1. Introduction

In today's rapidly developing world, various types of explorations are taking place continuously, such as topographic exploration, rescue exploration, mineral exploration, and so on. The use of various robots enables adaptation to complex and dangerous exploration environments, thereby reducing the risk of injury associated with these conditions. Nowadays, a variety of special upgrading and transforming robots have been developed, enabling them to specially adapt to specific environments. For example, underwater robots that play an important role in marine resource exploration, environmental monitoring and protection, and auxiliary construction [1], programmable shaped hydrogel fibers that can cope with solvents and ambient humidity [2], and fuzzy control algorithms designed in balanced robots for improved responsiveness, robustness and stability [3].

One of them is the Intelligent Spring with Programmable Stiffness (ISPS), which is composed of low-melting-point alloy (LMPA) as the key material, and it has become a crucial structure of the Bioinspired Continuum robot. Nowadays, the applications of low-melting-point alloys have been extremely extensive. For example, in the process of forming the tooling for shaped composite parts, the use of low-melting-point alloys can improve the dimensional and surface accuracy of the parts [4]. By utilizing the penetration mechanism of low-melting-point alloy in wood, metalized poplar wood is prepared, which enhances its compressive strength along the grain and shows good application prospects in the field of geothermal floor heating [5]. And in order to solve the heat dissipation problem of electronic devices when they operate with short-term dynamic high power in an environment without wind and liquid, a low-melting-point alloy phase change heat sink with a heat conducting fin structure was proposed [6]. The low-melting-point alloy used in this paper is Cerrolow 147, which belongs to the bismuth-tin alloy. Its melting point is 47°C, and its physical properties are stable in the molten state, with excellent cooling characteristics [7]. When heated, the low-melting-point alloy changes from a solid state to a liquid state, causing the ISPS to soften. When cooled, the alloy solidifies, and the ISPS regains its rigidity. This endows the robot with the characteristic of programmable stiffness, which is of great significance in the design and performance realization of continuum robots. The bionic Continuum robot makes use of the characteristics of low-melting-point alloys and the key structure of the elephant trunk, enabling it to handle scenes with different curvatures. It overcomes the limitations of existing continuum robots by programming the structural stiffness [8]. During the exploration process, the reaction rate is of vital importance and is one of the key factors affecting efficiency [9]. However, in the heating and softening experiment of the ISPS part of the bionic Continuum robot, under the single cantilever beam configuration, when it bears a weight of 50 g, the slight displacement at the tip is 0.53 ± 0.12 mm. When heated by Joule heating (T > Tm of 47 °C), the LMPA will undergo a phase transition from solid to liquid, softening the ISPS, which in turn leads to a large bending deformation at an angle of 90.17° ± 5.32° under the same weight. It takes about 8 minutes for the ISPS to complete the large bending deformation from the start of heating when it bears a weight of 50 g. While after removing the 50 g load, it takes about 10 minutes from the start of heating to approach the restoration of the initial position [8]. Obviously, the speed of the bending change is too slow and the efficiency is too low, which may not be able to meet the purpose of making quick turns during the exploration process, thus affecting the reaction speed of the final overall machinery.

Therefore, the aim of this article is to propose a concept of a design similar to that of the Variable single-axis magnetic-field generator, which is nested on the basis of the ISPS in Continuum robots [10]. Through the prediction of the data size of the equipment and the simulation calculations in the formulas, it is concluded that this device can generate a variable magnetic field and apply an additional magnetic force to a single ISPS. This can increase the bending speed of the ISPS structure when it is heated, softened and subjected to force, thereby enhancing the overall adaptability and usage efficiency of this mechanism in complex exploration environments, and providing a practical vision for the development of future bionic robots [11].

2. Literature review

2.1. Principles and defects of programmable stiffness bioinspired continuum robot

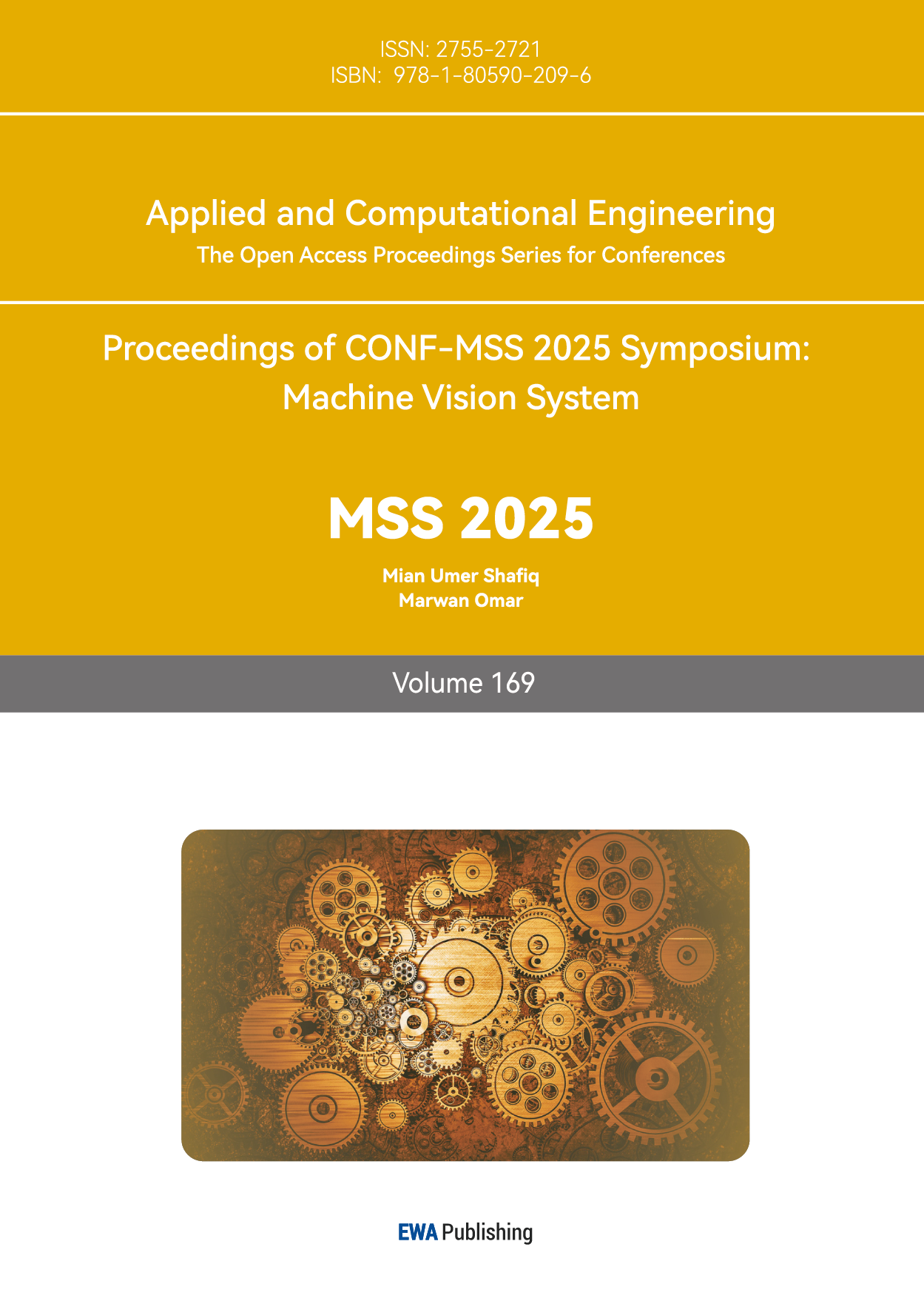

Based on the structural characteristics of the elephant trunk, Zhang designed the Cable-driven Continuum Robot (CCR), which is applied as a key structure in a bioinspired continuum robot with programmable stiffness. The CCR is composed of 12 modular tensegrity structures and is divided into three independently controllable segments [8]. The power source selectively supplies current to each segment. Through the current, the structural stiffness of each segment can be actively adjusted, enabling the CCR to exhibit eight stiffness sequences. Then, each segment is actuated by heating or cooling the Intelligent Spring with Programmable Stiffness(ISPS), allowing the CCR to still show different profiles after deformation. As a result, it can be applied to various deformation scenarios [8]. Among them, the ISPS is composed of low melting point alloy (LMPA) as the key material, copper wires as the conductors, and silicone rubber tubes(Figure 1). When the wire is energized and heats up to reach the liquefaction temperature of the LMPA, the ISPS undergoes deformation under the action of the pulling force. As a result, after the segmented regulation, the CCR can exhibit different morphologies.

In the experiment to separately test the performance of the ISPS, the horizontally fixed ISPS structure, under the combined action of the vertical pulling of a 50g weight and heating softening, took about 8 minutes to bend from zero to 90°. Moreover, the natural recovery process took as long as about 10 minutes [8]. However, during the actual survey process, the robotic arm often encounters places where large and rapid turns are required. The original ISPS device has too low efficiency, which is likely to lead to the failure of some urgent survey tasks. Therefore, improving the bending efficiency of the ISPS is the central focus of this design.

2.2. The principle of nested Halbach cylindrical arrays adopted for deficiencies

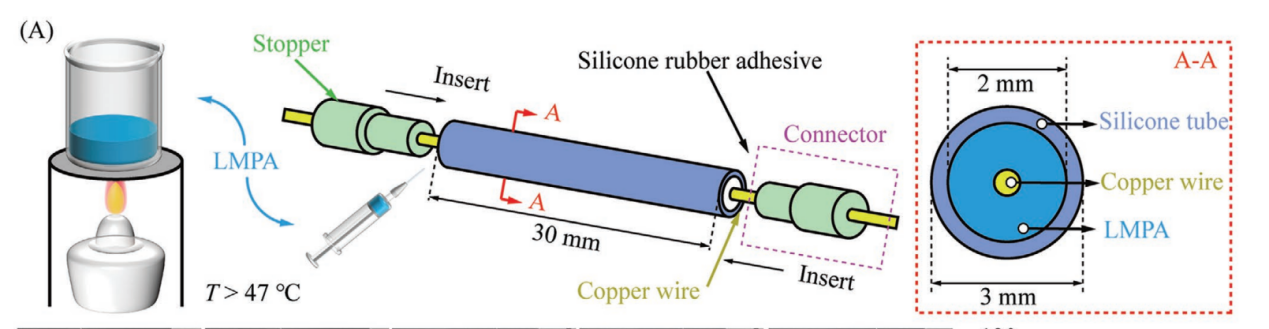

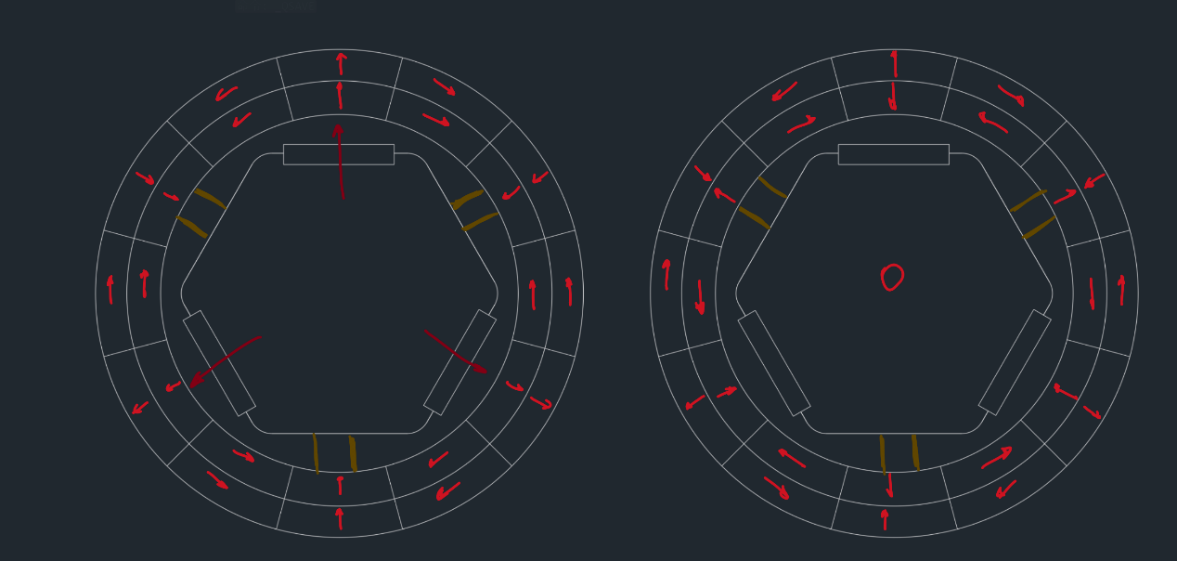

To improve the bending efficiency of the ISPS, this paper adopt nested Halbach cylindrical arrays composed of Halbach arrays, shown in Figure 2. Magnets with different orientations are arranged according to a certain pattern, causing the magnetic field lines on one side to converge and those on the other side weaken, thereby obtaining a relatively ideal unilateral magnetic field [12].

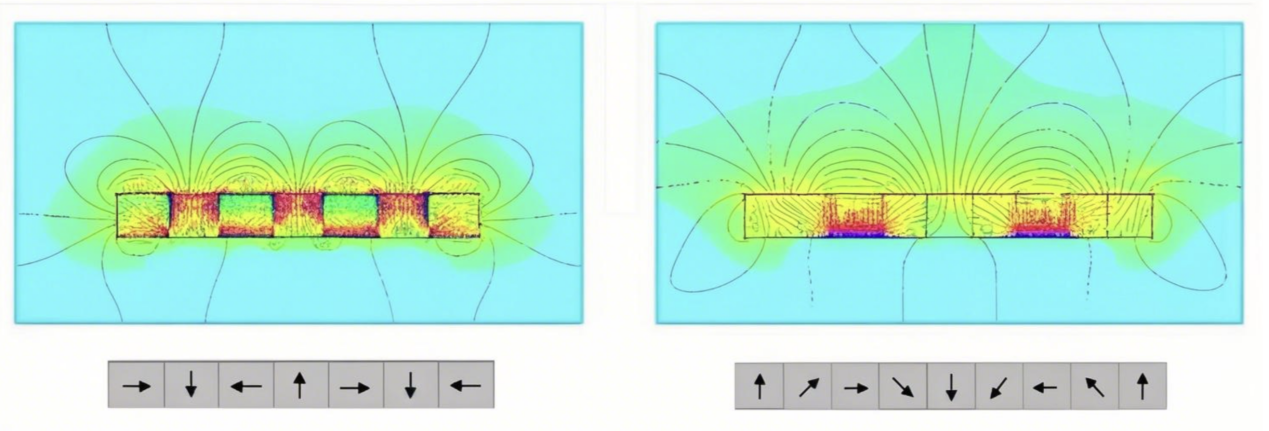

The circular Halbach array can be regarded as a circular ring shape formed by connecting the head and the tail of the linear Halbach array [10]. As shown in Figure 3, the annular Halbach arrays that are arranged in different rule can provide different forms of magnetic field directions. This characteristic of the unilateral magnetic field enables the circular Halbach array to generate a magnetic field inside while not generating a magnetic field outside. Therefore, it has no impact on the external mechanical structure, and the internal magnetic field can serve as the magnetic field for the CCR component of the bionic elephant trunk mechanism.

The principle of this Variable single-axis magnetic-field generator is that, based on the superimposed application of the Halbach array, the magnetic field can be regulated by rotating the inner and outer Halbach arrays to the corresponding relative positions [10]. As shown in Figure 4, in the left diagram, the directions of the outer ring and the inner ring are the same, and the overlapping magnetic fields show an enhancement, achieving the effect of enhancing the internal magnetic field. In the right figure, the directions of the outer ring and the inner ring are opposite, causing the overlapping magnetic fields to cancel each other out, achieving the effect of weakening the internal magnetic field. This device can provide a stronger magnetic field when the magnetic field is required. When the magnetic field is not needed, it can offset the magnetic field to achieve the effect that the internal magnetic field is zero. In this way, when the magnetic field is not required, it can prevent the magnetic field from affecting the operation of the machinery. The device as a whole achieves a unilateral magnetic field, so it can avoid the influence of the external magnetic field of the device on external machinery during its operation.

3. Methodology

3.1. The magnetic force increases the bending speed of the ISPS under force

For an ideal cylindrical Halbach dipole, considering it as an infinitely long tube, the calculation formula for the magnetic field strength it generates in the cross-sectional plane is as follows:

Among them,

When

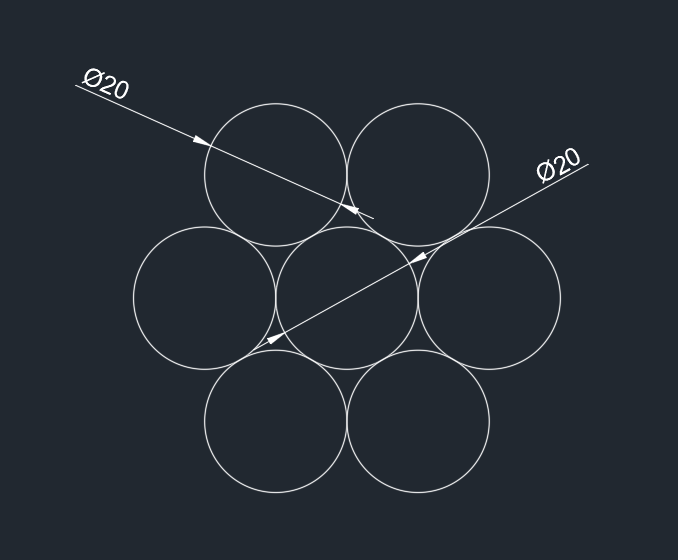

In this way, the magnitude and variation range of the magnetic field generated by the nested Halbach dipole pairs can be theoretically analyzed. According to the dimensions in Figure 4, a single hexagonal ring-shaped layer is alternately connected by three rigid crossbars (with a length of

In addition, according to the definition of the magnetization intensity

Among them,

For a spherical sample,

Where

Since

According to the relationship between the magnetic induction intensity

Where

Substitute the magnitude of the centrally synthesized magnetic field, then:

Calculate the magnetic force by combining with the magnetic field gradient. If the magnetic field gradient

Where

Under the assumption that the direction of the magnetic moment m is parallel to the direction of the magnetic field gradient, that is,

Therefore, a single small magnetic bead can provide a magnetic force of

3.2. The nested Halbach cylindrical arrays can provide a variable magnetic field for the ISPS of the small magnetic beads nested in the middle

The nested Halbach cylindrical array is connected to the CCR in the manner shown in Figure 4. Figure 6 illustrates the sectional view of a single hexagonal ring-shaped layer on the CCR. Through the dimensional design of the double-layer ring, the magnitudes of the magnetic fields generated by the inner and outer rings are made to be the same, that is,

Upon observation, when the magnetic field directions of the inner and outer rings are opposite (Figure 4, Right), it is precisely obtained by rotating the state when the magnetic field directions of the inner and outer rings are the same (Figure 4, Left) 60° to the right. Therefore, the inner and outer rings can be positioned at different locations by controlling the angle of rotation. When the angle varies between 0° and 60°, a gradually decreasing magnetic field can be generated, thereby providing the nested Halbach cylindrical array provides a variable magnetic field for the ISPS of the small nested magnetic bead in the middle. Finally, this variable magnetic field is utilized. It can achieve the following function: when the magnetic force is required to accelerate the bending of the ISPS, the magnetic field can be provided. When the magnetic force is not needed, the magnetic field can be turned off. In this way, the generation of an excessive magnetic field that might affect other components can be prevented.

4. Discussion

In this paper, a nested Halbach cylindrical array is combined with the CCR part of the bionic elephant trunk. Small magnetic beads are added to the ISPS within the CCR. In this way, magnetic force can be generated under the action of a magnetic field and act on the ISPS. By accelerating the bending deformation of the ISPS, the deformation efficiency of the entire CCR is increased, thereby accelerating the overall work efficiency of exploration. In the research on the methods of providing force, shape memory alloys can also be employed. By reaching their phase transition temperature, the shape memory alloys will recover their original shapes, thereby providing a pulling force to the ISPS, which is a way to accelerate the bending efficiency of the ISPS. However, the phase transition temperature of shape memory alloys is related to their specific types, compositions, processing techniques, and usage requirements. The control over the applied force is relatively weak, and this material cannot be used to conduct relevant result tests through simulation. In addition, a temperature-related low melting point alloy (LMPA) was also involved in the fabrication of the ISPS. However, the situation of using LMPA in combination with shape memory alloys imposes relatively high requirements on the experimental conditions, which cannot be met currently. Therefore, in this design, priority is given to completing the relevant design based on the provision of force by means of magnetic force and a variable magnetic field. Since the electromagnet controls the magnitude of the magnetic force through electricity, taking into account the large variety of electrical components available for selection, the requirements for the arrangement and use of wires, practicality, the difficulty of controlling the generation of a magnetic field in a single direction, the need for equipment simplification, and the impact of the excess magnetic field on other equipment, etc., this paper designs a Halbach array as the component for providing the magnetic field effect, which stabilizes the supply of the magnetic force and ensures the correct operation of the equipment. The application of the Halbach array is quite common in daily life. For instance, the single-sided magnetic attraction of refrigerator magnets. Therefore, the manufacturing cost of this nested Halbach cylindrical array is not high, and its size is relatively small. It can be well integrated with the CCR without appearing cumbersome. Therefore, in this study, the nested Halbach cylindrical arrays are utilized to provide the magnetic field effect. This approach can achieve the effect of providing a variable magnetic field without generating any excessive magnetic field to the outside environment, which is highly suitable for the bionic elephant trunk manipulator, the main subject of this study, and its working environment.

5. Conclusion

In the exploration environment, in order to enhance the working ability of the Bioinspired Continuum robot with programmable stiffness of the biomimetic elephant trunk and improve the work efficiency, this article combines the nested Halbach cylindrical arrays and utilizes the characteristics of the Halbach array to act on the CCR part of the target elephant trunk robot. In this way, a magnetic force is provided for the ISPS (which is installed with small magnetic beads), thereby accelerating the bending efficiency of the ISPS, and finally achieving an improvement in the efficiency of the exploration work. However, this concept still has its drawbacks. Firstly, the magnetic field provided by this method is still relatively weak, resulting in a small generated force. It is necessary to discuss how to provide a stronger magnetic field to further enhance the bending effect of the ISPS. In the second aspect, since the CCR is composed of multiple single hexagonal ring-shaped layers, and in order to achieve bending, it is inevitable that there will be gaps between the adjacent two layers of hexagonal ring-shaped layers for the nested Halbach cylindrical arrays. However, the generation of these gaps may lead to the leakage of the internal magnetic field to the outside of the machinery, which may affect the operation of other unrelated machinery. In the future, the development of robots in the exploration field will still be popular, and the significance of robot development in the exploration field will remain extremely substantial. There is still a vast development space for this trunk-like robot, and there are still numerous ways to enhance the working efficiency of robots. In terms of improving the bending efficiency of the ISPS, in the future, it is possible to attempt to use shape memory alloys and replace the low-melting-point alloy of the central material, so as to improve the overall bending efficiency of the ISPS. There is also room for improvement in the way the magnetic field is provided and in the form and material of the small magnetic beads, so that they can work together to achieve a greater magnetic force effect.

References

[1]. Tang Z.S.H.(2024). Innovation and Practice of Underwater Robot Technology in Marine Engineering [J]. Pearl River Water Transport. (6): 108-110. DOI: 10.14125/j.cnki.zjsy.2024.06.005.

[2]. Zhai, Y.D., Gong, C., Chen, J.H. & Chang, C.Y. (2023). Magnetic-field induced asymmetric hydrogel fibers for tough actuators with programmable deformation, Chemical Engineering Journal. Vol. 477, 147088., DOI: 10.1016/j.cej.2023.147088.

[3]. Liu H., Li Z., Yang M.H., Deng X.G. & Cao Y.P. (2023). Design of a Full-Displacement Balanced Robot Based on Fuzzy Control [J]. Measurement & Control Technology. 42(7): 102-109.DOI: 10.19708/j.ckjs.2022.08.298.

[4]. Cao C., Hong X.M. & Dang X.L. (2025). Application of Low-Melting-Point Alloys in the Forming Tooling of Special-Shaped Composite Parts [J]. Die & Mould Manufacture. 25(01): 25-26 + 29. DOI: 10.13596/j.cnki.44-1542/th.2025.01.008.

[5]. Sun Y.P., Yu X.D., Chai X.J., Xu, K.M. & Xie L.K. (2024). Study on the Properties and Mechanism of Poplar Wood Impregnated by Low-Melting-Point Alloy under High and Low Temperature Cycling [J]. China Forest Products Industry. 61(04): 1-6. DOI: 10.19531/j.issn1001-5299.202404001.

[6]. Chen X.C., Huang G.C. & Gu Z.C. (2024). Research on the Design and Heat Dissipation Performance of a Low-Melting-Point Alloy Phase Change Heat Sink [J]. Electro-Mechanical Engineering. 40(04): 22-27. DOI: 10.19659/j.issn.1008-5300.2024.04.006.

[7]. Dušek, K., Bušek, D., Veselý, P., Pražanová, A., Plaček, M. & Re, J.D. (2022). Understanding the Effect of Reflow Profile on the Metallurgical Properties of Tin–Bismuth Solders. Metals. 12, 121. DOI: 10.3390/met12010121.

[8]. Zhang, J., Wang, B., Chen, H., Bai, J., Wu, Z., Liu, J., Peng, H. & Wu, J. (2023). Bioinspired Continuum Robots with Programmable Stiffness by Harnessing Phase Change Materials. Adv. Mater. Technol. 8, 2201616. DOI: 10.1002/admt.202201616.

[9]. Mu X.H. & Ding Y. (2024). Exploration on the Application of Comprehensive Geological Exploration Methods [J]. Inner Mongolia Coal Economy. (22): 181-183. DOI: 10.13487/j.cnki.imce.026051.

[10]. Tretiak, O., Blümler P. & Bougas, L. (November, 2019). Variable single-axis magnetic-field generator using permanent magnets. AIP Advances. 9(11): 115312. DOI: 10.1063/1.5130896.

[11]. Zhang X.F., Wu Z.Y., Xu X.R., Zhang, E., Wei, S.B. & Xie, F. (2024). Research on a Quadruped Bionic Robot for Intelligent Exploration and Rescue in Air and on Land in Complex Terrains [J]. Automation Application. 65(15): 31-34+37. DOI: 10.19769/j.zdhy.2024.15.009.

[12]. Li C., Hong Q., Yang X.B., Chen, R., Sun, Y.D. & Liang, L.L. (2021). Numerical Simulation Based on C++ of the Magnetic Field Distribution and Magnetic Induction Lines of a Circular Current [J]. Physical Experiment of College. 34(03): 28-30. DOI: 10.14139/j.cnki.cn22-1228.2021.03.008.

[13]. Zhan Y.Z., Pan Y.F., Huang J.F., Liang J. & Wang X.Z. (2015). Research Progress in the Application of Soft Magnetic Materials [J]. Guangxi Sciences. 22(5): 467-472. DOI: 10.13656/j.cnki.gxkx.20151027.017.

[14]. Qin W.N., Wei L.X. & Jia X.L. (2024). Preparation of Fe3N Magnetic Nanoparticles and Research Progress of Their Applications [J]. Chemical Engineer. 38(01): 61-65+74. DOI: 10.16247/j.cnki.23-1171/tq.20240161.

Cite this article

Jiang,Y. (2025). Based on the Design Concept of a Bioinspired Continuum Robots with Programmable Stiffness Combined with a Nested Halbach Cylindrical Arrays in Exploration Activities. Applied and Computational Engineering,169,68-76.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of CONF-MSS 2025 Symposium: Machine Vision System

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Tang Z.S.H.(2024). Innovation and Practice of Underwater Robot Technology in Marine Engineering [J]. Pearl River Water Transport. (6): 108-110. DOI: 10.14125/j.cnki.zjsy.2024.06.005.

[2]. Zhai, Y.D., Gong, C., Chen, J.H. & Chang, C.Y. (2023). Magnetic-field induced asymmetric hydrogel fibers for tough actuators with programmable deformation, Chemical Engineering Journal. Vol. 477, 147088., DOI: 10.1016/j.cej.2023.147088.

[3]. Liu H., Li Z., Yang M.H., Deng X.G. & Cao Y.P. (2023). Design of a Full-Displacement Balanced Robot Based on Fuzzy Control [J]. Measurement & Control Technology. 42(7): 102-109.DOI: 10.19708/j.ckjs.2022.08.298.

[4]. Cao C., Hong X.M. & Dang X.L. (2025). Application of Low-Melting-Point Alloys in the Forming Tooling of Special-Shaped Composite Parts [J]. Die & Mould Manufacture. 25(01): 25-26 + 29. DOI: 10.13596/j.cnki.44-1542/th.2025.01.008.

[5]. Sun Y.P., Yu X.D., Chai X.J., Xu, K.M. & Xie L.K. (2024). Study on the Properties and Mechanism of Poplar Wood Impregnated by Low-Melting-Point Alloy under High and Low Temperature Cycling [J]. China Forest Products Industry. 61(04): 1-6. DOI: 10.19531/j.issn1001-5299.202404001.

[6]. Chen X.C., Huang G.C. & Gu Z.C. (2024). Research on the Design and Heat Dissipation Performance of a Low-Melting-Point Alloy Phase Change Heat Sink [J]. Electro-Mechanical Engineering. 40(04): 22-27. DOI: 10.19659/j.issn.1008-5300.2024.04.006.

[7]. Dušek, K., Bušek, D., Veselý, P., Pražanová, A., Plaček, M. & Re, J.D. (2022). Understanding the Effect of Reflow Profile on the Metallurgical Properties of Tin–Bismuth Solders. Metals. 12, 121. DOI: 10.3390/met12010121.

[8]. Zhang, J., Wang, B., Chen, H., Bai, J., Wu, Z., Liu, J., Peng, H. & Wu, J. (2023). Bioinspired Continuum Robots with Programmable Stiffness by Harnessing Phase Change Materials. Adv. Mater. Technol. 8, 2201616. DOI: 10.1002/admt.202201616.

[9]. Mu X.H. & Ding Y. (2024). Exploration on the Application of Comprehensive Geological Exploration Methods [J]. Inner Mongolia Coal Economy. (22): 181-183. DOI: 10.13487/j.cnki.imce.026051.

[10]. Tretiak, O., Blümler P. & Bougas, L. (November, 2019). Variable single-axis magnetic-field generator using permanent magnets. AIP Advances. 9(11): 115312. DOI: 10.1063/1.5130896.

[11]. Zhang X.F., Wu Z.Y., Xu X.R., Zhang, E., Wei, S.B. & Xie, F. (2024). Research on a Quadruped Bionic Robot for Intelligent Exploration and Rescue in Air and on Land in Complex Terrains [J]. Automation Application. 65(15): 31-34+37. DOI: 10.19769/j.zdhy.2024.15.009.

[12]. Li C., Hong Q., Yang X.B., Chen, R., Sun, Y.D. & Liang, L.L. (2021). Numerical Simulation Based on C++ of the Magnetic Field Distribution and Magnetic Induction Lines of a Circular Current [J]. Physical Experiment of College. 34(03): 28-30. DOI: 10.14139/j.cnki.cn22-1228.2021.03.008.

[13]. Zhan Y.Z., Pan Y.F., Huang J.F., Liang J. & Wang X.Z. (2015). Research Progress in the Application of Soft Magnetic Materials [J]. Guangxi Sciences. 22(5): 467-472. DOI: 10.13656/j.cnki.gxkx.20151027.017.

[14]. Qin W.N., Wei L.X. & Jia X.L. (2024). Preparation of Fe3N Magnetic Nanoparticles and Research Progress of Their Applications [J]. Chemical Engineer. 38(01): 61-65+74. DOI: 10.16247/j.cnki.23-1171/tq.20240161.