1. Introduction

The rapid advancement of technology in recent years has propelled the field of robotics to the forefront of innovation, making it an integral part of various industries ranging from manufacturing to healthcare. Actuators, as the "muscles" of a robot, are responsible for converting energy into motion, allowing robots to interact with their surroundings. They are the driving force behind a robot's movement and actions, enabling it to perform tasks such as gripping, lifting, and navigating through its environment [1]. Due to unremitting research and development efforts, many important advances have been made in the field of robot actuators. Current research scholars have accumulated rich knowledge and practical experience in the field of advanced materials, efficient design, and innovative control strategies, enabling the current generation of actuators to improve performance and reliability. Due to these advances, today's actuators exhibit greater durability, higher accuracy, and lower energy consumption, paving the way for the development of more complex and efficient robotic systems in various industries [2].

Current Actuators research faces several shortcomings, including Limited torque-to-weight ratio, Backlash, mechanical wear, Control complexity: Traditional Actuator often face a challenge in providing sufficient torque while maintaining a low weight. This limitation restricts the overall performance of robotic systems, particularly in applications that require high payload capacity and precise movements [3]. Backlash and mechanical wear: gear systems can introduce backlash, which affects the accuracy and repeatability of the robotic system. Control complexity: Actuators often requires sophisticated control algorithms and feedback mechanisms to ensure accurate and smooth motion [4]. This complexity can pose challenges in terms of system design, implementation, and computational resources. Lastly, many joint motors are sensitive to temperature, humidity, and other environmental factors that can impact their performance and reliability. For instance, electric motors may experience reduced efficiency in high-temperature environments, while pneumatic and hydraulic actuators can be affected by changes in ambient pressure and temperature. It can be seen that actuator still require deeper research [5].

The primary purpose of this research paper is to provide an overview of the current status of different actuators, analyze the applications and shortcomings of existing actuators, while also discussing the future prospects of this essential component and providing valuable insights for researchers, engineers, and industry professionals.

2. Types of actuators used in robotics

2.1. Electromagnetic actuators

Electromagnetic actuators are widely used in robotics due to their high efficiency, precision, and scalability. Among the various types of electromagnetic actuators, geared drive motors and direct drive motors are two of the most employed options in robotic systems. Both types of actuators operate based on the principle of converting electrical energy into mechanical motion through the interaction of magnetic fields [6]. Table 1 is the linear Actuator and Rotary Actuator formular.

Output | Linear Actuator | Rotary Actuator |

Torque (Nm) | T = F * l | T = Kt * i |

Speed (m/s or rad/s) | v = d / t | ω= 2π * (N * f) / P |

Power (Watts) | Pw= F * v | Pw = T *ω |

Table 1. Linear Actuator and Rotary Actuator formular.

“F” is force (N)

“l” is the length of the actuator

“d” is displacement (m)

“t” is time (s)

“Kt” is the torque constant (Nm/A)

“i” is current (A)

“ω” (angular velocity) is the rotational speed in radians per second (rad/s)

“N” is the number of rotor poles

“f “is the electrical frequency in Hertz (Hz)

“P” is the number of pole pairs (P = N/2, since each pole pair includes a north and a south pole)

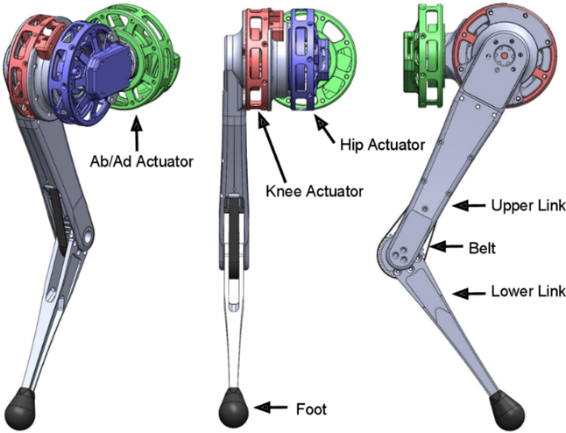

2.1.1. Geared drive motors. Geared drive motors are typically composed of an electric motor, such as brushed or brushless DC motors, paired with a gear reduction system to amplify torque and control the speed of the output shaft [7]. The gear system allows for precise positioning and high torque capabilities while maintaining a compact form factor. Figure 1 is the planetary reduction actuator for dynamic robots.

Figure 1. Planetary reduction actuator for dynamic robots [3].

Geared drive motors employ various reduction systems, such as traditional reducers, planetary reduction, harmonic reduction, and cycloidal pinwheel reduction, to amplify torque and control the speed of the output shaft [8]. Table 2 shows a comparison of common restore types.

Table 2. Common reduction type compare.

Reduction Type | Cost | Backlash | Efficiency | Torque Density | Compactness |

Traditional reducer | Low | High | Moderate | Low | Low |

Planetary reduction | Moderate | Low | High | High | High |

Harmonic reduction | High | Very low | High | Very high | Very high |

Cycloidal pinwheel reduction | Moderate | Low | Moderate | High | Moderate |

Traditional reducers, being the most basic and economical, are characterized by moderate backlash, efficiency, and torque density but are less compact and may require more maintenance. Planetary reducers, on the other hand, are known for their high efficiency, torque density, and compactness but tend to be more expensive and may necessitate sophisticated lubrication systems. Harmonic reducers excel in providing very low backlash, high torque density, and excellent compactness but can be considerably more expensive and sensitive to high shock loads or high-speed applications. Lastly, cycloidal pinwheel reducers offer low backlash, high torque density, and moderate compactness but may have lower efficiency and are generally more expensive than traditional reducers but less costly than harmonic reducers. Each reduction system has its unique advantages and drawbacks, making them more or less suitable for specific applications depending on factors such as cost, size, efficiency, torque density, and backlash [9].

However, the use of gears introduces backlash, which can affect the accuracy and repeatability of the robotic system. Additionally, gears are subject to wear and tear, which may lead to reduced efficiency and the need for regular maintenance.

2.1.2. Direct drive motor. Direct drive motors eliminate the need for a gear system by directly coupling the motor output shaft to the load, Since the direct drive motor does not include mechanical components such as gearboxes that are subject to continuous friction, this design usually does not have any backlash, and reduced mechanical wear, and potential sources of failure. A direct drive motor is often a synchronous permanent magnet motor [10]. The rotor of a synchronous permanent magnet motor is embedded with a permanent magnet, which eliminates the need for additional excitation, compared to induction motors that require a separate excitation source. The synchronous characteristics of these motors mean that the rotor rotates at the same frequency as the magnetic field generated by the stator winding, achieving efficient and accurate speed control. In direct drive design, the extremely low rotor losses enabling higher stator current loading and a reduced the size of motor frame. The elimination of slip improves both motor efficiency and dynamic control performance of the entire drive. This type of design resulting in increased accuracy, responsiveness, and overall system reliability. Common examples of direct drive motors include torque motors and linear motors. Figure 2 is a schematic diagram of a direct drive motor.

Figure 2. Direct drive motor [6].

Direct drive motors have gained widespread popularity in applications that require high precision and rapid response, such as gimbal stabilizers used in photography. The gimbal stabilizer has been largely replaced by direct drive motors, which offer superior performance. Figure 3 is the schematic diagram of Zenmuse X7 three-axis universal joint.

Figure 3. Zenmuse X7 3-axis gimbal [3].

The DJI Zenmuse X7 gimbal camera, for example, by using the direct drive motor, can achieve a gimbal's angular vibration range of ±0.005 degrees. The unparalleled precision and speed of direct drive motors have made them the preferred choice for a wide range of applications that demand high accuracy and responsiveness.

Despite these advantages, direct drive motors often require larger, more powerful motors to produce the desired torque, which can result in increased weight and size, as well as higher costs compared to geared drive motors.

2.2. Hydraulic actuators

Hydraulic actuators are devices that produce mechanical movements and forces using pressured hydraulic fluids. They are commonly used in various industrial and automotive applications and provide high force and speed capabilities as well as accurate motion control. The main functions of hydraulic transmission systems are transmission and movement, transportation of hydraulic oil, entry into the oil cylinder cavity, and control of the expansion or withdrawal of the oil cylinder piston rod to perform various functions. Due to the incomprehensible nature of liquids, hydraulic actuators can exert significant forces. However, due to the same properties, hydraulic actuators usually move slowly.Table 3 provides the motor parameters.

Table 3. Motor parameters.

Output | Linear Actuator | Rotary Actuator |

Speed | V=Qc/Ac | W=Qc/Dm |

Force or torque | F=AcPl | T=DmPl |

Mechanical power | Pmech=QcPl | Pmech=QcPl |

“v” represents the linear velocity of the linear actuator (m/s)

“Qc” is the volumetric flow rate (m3/s)

“Ac” is the piston or rod area of the linear actuator (m2)

“Pl” is the load pressure drop of the linear actuator (Pa)

“T” is the rotary torque of the rotary actuator (Nm)

“w” is the angular velocity of the rotary actuator (rad/s)

“Dm” is the volumetric displacement per radian of rotation

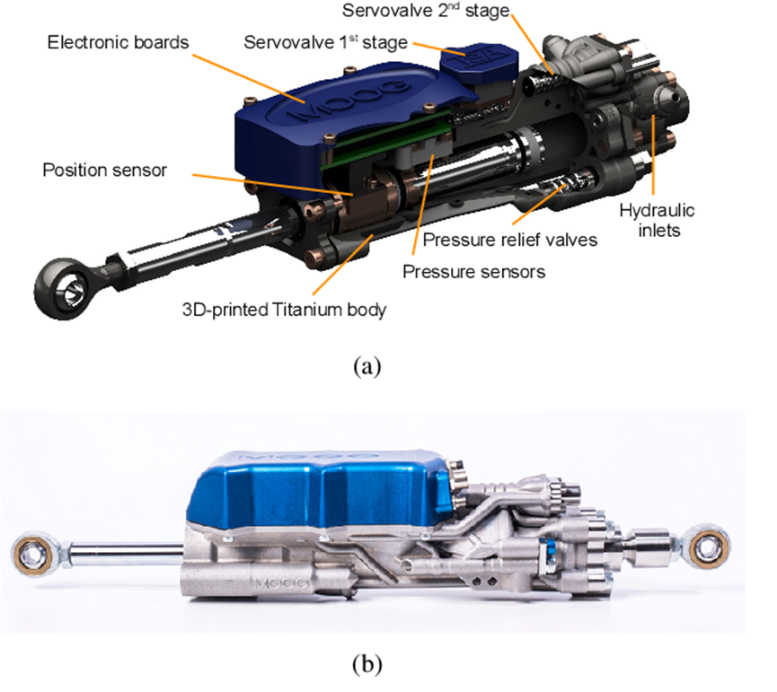

Hydraulic systems are often used on humanoid and high load robots due to their high power to weight ratio. Boston Dynamics, for example, a robotics company known for its advanced robot designs, has conducted extensive research on hydraulic actuators for use in their robots. One of their most famous robots, Atlas, uses hydraulic actuators to achieve impressive feats of agility and mobility, such as walking on uneven terrain, climbing stairs, and even performing backflips. The company's research on hydraulic actuators has led to significant advancements in the field of robotics, as well as other industries that use hydraulic systems. Figure 4 is an example of a hydraulic actuator.

Figure 4. Hydraulic actuators example [2]: (a) inner-structure, (b) front side.

The advantages of hydraulic actuators include their high-power density, ruggedness, and durability. However, they also have some drawbacks, such as the potential for hydraulic fluid leaks, which can cause environmental and safety hazards. Nevertheless, their versatility and reliability make them a popular choice for many applications, including heavy machinery, construction equipment, and aerospace systems.

Compared to electric motor drive systems, traditional hydraulic systems offer higher power density, making them a popular choice for many modern mobile robots. Due to high energy loss from throttling, typical hydraulic systems using servo or proportional valves frequently exhibit low efficiency. As a result, digital hydraulic technology has been developed, which has a few benefits including decreased throttling loss, increased reliability, higher pollutant resistance, and cheaper costs. As a result, digital hydraulic systems are emerging as a competitive alternative to conventional hydraulic systems in various robotic applications.

2.3. Pneumatic actuators

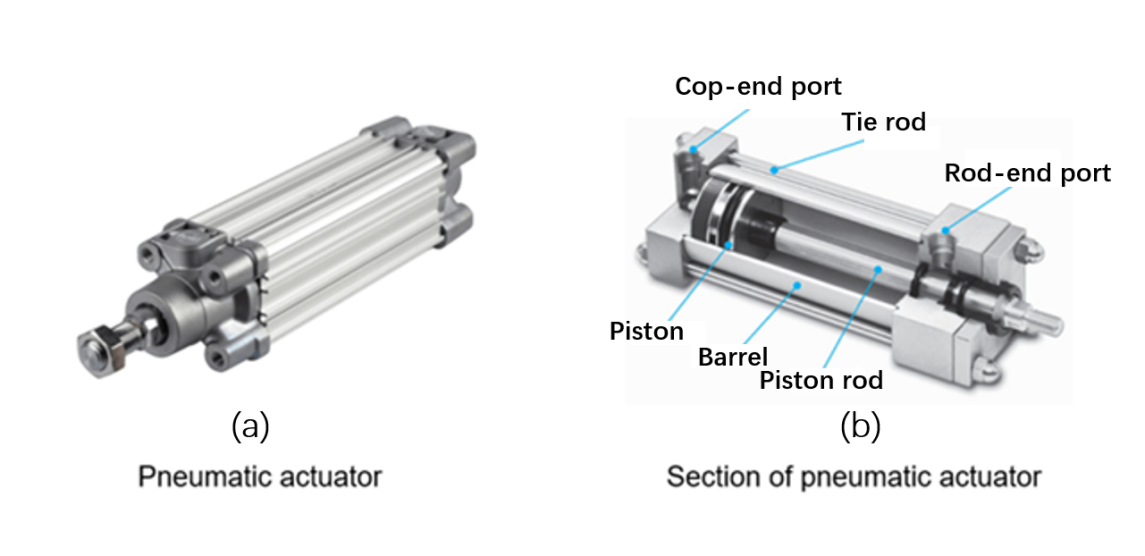

Pneumatic actuators are widely used in various industrial automation applications because of their unique combination of reliability, flexibility, and cost-effectiveness. These actuators convert compressed air energy into linear or rotating mechanical movements and accurately control the position, speed, or force of output elements. Pneumatic actuators offer several advantages, such as fast response times, a high power-weight ratio, and intrinsic safety, by using non-explosive, non-toxic air as a drive. Although pneumatic actuators are sensitive to fluctuations in air pressure and require reliable air supply systems, they remain popular in applications ranging from simple off-line control to complex closed loop systems. Figure 5 is a schematic diagram of the pneumatic actuator.

Figure 5. Pneumatic actuators [3]: (a) front side, (b). inner structure.

While pneumatic actuators offer numerous advantages, they also present some disadvantages that need to be considered when selecting an actuator for a specific application. One notable limitation of pneumatic actuators is their generally lower energy efficiency when compared to their electric counterparts. The energy conversion process from electrical power to compressed air is inherently inefficient, and air leaks in the system can further exacerbate this issue. Additionally, pneumatic actuators may exhibit less precise control due to the compressibility of air, which can make it difficult to achieve the same level of positioning accuracy as with electric actuators. Lastly, pneumatic systems can be noisier than other actuation methods, which may not be suitable for certain environments. The noise produced by pneumatic actuators primarily results from the venting of exhaust air, which can be mitigated to some extent with the use of silencers or mufflers. Despite these disadvantages, pneumatic actuators remain an indispensable component in many industrial automation systems, with their suitability being determined by the specific requirements of each application.

2.4. Selection criteria for actuators in robotics

2.4.1. Geared drive motors. These electromagnetic actuators offer a wide range of speeds and are capable of generating high torque when coupled with appropriate gear ratios. They are moderately priced and provide relatively high precision, making them suitable for various robotic applications. Their energy efficiency is also relatively high compared to other actuation methods.

2.4.2. Direct drive motors. Direct drive motors, another type of electromagnetic actuator, can offer low to high speeds and high torque without the need for additional gearing. They are characterized by high precision and high energy efficiency but come with a higher price tag. Their direct coupling with the load minimizes backlash and increases accuracy, making them ideal for high-precision robotic tasks.

2.4.3. Hydraulic actuators. Hydraulic actuators are known for their capability to produce very high torque and offer moderate speeds. They provide high precision but are typically more expensive than other actuators due to their complex infrastructure requirements. Energy efficiency is moderate for hydraulic actuators, and their potential leakage of hydraulic fluid may be a concern in some applications.

2.4.4. Pneumatic actuator. Pneumatic actuators excel in terms of high speed and relatively low cost. However, their torque generation is moderate, and their precision may be lower than other types of actuators due to the compressibility of air. Energy efficiency is also lower in pneumatic actuators, mainly because of the inefficiencies in converting electrical power to compressed air and potential air leaks. Table 4 compares different actuators.

Table 4. Compare of different Actuator.

Actuator Type | Speed | Torque | Cost | Precision | Energy Efficiency |

Geared Drive Motor | Moderate to High | Moderate to High (with gears) | Moderate to High | Moderate | High |

Direct Drive Motor | Low to High | Low | High | High | High |

Hydraulic Actuator | Low | High | High | High | Moderate |

Pneumatic Actuator | Moderate to High | Low | Low to Moderate | Low | Low |

Different actuators have different characteristics and need to be selected according to the usage scenario, environment, and requirements. Usually used for robotic dogs and small robotic arms is the Geared Drive Motors; Direct drive Motors are typically used for end effectors or collaborative robotic arms that require force feedback and precise applications; Hydraulic and pneumatic systems are used for industrial or large mechanical applications.

3. Current status of actuators in robotics and application

3.1. Current status of actuators in robotics

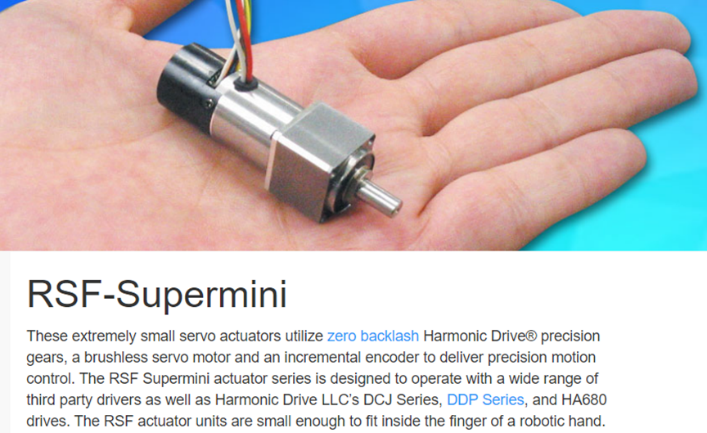

3.1.1. Miniaturization. Electromagnetic actuators are widely used in robotics due to their high efficiency, precision, and scalability. Among the various types of electromagnetic actuators, geared drive motors and direct drive motors are two of the most employed options in robotic systems. Both types of actuators operate based on the principle of converting electrical energy into mechanical motion through the interaction of magnetic fields. Figure 6 is a schematic diagram of a very small servo actuator.

Figure 6. extremely small servo actuators [7].

The drive towards miniaturization is primarily fueled by the increasing demand for smaller, more agile robots capable of performing tasks in confined spaces or within intricate environments, such as in microsurgery, microassembly, or inspection applications.

3.1.2. Energy efficiency. Energy efficiency has become a critical aspect of actuator development, as more efficient actuators contribute to longer operating times, reduced heat generation, and overall lower energy consumption in robotic systems. Recent advancements in actuator technologies, such as the optimization of electromechanical designs and the incorporation of advanced materials, have led to more energy-efficient solutions. For instance, the development of high-performance, low-loss electric motors that utilize permanent magnets, improved winding techniques, and advanced control algorithms has resulted in reduced energy losses and enhanced performance. Additionally, advances in power electronics and energy storage systems, such as high-capacity batteries and supercapacitors, enable better energy management and improve the overall efficiency of robotic systems. As energy efficiency remains a critical concern for the future of robotics, further research and development in this area will be essential to create sustainable and environmentally friendly robotic solutions.

3.1.3. Control and precision. Enhancements in control and precision are vital for the performance of robotic systems, especially in applications that demand high levels of accuracy and repeatability, such as in manufacturing, healthcare, and research. Recent developments in actuator technology have led to significant improvements in control and precision capabilities. For example, advancements in sensor technology, such as high-resolution encoders and advanced feedback mechanisms, have enabled more accurate monitoring of actuator position, speed, and force, resulting in better closed-loop control. Figure 7 is a schematic diagram of a high-precision gear transmission actuator.

Figure 7. High precision gear drive actuator [8].

Numerous joint motors, designed as highly integrated power units, already encompass control algorithms at the foundational level of the motor. As a user, one simply needs to transmit relevant commands to the joint motor, which can autonomously complete the entire process, from receiving commands to applying joint torque.

For the underlying control algorithm of the motor, the sole required control objective is the output torque. However, in robotic applications, it is often necessary to establish the position, speed, and torque of the joints. Consequently, hybrid control must be employed to effectively manage the joint motor's performance, catering to the complex requirements and specific demands of robotic systems. The following is the hybrid control algorithm used by the A1 motor in the picture, a PD controller is used to feedback the deviation of the motor at the output position to the torque input.

\( τ={τ_{ff}}+{k_{p}}⋯({p_{des}}-p)+{k_{d}}⋯({ω_{des}}-ω) \) (1)

In the formula, τ is the output torque of the motor rotor of the joint motor, and p is the current angular position of the motor rotor, ω is the angular velocity of the motor rotor.

By transmitting these five parameters to the motor via a microcontroller through the communication bus, the actuator can operate according to our expectations. It is evident that position control and feedback play a crucial role in the functioning of joint motors. The position feedback of the joint motor is derived from the encoder, ensuring accurate and reliable operation within the system.

Absolute Encoder is widely used in actuators. The number of discrete positions of an absolute encoder limit the control accuracy of motor. Formular to calculate the Encoder minimum angle resolution in 360 degree rotation:

\( N=\frac{360}{I} \) (2)

The resolution is measured in terms of bits N, with the encoder measuring 2^N positions per revolution.

In the gear drive actuator example above, the motor has a single absolute position encoder installed on the motor shaft, the encoder resolution is specified as 15 bits. Utilizing the formula N = 2^15, it is determined that there are 32,768 distinct positions that the encoder can detect. Consequently, the smallest angular increment discernible by this motor is 0.001099 degrees. This high resolution enables the motor to detect minute changes in angular position and apply precise position control based on these detected changes, thereby ensuring enhanced accuracy and performance in robotic applications.

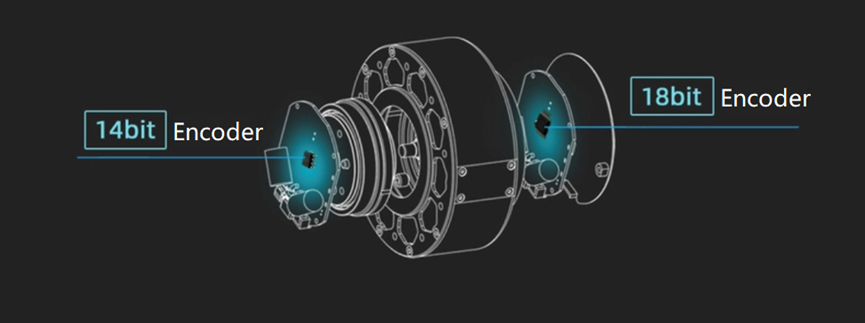

In addition to the single encoder joint motor example shown above, some actuator motors are equipped with dual encoders to enhance the performance, accuracy, and reliability of the system. Dual encoder configurations typically include two separate encoders, one installed on the motor shaft and the other on the output shaft or load side. The primary purpose of using a double encoder setup is to achieve greater precision and control by monitoring both the motor's input and the output of the overall actuator system (Figure 8).

Figure 8. Double encoder Actuator from K-tech (MG6010E-i6 V3) [8].

A notable advantage of this dual encoder arrangement is the ability to remember the "absolute zero point." This means that even if the joint is rotated by external forces when the motor is not powered, the motor can still calculate the accurate angle using the combined data from both the output shaft and motor end encoders. Moreover, this setup allows for multi-turn absolute position feedback, further improving the overall precision and control capabilities of the actuator system. By employing dual encoders in reduction joint motors, enhanced accuracy, reliability, and advanced control strategies can be achieved, making them suitable for applications that demand high levels of precision and dependability.

Moreover, sophisticated control algorithms, combined with powerful microcontrollers and real-time computing platforms, have facilitated the implementation of advanced control strategies, such as model-based control, adaptive control, and machine learning techniques. These strategies enable better compensation for system uncertainties, nonlinearities, and disturbances, ultimately improving the precision and reliability of actuator performance. The ongoing advancements in control and precision capabilities will continue to drive innovation in robotics, enabling new applications and pushing the boundaries of what is achievable with robotic systems.

3.2. Common applications and use cases

Common applications and use cases for advanced actuators span a wide range of industries and sectors, reflecting the versatility and adaptability of robotic systems. Industrial robots, equipped with high-performance actuators, are extensively employed in manufacturing and assembly lines to enhance efficiency, precision, and productivity. These robots perform tasks such as welding, painting, and material handling, thereby improving the overall quality and speed of production. Medical robots, including surgical and rehabilitation robots, rely on actuators with exceptional control and precision to ensure patient safety and provide optimal healthcare outcomes. These robots assist in delicate surgical procedures, perform patient diagnostics, and facilitate therapeutic interventions.

In the realm of service robots, actuators are integral to the development of devices that support various tasks in domestic, commercial, and public environments. Examples of service robots include autonomous vacuum cleaners, robotic waiters, and customer service robots designed to interact with humans and perform a multitude of tasks. Military and security robots, on the other hand, necessitate actuators capable of withstanding harsh and unpredictable conditions while providing reliable performance. These robots undertake diverse roles, such as surveillance, search and rescue, explosive ordnance disposal, and reconnaissance, significantly improving the safety and effectiveness of military and security operations. The widespread applicability of actuators in these various domains underscores their critical role in shaping the future of robotics and driving innovation across numerous industries.

3.3. Limitations and challenges

Limitations and challenges in the development and application of advanced actuators can be broadly categorized into two main areas: cost and manufacturing constraints, as well as performance and reliability issues.

3.3.1. Cost and manufacturing constraints. Cost and manufacturing constraints: The implementation of advanced actuators in robotic systems often comes with a higher price tag due to the use of specialized materials, complex designs, and intricate fabrication processes. Manufacturing these actuators may require sophisticated equipment and skilled labor, further adding to the overall cost. As a result, the high expense associated with advanced actuators can limit their accessibility and adoption, particularly for small-scale or budget-constrained applications. Moreover, the complexities in manufacturing can sometimes hinder the scalability of production, impeding the ability to meet growing demands and rapid technological advancements.

3.3.2. Performance and reliability issues. Performance and reliability issues: Despite the significant improvements in actuator technology, challenges related to performance and reliability still persist. Factors such as wear and tear, fatigue, and environmental conditions can adversely affect the performance of actuators over time. Ensuring consistent and reliable operation under varying load conditions, temperature extremes, and other external factors is critical for the long-term success of robotic systems. Furthermore, the integration of advanced actuators with other components, such as sensors, control systems, and power electronics, can introduce additional challenges in terms of compatibility and communication, potentially impacting overall system performance and reliability.

4. Prospects and future developments

As the field of robotics continues to evolve, emerging actuator technologies and advancements in existing ones promise to significantly impact the industry. Soft robotics and artificial muscles, as well as electroactive polymers, represent some of the innovative approaches to actuation that could transform robotic systems' capabilities, particularly in terms of flexibility, adaptability, and safety.

These novel technologies hold great potential for various applications, such as human-robot interaction and collaboration, where robots can work alongside humans in shared environments with improved safety and efficiency. Similarly, exploration and search and rescue robots can benefit from these advanced actuators, enabling them to navigate and operate in complex, unstructured environments more effectively.

Integration with other technologies, such as artificial intelligence and machine learning, will further augment the capabilities of actuator-driven robotic systems. A prime example of this integration is the Tesla bot, which combines advanced actuation with AI to achieve remarkable autonomy and functionality. Additionally, the fusion of sensors and advanced control algorithms can further enhance the performance and adaptability of robotic systems.

Force feedback advancements, such as improved electric actuators for enhanced haptic experiences, will also play a crucial role in the development of future robotic systems. These improvements will enable more realistic and responsive interactions between robots and their environments, as well as human users.

5. Conclusion

In conclusion, the current status and future prospects of actuators in robotics suggest an exciting and transformative path for the field. The ongoing development and integration of novel technologies hold the potential to redefine the capabilities and applications of robotic systems. To fully realize these possibilities, continued research and development efforts must be pursued to overcome current limitations and unlock the untapped potential of advanced actuation technologies.

References

[1]. Haring T., Forman K., Huhtanen T., Zawadzki M. (2003) Direct drive-opening a new era in many applications. Conference Record of the 2003 Annual Pulp and Paper Industry Technical Conference, 20: 171-179.

[2]. Semini C., Barasuol V., Focchi M., Boelens C. (2020) Brief introduction to the quadruped robot HyQReal. Energy, 20: 120-125.

[3]. De A., Bertoldi P., Leonhard W. (2012) Energy efficiency improvements in electric motors and drives. Springer Science & Business Media, 67(7): 230-241.

[4]. Wu G., Yang J., Shang J., Fang D. (2020) A rotary fluid power converter for improving energy efficiency of hydraulic system with variable load. Energy, 195: 116957.

[5]. Ali H I., Noor S B B M., Bashi S M., Marhaban M H. (2009) A review of pneumatic actuators (modeling and control). Australian Journal of Basic and Applied Sciences, 3(2): 440-454.

[6]. Hunter I W., Hollerbach J M., Ballantyne J. (1991) A comparative analysis of actuator technologies for robotics. Robotics Review, 2: 299-342.

[7]. Knestel M., Hofer E P., Barillas S K. (2008) The artificial muscle as an innovative actuator in rehabilitation robotics. IFAC Proceedings Volumes, 41(2): 773-778.

[8]. Wang X D., Chen H W., Wang L. (2021) Design and Analysis of Pneumatic Bending Actuator Used in Soft Robotics. Advances in Science and Technology, 105: 194-201.

[9]. Ghosh B., Jain R K., Majumder S. (2017) Experimental performance evaluation of smart bimorph piezoelectric actuator and its application in micro robotics. Microsystem Technologies, 23(10): 1-17.

[10]. Case J C., White E L, Sunspiral V. (2018) Reducing Actuator Requirements in Continuum Robots Through Optimized Cable Routing. Soft Robotics, 5(1): 109.

Cite this article

Yuan,Z. (2023). Current status and prospects of actuator in robotics. Applied and Computational Engineering,11,181-191.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2023 International Conference on Mechatronics and Smart Systems

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Haring T., Forman K., Huhtanen T., Zawadzki M. (2003) Direct drive-opening a new era in many applications. Conference Record of the 2003 Annual Pulp and Paper Industry Technical Conference, 20: 171-179.

[2]. Semini C., Barasuol V., Focchi M., Boelens C. (2020) Brief introduction to the quadruped robot HyQReal. Energy, 20: 120-125.

[3]. De A., Bertoldi P., Leonhard W. (2012) Energy efficiency improvements in electric motors and drives. Springer Science & Business Media, 67(7): 230-241.

[4]. Wu G., Yang J., Shang J., Fang D. (2020) A rotary fluid power converter for improving energy efficiency of hydraulic system with variable load. Energy, 195: 116957.

[5]. Ali H I., Noor S B B M., Bashi S M., Marhaban M H. (2009) A review of pneumatic actuators (modeling and control). Australian Journal of Basic and Applied Sciences, 3(2): 440-454.

[6]. Hunter I W., Hollerbach J M., Ballantyne J. (1991) A comparative analysis of actuator technologies for robotics. Robotics Review, 2: 299-342.

[7]. Knestel M., Hofer E P., Barillas S K. (2008) The artificial muscle as an innovative actuator in rehabilitation robotics. IFAC Proceedings Volumes, 41(2): 773-778.

[8]. Wang X D., Chen H W., Wang L. (2021) Design and Analysis of Pneumatic Bending Actuator Used in Soft Robotics. Advances in Science and Technology, 105: 194-201.

[9]. Ghosh B., Jain R K., Majumder S. (2017) Experimental performance evaluation of smart bimorph piezoelectric actuator and its application in micro robotics. Microsystem Technologies, 23(10): 1-17.

[10]. Case J C., White E L, Sunspiral V. (2018) Reducing Actuator Requirements in Continuum Robots Through Optimized Cable Routing. Soft Robotics, 5(1): 109.