1. Introduction

The unmanned aerial vehicle (UAV) is operated by RF remote control and corresponding control programs. Compared with manned aircraft, its advantages are small and flexible, low manufacturing cost, easy to use, low environmental requirements and strong battlefield viability, etc. Today, with the increasingly wide application of UAVs, a new power structure is urgently needed in the market to replace the traditional fuel engine and lithium battery. Considering the energy density, gravimetric specific power, economic benefits and environmental protection, fuel cell becomes the best choice to solve the problem of UAV endurance. The gravimetric specific power of fuel cells is low, and it is difficult to cope with the large range fluctuation of load power when the UAV performs complex flight tasks. At present, fuel cells and other kinds of power sources are generally combined to form a hybrid power system to solve this problem. This paper focuses on fuel cell and battery hybrid power systems.

Although fuel cell has many advantages as the power source of UAVs, it also has the main problem of low power density. Researchers at home and abroad have done much research on how to improve the hybrid power system based on fuel cells [1].

This paper mainly introduces the composition of the fuel cell power system of UAVs. Then, analyze the advantages and disadvantages of current advanced cases in the industry. In the end, put forward prospects for future development.

2. Composition of fuel cell power system for UAV

The power system of a fuel cell UAV is mainly composed of a hydrogen storage device, fuel cell, electronic governor, motor, propeller and other auxiliary power electronic equipment (Figure 1). Fuel cells and auxiliary power supply are the energy sources of UAVs, which are directly related to the important indicators of UAVs, such as endurance, flight distance and maximum load weight [2].

Figure 1. Multi-Rotor unmanned aerial vehicle system composition.

2.1. Operating principle of fuel cell

The UAV needs a power system with high energy density and light volume, which enables the UAV to carry more equipment, achieve more functions and extend its endurance. The fuel cell can directly convert the energy stored in the fuel into electric energy without driving the motor through fuel combustion, thus simplifying the power system structure.

Fuel cells are divided into different types according to the different electrolytes inside. The following chart shows the performance comparison of several main fuel cells.

Table 1. Performance comparison of different fuel cells.

Type | Proton exchange membrane fuel cell | Solid oxide fuel cell | Direct methanol fuel cell |

Type of fuel | Hydrogen | Hydrogen or hydrocarbons such as methane, propane, etc. | Methanol |

Product | Water | Water | Water, carbon dioxide |

Working temperature(℃) | 30-110 | 600-1000 | 30-90 |

Power density of reactor(W/kg) | >500 | >800 | >70 |

System Power Density (W/kg) | >150 | >100 | >50 |

Table 1 shows that the operating temperature of proton exchange membrane fuel cells is lower than that of other types of fuel cells. And its product, water, is environmentally friendly, making the proton exchange membrane fuel cells the most suitable for unmanned power systems.

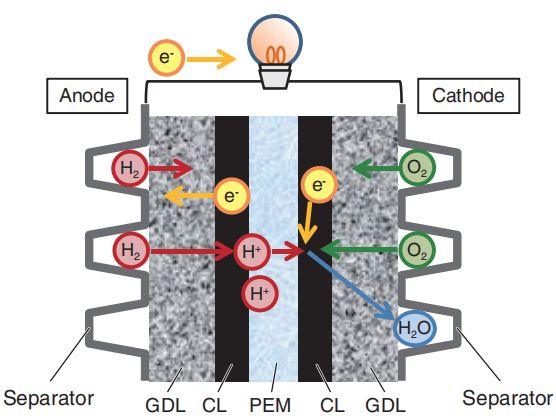

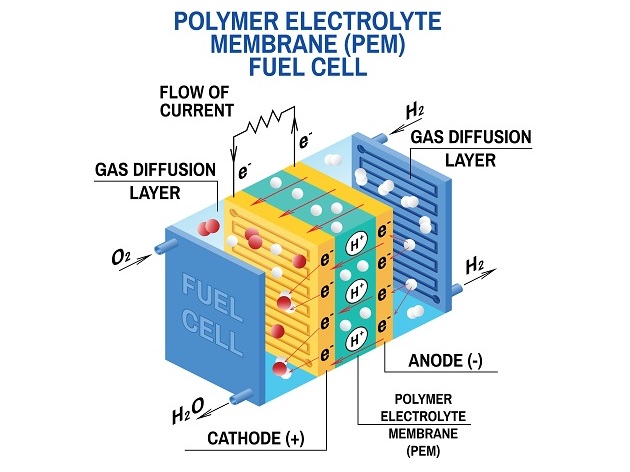

The operating principle of a proton exchange membrane fuel cell is shown in Figure 2. Hydrogen is decomposed into hydrogen ions and electrons at the anode when the fuel cell is operating. The chemical formula for the anodic reaction is:

\( {H_{2}}→2{H^{+}}+2{e^{-}} \) (1)

Oxygen and electrons react with hydrogen ions at the cathode to produce water. The chemical formula for the cathodic chemical reaction is:

\( 2{H^{+}}+\frac{1}{2}{O_{2}}+2{e^{-}}→{H_{2}}O \) (2)

The total chemical reaction equation is:

\( {H_{2}}+\frac{1}{2}{O_{2}}→{H_{2}}O \) (3)

Figure 2. Operating principle of fuel cell

2.2. Structure of fuel cells

Fuel cells are classified into air-cooled, liquid-cooled and many other types. Air-cooled type can be divided into cathode open type, and cathode closed type. The cathode open fuel cell has a relatively simple structure and high gravimetric specific power, suitable for UAV application as a power supply [3].

The operating voltage of the proton exchange membrane fuel cell (PEMFC) is usually between 0.5V and 0.7V, which is lower than required in most practical applications. Therefore, several cell units are usually used in series to form PEMFC stacks [4]. The reactor structure of open cathode fuel cells combines the above two structures, which means that while air passes through the cooling reactor from the reactor, it is used directly to provide oxygen for the reactions of the cathodes of each battery in the reactor. This structure reduces the mass and volume of the whole power system greatly based on output power, so it is suitable for use as the power supply for UAVs.

The cathode open fuel cell stack can be divided into two typical structures: the air self-breathing structure and the forced air convection structure with passive intake, as shown in Figure 3.

Figure 3. Structure schematic of open cathode fuel cell.

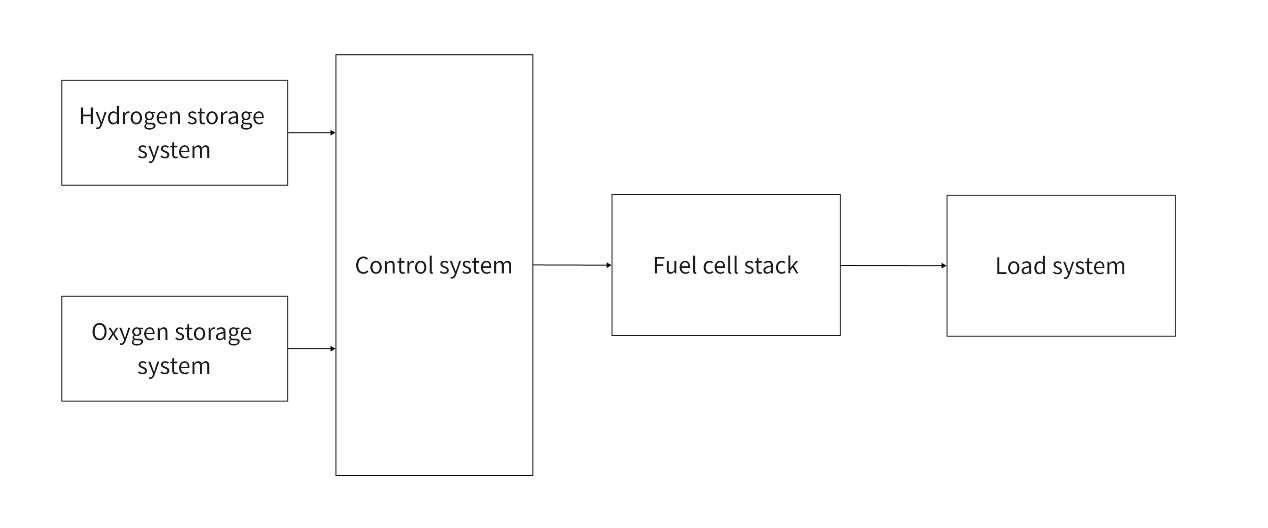

Compared with common fuel cell systems used on the ground, fuel cell systems for unmanned aerial vehicles have slightly different structures due to changes in temperature, air pressure, etc., due to changes in altitude [5]. Figure 4 shows the system structure of a fuel cell at a high altitude. It is mainly divided into four parts: fuel cell stack, hydrogen and oxygen storage supply system, control system and load system.

Figure 4. Unmanned aerial vehicle fuel cell system structure.

2.3. Hydrogen storage structure

The main type of hydrogen fuel used for UAVs is gaseous hydrogen. At present, a high-pressure cylinder is the most widely used hydrogen storage equipment. According to material and hydrogen storage pressure, gas cylinders can be divided into 4 categories [6]. As shown in Table 2, gas hydrogen storage pressure is generally 20-70 MPa. The maximum pressure of the hydrogen storage unit made of stainless steel is only 20 MPa, with the hydrogen storage ratio not exceeding 3%. It is generally used as an industrial hydrogen storage cylinder. Hydrogen storage with carbon fiber winding and high-density polymer lining can withstand the pressure of 70 MPa and a hydrogen storage ratio of 11.3%, which is suitable for unmanned aerial vehicles.

Table 2. Types of high-pressure hydrogen storage bottles [7].

Type | Material | Maximum pressure/ MPa | Hydrogen storage ratio/ % |

Ⅰ | Stainless steel | 20 | 1~3 |

Ⅱ | Composite winding on steel/Aluminium substrates | 30 | |

Ⅲ | Composites (FRP, high-strength synthetic fiber or carbon fiber) | 44 | |

Ⅳ | Carbon fiber wound high density polymer lining | 70 | 11.3 |

2.4. Auxiliary power supply

There is a wide range of auxiliary power options in hybrid power systems. Lithium batteries and supercapacitors are common types of auxiliary power.

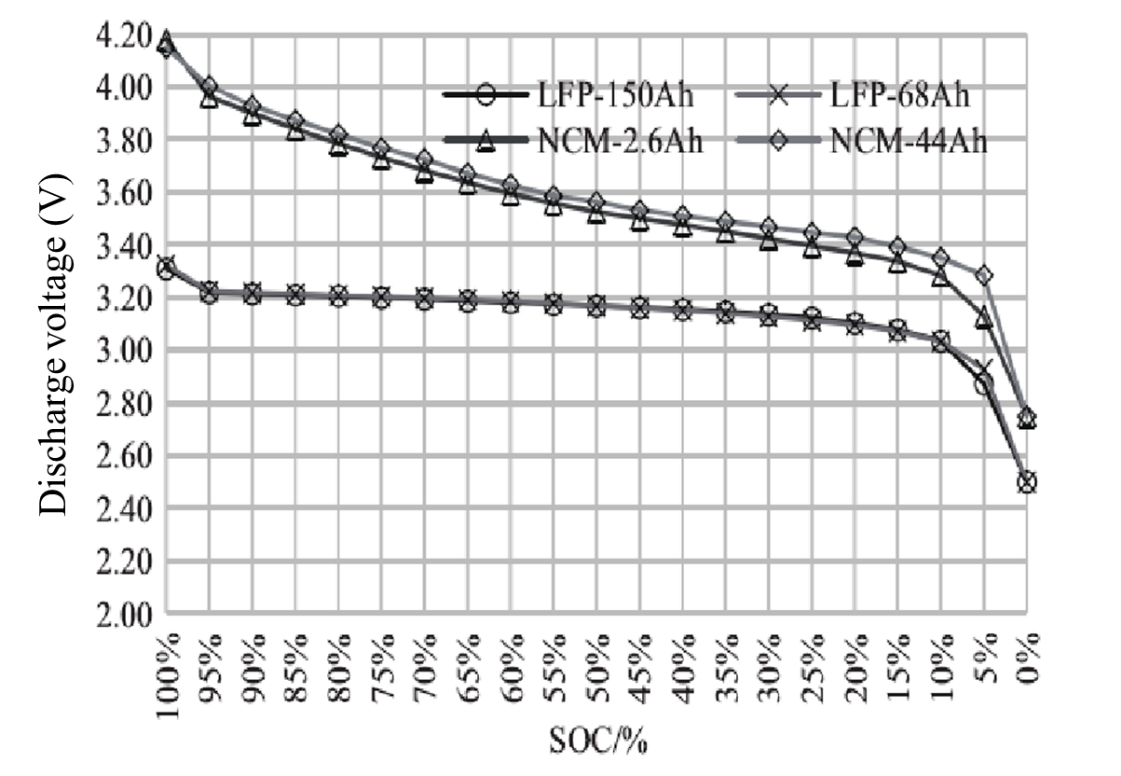

Lithium batteries have high energy storage density, long service life and up to 10,000 charge and discharge cycles. They usually form battery power packs in series to meet the needs of different voltage levels. The self-discharge rate of lithium batteries is as low as 1%, and their weight is about 1/5 of that of lead acid products at the same volume. With the development of battery technology, lithium batteries are widely used in new energy vehicles, energy storage devices and hybrid power systems. The relationship between voltage and SOC of a typical lithium battery is shown in Figure 5.

Figure 5. Change diagram of lithium battery voltage and SOC [8].

Ultracapacitor generally refers to double-layer capacitance, a new type of energy storage device. Ultracapacitors are between batteries and capacitors, and their enormous capacity can be used as batteries. From the perspective of practicality, ultracapacitors have short charging times and long service life. At the same time, it can work stably under various temperature conditions without harm to the environment. In the research and development process in related fields, lithium-ion supercapacitor has become the industry's preferred energy density with a relatively large increase compared with general double-layer capacitance. Typical lithium-ion ultracapacitor parameters are shown in Table 3.

Table 3. Lithium-ion capacitor parameters [9].

Enterprise | Voltage window/V | Internal resistance/mΩ | Energy density/(W·h/kg) | Gravimetric specific power/(Kw/kg) |

JM Energy | 2.2-3.8 | 1.2 | 10 | 21.5 |

JM Energy | 2.2-3.8 | 6.9 | 24 | 4.7 |

TAIYO YUDEN | 2.2-3.8 | -50AC | 10 | |

AFEC | 2.0-4.0 | 1.5 | 10 | 17.2 |

SHINKOBE-DENKI | 2.2-3.8 | 3.5 | 8 | 7.4 |

IEECAS | 2.0-4.0 | 2.0 | 30 | 20 |

3. Industry case studies

Following the application of fuel cells in different sizes of UAVs, Doosan Corporation of Korea, Proonex, AMI, EnergyOr, and HES in Europe and America, Troowin, and Ear in China started to develop fuel cells for light and small UAVs. AMI mainly develops solid oxide fuel cells, while other companies develop proton exchange membrane fuel cells. Some basic parameters are shown in Table 4.

Table 4. Parameters of commercial fuel cells for light and small unmanned aerial vehicles [7].

Model | Manufacturer | Cooling mode | Output power/W | Mass/kg | Specific power/W· \( {kg^{-1}} \) |

200W | Protonex | Liquid | 200 | 2.7 | 74 |

500W | Protonex | Liquid | 500 | 2.0 | 280 |

550W | Protonex | Liquid | 550 | 1.9 | 289 |

600W | Protonex | Liquid | 600 | 1.8 | 333 |

1200W | Protonex | Liquid | 1 200 | 4.0 | 300 |

D245 | AMI | SOFC | 245 | 2.5 | 96.1 |

310-XLE | EnergyOr | Air | 310 | 3.9 | 78.5 |

210-XLE | EnergyOr | Air | 210 | 3.6 | 57.5 |

410-LE | EnergyOr | Air | 410 | 3.4 | 120.6 |

A-200 | HES | Air | 200 | 0.7 | 310 |

A-500 | HES | Air | 1 500 | 1.4 | 360 |

A-1000 | HES | Air | 1 000 | 2.3 | 440 |

H1 | MMC | Air | 1 800 | 5.2 | 340 |

EOS600 | Pearl | Air | 600 | 3 | 200 |

EOS1000 | Pearl | Air | 1 000 | 4 | 250 |

HyLite1200 | Troowin | Air | 1 200 | 4 | 300 |

Table 5. Current research status of fuel cell unmanned aerial vehicle abroad [10].

Company | Name | Battery | Power/W | Time of flight |

Duralite Powe | DP-A-3000 | PEMFC | 2 | |

AMI | SOFC | 60 | 4.3 | |

Georgia Institute of Technology | PEMFC | 550 | 0.75 | |

EnergyOr | H2Quad | PEMFC | 2 | |

United States Naval Research Laboratory | Ion Tiger | PEMFC | 48 | |

H2GO | 1.5 | |||

DOOSAN | DT20 | PEMFC | 2100 | 2 |

Intelligent Energy | PEMFC | 12 |

Due to the characteristics of the fuel cell, such as high-power generation efficiency, portability, environmental protection and low power density, domestic and foreign researchers have conducted several studies on unmanned aerial vehicles with the hybrid power system (Table 5). Gong A and others compared the performance of a fuel cell/battery hybrid UAV under different mission scenarios. The comparison results show that the selection of a UAV mission profile through fuel cell performance is conducive to reducing hydrogen consumption during UAV flight. Kim T. et al. designed and built a fuel cell/hybrid battery system UAV, which consists of a fuel cell stack and a hydrogen generator, and conducted flight tests. The UAV successfully flew for two hours [10]. In 2019, MetaVista Corporation of Korea, in conjunction with Intelligent Energy, a British fuel cell engineering company, developed a four-wing fuel cell unmanned aircraft (Figure 6). It uses an ultra-light liquid hydrogen storage tank that provides 1860 watt-hours per kilogram of energy density for 11 hours of flight time, breaking the world record for multirotor unmanned aerial vehicles.

Figure 6. MetaVista UAV.

On January 23, 2022, the first flight of the Green Gull 30, a Hydrogen-powered UAV independently developed by the Research Center for Hydrogen Power and Low Carbon Energy in Chongqing Research Institute of Harbin Institute of Technology, was successfully completed. The maximum take-off weight of the Green gull 30 is 30kg, and its wingspan of it is 4m. Its cruise speed is 18-25ms². The cruise time is 9h, the load is 3kg, and the range is 800km. The endurance of this UAV is about 3-4 times higher than that of the lithium battery UAV of the same power level. The original impingement ventilation fuel cell power system was used on this UAV, which reduces power loss due to the additional load of the fuel cell system and greatly improves the operating efficiency of the system. The Green gull 30 is now the fixed-wing UAV with the longest endurance in China. It can be applied to scenes such as long-term investigation, line patrol, aerial surveys, material transportation and fire warning.

4. Conclusion

Through the above research, the most suitable power system for UAV should be a hybrid power supply consisting of proton exchange membrane fuel cell and lithium-ion battery or ultracapacitor, supplemented by carbon fiber winding and high-density polymer lined hydrogen storage system. After years of research and development, the development of fuel cell/battery hybrid UAVs has rapidly moved from new concept exploration and key technology research to practicality and engineering. In the future, the potential of fuel cell energy density should be fully exploited, and the lightweight of UAV power system should be further studied to maximize the endurance time; Carry out research on the overall design method of aerodynamic, structural, energy and power integration to improve the payload ratio. Integrating auxiliary energy sources such as lithium batteries and ultracapacitors to optimize overall system power output, improve economic benefits and expand application scope.

References

[1]. Zhang X H, Liu L, Dai Y L, et al. 2018 Acta Aeronautica et Astronautica Sinica, 39(8):221874

[2]. Zhang Z X. 2018 Design of Fuel Cell Multi-Rotor Unmanned Aerial Vehicle Hybrid Power System. Zhejiang: Zhejiang University College of Control Science and Engineering, 2018:9.

[3]. Ling H L. Power Electronics, 54(12):47-51.

[4]. Liu W M. 2017 Research on Structure and Performance of Cathode Open Air-Cooled Proton Exchange Membrane Fuel Cell. Jiangsu: Nanjing University

[5]. Wang Z M, Quan W X, Yan H Z et al. 2019 CIESC Journal, 70(S2):329-335

[6]. Gong A, Verstraete D. 2017 International Journal of Hydrogen Energy, 42(33):21311-2133.

[7]. Liu L, Cao X, Zhang X H, et al. 2020 Acta Aeronautica et Astronautica Sinica, 41(3):623474

[8]. Zhang F Q. 2021 Mechanical & Electrical Technology, (01):48-52+67.

[9]. Tran N A, Leprêtre J C, Alloin F. 2021 Electrochimica Acta, 375.

[10]. Yang G. 2018 Dynamic Performance and Configuration Optimization of Fuel Cell Unmanned Aerial Vehicle Power System. Sichuan: University of Electronic Science and Technology of China

Cite this article

Xu,J. (2023). Current status of power system for unmanned aerial vehicle fuel cell under different scenarios. Applied and Computational Engineering,28,25-32.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2023 International Conference on Mechatronics and Smart Systems

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Zhang X H, Liu L, Dai Y L, et al. 2018 Acta Aeronautica et Astronautica Sinica, 39(8):221874

[2]. Zhang Z X. 2018 Design of Fuel Cell Multi-Rotor Unmanned Aerial Vehicle Hybrid Power System. Zhejiang: Zhejiang University College of Control Science and Engineering, 2018:9.

[3]. Ling H L. Power Electronics, 54(12):47-51.

[4]. Liu W M. 2017 Research on Structure and Performance of Cathode Open Air-Cooled Proton Exchange Membrane Fuel Cell. Jiangsu: Nanjing University

[5]. Wang Z M, Quan W X, Yan H Z et al. 2019 CIESC Journal, 70(S2):329-335

[6]. Gong A, Verstraete D. 2017 International Journal of Hydrogen Energy, 42(33):21311-2133.

[7]. Liu L, Cao X, Zhang X H, et al. 2020 Acta Aeronautica et Astronautica Sinica, 41(3):623474

[8]. Zhang F Q. 2021 Mechanical & Electrical Technology, (01):48-52+67.

[9]. Tran N A, Leprêtre J C, Alloin F. 2021 Electrochimica Acta, 375.

[10]. Yang G. 2018 Dynamic Performance and Configuration Optimization of Fuel Cell Unmanned Aerial Vehicle Power System. Sichuan: University of Electronic Science and Technology of China