1. Introduction

Steel bars in conventional reinforced concrete structures will corrode more quickly in the severe maritime environment because chloride ions continually erode the steel bars, which makes the structure face the problem of insufficient durability prematurely. As a new generation of promising construction materials, FRP (Fiber Reinforced Polymer) bars would be the most likely new material to replace reinforcement due to its various benefits such as low weight, high strength, resistance to fatigue and corrosion, design-ability, and production simplicity. However, using FRP bars in civil engineering is not completely immune to the adverse external environment, according to Benmokrane, Wang et al. [1-5]. While an alkaline atmosphere significantly affects the mechanical characteristics of FRP material. The major causes of this are the prolonged hydrolysis of the resin matrix in an alkaline environment and the debonding of the fiber-matrix interface brought on by the presence of hydroxyl groups in solution. At present, the research on FRP bars is mainly done through accelerated corrosion experiments to obtain the influence of temperature, corrosion environment, and other environmental factors on the durability of FRP bars, but their long-term performance still requires more research. This paper primarily examines how various environmental factors affect FRP's durability in alkaline environments and summarizes the current widely used life prediction models, this can serve as a resource for future studies on FRP bars.

2. Influencing factors analysis of FRP bars' durability in the alkaline environment

The durability of FRP material may be easily assessed by contrasting the tensile strength retention rate value before and after exposure to various situations since the change in tensile strength value is a trustworthy predictor of durability. The mechanical deterioration law of FRP bars under various environmental influences is summarized in Table 1. The main experimental samples were three FRP bars, namely GFRP bars, BFRP bars and CFRP bars, denoted by G, B and C. The number after this character represents the diameter of the FRP bars. The character T stands for temperature, followed by the number Celsius. For example, G16T40 denotes that GFRP bars with a diameter of 16mm are placed at a temperature of 40°C. The experiment was mainly carried out in two kinds of solution, namely alkaline solution and the solution simulating normal concrete environment.

Table 1. FRP bar tensile strength in an alkaline environment.

Author, Ref. | FRB types | Environmental conditioning | Duration(days) | Tensile Strength (MPa) | TS Retention(%) |

Wang et al. | G12.7T60 | pH12.8 (Alkaline) | 183 | 300.0 | 43.92 |

G16T40 | pH12.8 (Alkaline) | 183 | 356.9 | 65.03 | |

G16T60 | pH12.8 (Alkaline) | 183 | 281.0 | 51.19 | |

G16T80 | pH12.8 (Alkaline) | 183 | 170.2 | 31.15 | |

G19T60 | pH12.8 (Alkaline) | 183 | 353.0 | 52.92 | |

Rifai et al. | B11T20 | pH12 (Alkaline) | 90 | 1218.0 | 95.98 |

B11T20 | pH12 (Alkaline) | 180 | 1250.0 | 98.50 | |

B11T20 | pH12 (Alkaline) | 270 | 1220.0 | 96.13 | |

B11T40 | pH12 (Alkaline) | 90 | 1240.0 | 97.71 | |

B11T40 | pH12 (Alkaline) | 180 | 1207.0 | 95.11 | |

B11T40 | pH12 (Alkaline) | 270 | 1110.0 | 87.47 | |

B11T60 | pH12 (Alkaline) | 90 | 1163.0 | 91.65 | |

B11T60 | pH12 (Alkaline) | 180 | 1055.0 | 83.14 | |

B11T60 | pH12 (Alkaline) | 270 | 910.0 | 71.71 | |

B11T20 | pH12.5 (Concrete) | 90 | 1199.0 | 94.48 | |

B11T20 | pH12.5 (Concrete) | 180 | 1192.0 | 93.93 | |

B11T20 | pH12.5 (Concrete) | 270 | 1153.0 | 90.86 | |

B11T40 | pH12.5 (Concrete) | 90 | 1190.0 | 93.77 | |

B11T40 | pH12.5 (Concrete) | 180 | 1145.0 | 90.23 | |

B11T40 | pH12.5 (Concrete) | 270 | 1150.0 | 90.62 | |

B11T60 | pH12.5 (Concrete) | 90 | 1118.0 | 88.10 | |

B11T60 | pH12.5 (Concrete) | 180 | 1125.0 | 88.65 | |

B11T60 | pH12.5 (Concrete) | 270 | 1080.0 | 85.11 | |

Chen et al. | G9.35T60 | pH12.7 (Alkaline) | 120 | 711.0 | 64.00 |

G9.35T60 | pH13.6 (Alkaline) | 120 | 455.0 | 38.00 | |

Benmokrane et al. | G13T60 | pH13 (Alkaline) | 90 | 1108.0 | 69.00 |

B13T60 | pH13 (Alkaline) | 90 | 896.0 | 60.00 | |

C13T60 | pH13 (Alkaline) | 90 | 1914.0 | 98.00 | |

Ali et al. | B9.5T60 | pH12.8 (Alkaline) | 90 | 1010.0 | 81.45 |

B12.7T60 | pH12.8 (Alkaline) | 90 | 705.0 | 67.14 | |

B15.9T60 | pH12.8 (Alkaline) | 90 | 1178.0 | 84.87 | |

B19T60 | pH12.8 (Alkaline) | 90 | 1270.0 | 84.22 | |

B25T60 | pH12.8 (Alkaline) | 90 | 821.0 | 80.25 |

2.1. Alkalinity

The main element impacting the durability of FRP material is alkalinity. Chen et al. [6] found that after being exposed to the simulated pore solution of high-performance concrete (PH=12.7) at 60 degrees for 120 days, GFRP bars retained their tensile strength at a rate of 64%. However, when GFRP bars were placed in simulated ordinary concrete’s pore solution (PH=13.6) under identical circumstances, just 38% of the tensile strength was retained. The experimental findings indicate that GFRP bars deteriorate to a greater extent the higher the alkalinity of the solution. According to studies [7, 8], the rate of deterioration of BFRP bars submerged directly in laboratory-simulated pore fluid is faster than the actual internal environment of concrete structures. Rifai et al. [4] place 11mm diameter BFRP bars to wet concrete (pH=12.5) and alkaline solution (pH=12) imitating concrete pore solution to investigate how BFRP bars behave differently in these two different settings. When the temperature was adjusted to 20℃, 40℃ and 60℃ respectively, in the first three months of the experiment, in comparison to BFRP bars exposed in a concrete environment, the bars soaked in a solution that mimicked pore water had a higher tensile strength. After nine months of continuous testing, BFRP bars retained their tensile strength at a rate of 85.11% in the concrete environment, which is greater than that of 71.71% in the solution of the simulated concrete pore water. This may be because the concrete environment have higher alkalinity in the early stage of the experiment leading to a faster breakdown of the BFRP bars in it. As the test duration lengthens, compared with the internal environment of concrete, the alkaline solution simulated concrete pore solution has a larger hygroscopic rate and can produce more hydroxyl groups, which causes the resin to dissolve and the fiber-matrix interface to debond, even farther lowering the tensile strength retention rate.

2.2. Time and temperature

The durability of FRP bars will also be impacted by exposure duration and temperature in an alkaline environment. Wang et al. [2] examined the mechanical characteristics of GFRP bars with a diameter of 16mm under alkaline conditions of 40 degrees, 60 degrees and 80 degrees. After 3.65 days of erosion, tensile strength degradation rates for GFRP bars were 2.55%, 2.55%, 7.65% and 14.75%, respectively. After 183 days of erosion, GFRP bars’ attenuation rates of tensile strength can reach 34.97%, 48.81%, and 68.85%, respectively. The comparison demonstrates that both time and temperature have an effect on the mechanical characteristics of GFRP material in alkaline solution. Additionally, in the alkaline solution with higher temperatures and longer exposure time, the mechanical properties of GFRP bars decline more significantly. Rifai et al. [4] discovered that the tensile strength retention rate of BFRP bars in alkaline solution and simulated concrete pore solution is about the same when the temperature is below 40 degrees, and the exposure period has little effect on the tensile strength of BFRP bars. However, compared to the alkaline solution at 20 degrees, the tensile strength of BFRP bars dropped in the alkaline solution at 60 degrees by 4.33%, 15.36%, and 24.42%, respectively. The extra tensile strength was roughly 6.5% less in the simulated concrete pore solution. It tends to be found that the abatement of mechanical characteristics of BFRP bars is clearer with the increment of temperature over the long run. As a result, temperature has a greater impact than time on the degree of deterioration of BFRP material.

2.3. FRP types

FRP bars tensile strength is mostly determined by their fiber characteristics. Benmokrane et al. [9] studied three different types of FRP bars (CFRP/BFRP/GFRP) exposed to alkaline solution with a PH of 13 and a temperature of 60 degrees for three months, and the retention of BFRP bars and GFRP bars' tensile strength is 60% and 69% respectively, while that of CFRP bars only decreased by 2%. The experimental results demonstrate that carbon fiber-reinforced polymer (CFRP) bars have superior mechanical qualities and durability in the alkaline environment. However, the expensive price of CFRP bars prevents them from being utilized in the Construction industry. Therefore, GFRP materials are still widely employed in the civil engineering industry, although they are easy to deteriorate in an alkaline condition, similar to BFRP material.

2.4. Diameter of FRP bar

Some studies on the impact of the diameter of FRP bars on their durability show that the tensile strength of FRP bars increases with the increase in diameter. Wang et al. [2] eroded GFRP bars with diameters of 12.7, 16.0 and 19.0mm at 60-degree alkaline environment for 183 days, and the tensile strength attenuation was 56.08%, 48.81% and 47.08%, respectively. This is because GFRP bars with larger diameters may have larger proportions of fiber dimension and resin that has not been eroded, and can distribute tensile stress well. However, Ali et al. [10] performed accelerated alkaline corrosion tests on BFRP bars with various diameters of 9.5mm, 12.7mm, 15.9mm, 19mm, and 25mm to ascertain the deteriorating rule of tensile strength. They soaked the bars in an alkaline solution, whose pH is 12.8, at 60 degrees for three months. According to the test, the tensile strength of five different diameters of BFRP bars decreased by 18.55%, 32.86%, 15.13%, 15.78% and 19.75%, respectively. Accelerated aging had a significant influence on the 12.7mm diameter BFRP bars, retaining just 67% of their ultimate tensile strength. This FRP bar's larger loss of tensile strength is probably caused by the gradual increase in moisture absorption, which has plasticizing effects on the polymer matrix [11]. By comparing other diameters of BFRP bars, it is found that their diameters have no direct correlation with durability.

3. SEM (Scanning Electron Microscopy) analysis

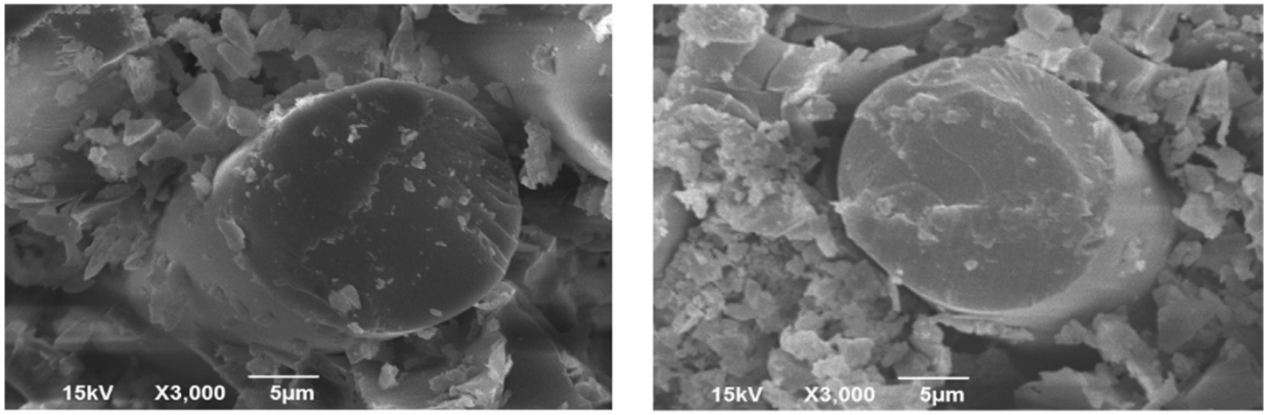

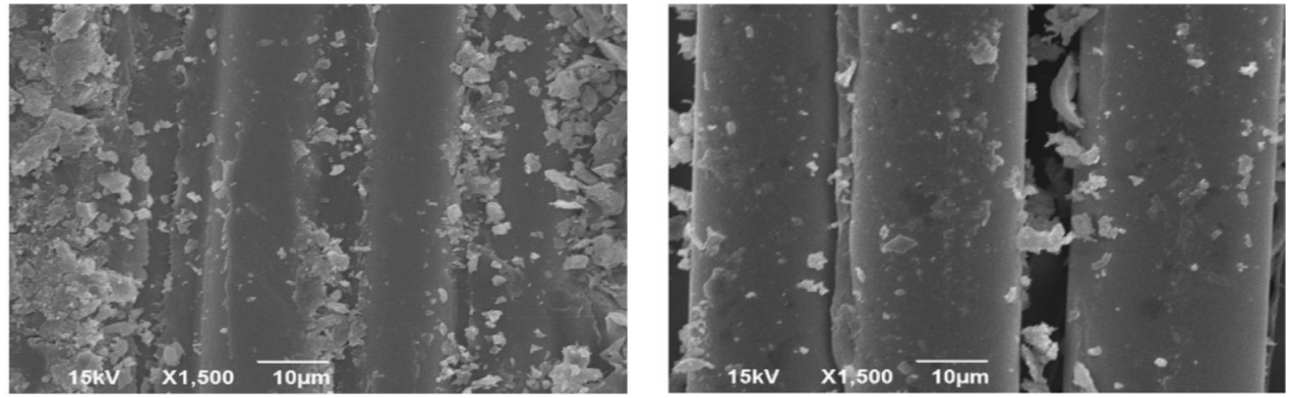

The main reasons [12] for the deterioration of the mechanical characteristic of FRP material are the debonding of the fiber-matrix interface and the resin dissolving. FRP bars are anisotropic materials having longitudinal fiber-matrix collaboration, so the interface of FRP bars is easily detachable during the process of stress. Since the fiber-matrix interface is around one nanometer thick and is not uniformly distributed, the main degradation processes are the fiber matrix interface debonding and delamination and matrix permeability cracking. The resin degrades because the resin absorbs water molecules and corrosive ions from the solution, forming microcracks that expand at the interface between the resin and the fiber, eventually causing the fiber to crack. Figure 1(a) and Figure 2(a) display the longitudinal and cross-sectional SEM of BFRP bars in untreated conditions, respectively. Figures 1(b) and 2(b) are cross-section and longitudinal section SEM of BFRP bars after nine months of soaking in an alkaline solution at 60 degrees (Figures resources are from [4]). In the group in untreated circumstances, the resin matrix around the BFRP bars is substantially unaltered, with only a few scattered resin matrix fragments, can clearly see the good binding of the fiber-matrix interface, as shown in Figure 1. However, in the experimental group after nine months, there were numerous resin matrix fragments visible since the majority of the resin matrix around the BFRP bars had been hydrolyzed. Long-term exposure of BFRP bars to an alkaline environment hastened the reaction between the free hydroxyl group and the resin matrix, leading to the destruction of the resin matrix. As shown in Figure 2, the longitudinal profile surface of the untreated BFRP bars is relatively complete, and the resin matrix filled with cracks is also relatively intact, with no obvious corrosion traces. Following nine months of experimentation, it was discovered that the fibre matrix interface of BFRP bars had separated, the fibre surface had become increasingly smooth, and the majority of the resin matrix that had filled the gap had decomposed. Clearly, the surface of debonding and the surface of fracture may connect to create a continuous crack. This severe degradation [4] accelerates the diffusion of water molecules into the microstructure by increasing the number of channels and void spaces, which make uneven distribution of load between fibres, thereby affecting BFRP bars' mechanical characteristic. From the SEM graph of BFRP bars at the microscopic level, it can be observed that the hydrolysis of resin is the main factor for BFRP bars to fail, followed by the debonding of the fiber-resin interface and fiber degradation, which ultimately causes FRP bars to fail [5].

\( R-COO-{R^{ \prime }}+{OH^{-}}→R-{COO^{-}}+HO-{R^{ \prime }}\ \ \ (1) \)

\( 2{SiO_{2}}+{OH^{-}}→SiO_{5/2}^{-}+{SiO_{5/2}}H\ \ \ (2) \)

\( SiO_{\frac{5}{2}}^{-}+{OH^{-}}+\frac{1}{2{H_{2}}O}→{H_{2}}SiO_{4}^{2-}\ \ \ (3) \)

| |

(a) | (b) |

Figure 1. Cross-sectional SEM of BFRP bars in an alkaline conditioned, (a)unconditioned, (b) 60 °C for 270 days [4]. | |

| |

(a) | (b) |

Figure 2. Longitudinal SEM of BFRP bars in an alkaline conditioned, (a)unconditioned, (b) 60°C for 270 days [4]. | |

4. Service life prediction of FRP bars in alkaline environment

When the long-term service life is predicted based on short-term test data, the Arrhenius equation [13] is often used to analyze the degradation rate of tensile strength of FRP bars under different temperatures and time.

\( k=Aexp{(\frac{-{E_{a}}}{RT})}\ \ \ (4) \)

Where A is a constant related to material properties and deterioration process, k is the degradation rate of tensile strength, Ea is the activation energy that causes the degradation of tensile strength, T is the temperature and R is the Molar gas constant.

Equation (1) can be rewrite as follow:

\( ln{(\frac{1}{k})}=\frac{{E_{a}}}{R}\frac{1}{T}-ln{(A)}\ \ \ (5) \)

Equation (2) demonstrates the logarithm of time has a linear relationship with the reciprocal of the absolute ambient temperature. The key premise is that the single major degradation mechanism is unaffected by time or temperature, but that at higher temperatures, the pace of deterioration would accelerate. In addition to the above factors, the tensile strength of FRP bars is also affected by many factors such as the composition, size, solution concentration and action mode of the bars. These factors cannot be expressed in the traditional model (single exponential function), so the deficiencies in the expression of exponential function model can be adjusted by adding constant variables on the basis of the exponential function. The three most widely used forecasting models are listed.

4.1. Phani et al’s model

\( Y=100exp{(-\frac{t}{τ})}\ \ \ (6) \)

In this model [14], Y is the tensile strength retention, τ is the fitted constant and t is the time. This mode demonstrates that the debonding of the fiber-resin interface is the main contributor to the degradation of FRP materials and is successful in forecasting the long-term durability of GFRP and BFRP bars [3, 6, 15] in the concrete alkaline condition. It is assumed in this model that the tensile strength of FRP bars begins to degrade rapidly, gradually slow down, and finally reaches zero when the exposure time is infinite. Compared with other life prediction models, the tensile strength predicted by this model will decline faster with the increase of time.

4.2. Bank et al’s model

\( Y=alog{(t)}+b\ \ \ (7) \)

Where a and b represent the two constants of the fitting function. This model [16] accurately predicts the durability attenuation law of FRP bars in the real concrete environment [1-2, 17]. Nevertheless, this model is only a linear fitting for the long-term durability of FRP bars, which belongs to the empirical equation and does not reveal the FRP bars' deterioration mechanism. Furthermore, it is obvious that the retention rate of tensile strength is infinite when the time is zero, which is unreasonable.

4.3. Tannous et al’s model

\( Y=100{(1-\frac{\sqrt[]{2DCt}}{{r_{0}}})^{2}}\ \ \ (8) \)

Where C stands for the solution concentration and D for diffusion coefficient, r0 is the FRP bars’ radius. Tannous et al’s model [18] aims to predict the link between the moisture absorption rate and the tensile strength retention of FRP bars, and successfully predicts the long-term durability of FRP bars in experiments [19]. However, because it assumes that the impacted region has entirely degraded [20], this model could not precisely reflect the real condition of FRP bars. Additionally, it is somewhat challenging to determine D and C. The use of this model is constrained by these drawbacks.

5. Conclusion

Alkaline erosion is the primary factor causing FRP bars to become less durable, and when temperature and exposure time rise, the degradation of its mechanical characteristics increases. And directly exposed FRP bars to an alkaline solution cannot effectively reflect the deterioration condition of those bars buried in concrete. Direct placement in an alkaline solution causes FRP bars' mechanical characteristics to deteriorate more quickly than wet concrete does. Besides, the durability of FRP bars is also influenced by the type of fiber material utilized. In alkaline conditions, CFRP materials have better corrosion resistance than B/GFRP materials, but its high manufacturing cost limits their wide use. Meanwhile, the tensile strength of FRP bars is not directly influenced by their diameter, but it may be affected by how much of the fiber and resin are corroded. Scanning electron microscopy reveals the FRP bars’ microscopic deterioration mechanism in alkaline condition. The reason for this is that as test duration increases, FRP bars have a higher rate of moisture absorption and more hydroxyl groups are produced, which results in the fiber matrix interface debonding and the dissolution of resin. The current life prediction model of FRP material is established by using the Arrhenius equation, this ignores the impact of environmental elements and long-term sustained stress, which means that the deterioration of FRP bars will be more severe in the actual application environment. Most of the existing studies are carried out in the laboratory under relatively ideal conditions in the short term. The subsequent experiments should consider the application of changing stress and long-term observation of the change in the mechanical characteristics of FRP material to obtain more accurate data. Environmental correction variables and continuous stress may be considered in the long-term durability forecasting model of FRP material to achieve a more sophisticated prediction model.

References

[1]. M. Robert, P. Cousin, B. Benmokrane, Durability of GFRP reinforcing bars embedded in moist concrete, J. Compos. Construct. 13 (2) (2009) 66–73.

[2]. Wang W, Xue W. C. Accelerated aging tests for evaluations of tensile properties of GFRP rebars exposed to alkaline solution [J]. Journal of Building Materials, 2012,15:760-766.

[3]. Y. Pan, D. Yan, Study on the durability of GFRP bars and carbon/glass hybrid fiber reinforced polymer (HFRP) bars aged in alkaline solution, Compos. Struct. 261 (2020), 113285.

[4]. M.A. Rifai, H. El-Hassan, T. El-Maaddawy, F. Abed, Durability of basalt FRP reinforcing bars in alkaline solution and moist concrete environments, Constr. Build. Mater. 243 (2020), 118258,

[5]. Hamed Fergani, Benedetti Di, Mias Matteo, Cristina Oller, Cyril Lynsdale, Durability and degradation mechanisms of GFRP reinforcement subjected to severe environments and sustained stress, Construct. Build. Mater. 170 (2018) 637–648.

[6]. Y. Chen, J.F. Davalos, I. Ray, Durability prediction for GFRP reinforcing bars using short-term data of accelerated aging tests, J. Compos. Construct. 10 (4) (2006) 279–286.

[7]. W. Wu, X. He, W. Yang, L. Dai, Y. Wang, J. He, Long-time durability of GFRP bars in the alkaline concrete environment for eight years, Constr. Build. Mater. 314 (2022), 125573.

[8]. A. Manalo, G. Maranan, B. Benmokrane, P. Cousin, O. Alajarmeh, W. Ferdous, R. Liang, G. Hota, Comparative durability of GFRP composite reinforcing bars in concrete and in simulated concrete environments, Cem. Concr. Compos. 109 (2020) 103564,

[9]. B. Benmokrane, M. Hassan, M. Robert, P.V. Vijay, A. Manalo, Effect of different constituent fiber, resin, and sizing combinations on alkaline resistance of basalt, carbon, and glass FRP bars, J. Compos. Construct. 24 (3) (2020) 101–108.

[10]. B. Benmokrane, M. Hassan, M. Robert, P.V. Vijay, A. Manalo, Effect of different constituent fiber, resin, and sizing combinations on alkaline resistance of basalt, carbon, and glass FRP bars, J. Compos. Construct. 24 (3) (2020) 101–108.

[11]. Montaigu M, Robert M, Ahmed E, Benmokrane B. Durability performance of new GFRP dowels for concrete pavement. J Compos Construct 2013;17(2):176–87.

[12]. Guangyan Feng, Deju Zhu, Shuaicheng Guo, Md Zillur Rahman, Zuquan Jin, Caijun Shi. A review on mechanical properties and deterioration mechanisms of FRP bars under severe environmental and loading conditions, Cement and Concrete Composites.134 (2022) 104758.

[13]. W. Nelson, Accelerated Testing: Statistical Models, Test Plans, and Data Analyses, Wiley, New York, 1990.

[14]. K.K. Phani, N.R. Bose, Temperature dependence of hydrothermal ageing of CSMLaminate during water immersion, Compos. Sci. Technol. 29 (2) (1987) 79–87.

[15]. G. Wu, Z.Q. Dong, X. Wang, Y. Zhu, Z.S. Wu, Prediction of long-term performance and durability of BFRP bars under the combined effect of sustained load and corrosive solutions, J. Compos. Construct. 19 (3) (2015), 04014058.

[16]. L.C. Bank, T.R. Gentry, B.P. Thompson, J.S. Russell, A model specification for FRP composites for civil engineering structures, Construct. Build. Mater. 17 (6/7) (2003) 405–437.

[17]. J.F. Davalos, Y. Chen, I. Ray, Long-term durability prediction models for GFRP bars in concrete environment, J. Compos. Mater. 46 (16) (2012) 1899–1914.

[18]. F.E. Tannous, H. Saadatmanesh, Environmental effects on the mechanical properties of E-glass FRP rebars, ACI Mater. J. 95 (1998) 87–100.

[19]. Y. Li, S. Yin, Y. Lu, C. Hu, Experimental investigation of the mechanical properties of BFRP bars in coral concrete under high temperature and humidity, Construct. Build. Mater. 259 (2020), 120591.

[20]. Z. Dong, G. Wu, X. L. Zhao, Z. K. Wang, A refined prediction method for the long term performance of BFRP bars serviced in field environments, Construct. Build. Mater. 155 (2017) 1072–1080.

Cite this article

Zhou,Z. (2023). A Review on Durability Analysis of FRP Bars based on Different Factors in Alkaline Environment. Applied and Computational Engineering,25,9-15.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2023 International Conference on Functional Materials and Civil Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. M. Robert, P. Cousin, B. Benmokrane, Durability of GFRP reinforcing bars embedded in moist concrete, J. Compos. Construct. 13 (2) (2009) 66–73.

[2]. Wang W, Xue W. C. Accelerated aging tests for evaluations of tensile properties of GFRP rebars exposed to alkaline solution [J]. Journal of Building Materials, 2012,15:760-766.

[3]. Y. Pan, D. Yan, Study on the durability of GFRP bars and carbon/glass hybrid fiber reinforced polymer (HFRP) bars aged in alkaline solution, Compos. Struct. 261 (2020), 113285.

[4]. M.A. Rifai, H. El-Hassan, T. El-Maaddawy, F. Abed, Durability of basalt FRP reinforcing bars in alkaline solution and moist concrete environments, Constr. Build. Mater. 243 (2020), 118258,

[5]. Hamed Fergani, Benedetti Di, Mias Matteo, Cristina Oller, Cyril Lynsdale, Durability and degradation mechanisms of GFRP reinforcement subjected to severe environments and sustained stress, Construct. Build. Mater. 170 (2018) 637–648.

[6]. Y. Chen, J.F. Davalos, I. Ray, Durability prediction for GFRP reinforcing bars using short-term data of accelerated aging tests, J. Compos. Construct. 10 (4) (2006) 279–286.

[7]. W. Wu, X. He, W. Yang, L. Dai, Y. Wang, J. He, Long-time durability of GFRP bars in the alkaline concrete environment for eight years, Constr. Build. Mater. 314 (2022), 125573.

[8]. A. Manalo, G. Maranan, B. Benmokrane, P. Cousin, O. Alajarmeh, W. Ferdous, R. Liang, G. Hota, Comparative durability of GFRP composite reinforcing bars in concrete and in simulated concrete environments, Cem. Concr. Compos. 109 (2020) 103564,

[9]. B. Benmokrane, M. Hassan, M. Robert, P.V. Vijay, A. Manalo, Effect of different constituent fiber, resin, and sizing combinations on alkaline resistance of basalt, carbon, and glass FRP bars, J. Compos. Construct. 24 (3) (2020) 101–108.

[10]. B. Benmokrane, M. Hassan, M. Robert, P.V. Vijay, A. Manalo, Effect of different constituent fiber, resin, and sizing combinations on alkaline resistance of basalt, carbon, and glass FRP bars, J. Compos. Construct. 24 (3) (2020) 101–108.

[11]. Montaigu M, Robert M, Ahmed E, Benmokrane B. Durability performance of new GFRP dowels for concrete pavement. J Compos Construct 2013;17(2):176–87.

[12]. Guangyan Feng, Deju Zhu, Shuaicheng Guo, Md Zillur Rahman, Zuquan Jin, Caijun Shi. A review on mechanical properties and deterioration mechanisms of FRP bars under severe environmental and loading conditions, Cement and Concrete Composites.134 (2022) 104758.

[13]. W. Nelson, Accelerated Testing: Statistical Models, Test Plans, and Data Analyses, Wiley, New York, 1990.

[14]. K.K. Phani, N.R. Bose, Temperature dependence of hydrothermal ageing of CSMLaminate during water immersion, Compos. Sci. Technol. 29 (2) (1987) 79–87.

[15]. G. Wu, Z.Q. Dong, X. Wang, Y. Zhu, Z.S. Wu, Prediction of long-term performance and durability of BFRP bars under the combined effect of sustained load and corrosive solutions, J. Compos. Construct. 19 (3) (2015), 04014058.

[16]. L.C. Bank, T.R. Gentry, B.P. Thompson, J.S. Russell, A model specification for FRP composites for civil engineering structures, Construct. Build. Mater. 17 (6/7) (2003) 405–437.

[17]. J.F. Davalos, Y. Chen, I. Ray, Long-term durability prediction models for GFRP bars in concrete environment, J. Compos. Mater. 46 (16) (2012) 1899–1914.

[18]. F.E. Tannous, H. Saadatmanesh, Environmental effects on the mechanical properties of E-glass FRP rebars, ACI Mater. J. 95 (1998) 87–100.

[19]. Y. Li, S. Yin, Y. Lu, C. Hu, Experimental investigation of the mechanical properties of BFRP bars in coral concrete under high temperature and humidity, Construct. Build. Mater. 259 (2020), 120591.

[20]. Z. Dong, G. Wu, X. L. Zhao, Z. K. Wang, A refined prediction method for the long term performance of BFRP bars serviced in field environments, Construct. Build. Mater. 155 (2017) 1072–1080.