1. Introduction

With the increasing demand for space exploitation in the new era and the need for more efficient and stable transportation method, reusable launch vehicles, as an importance branch of launch vehicle development, are gradually being studied and applied by more countries and organizations. This research has received attention for many years. For example, the Vulcan launch vehicle, New Glenn launch vehicle, and Falcon 9 launch vehicle have realized or plan to realize the recovery and reuse of sub-stages. Countries and organizations with launch vehicle technology foundations, including the Russian State Space Corporation, the European Space Agency, Japan, India, and China, attach great importance to the research of reusable vehicles and show concern about the latest progress in the international space field. SpaceX's Falcon 9 is the most groundbreaking and successful case. With the successful trial operation of Falcon 9 launch vehicle reusing operation in 2015, a batch of research projects or analysis reports on reusable launch vehicles appeared in a short period of time, including but not limited to its soft-landing algorithm, the lander (landing platform) structural design scheme, and the economy (cost analysis) of reusable equipment. The research propositions are varied and detailed, but they are still not available enough for screening. There is still a lot of room for research and innovation in the future.

The purpose of this paper is to facilitate the further research of reusable launch vehicle technology and summarize the experience for the future commercialization. This article summarizes the developments of SpaceX and its reusable launch vehicles. The Falcon 9 is taken as an example to sort out the technical points of research background, significance in the field of aerospace and possible pioneering and prospects of reusable launch vehicle technology. In addition, the development of SpaceX has been sorted out, and its contribution to the field of reusable launch vehicles and business mode are summarized. This article may offer a reference for the reusable rocket technology development.

2. Development of reusable launch vehicle

The concept of a reusable launch vehicle is proposed in the mid-20th century, which generally refers to the ability to quickly and steadily traverse the atmosphere, to travel between the surface and space, for projection, logistics, exploration, maintenance, military and other tasks. Subsequently, specific tasks are performed on the preset tracks, requiring the ability to adjust posture and orbit for multiple ignitions. In the reusing phase, after the reusable vehicle re-enters into the atmosphere, the optional forms are parachute, vertical return, and winged return to the surface. At present, it is mainly divided into three categories: space shuttle, reusable spaceship, and reusable launch vehicle [1].

2.1. History of reusable launch vehicle

Space shuttle is the world's first form of reusable vehicle. The United States and the Soviet Union respectively put forward the demand, advocated the development and practical use. Space shuttle consists of an external fuel capsule, two vehicle boosters and an orbiter, of which only the external fuel capsule is disposable.

Today, the aerospace plane that can take off and land at the same level as ordinary aircraft is still the highest pursuit of reusable vehicle recognized by the scientific community. The Skylon, developed by the British Reaction Engine Company, is a new generation of single stage to orbit vehicle under this design concept, but it is still in the key technology research and development stage because of the high technical difficulty and huge research consumption [2].

In contrast, the recycling and reuse of spacecraft and space vehicles, namely boosters, can be directly expanded on mature aviation technology, which is easier to achieve. At present, the reusable launch vehicle technology focuses more on the recovery, that is, based on the existing aircraft, adding more functional components to achieve the purpose of easy recovery or direct recovery.

The earliest recovery method developed and put into use is parachute recovery, which is the most simple and effective recovery scheme. The optional methods are marine recovery, land recovery, and helicopter air recovery. The K-1 launch vehicle of the United States Kistler Company is the land recovery adopted a large number of parachute and air bag combination schemes, and the helicopter air recovery using the Vulcan launch vehicle of the United States Joint Launch Alliance as an example focuses on the recovery of launch vehicle core components such as engines [3, 4].

At this stage, the most widely used and commercialized way is vertical return. In 1993, this scheme was first used on the Delta Clipper of McDonnell Douglas. Taking the Falcon 9 series launch vehicle of SpaceX Company of the United States as an example, the stable recovery of the first stage launch vehicle and the second stage launch vehicle has been achieved. Around 1999, Rotary Company of the United States proposed a vertical-return fully reusable launch vehicle Roton with helicopter rotor system.

The scheme of flying back with wings only exists in the conceptual design. Taking the design scheme of the Russian Baikal winged booster as an example. However, it has a great impact on the overall structure of the booster and will also cause a large loss of the carrying capacity. The overall feasibility is not as good as the former two.

China's research on reusable vehicle technology continues steadily, and always pays close attention to the international research trends. Since 2002, 863 program has given great support to reusable vehicle technology. With the successful recovery of SpaceX's Falcon 9 in 2015, China's space industry once again set off a research boom on reusable launch vehicles, and then enter the critical stage of technological breakthroughs [5].

2.2. SpaceX's research on reusable launch vehicle

SpaceX is an aerospace manufacturer and space transportation company, which is mainly responsible for designing, testing and manufacturing important parts of spacecraft. It is the first private enterprise in the world to realize manned spaceflight [6].

Falcon 1 launch vehicle is designed as a small, low-cost, two-stage launch vehicle and carried out a total of five missions. It is designed to be recovered via parachute descent. A similar attempt was made on the future Falcon 9 v1.0, but with poor results, the first stage is destroyed on re-entry due to varying degrees of force and thermal loads, prompting SpaceX to shift its focus to vertical take-off and landing technology [7, 8].

Since then, SpaceX has launched Falcon 9 v1.0 and Falcon 9 v1.1, which had their first successful launches in 2010 and 2013, respectively. The latter was already capable of being recovered, but failed to do so. During this period, SpaceX transform the Grasshopper and Falcon 9R-Dev validation aircraft on the basis of a substage of the above two types of space vehicle, respectively, and verified the feasibility of the technologies such as large range adjustment of engine thrust, attitude adjustment and steering of the grid rudder, and stability and support of the lander. The recovery of first stage has made steady progress, successfully landing it in a vertical position in 2014.

The Falcon 9 v1.2 launch vehicle was first launched in 2015. After this, the fully improved Falcon 9 v1.2Block5 configuration was successfully launched in 2018, and the Falcon Heavy, which is suitable for larger launch loads, was successfully launched in the same year. The above three models realize the recovery and reuse of the first substage, second sub-stage and fairing, and are the main launch vehicle in active service of SpaceX. The fairing adopts the parachute recovery method, which was successfully implemented in 2019 and is more practical.

Recycling is only the first step in commercial space transportation. Bringing old vehicles back into service is the immediate goal, with lower costs. In 2017, a used, maintained first-stage launch vehicle was put into service for the first time, and nearly 70 percent of the 80 or so missions launched over the next three years will use reusable one-stage vehicles.

SpaceX previously unveiled the concept of an Interplanetary transport system in 2016, which has since evolved into the superheavy Starship transport system, which is planned to consist of a sub-class superheavy launch vehicle and a subclass starship, designed with a theoretical capacity of up to 100 tons. Since 2018, it has successively developed the insect-jumping testing machine, the Mk series full-size testing machine and the SN series testing machine, in order to tackle and verify key technologies [9].

In 2022, SpaceX reintroduced the modifications to the Superheavy Starship program, indicating that it would use a new version of the Merlin 2 engine. The system's launch acquisition tower, the Mechazilla, will be the centerpiece of the partial recovery of the Starship. Its unique chopstick-like robotic arm is used to lock onto the Star ship after the launch vehicles hovers vertically and completes its orientation adjustment. The arm is then lowered to complete the placement maneuver. The Starship segment is planned to have a fully recyclable design, including fairing for opening and closing control.

3. Key technologies of reusable launch vehicle

Reusable launch vehicle technology does not exist alone, but is closely related to the development of other spacecraft technologies. Its technical system is gradually evolved from one-time launch vehicle technology and some reusable launch vehicle technology. After continuous iteration of the internal technology of the system and technical compatibility with other systems, this technology will inevitably conform to the modern society-oriented space requirements and form a more stable modern technical system.

Against the background of the great success of the Falcon 9 Reusable Launch Vehicle, its unique structure form and scheme selection reflects the innovations in the Reusable Launch Vehicle, including the down-phase guidance and control technology, engine thrust adjustable technology, and aircraft landing buffer technology. These unique structures also depend on the long-term trial and error optimization of the research team. It is closely related to the traditional disposable vehicle structure.

3.1. General picture of Falcon 9

The active Falcon 9 launch vehicle has a height of 70 meters in the first stage and 75.2 meters in the second stage. It contains an extended rectifier cover with a diameter of 3.66 meters. It is mainly composed of fuel storage chamber, housing, structural beam and engine. The space vehicle housing is made of aluminum-lithium alloy, intended to maintain sufficient strength while reducing mass. The fuel tank is supported by an aluminum star structure. In earlier versions, the suspension support scheme of a joint bearing rod was used, which proved to be less reliable, storing liquid oxygen and RP-1 kerosene as space vehicle propellant [10].

The Falcon 9 vehicle launch process is powered on about 10 hours from launch, and propellant is refilled from 2-3 hours. Multiple rounds of checks and self-checks are conducted 10 minutes before launch, 40 seconds before the fuel chamber is pressurized, 3 seconds after the computer starts the ignition process, and 0 seconds after the launch. After the launch of the vehicle, the first and second stages of the launch vehicle execute the shutdown-separation-ignition separation procedure with the upper stage in turn until the load is put into the intended orbit.

Table 1. SpaceX vehicle research and development record.

Model | First launch date | Theoretical load | Reusable situation | Service status |

Falcon 1 | 24.Mar.2006 | 670kg | No | Retire |

Falcon 9 v1.0 | 4.Jun.2010 | 9.9t | No | Retire |

Falcon 9 v1.1 | 29.Sep.2013 | 10.45t | Yes, but unrealized | Retire |

Falcon 9 v1.2(FT) | 22.Dec.2015 | 22.8t | Yes | Active |

Falcon 9 v1.2(Block 5) | 11.May.2018 | 54.4t | Yes | Active |

Falcon Heavy | 6.Feb.2018 | 63.8t | Yes | Active |

Starship Overview | 250t | Yes | Researching |

3.2. Return stage guidance algorithm

The launch vehicle return segment guidance algorithm originates from the early lunar probe soft landing guidance and control scheme. At this stage, the main goal is to landing safely. The guidance method is relatively simple, only has the basic obstacle avoidance function, and there are also artificial obstacle avoidance control methods. With the increasing demand for space resource development, the demand for fixed-point precise guidance and control technology is also increasing [11].

On a reusable launch vehicle, the current trajectory of the vehicle needs to be planned in real time to control the engine to move to the desired location, that is, to solve the trajectory quickly by using optimization method. In 2005, lossless convex optimization was proposed, which was transformed into a second-order cone problem and extended to solve general trajectories. Compared with the traditional numerical iteration algorithm, it can ensure that the solution time is short enough while satisfying the equivalence of the solution. Then, convex optimization was extended to solve two-dimensional and three-dimensional problems, which solved the guidance problem for six-degree-of-freedom reusable launch vehicle [12].

This method has become an important blueprint for SpaceX's guidance and control algorithm, which was officially applied to test machines in 2013. Over the next few years, with the success of the Falcon 9 launch vehicle test and its commissioning, the technology will gradually mature. In recent years, the control algorithm is robust against atmospheric disturbance, thrust execution error, navigation system error, system delay and other disturbance factors.

3.3. Merlin-1 series engines

Merlin series engine is a pin-and-throttle injector engine developed by SpaceX Company in 2002. Using liquid oxygen and airborne kerosene RP-1 as vehicle propellant, it has undergone five major upgrade changes. The active Falcon 9 launch vehicle is equipped with Merlin-1D and Merlin-1D+ models. Its theoretical thrust at sea level is 66.7t and 77.2t, and its push-weight ratio is 160 and 180, respectively. Among them, the Merlin-1D+ model has reached 232 weight-to-weight ratio in the dive test, and can work under 111% thrust. The Falcon 9 launch vehicle equipped with this model is also called the Falcon 9 full-thrust version [13].

Table 2. Performance parameters of Merlin-1 series engines [13].

Model | Mass flow | Thrust/Weight | Sea level thrust | Sea level specific impulse | Vacuum thrust | Vacuum specific impulse |

Merlin-1A | 130.5kg/s | 33.1t | 253s | 37.67t | 286s | |

Merlin-1B | 133.2kg/s | 35.6t | 264s | 40.2t | 303s | |

Merlin-1C | 161.3kg/s | 75 | 43.1t | 267s | 49.24t | 304s |

Merlin-1C Block II | 202.4kg/s | 96 | 55.7t | 275s | 63.0t | 311s |

Merlin-1D | 236.6kg/s | 160 | 66.7t | 282s | 75.7t | 320s |

Merlin-1D+ | 269.6Kg/s | 180 | 77.2t | 286s | 84.2t | 312s |

Nothing is more important in active service than adjustable thrust technology based on pin-and-tie injector, engine depth throttling technology, and combustion chamber cooling technology [14, 15].

The pin-and-pin injector engine has obvious advantages over the conventional cluster nozzle engine. Structurally consisting of only a central oxidant nozzle and a fuel injection ring that surrounds it, it is highly competitive with a minimal structure, high reliability, and low cost. This type of engine can control the fuel flow area by adjusting the axial position of the pin bolt, thus achieving adjustable thrust. Typically, conventional engines will experience severe combustion instability below 50% thrust, while pin-and-tether engines will have a more stable combustion efficiency over a wider range of pressures.

The cooling scheme of vehicle combustor is divided into regenerative cooling and ablative-liquid film cooling. Regenerative cooling is the traditional and most common cooling scheme for liquid-fueled launch vehicle combustor. It mainly passes through small pipes around the combustor and convection heat transfer of high-temperature gas to achieve the purpose of cooling the combustor while recovering heat. This cooling scheme has no obvious drawbacks, but the structure and pipes of this combustor need to be carefully designed and the process costs remain high. Another low-cost scheme is ablation-liquid film cooling, which constructs a combustion chamber wall thick enough for high-temperature gas corrosion and adds an injection guide ring so that a small amount of liquid fuel splashes onto the combustion chamber wall to form a liquid film, which slows down the corrosion rate. It is feasible as a one-time launch vehicle design scheme.

Ablation-liquid film cooling was used on the original Merlin-1A and Merlin-1B engines. Although this small, low-cost engine consumes only a tenth of the cost of a conventional engine, its design flaws and SpaceX's demand for reusable launch vehicle optimize it after a handful of launches. Regenerative cooling has been used since Merlin-1C, which increases the cost of manufacturing Merlin engines and lays the foundation for their reuse. It is worth mentioning that the pin-and-pin injector of this engine uses a cluster structure, and the combustion chamber wall is made of copper alloy with high thermal conductivity. So far, the basic scheme of Merlin engine has been shaping, the Merlin-1D in 2013 and the Merlin-1D+ in 2015 are both improved versions of the original scheme, with more details optimized and the weight ratio nearly doubled.

Figure 1. The 100th Merlin-1D engine [13].

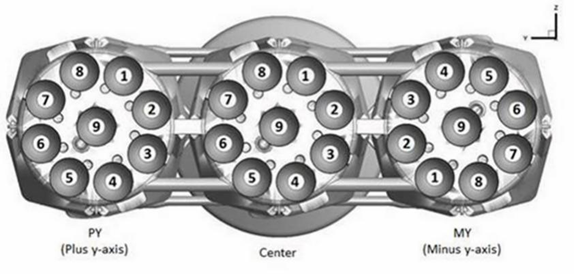

In particular, the Falcon 9 launch vehicle stage I employs nine engine configurations evenly distributed in Octaweb, with multiple low-thrust engines in parallel. In general, the multi-engine parallel scheme, taking the Soviet Union N-1 as an example, is considered to be extremely unreliable. Uncertainty coupling vibration caused by too many parallel engines can be harmful or even destructive, and all four N-1 vehicle launches fail. The Falcon 9 program is undoubtedly pioneering. The 27-engine parallel operation of the Falcon Heavy launch vehicle is close enough to the 30-engine of the N-1 launch vehicle, but the actual operation is very stable. Some scholars believe that the overall stability of Merlin engine is greatly improved due to the excellent design scheme and individual stability. Modern higher production technology and effective design scheme may become the key to achieve technological breakthrough. Falcon space vehicles are of guiding value in solving coupled vibration, especially longitudinal vibration and synchronous engine operation. Actual usage also proves that redundancy design is effective and Falcon 9 can deliver loads to a predetermined orbit with up to two engines damaged. At the same time, the scheme to achieve combined high-thrust by parallel low-thrust engines greatly reduces the technical difficulties and research and development costs.

Figure 2. Layout of Falcon Heavy one stage engine [16].

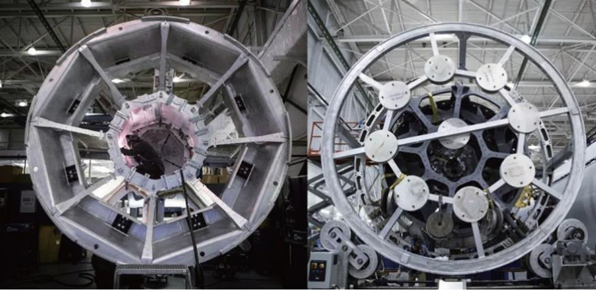

Until the final version of the Falcon 9 Block5 configuration was released, Merlin engines were optimized for launch vehicle recyclability and ease of maintenance. Includes improved engine brackets with detachable bolts for fastening, enabling them to be detached, repaired or replaced in case of irreversible deformations [17].

Figure 3. Modular improvement of the engine frame [17].

Merlin series engines are essentially small vehicle engines, with lower overall thrust and specific impulse, and cannot achieve greater thrust through an infinite parallel engine. The overall size of the launch vehicle also limits the number of propellants. Merlin engine is considered to be limited by kerosene combustion performance due to the serious carbon deposit, which is expected to be avoided by maintenance and refurbishment.

3.4. Leg lander

Landers are the main form of landing buffers for reusable launch vehicle. Landers for reusable launch vehicle have evolved from landing buffers for conventional ballistic return vehicles. Usually, in the landing phase of an aircraft, the parachute system alone cannot slow it down to a safe soft-landing state, and additional buffers are needed to reduce the impact of the aircraft on landing. Mainly used as parachute systems, gliding wings, landing buffer vehicles, legged landers, suspension or buffer materials. Landers used for fully reusable launch vehicle press mainly refer to legged landers, which usually surround the bottom of the vehicle in a number of sets of matches to work together [18].

The main structure of the current reusable launch vehicle lander can be divided into two main forms, simple pillar and space rocker [19, 20].

A simple pillar lander, taking a triangular fast sail test machine as an example, uses four telescopic sleeve legs to support the lander. The buffer legs are connected directly to the main beam of the ship body. The structure is designed to land on both flat and soft sand, and can withstand a maximum load of 14.5t with an accuracy of 4.2g, allowing a vertical speed of 6.1m/s and a horizontal speed of 2.44m/s. Buffer columns have a three-stage strut structure, which is mainly damped by oil pressure, a one-time honeycomb damper to cope with insufficient oil damp travel, and a sliding footpad at the bottom which is connected by a joint bearing to the buffer column. The structure has few force conduction paths and is considered to be less stable.

| Figure 4. Landing status of Delta clipper [19]. |

A space rocker lander, taking the Falcon 9 launch vehicle as an example, has a main support column that can be deployed and retracted under the control of a multistage pneumatic pusher, locking and releasing through fire bolts and locking mechanisms at the highest and lowest points, respectively. This lander structure scheme is installed on the outer side of the launch vehicle, which provides more freedom in layout design. Under the same efficiency of the damper, it can get higher efficiency according to the comprehensive optimization of the vehicle. At the same time, the flip-out extended support column is oblique support, has good force transmission path, high stability, and the main structure is external, which is easy to retrofit and maintain. The effect is remarkable in the actual application process. However, compared with the former, the space rocker lander has a higher degree of mechanical complexity. Besides the basic damper, it also contains additional auxiliary pillars and hinges, which are less reliable, and the lander is placed on the outside of the vehicle shell. Additional fairing cover is required, which also causes unnecessary aerodynamic resistance and more wastage of transportation.

Figure 5. Falcon 9 landing status and landing pad [19].

It has been proved that the four-legged structure is more stable than the three-legged structure when the road surface is horizontal or inclined as a whole, and the beam-type legged lander with concentrated mass at the end has better stability. The two-pole down-folding mechanism is more conducive to the execution of air unfolding than the one-pole up-folding mechanism.

In the Falcon 9 Block5 configuration, several independent legged landers have been redesigned and integrated, and the new scheme uses an active actuator inside the launch vehicle to drive eight small bodies to operate simultaneously.

3.5. Application of conventional structure

The launch vehicle interstage separation mechanism is designed to provide the multistage launch vehicle with a separation action between the lower stage and the upper stage after the lower stage is shut down, requiring a small disturbance to be maintained to ensure safe ejection from the lower stage. The traditional thermal separation scheme relies on the split-free explosive bolt, which is not feasible on the reusable launch vehicle. The cold separation scheme, in the case of the Falcon 9, involves a composite frame of carbon fiber plates with an aluminum alloy honeycomb core, as well as a release and separation system. A high-pressure helium full pneumatic actuator is used to unlock the stage separation [21].

Grid rudder is a kind of flight attitude control device located all around the vehicle. It is generally used to ensure that the vehicle remains fall into the safety zone accurately. It is an important part of the reusable pneumatic control mechanism of the vehicle. On the Falcon 9 launch vehicle, the grid rudder is made of either aluminum alloy or titanium alloy with an insulating coating.

Thermal protection is a solution to the severe aerodynamic heating problem faced by the vehicle during near-space flight. Take the US space shuttle as an example, its main heating area uses RCC carbon fiber reinforced carbon-based materials, rigid ceramic heat insulation tiles, and flexible heat insulation felt. For the Falcon 9 launch vehicle thermal protection, ablative materials and tile Bakelite impregnated carbon ablators are used, but details are scarce [22].

4. Economics analysis and business model of Space X

4.1. Economic analysis of reusable launch vehicles

For cost accounting of launch vehicles, the vehicle engine and main structure account for the main part, and even up to 75% of the cost savings on first-stage vehicles. The reuse of launch vehicles means that most of the subsequent production costs can be saved. These saved costs are then used to make the necessary repairs and refurbishments to the used vehicles [23].

In the case of the Falcon 9, although the groundbreaking update to Merlin 1C and the structural optimization of the final version of the Falcon 9 increased production costs, recycling enabled the total cost to be spread over multiple missions, thus reducing the average cost and hardware waste of the vehicle's main structure. At the same time, reusable vehicles greatly simplify the overall mission cycle and increase launch density. The ground control process has been significantly simplified, the Falcon 9 can be autonomously recovered from a self-operating offshore recovery platform, and the maintenance and refurbishment program has been optimized and shortened over the years.

Often, the overall development cycle of space equipment is long, the technology is complex, the quality requirements are high, and the information between producers and scientific research units is often highly unequal, which often creates unnecessary extra costs under the mode of market competition. SpaceX actively chooses self-developed key components in its products, such as engines, body structures, etc. There are very few suppliers of such components. As a buyer with low bargaining power, self-developed parts can effectively control costs and avoid being subject to market conditions. SpaceX actively uses the outsourced production model for the workpieces that are in great demand. The United States has strong industrial technology and standardized workpieces have sufficient capacity and are inexpensive. At this time, independent production will no longer be cost -effective [24, 25].

The effect of launch vehicle reuse is immediate. The price-to weight ratio of Falcon 9 has reached a point far beyond that of its friends, and it has a higher price advantage in the commercial launch market. According to SpaceX, recycling just one child of the vehicle can save 80 percent of the total launch cost.

It is worth noting that the development cycle of space equipment is highly planned and not entirely dominated by economic benefits. Although SpaceX once showed a pathological pursuit of low cost, its R&D process is cost-free, and it obtains stable operating parameters through a large number of experiments, many of which failures are directly related to the early imperfect design.

Table 3. Cost Composition of Typical Launch Vehicles [22].

|

4.2. Experience of business model

It is widely believed that the support of authority is the premise of SpaceX's rapid development. In 2006, NASA launched the Commercial Orbital Transportation Service program, and SpaceX won a $2.78 investment in a bidding contest that year, and began a $1.6 billion cargo delivery contract to the ISS in 2010. On top of that, NASA also provided SpaceX with a lot of support, such as technology transfer, equipment and space, and policy support, which greatly reduced its initial research and development investment. In 2010, the new version of the National Space Policy of the United States was issued, which officially and comprehensively promoted the development of private space enterprises in the United States.

Since its inception, SpaceX has always operated with the philosophy of low cost, high reliability. Musk has said his goal with SpaceX is to reduce the cost of space launches by a factor of 10 and the risk of carrying out space missions by a factor of 10. Also officially under such a concept, greatly simplified launch vehicle design scheme, and actively make attempts to recycle.

What SpaceX has achieved is a combination of selective inheritance of proven technologies and radical innovation. The United States is a country with an extremely high level of technology and a sound industrial system. It has rich experience in manufacturing and aerospace technologies. SpaceX pays attention to the application of existing mature technologies, and relevant products can be directly outsourced, such as the engine nozzle design for the lunar module descending stage of the Apollo program, as well as 2195 aluminum-lithium alloy and friction mix welding technology, which will effectively reduce research and development costs and improve system reliability. On the other hand, SpaceX's groundbreaking research, such as the Merlin engine, guidance system and fuel storage capsule, laid the foundation for the vertical takeoff and landing of the Falcon 9. On top of that, SpaceX has created a relatively tolerant research and development environment for space missions, allowing for a fair degree of innovation and trial and error in new technologies, which is positive for the development of technology.

SpaceX's management system adopts a flat management model, in which small elite teams collaborate efficiently. From the perspective of vertical management structure, the entire company consists of only three layers. Each department takes the supervisor as the core to provide accurate guidance, and can realize the refinement to individual roles, so that the work efficiency and accuracy are greatly improved. Thanks to its human management mode, information communication and decision transmission is efficient, R&D and production can also exchange views in time, which is convenient to realize the guarantee of technology and efficiency.

5. Conclusion and prospect

Aiming at the development of reusable vechile, this paper summarizes and analyzes its existing form and design scheme and focuses on the scheme proposed and implemented by SpaceX which has practicability, pioneering and reference value at present. Taking the Falcon 9 launch vehicle as an example, this paper summarizes the key technologies of the vertical return reusable vehicle and the improvement of the conventional structure of the above products. In addition, according to the development history and research overview of SpaceX, the paper summarizes the lessons of its business model and the commercial value of reusable launch vehicle technology.

The reusable vehicle is definitely the trend of spacecraft development in the future, but according to the rule of technological system evolution, the technology is still in its infancy. At present, space launch technology is becoming mature, and the threshold of technology and capital is decreasing. Active international cooperation can facilitate the solution of technical problems. The reusable vehicle technology is not an independent form of technology, and the breakthrough of any basic subject may become an opportunity for its rapid development. In the short term, reusable vehicle technology is expected to have a positive impact on the implementation of a flight-like space transportation system, removing the threat of launch vehicle debris to the ground, and replacing the current unreliable disposal of hazardous materials.

References

[1]. Lu Y, Wang X, Gao Z, Shen L and Zhuang F 2017 Progress and Prospect of Reusable Launch Vehicle Technology. Missile and Space Launch Technology 5 1-7

[2]. Ma Y 2022 Structural Design and Structural Improvement Ideas for Yunxiao Tower Aerospace Vehicle. Aircraft Design 42(03) 50-55

[3]. Wang X, Zhang P, Wu S and Shen L 2016 Research on rocket sub stage recovery technology. Aerospace Return and Remote Sensing 37(03) 19-28

[4]. Chen Z, Ning L and Wang P 2021 Analysis and Enlightenment of Carrier Rocket Booster Recovery Technology. Aerospace General Technology 5(05) 66-74

[5]. www.cnsa.gov.cn.

[6]. Yang W, Cheng L, Pang Y and Yang R 2021 Analysis of the Development of SpaceX Company. International Space Journal 3 39-45

[7]. Pang J and Su X 2016 Analysis of the low-cost path of SpaceX Company. Air Missile 9 13-15

[8]. Shan W and Gao X 2012 Lenovo triggered by SpaceX's concept of "low cost, high reliability". Aerospace Industry Management 1 37-41

[9]. Yan N, Hu D and Hao Y 2020 Analysis of SpaceX's "starship overview" transportation system solution. International Space Journal 11 11-17

[10]. www.spacex.com.

[11]. Song Z, Cai Q, Han P, Wang C, Pan H, Zhang G and Li X 2021 Overview of guidance and control technology for reusable launch vehicles. Journal of Aviation 42(11) 37-65

[12]. Song Y, Zhang W, Miao X, Zhang Z and Gong S 2021 Online guidance algorithm for recoverable rocket power landing phase. Journal of Tsinghua University (Natural Science Edition) 61(03) 230-239

[13]. Zhang X 2017 The Foundation of the Falcon Rocket: The Continuously Upgraded Meilin Engine. Satellite and Network 6 40-41

[14]. Yuan Y 2014 Design Features of Falcon Rocket Engine. Space Exploration 7 19-20

[15]. Pang Z 2016 The Significance and Key Technologies of Recovering Rockets. Science and Technology Herald 34(01) 15-19

[16]. SpaceX 2021 Falcon Users Guide.

[17]. Mou Y, Sun J and Qin X 2018 Analysis of the first flight mission of the Falcon 9 rocket Block 5 configuration. Aerospace General Technology 2(05) 1-7

[18]. Lu Y, Zhang X, Li Q, Zhang Z, Huang J and Xing L 2021 Overview of the approach to landing buffer technology for spacecraft. Aerospace Return and Remote Sensing 42(01) 39-47

[19]. Tao H 2017 Research on the Soft-Landing System of Vertical Takeoff and Landing Reusable Launch Vehicle. Nanjing University of Aeronautics and Astronautics

[20]. Hu Y 2011 Study on Dynamics and Stability of a Legged Planet Lander. Harbin Institute of Technology

[21]. Song Q 2020 Full Interpretation of Falcon 9 Series Mission Manual. Satellite and Network 9 20-33

[22]. Huang H, Su L, Lei C, Li J, Zhang E, Li W, Yang J, Zhao Y, Pei Y and Zhang H 2020 Application and Research Progress of Reusable Thermal Protective Materials. Journal of Aviation 41(12) 6-40

[23]. Li L and Wei W 2018 SpaceX r Low Cost Analysis and Implications from a Financial Management Perspective. China Aerospace 8 51-55

[24]. Pang J and Su X 2016 Analysis of the low-cost path of SpaceX Company. Air Missile 9: 13-15

[25]. Yang H and Yu J 2021 Life cycle cost and economic evaluation of reusable spacecraft. Manned Space 27 (01) 81-85

Cite this article

Wu,H.;Zhang,Z. (2023). Analysis of the development of reusable launch vehicle technology. Applied and Computational Engineering,11,65-75.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2023 International Conference on Mechatronics and Smart Systems

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Lu Y, Wang X, Gao Z, Shen L and Zhuang F 2017 Progress and Prospect of Reusable Launch Vehicle Technology. Missile and Space Launch Technology 5 1-7

[2]. Ma Y 2022 Structural Design and Structural Improvement Ideas for Yunxiao Tower Aerospace Vehicle. Aircraft Design 42(03) 50-55

[3]. Wang X, Zhang P, Wu S and Shen L 2016 Research on rocket sub stage recovery technology. Aerospace Return and Remote Sensing 37(03) 19-28

[4]. Chen Z, Ning L and Wang P 2021 Analysis and Enlightenment of Carrier Rocket Booster Recovery Technology. Aerospace General Technology 5(05) 66-74

[5]. www.cnsa.gov.cn.

[6]. Yang W, Cheng L, Pang Y and Yang R 2021 Analysis of the Development of SpaceX Company. International Space Journal 3 39-45

[7]. Pang J and Su X 2016 Analysis of the low-cost path of SpaceX Company. Air Missile 9 13-15

[8]. Shan W and Gao X 2012 Lenovo triggered by SpaceX's concept of "low cost, high reliability". Aerospace Industry Management 1 37-41

[9]. Yan N, Hu D and Hao Y 2020 Analysis of SpaceX's "starship overview" transportation system solution. International Space Journal 11 11-17

[10]. www.spacex.com.

[11]. Song Z, Cai Q, Han P, Wang C, Pan H, Zhang G and Li X 2021 Overview of guidance and control technology for reusable launch vehicles. Journal of Aviation 42(11) 37-65

[12]. Song Y, Zhang W, Miao X, Zhang Z and Gong S 2021 Online guidance algorithm for recoverable rocket power landing phase. Journal of Tsinghua University (Natural Science Edition) 61(03) 230-239

[13]. Zhang X 2017 The Foundation of the Falcon Rocket: The Continuously Upgraded Meilin Engine. Satellite and Network 6 40-41

[14]. Yuan Y 2014 Design Features of Falcon Rocket Engine. Space Exploration 7 19-20

[15]. Pang Z 2016 The Significance and Key Technologies of Recovering Rockets. Science and Technology Herald 34(01) 15-19

[16]. SpaceX 2021 Falcon Users Guide.

[17]. Mou Y, Sun J and Qin X 2018 Analysis of the first flight mission of the Falcon 9 rocket Block 5 configuration. Aerospace General Technology 2(05) 1-7

[18]. Lu Y, Zhang X, Li Q, Zhang Z, Huang J and Xing L 2021 Overview of the approach to landing buffer technology for spacecraft. Aerospace Return and Remote Sensing 42(01) 39-47

[19]. Tao H 2017 Research on the Soft-Landing System of Vertical Takeoff and Landing Reusable Launch Vehicle. Nanjing University of Aeronautics and Astronautics

[20]. Hu Y 2011 Study on Dynamics and Stability of a Legged Planet Lander. Harbin Institute of Technology

[21]. Song Q 2020 Full Interpretation of Falcon 9 Series Mission Manual. Satellite and Network 9 20-33

[22]. Huang H, Su L, Lei C, Li J, Zhang E, Li W, Yang J, Zhao Y, Pei Y and Zhang H 2020 Application and Research Progress of Reusable Thermal Protective Materials. Journal of Aviation 41(12) 6-40

[23]. Li L and Wei W 2018 SpaceX r Low Cost Analysis and Implications from a Financial Management Perspective. China Aerospace 8 51-55

[24]. Pang J and Su X 2016 Analysis of the low-cost path of SpaceX Company. Air Missile 9: 13-15

[25]. Yang H and Yu J 2021 Life cycle cost and economic evaluation of reusable spacecraft. Manned Space 27 (01) 81-85