure, can produce high yields of biogas under suitable conditions. However, if the raw material contains too many impurities, such as soil and sand, it will affect the efficiency of biogas production. The degradability of the raw material also affects the biogas yield.

Temperature is an important factor affecting the efficiency of biogas fermentation. Mesophilic fermentation (30 - 40°C) and thermophilic fermentation (50 - 60°C) usually have higher gas production rates and biogas yields than low-temperature fermentation (10 - 20°C). However, thermophilic fermentation requires more energy input to maintain the temperature, so the cost and benefits need to be considered comprehensively.

4. Pyrolysis Gasification

4.1. Principle

Pyrolysis gasification is a technology that decomposes biomass into flammable gases, bio-oils, and charcoal under oxygen-deficient or low-oxygen conditions.

4.1.1. Chemical Reactions in Pyrolysis Process

Biomass is mainly composed of cellulose, hemicellulose, and lignin. During the pyrolysis process, these large molecular organic substances first undergo thermal decomposition reactions, decomposing into smaller molecules. For example, cellulose will decompose into levoglucosan and other intermediate products during the pyrolysis process, which then further decompose into volatile gases and charcoal.

4.1.2. Three Stages of Pyrolysis Gasification

Drying stage: At lower temperatures (usually between 100 - 150°C), the moisture in the biomass is first evaporated. This stage is mainly a physical change, and the chemical composition of the biomass has not changed.

Pyrolysis stage: As the temperature rises, the biomass begins to undergo pyrolysis reactions. In this stage, the large molecular organic substances in the biomass decompose into volatile gases, bio-oils, and charcoal. Different temperature ranges produce different products. At lower temperatures, bio-oil is mainly produced; at higher temperatures, flammable gases are mainly produced.

Gasification stage: At higher temperatures (usually between 600 - 1000°C), the charcoal and some volatile gases produced by pyrolysis react with gasification agents (such as air, steam, etc.) to produce flammable gases. The reactions in this stage mainly include the oxidation reaction of charcoal and steam reforming reaction.

4.2. Utilization Forms of Products

Biomass pyrolysis and gasification technology decomposes biomass feedstock under oxygen-deficient or low-oxygen conditions, producing products such as combustible gases, bio-oil, and biochar. Combustible gases (such as syngas) can be directly used for power generation or heating through combustion, and can also be used as industrial fuels. Bio-oil is a liquid fuel that can be further refined for power generation, heating, or as an alternative to transportation fuels. Biochar can be used for soil improvement, enhancing soil fertility and moisture retention, and can also be used as an adsorbent for water treatment or air purification. Through these diverse utilization methods, biomass pyrolysis and gasification technology not only achieve efficient conversion of biomass energy but also provides new pathways for environmental protection and resource recycling.

4.3. Problems

In terms of efficiency, there is complexity in composition. Different biomass or waste materials have different compositions, and their pyrolysis reactivity varies. For example, in lignocellulosic materials, lignin has a higher pyrolysis temperature and relatively low reactivity, while cellulose and hemicellulose are easier to pyrolyze. If the raw material has a high lignin content, it will lead to an overall reduction in the efficiency of pyrolysis gasification because higher temperatures and longer reaction times are required to decompose lignin, which may make it difficult for pyrolysis gasification equipment to accurately adapt to a variety of different raw materials, affecting efficiency.

5. Comparison of Different Technologies

Table 1 provides a comparative analysis of different pyrolysis technologies and gasification based on various parameters such as technology type, reaction conditions, product composition, product characteristics, application fields, advantages, and disadvantages. Each technology has its specific conditions, yields, and applications, with varying advantages and disadvantages related to process complexity, energy consumption, and product quality.

Table 1: Comparison of different technologies

Technology types | Reaction Conditions | Product Composition | Product Characteristics | Application Fields | Advantages | Disadvantages |

Slow Pyrolysis | Low temperature (300-500°C),oxygen-free | Bio-oil (60-80%), combustible gas (10-20%), biochar (10-20%) | High bio-oil yield, low calorific value of combustible gas | Bio-oil production, soil improvement | High bio-oil yield, simple process | Low calorific value of gas, bio-oil requires further refining |

Fast Pyrolysis | High temperature (500-1000°C), rapid heating | Bio-oil (50-70%), combustible gas (20-30%), biochar (10-20%) | High bio-oil yield, high calorific value of combustible gas | Bio-oil production, power generation | High bio-oil yield, high calorific value of combustible gas | Complex equipment, high energy consumption |

Gasification | High temperature (800-1200°C), partial oxidation | Combustible gas (70%-90%), bio-oil(5%-15%), biochar(5%-15%) | High calorific value of gas, low bio-oil yield | Power generation, industrial fuel | High calorific value of gas, high energy conversion efficiency | Low bio-oil yield, complex equipment |

Catalytic Pyrolysis | Low temperature(300-600°C), presence of catalyst | Bio-oil (50-70%), combustible gas (20-30%), biochar (10-20%) | High quality bio-oil, high calorific value of gas | Bio-oil production, power generation | High quality bio-oil, high calorific value of gas | High catalyst cost, requires regular replacement |

6. Outlook

In the future, biomass energy technology will show a multifaceted development trend. In terms of technological innovation, efficient conversion technologies will continue to emerge. The biomass waste energy conversion technology can convert straw, solid waste and other rural biomass resources into power, heat and gas through pyrolysis gasification and waste gas generation, so as to realize energy utilization of biomass resources [13]. In the field of thermochemical conversion, pyrolysis and gasification technologies will continue to be improved, optimizing reaction conditions and developing new catalysts will improve the conversion efficiency and quality of energy products such as bio-oil and synthesis gas; bioconversion microbial fermentation technology will be further upgraded to increase the yield and production efficiency of biofuels such as bioethanol and biodiesel, reducing costs.

In terms of raw material utilization, it will become more diversified. In addition to traditional crop straw and wood waste, new types of biomass resources such as algae, urban organic garbage, and industrial organic wastewater will be widely developed and utilized.

In terms of environmental friendliness, more attention will be paid to the application of carbon capture, storage, and utilization technologies in the production process of biomass energy to reduce carbon emissions; and strengthen ecological and environmental protection during the development and utilization process, and plan the collection and planting of biomass resources reasonably. In summary, future biomass energy technology will continue to develop in the direction of high efficiency, diversity, environmental protection, and sustainability.

7. Conclusion

This paper reviews the status and future trends of biomass waste energy technology. As a renewable resource, the energy utilization of biomass waste is of great significance for alleviating energy crises and environmental issues. This paper first analyzes the biomass waste energy technology, including anaerobic digestion to produce biogas, pyrolysis gasification to produce bio-oil and solid fuels, etc. Then, it discusses the challenges faced by these technologies in terms of raw material collection, conversion efficiency, product stability, and market application. Looking forward, biomass waste energy technology needs further optimization to achieve large-scale application, especially in improving energy conversion efficiency and reducing environmental impact. This will provide important support for achieving sustainable development and the goal of "carbon neutrality".

References

[1]. HOU Dan. Technologies for recovering low‐temperature heat in delayed coking units[J. Sino‐Global Energy,2015,20(3):98.

[2]. Lu Junqiang, Zhou Yuan. Analysis of the Causes of Global Warming Triggered by the Warm Winter Phenomenon[J]. Rural Economy Technology, 2008, (04): 88 90.

[3]. S.B. Wang, S.L. Sun, E.L. Zhao, S.Y. Wang. Urban and rural differences with regional assessment of household energy consumption in China [J]. Energy,2021, 232:121091

[4]. H. Zhang, L. Wang, J.V. Herle. Techno-economic evaluation of biomass-to-fuels with solid-oxide electrolyzer [J]. Applied Energy, 2020, 270:115113

[5]. Rexiati Aierken. Discussion on the Efficient Utilization Technology of Biomass Pyrolysis and Gasification [J]. Energy and Energy, 2024, (08): 6-10. DOI: 10.16643/j.cnki.1-1360/td.2024.08.004.

[6]. BACH Q V,TRINH T N,TRAN K Q,et al. Pyrolysischaracteristics and kinetics of biomass torrefied in various atmospheres [J]. Energy Conversion and Management,2017,141:72-78.

[7]. Kalyani A. Motghare b, Ajit P. Rathod b , Kailas L. Wasewar b , Nitin K. Labhsetwar a, , et al. Comparative study of different waste biomass for energy application. K.A. Motghare et al. / Waste Management 47 (2016) 40–45.

[8]. Ren Yongzhi, Liu Honggang, Cui Henzhe, et al. Research on a 50 kW fixed-bed biomass gas CHP system [C] // 2003 Annual Conference of the Chinese Solar Energy Society. Shanghai: Chinese Solar Energy Society, 200: 30-31

[9]. Jia Jingdun, Sun Kangtai, Jiang Dahua, et al. Study on the Development Countermeasures of Technological Innovation China's Biomass Energy Industry [J]. Chinese Agricultural Science and Technology, 2014, 16(1): 1-6

[10]. SHI Yuanchun. Overview of biomass energy development in China[J].Smart Power,2017,45(7):1-5,42.

[11]. TIAN Donglian,ZHANG Hui,GAO Haiyang. Analysis on the policy measures of promoting the application of vehicle biofuels abroad[J].Bus Technology and Research,2009,32(2):58-61.

[12]. YU Xiongfei.Bring you comprehensively understand biomass power generation[J].Green China,2018(4):44-47.

[13]. Ju, L., Lu, X., Yang, S., Li, G., Fan, W., Pan, Y., & Qiao, H. (2022). A Multi-time Scale Dispatching OptimalModel for Rural Biomass Waste Energy Conversion System-Based Micro-Energy Grid Considering Multi-energyDemand Response. Applied Energy, 327, Article 120155.

Cite this article

Wang,Y. (2025). Research on Technical Process Development Trends of Biomass Waste Energy Technology. Applied and Computational Engineering,144,41-51.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 3rd International Conference on Functional Materials and Civil Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. HOU Dan. Technologies for recovering low‐temperature heat in delayed coking units[J. Sino‐Global Energy,2015,20(3):98.

[2]. Lu Junqiang, Zhou Yuan. Analysis of the Causes of Global Warming Triggered by the Warm Winter Phenomenon[J]. Rural Economy Technology, 2008, (04): 88 90.

[3]. S.B. Wang, S.L. Sun, E.L. Zhao, S.Y. Wang. Urban and rural differences with regional assessment of household energy consumption in China [J]. Energy,2021, 232:121091

[4]. H. Zhang, L. Wang, J.V. Herle. Techno-economic evaluation of biomass-to-fuels with solid-oxide electrolyzer [J]. Applied Energy, 2020, 270:115113

[5]. Rexiati Aierken. Discussion on the Efficient Utilization Technology of Biomass Pyrolysis and Gasification [J]. Energy and Energy, 2024, (08): 6-10. DOI: 10.16643/j.cnki.1-1360/td.2024.08.004.

[6]. BACH Q V,TRINH T N,TRAN K Q,et al. Pyrolysischaracteristics and kinetics of biomass torrefied in various atmospheres [J]. Energy Conversion and Management,2017,141:72-78.

[7]. Kalyani A. Motghare b, Ajit P. Rathod b , Kailas L. Wasewar b , Nitin K. Labhsetwar a, , et al. Comparative study of different waste biomass for energy application. K.A. Motghare et al. / Waste Management 47 (2016) 40–45.

[8]. Ren Yongzhi, Liu Honggang, Cui Henzhe, et al. Research on a 50 kW fixed-bed biomass gas CHP system [C] // 2003 Annual Conference of the Chinese Solar Energy Society. Shanghai: Chinese Solar Energy Society, 200: 30-31

[9]. Jia Jingdun, Sun Kangtai, Jiang Dahua, et al. Study on the Development Countermeasures of Technological Innovation China's Biomass Energy Industry [J]. Chinese Agricultural Science and Technology, 2014, 16(1): 1-6

[10]. SHI Yuanchun. Overview of biomass energy development in China[J].Smart Power,2017,45(7):1-5,42.

[11]. TIAN Donglian,ZHANG Hui,GAO Haiyang. Analysis on the policy measures of promoting the application of vehicle biofuels abroad[J].Bus Technology and Research,2009,32(2):58-61.

[12]. YU Xiongfei.Bring you comprehensively understand biomass power generation[J].Green China,2018(4):44-47.

[13]. Ju, L., Lu, X., Yang, S., Li, G., Fan, W., Pan, Y., & Qiao, H. (2022). A Multi-time Scale Dispatching OptimalModel for Rural Biomass Waste Energy Conversion System-Based Micro-Energy Grid Considering Multi-energyDemand Response. Applied Energy, 327, Article 120155.