1. Introduction

Superhydrophobic materials are popular choices for potential applications in several fields due to their excellent waterproofing, self-cleaning, frost and oil-water separation properties, as well as their excellent chemical stability and biocompatibility in Figure 1. For example, in building design, a superhydrophobic coating can be applied to the surface to allow water droplets and stains to slide off easily, reducing the accumulation of contamination and improving the durability and cleaning efficiency of the building. In the field of oil-water separation technology, the specially designed superhydrophobic surface shows its excellent oil droplet separation efficiency, which is of great significance for the treatment of industrial wastewater and the response to offshore oil spills, reducing environmental pollution and improving the efficiency of resource recovery. In the biomedical field, the application of superhydrophobic surfaces can reduce frictional resistance during drug delivery, improving delivery efficiency and stability. This article uses a literature review method by reading relevant papers in the field of hydrophobic and self-cleaning. In conclusion, the continuous advancement and application of superhydrophobic surfaces has brought unprecedented innovation opportunities to various fields, demonstrating their important value as a multifunctional tools in modern technology.

Figure 1: Superhydrophobic surface applications in everyday life. (a)Aircraft anti-icing (b) The kitchen is oil-proof (c)Anti-fogging mirrors (d)Non-stick pan coating

2. Overview of Superhydrophobic Materials

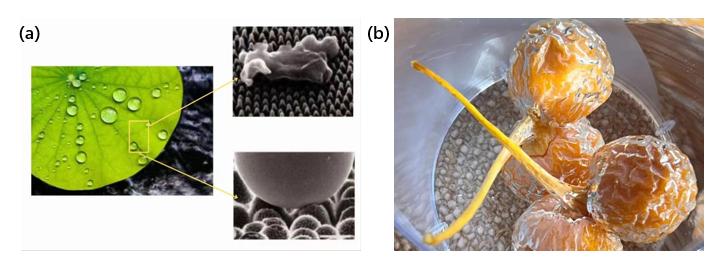

In nature, many organisms exhibit remarkable hydrophobic properties due to the unique micro- and nano-structures present on their surfaces. This structure not only gives the biological surface the ability to self-clean, but also promotes various biological processes follow Figure 2 [1]. For example, the micron-sized papillae structure on the surface of the lotus leaf, coupled with the waxy layer on it, which works together to make it have the function of self-cleaning. Similarly, the micro-nano structure and white waxy layer of ginkgo biloba allow it to form a stable bubble film in water and present a unique silvery luster under light, which is due to the total reflection effect of light.

Researchers have successfully designed a variety of superhydrophobic surfaces by in-depth research and imitation of these biological surface microstructures in nature. For example, the EP-SiO2/Al2O3 coating developed by Shi and the ZIF-8/ZnO layer developed by Liu have the potential to reduce scaling and corrosion in oilfield pipelines, as well as excellent corrosion resistance and bacteriostatic abilities, respectively [2-3]. However, the preparation process of superhydrophobic surfaces remains relatively complex, and how to maintain the stability and hydrophobicity of the surface while simplifying the hydrophobic preparation steps is a key challenge for researchers.

Figure 2: (a) Lotus leaf and its surface micro-nano structure (b) The "discoloration" effect of ginkgo biloba

3. Superhydrophobic theory

Wettability is one of the important properties of solid surfaces, with the contact angle θc (Contact angle, CA) and the sliding angle θs (Slide angle, SA) being key indicators for characterizing the wettability of solid surfaces. When the contact angle CA < 90°, the surface is referred to as hydrophilic; when the contact angle CA > 90°, the surface is termed hydrophobic; and when the contact angle 180°> CA > 150° and the sliding angle SA < 10°, the surface exhibits superhydrophobicity.

3.1. Hydrophobic mechanism

In the realm of surface wetting studies, four principal theoretical models are prominent in elucidating the wetting characteristics of solid surfaces [4]: the Young's model, Wenzel model, Cassie model, and Cassie-Baxter model. In 1805, Thomas Young first proposed the famous Young's equation to explain the contact mechanism of liquid droplets on an ideally smooth solid surface. This equation establishes the quantitative relationship between the intrinsic contact angle on a flat, smooth surface and the interfacial tensions of the three phases, indicating that the larger the contact angle, the stronger the surface hydrophobicity, and vice versa. Equation (1) describes the relationship between the intrinsic contact angle θe of a droplet on a smooth solid surface and the solid-gas, solid-liquid, and liquid-gas interfacial tensions:

\( {γ_{sv}}-{γ_{sl}}={γ_{lv}}cos{θ} \) (1)

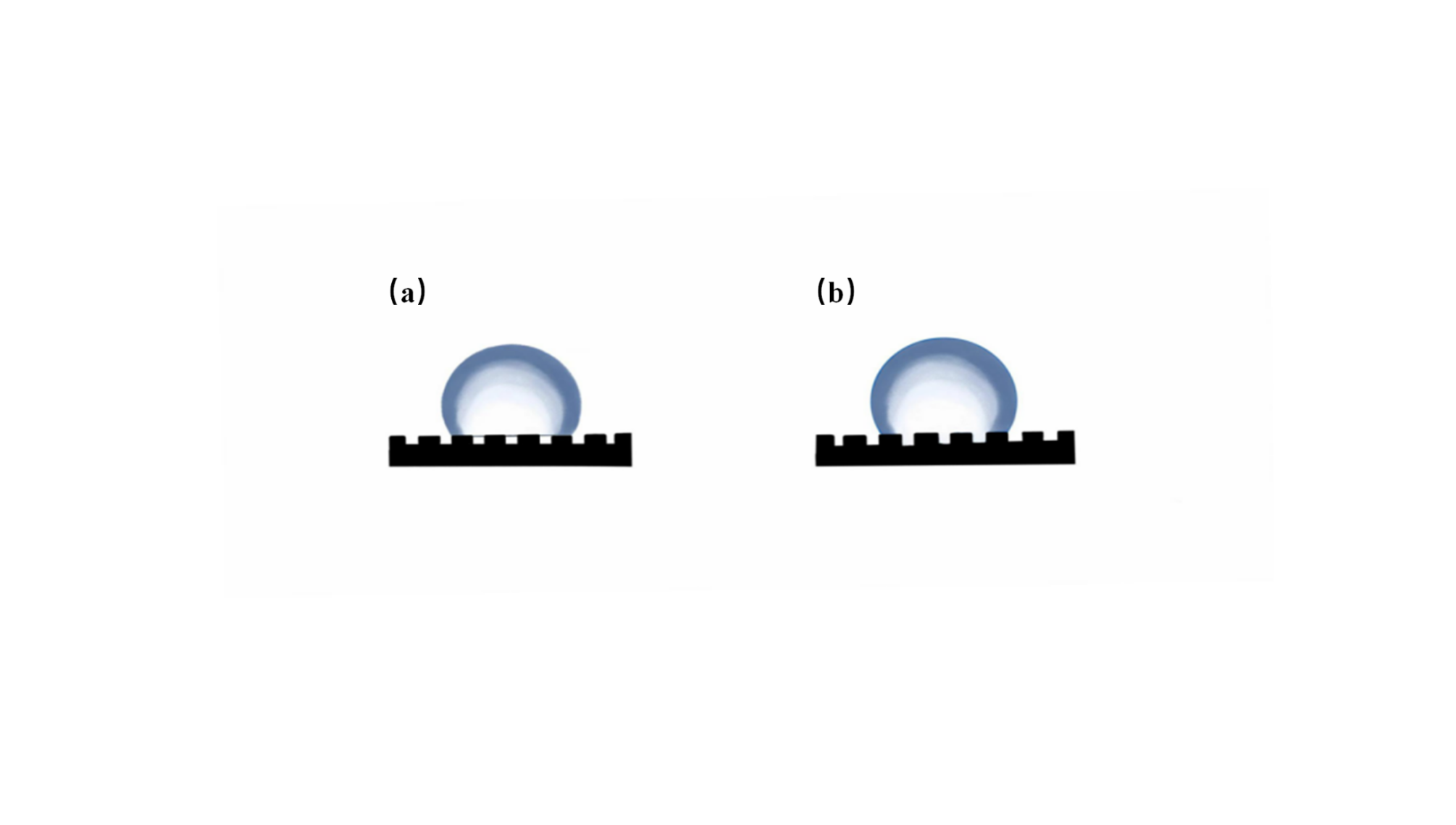

Among them, γsv, γsl and γlv respectively signify the interfacial tensions at the solid-gas, solid-liquid and liquid-gas interfaces, respectively, and θ denotes the contact angle at equilibrium. The wetting behavior of a liquid droplet on a solid surface is closely related to the surface morphology and is generally considered to result from the combined effects of the solid-liquid-gas three-phase interfacial tensions [5]. In practical applications, the wetting characteristics of solid surfaces are often influenced by both their surface chemical composition and surface roughness. These two factors jointly determine the surface wettability. In 1936, Wenzel proposed the famous Wenzel model, pointing out that when a liquid comes into contact with an actual solid surface, it completely wets the rough gaps, resulting in only liquid-solid interface contact between the droplet and the surface in Figure 3.

Figure 3: (a) Interstitial no infiltration (b) Interstitial infiltration

Therefore, Wenzel made the following correction to Young's equation:

\( cos{{θ_{w}}}=γcos{θ} \) (2)

In the equation, γ is the roughness factor of the solid surface, defined as the ratio of the actual solid/liquid interface contact area to the apparent solid/liquid contact area. Typically, γ ≥ 1. θw represents the contact angle in the Wenzel model, which is the apparent contact angle, while θ denotes the contact angle in Young's model, which is the intrinsic contact angle. The Wenzel equation reveals an important relationship: when a rough surface is intrinsically hydrophilic (with a contact angle, CA, less than 90°), an increase in its roughness leads to enhanced wettability. On the contrary, when a rough surface is intrinsically hydrophobic (CA > 90°), an increase in roughness results in augmented hydrophobicity. In the context of this experiment, the introduction of hydrophobic silica nanoparticles creates numerous microstructures at the microscopic level, enhancing the surface roughness. This roughness allows the formation of a stable air layer when the liquid comes into contact with the solid surface, reducing the contact area and adhesion force between the droplet and the surface. As a result, the sliding angle is decreased, and the droplet’s rollability is improved.

3.2. Mechanism of self-cleaning

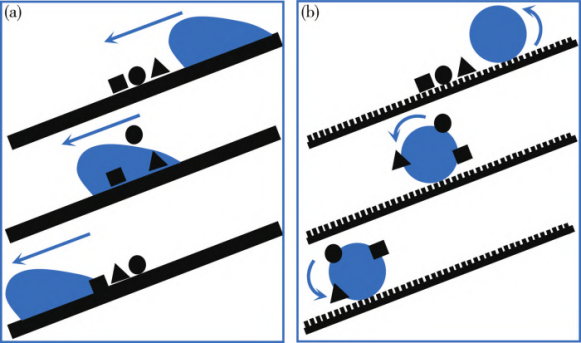

Figure 4 shows the movement behavior of the droplets on the solid surface and the transport mechanism to the pollutant particles. For the superhydrophobic surface, the pollutant particles are larger than the micro-nano structure of the rough surface. Consequently, the pollutant particles are only in contact with the top of the micro-nano structures. This minimal contact configuration leads to a small contact area and weak surface adhesion. When water droplets roll along the superhydrophobic surface, they can effortlessly "capture" the pollutant particles, thus rolling down together with the droplets. In contrast, for a smooth hydrophobic surface, the contaminant contact area with it is much larger, the water droplets roll away in a sliding manner, and the contaminant particles are only redistributed and cannot be carried away in large quantities, so the surface is not self-cleaning. For hydrophilic surfaces, the water droplets have strong viscosity with their surfaces, and the water droplets are difficult to slide off, let alone take away surface pollutants.

Figure 4: movement behavior of droplets on solid surface and transport mode of pollutant particles No structural surface (b) Micro structure surface

3.3. Preparation method of superhydrophobic coating

Superhydrophobic coatings require both a micro-nano rough structure and low surface energy [6]. The preparation methods for superhydrophobic surfaces can be broadly classified into chemical and physical methods [7]. Chemical methods mainly achieve hydrophobicity by changing the chemical composition of the surface of the material and reducing its surface energy. Physical methods mainly achieve hydrophobicity by constructing micro-nano structures on the surface of materials and increasing their roughness.

4. Applications of superhydrophobic materials

4.1. Self-cleaning surface

Self-cleaning materials effectively remove contaminants and surface impurities through functionalized surfaces. Their core mechanism relies on the material's ultra-low surface energy, which suppresses water molecules' interaction and enhances water phase movement. This property enhances the propulsion of water phase movement across the material, ultimately achieving self-cleaning functionality[8]. Self-cleaning technology have widespread applications in building facades, car windshields and solar panels. Wang's group developed a weather-resistant self-cleaning coating based on fluorosilicon synergistic modification, low surface energy polymers, and optimized monomer ratios [9]. The coating P3 has high light transmittance, excellent hydrophobicity, and mechanical stability, with minimal performance changes after 5000 hours of artificial accelerated aging. When applied to high-speed rail EMU, the coating shows significant anti-fouling, anti-graffiti, and long-term self-cleaning effects. After half a year of operation, no obvious stains appear in the coated area, while stains in the uncoated area accumulate. This research provides a low-cost, high-efficiency, and environmentally friendly self-cleaning solution for rail transit and has broad prospects for industrial application.

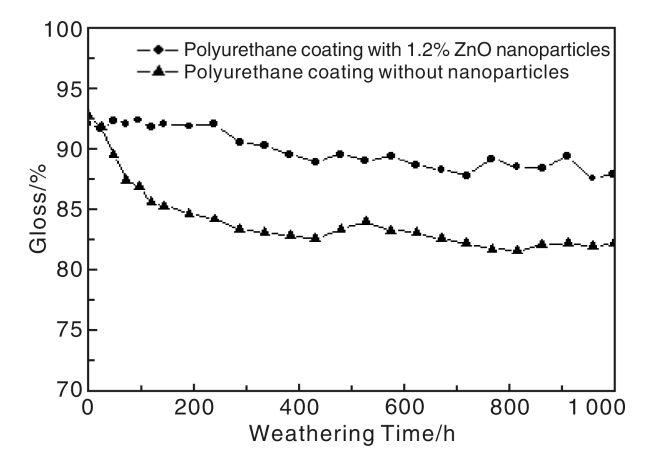

4.2. Anti-corrosion coating

By constructing a micro-nano rough structure and low surface energy modification (such as fluorination modification), with the contact angle of the surface of the superhydrophobic material over 150°, it can effectively block the penetration of corrosive media such as water and salt spray. In the field of corrosion protection, applications include: Inhibit electrochemical corrosion, reduce the contact between metal surface and electrolyte, and block the corrosion reaction path; Multifunctional compounding, combined with corrosion inhibitors or nanofillers (e.g., SiO2, ZnO) to synergistically enhance anti-corrosion durability. It is widely used in wet or marine environments such as ships, offshore platforms, bridges, etc., to extend the life of structures. Wang's research group investigated the effect of nano-silica and nano-zinc oxide concentrate on the improvement of the performance of marine epoxy coatings and polyurethane coatings in Figure 5 [10]. Through the salt spray test, xenon lamp aging test and artificial marine accelerated aging test, it was found that the bond strength of epoxy primer with 1.0% nano silica increased from 4.4 MPa to 5.6 MPa, and the corrosion resistance of salt spray was significantly enhanced. The gloss of 1.2% nano-zinc oxide polyurethane topcoat only decreased by 4.6% (11.2% for ordinary paint) after xenon lamp aging(Fig. 5), and the reduction ratio of C/O value after artificial accelerated aging (10.7%) was much lower than that of unmodified paint (20.1%). The research confirmed by TEM, FTIR, XPS and other technologies that the steric hindrance effect of the long carbon chain of the polymer dispersant makes the nanoparticles evenly dispersed, thereby improving the corrosion resistance, anti-aging and surface hydrophobicity of the coating. Nanocomposite coatings exhibit excellent comprehensive protection performance in the ocean, atmosphere and splash areas.

Figure 5: Gloss change curves of polyure rethane coating and nano-coating after 1000h aging of xenon lamp [10]

4.3. Anti-icing material

Anti-icing and de-icing technologies are not only has an urgent research need in the fields of electric power, transportation, power generation, wind turbines, etc, research in the field of aviation is also attracting attention [11-12]. Feng's study proposeda novel biomimetic superhydrophobic anti-icing surface preparation method. This approach integrated nanosecond laser etching with chemical modification, with cold - resistant bamboo leaves serving as the biomimetic model [13]. By analyzing the microscopic morphological characteristics of micropapillae, dumbbell-shaped arrays and groove structures on the surface of bamboo leaves, combined with the Cassie wetting model and heat transfer theory, the anti-icing mechanism of superhydrophobic surface to reduce the solid-liquid contact area and heat conduction efficiency by intercepting the air layer was proposed. The characterization results show that the static contact angle of the biomimetic surface is greater than 160°, the rolling angle is below 5°, and the surface free energy is as low as 20.366 mN/m, demonstrating excellent superhydrophobic characteristics.

4.4. Oil-water separation materials

Superhydrophobic materials exhibit a strong affinity for oils, enabling them to efficiently separate oil-water mixtures through selective wetting mechanisms, especially in scenarios such as oily wastewater treatment and marine oil spill recovery. In specific applications, superhydrophobic materials can play a role in two main forms. First, they can be utilized as separation membranes or filter media. By precisely controlling the pore size and leveraging their unique surface properties, these materials enable the selective penetration of the oil phase. Second, they can serve as adsorption materials, such as superhydrophobic sponges and aerogels. These materials rapidly adsorb oil and repel water through capillary action. For instance polydimethylsiloxane (PDMS)-modified superhydrophobic polyurethane sponges can re-adsorb crude oil by more than 30 times its weight with a separation efficiency of more than 99% [14]. Compared to raditional chemical demulsification method, this technology has the advantages of green environmental protection, low energy consumption and recyclability, and shows significant economic benefits in the treatment of industrial emulsified oil wastewater. Biomimetic designs, such as pitcher plant lubricated surfaces, provide new ideas to solve the problem of oil adhesion, while photothermally responsive superhydrophobic materials can be self-cleaning by solar drive [15].

5. Conclusion

This paper examines the security threats to mobile applications and the protection mechanisms used to safeguard them. As mobile applications become more integral to daily life and business operations, they face significant and growing security risks, including malware, data breaches, and network attacks. Robust security measures are crucial to protect user data and app integrity. Encryption, authentication, and technical solutions like code obfuscation and Runtime Application Self-Protection (RASP) are essential in defending against these threats. Advanced techniques like RASP provide real-time protection, identifying and blocking threats during the app's runtime. However, as the security landscape evolves, so must the strategies used to protect mobile applications. Cyber attackers constantly adapt, so security mechanisms must be consistently updated and refined. The challenge lies in developing advanced security technologies and ensuring they are effectively implemented and integrated into the app development lifecycle. The role of app developers, industry standards, and regulatory bodies is crucial in shaping mobile app security. The future of mobile app security may involve more innovative technologies like artificial intelligence and machine learning to predict and prevent potential threats. By staying ahead of evolving threats and continuously improving security measures, the mobile app industry can ensure a safer digital environment for users worldwide.

References

[1]. Neinhuis, C.; Barthlott, W. (1997)Purity of the sacred lotus, or escape from contamination in biological surfaces.Planta , 202(1), Page 1-8

[2]. Bing,L.;Song,X.;Bing,X.;Xiangkang,C.(2023)Superhydrophobic coating based on nano-ZIF-8/ZnO and its corrosion resistance and antibacterial properties.Journal of Chinese Society for Corrosion and Protection ,44(10),Page 18-24

[3]. Peiyu,S.;Zhaolong,C.(2024)Preparation and performance of superhydrophobic coatings for anti-scaling of oilfield pipelines.Adhesion magazine,51(2),Page 127-130

[4]. Zhicheng,L.;Jiayi,Z.;Yanshun,Y.(2021)Research progress on droplet-directed motion on wettable surfaces.Surface Science and Technology,50(1),Page 138-149

[5]. Yi,Z.;Jia,W.;Jiao,Z.;Mengyu,W.(2023)Research progress of self-cleaning technology of cement-based superhydrophobic materials.Materials Reports,37(6),Page 91-107

[6]. Yifan,W.;Junhuang,X.;Li,L.;Linyong,L.(2024)Research Progress of Superhydrophobic Coatings and Its Functionalization. Paint&Coating Industry, 54(2), Page 64-71

[7]. Le,Z.(2024)Research Progress of Superhydrophobic Materials and Their Coatings.Surface Technology, 53(24), Page 54-68

[8]. Zimei,Z.;Xingtao,M.;Fei,W.;Maodong,X.(2024)Research progress on self-cleaning materials.Modern Chemical Industry, 44(7), Page 31-35

[9]. Xin,W.;Yingbin,Z.;Kangle,J.;Ding,Y.(2023)Construction of weather resistant self-cleaning fluorosilicone coating and its application on high-speed trains.Fine Chemicals,40(11),Page 2544-2552

[10]. Zhenyu,W.;Enhou,H.;Fuchun,L.;Hongwei,S.(2014)Application Research of Marine Composite Nano-Coatings in Corrosion Protection of Ship.Materials China,33(1),Page 14-19

[11]. Frankenstein,S.;Tuthill,A. M.(2002)Ice adhesion to locks and dams: Past work; future directions.Journal of Cold Regions Engineering,16(2),Page 83-96

[12]. Baars,W. J.;Stearman,R. O.;Tinney,C. E.(2010)A Review on the Impact of Icing on Aircraft Stability and Control.Journal of Aeroelasticity and Structural Dynamics,2(1),Page 35-52

[13]. Xiaoming,F.;Zhizhong,W.;Bingbing,Y.;Baolin,Y.(2024)Experimental Design for the Preparation of Superhydrophobic Anti-icing Surface by Imitating the Microstructure of Cold-resistant Bamboo Leaves.Research and Exploration in Laboratory,43(11),Page 16-19

[14]. Surya,M. I.; Ajithkumar,M. P.; Siddhartha,P.(2023)Design and fabrication of nepenthes alata-inspired sweat collection patch using wettability patterning method.Chemical Engineering Journal,477,Page 147066

[15]. Kefeng,X.;Huan,Y.;Yuegan,S.;Yi,Y.(2023) Low Ice Adhesion Deicing/Anti-icing Surface of Porous Microcavity Inspired by Nepenthes. Surface Technology, 52(10),Page 313-320

Cite this article

Fan,K. (2025). Research on Progress and Development of Superhydrophobic Materials. Applied and Computational Engineering,143,35-41.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 3rd International Conference on Functional Materials and Civil Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Neinhuis, C.; Barthlott, W. (1997)Purity of the sacred lotus, or escape from contamination in biological surfaces.Planta , 202(1), Page 1-8

[2]. Bing,L.;Song,X.;Bing,X.;Xiangkang,C.(2023)Superhydrophobic coating based on nano-ZIF-8/ZnO and its corrosion resistance and antibacterial properties.Journal of Chinese Society for Corrosion and Protection ,44(10),Page 18-24

[3]. Peiyu,S.;Zhaolong,C.(2024)Preparation and performance of superhydrophobic coatings for anti-scaling of oilfield pipelines.Adhesion magazine,51(2),Page 127-130

[4]. Zhicheng,L.;Jiayi,Z.;Yanshun,Y.(2021)Research progress on droplet-directed motion on wettable surfaces.Surface Science and Technology,50(1),Page 138-149

[5]. Yi,Z.;Jia,W.;Jiao,Z.;Mengyu,W.(2023)Research progress of self-cleaning technology of cement-based superhydrophobic materials.Materials Reports,37(6),Page 91-107

[6]. Yifan,W.;Junhuang,X.;Li,L.;Linyong,L.(2024)Research Progress of Superhydrophobic Coatings and Its Functionalization. Paint&Coating Industry, 54(2), Page 64-71

[7]. Le,Z.(2024)Research Progress of Superhydrophobic Materials and Their Coatings.Surface Technology, 53(24), Page 54-68

[8]. Zimei,Z.;Xingtao,M.;Fei,W.;Maodong,X.(2024)Research progress on self-cleaning materials.Modern Chemical Industry, 44(7), Page 31-35

[9]. Xin,W.;Yingbin,Z.;Kangle,J.;Ding,Y.(2023)Construction of weather resistant self-cleaning fluorosilicone coating and its application on high-speed trains.Fine Chemicals,40(11),Page 2544-2552

[10]. Zhenyu,W.;Enhou,H.;Fuchun,L.;Hongwei,S.(2014)Application Research of Marine Composite Nano-Coatings in Corrosion Protection of Ship.Materials China,33(1),Page 14-19

[11]. Frankenstein,S.;Tuthill,A. M.(2002)Ice adhesion to locks and dams: Past work; future directions.Journal of Cold Regions Engineering,16(2),Page 83-96

[12]. Baars,W. J.;Stearman,R. O.;Tinney,C. E.(2010)A Review on the Impact of Icing on Aircraft Stability and Control.Journal of Aeroelasticity and Structural Dynamics,2(1),Page 35-52

[13]. Xiaoming,F.;Zhizhong,W.;Bingbing,Y.;Baolin,Y.(2024)Experimental Design for the Preparation of Superhydrophobic Anti-icing Surface by Imitating the Microstructure of Cold-resistant Bamboo Leaves.Research and Exploration in Laboratory,43(11),Page 16-19

[14]. Surya,M. I.; Ajithkumar,M. P.; Siddhartha,P.(2023)Design and fabrication of nepenthes alata-inspired sweat collection patch using wettability patterning method.Chemical Engineering Journal,477,Page 147066

[15]. Kefeng,X.;Huan,Y.;Yuegan,S.;Yi,Y.(2023) Low Ice Adhesion Deicing/Anti-icing Surface of Porous Microcavity Inspired by Nepenthes. Surface Technology, 52(10),Page 313-320