1. Introduction

In recent years, several major events have highlighted the risks of supply chain disruptions, especially in the manufacturing industry. The global outbreak of the COVID-19 pandemic in 2020 further exposed the vulnerability of the global supply chain. Supply chain disruptions, supply shortages, logistics paralysis, and a sudden decline in global demand have caused many companies to suffer significant losses and severely affected their operations [1]. In addition, geopolitical factors such as trade wars, sanctions, and tariff barriers can also lead to supply chain instability and affect the production and operation activities of the manufacturing industry.

In this context, the demand for supply chain flexibility in the manufacturing industry has become unprecedentedly urgent. Resilient supply chains can demonstrate a high degree of adaptability and rapid recovery in the face of disruptions, maintaining continuous operations and minimizing losses [2]. Improving supply chain resilience has become essential for manufacturing companies to maintain competitiveness and ensure sustainable development [3].

Blockchain technology has become a promising solution that may enhance supply chain resilience. Blockchain, with its decentralized, transparent, and immutable characteristics, can significantly improve data transparency, traceability, and security across the supply chain [4]. This study aims to explore the role of blockchain technology in enhancing the resilience of the manufacturing supply chain. Through a grounded theory approach, this research will identify key mechanisms by which blockchain can contribute to supply chain adaptability, risk management, and operational efficiency, thereby providing manufacturing companies with the tools they need to navigate an increasingly complex and uncertain global landscape.

2. Literature Review

2.1. Supply chain resilience and blockchain technology

2.1.1. Supply chain resilience

Supply chain resilience is described as the ability of a supply chain system to respond to potential risks in the face of varying degrees of risk, bringing the supply chain back to its original state or migrating to a better state [5]. Supply chain resilience consists of prevention and recovery, which describes the ability of the network to minimize the impact of an outage by avoiding it or starting to recover quickly. Resiliency refers to the ability of a network to return to a stable or improved system state in the event of an outage [6].

To help achieve this, many studies have been conducted to explore how to improve supply chain resilience and make recommendations: Artificial intelligence (AI) could be selected as a technology enabler to address problems associated with supply chain resilience [7]. There are also studies on how to improve supply chain resilience from the perspective of logistics service providers [8] and the effect of power-based behaviors on pharmaceutical supply chain resilience [9]. Other research suggests using supply chain knowledge as a critical enabler of organizational resilience [10]. However, a major drawback is that there is a lack of research on the impact of blockchain on supply chain resilience, so this article will focus on exploring the role of blockchain in supply chain resilience.

2.1.2. Blockchain technology

As a distributed ledger technology, blockchain technology has attracted extensive attention in the field of supply chain management in recent years. Its decentralization, immutability, and transparency bring many potential advantages to supply chain management. This paper reviews the application status of blockchain technology in supply chain management, and discusses its role in improving supply chain resilience. Blockchain technology is a distributed ledger technology that is secured by strong cryptography, including the private key that signs the transaction, the hash function that links the blocks, and the consensus mechanism. Disintermediation is another very important feature of blockchain technology, which avoids the need for intermediaries to repeatedly verify transactions.

At present, some scholars and enterprises have applied blockchain technology for supply chain management, including blockchain technology, which can significantly enhance the resilience of supply chains by improving the transparency and traceability of supply chains [11]. There is also research on how blockchain can protect sensitive information in the supply chain from the perspective of data security and prevent data leakage and tampering [12]. In addition, blockchain technology has shown great potential in optimizing inventory management and logistics efficiency. Studies have demonstrated the potential of blockchain technology to enhance supply chain management. Kouhizadeh and Sarkis discovered that real-time inventory tracking through blockchain can lead to substantial reductions in inventory overstocks and shortages [13]. Moreover, Saberi et al. proposed the utilization of blockchain technology for the development of a reliable supply chain information-sharing platform [14]. This platform could improve collaboration efficiency across all supply chain components and bolster the capacity to respond to potential risks. Furthermore, these studies show that blockchain technology has important application prospects in improving the efficiency and resilience of supply chain management.

3. Methodology

3.1. Research design

This study adopts a qualitative research method and uses grounded theory for data collection and analysis. Grounded theory is a qualitative research method whose main purpose is to build relevant theories based on empirical data. Grounded theory is generally suitable for exploratory research, especially in areas that are not fully covered by existing theories [15]. Through semi-structured interviews, this research can gain an in-depth understanding of the specific role of blockchain technology in improving supply chain resilience, thereby building a theoretical framework based on data.

3.2. Data Collection Methods

3.2.1. Selection of interviewees

In order to ensure the diversity and representativeness of the data, this study selected experts and practitioners from different types of manufacturing companies as interviewees. The purpose of this stage is to collect qualitative data on the views and attitudes of manufacturing executives on the role of blockchain technology in supply chain resilience, and to explore and understand the application of blockchain technology in practice. The manufacturing types include (1) electronic manufacturing (2) machinery manufacturing (3) stationery manufacturing (4) building materials manufacturing (5) medical device manufacturing. Finally, 11 valid original data were determined and statistically collated.

3.2.2. Interview outline design

According to the research questions and objectives, a semi-structured interview outline was designed. The interview outline (see Appendix 1) mainly covers the following aspects:

• The specific application of blockchain technology in supply chain management.

• How blockchain technology improves the transparency and traceability of the supply chain.

• The role of blockchain technology in improving supply chain data security

• How blockchain technology optimizes inventory management and improves logistics efficiency.

• How blockchain technology enhances the risk management capabilities and emergency response capabilities of the supply chain.

• Challenges and solutions for implementing blockchain technology in the supply chain.

3.2.3. Data Collection Process

The data collection process includes the following steps:

• Contact potential interviewees: Contact the selected interviewees by email and phone to introduce the purpose of the study and the content of the interview, and send them to the candidates three days in advance to seek their consent to participate.

• Arrange the time and place of the interview: Determine the specific time and place of the interview according to the schedule of the interviewee.

• Conduct the interview: Each interview lasts about 60 minutes, and the interview is recorded using a recording device. Detailed notes are taken after the interview, and the interviewee is contacted within 24 hours to reconfirm the interview content.

• Data storage and management: All interview data will be stored on a secure digital storage device with appropriate backup and encryption protection.

3.3. Data Analysis methods

In this study, this research used NVivo12 software for coding analysis. Coding analysis is divided into three stages: open coding, axial coding, and selective coding. In the open coding stage, this research analyzed all interview data line by line to identify preliminary concepts and categories. Subsequently, in the axial coding stage, this research classified and integrated these preliminary concepts to form initial categories and relationships. In the selective coding stage, this research determined the core category of the study and integrated all relevant concepts and categories into this core category to form a theoretical framework.

4. Result

4.1. Open coding

In the 11 original materials, 16 preliminary concepts were summarized and sorted out, including ensuring data security, information sharing mechanisms, increasing transaction transparency, and improving collaboration capabilities. After analyzing and sorting out these 16 preliminary concepts, this research found that some of the preliminary concepts had repeated information. Blockchain technology has similar aspects in improving the resilience of its supply chain. Therefore, this research summarized and sorted out the concepts with repeated relationships or similar expressions and merged them. Finally, six initial categories were obtained, including reaching consensus agreements, cross-platform information sharing, and processing indicators on the chain. The results of the conceptual analysis of open coding are shown in Table 1.

Table 1: Open Encoding

Example of raw materials | Frequency | Conceptualization |

Supply chain resilience is very important to us because it can help us quickly resume operations and reduce losses in the face of emergencies. The key factors affecting resilience include supplier diversity, inventory management, risk assessment, and emergency plans. | 6 | Regular risk assessment |

The most important aspect of blockchain technology is to ensure the immutability of data through encryption algorithms. Its characteristic is that it can enhance the data security, transparency, and trust of the supply chain, especially for the application of supply chain collaboration and information sharing in diverse supplier relationships. | 4 | Building a supply system |

The acceptance of partners is also a challenge. We introduce the advantages and applications of blockchain technology to supply chain partners through training and seminars, increase their understanding and trust, and ensure their active participation and cooperation. | 1 | Establishing trust mechanisms |

In addition, smart contracts can automatically execute emergency plans to ensure that the supply chain can quickly resume normal operations, maintain stability and continuity in the event of an emergency. | 7 | Design emergency plans |

After implementing blockchain technology, although data security has greatly improved, we also face issues of technology integration and system compatibility. To address these challenges, we have worked closely with technology providers, conducted system upgrades and employee training to ensure the smooth integration and maximum benefits of new technologies. | 6 | Improve collaboration performance |

The most important aspect of blockchain technology is to ensure the immutability of data through encryption algorithms. Its characteristic is that it can enhance the data security, transparency, and trust of the supply chain, especially for the application of supply chain collaboration and information sharing in diverse supplier relationships. | 12 | Ensure data security |

The most important aspect of blockchain technology is to ensure the immutability of data through encryption algorithms. Its characteristic is that it can enhance the data security, transparency, and trust of the supply chain, especially for the application of supply chain collaboration and information sharing in diverse supplier relationships. | 5 | Information sharing mechanism |

Blockchain technology, through its unique structure, makes information in each link of the supply chain public and transparent. Every transaction and operation can be recorded and tracked, so that any changes in the supply chain can be monitored and verified in real time. For example, when purchasing key minerals such as cobalt, Apple uses blockchain technology to track and verify the source of minerals and every link in the supply chain, ensuring transparency and accountability in the supply chain. | 13 | Increase transaction transparency |

Blockchain has particular advantages in the field of supply chain management that requires multi-party collaboration and information sharing, as it can significantly enhance data security, transparency, and trust. | 4 | Enhance collaboration skills |

Blockchain technology can optimize inventory management and improve logistics efficiency through real-time data sharing and smart contracts. For example, we use blockchain in inventory management, which can monitor inventory levels in real-time, automatically replenish inventory, and reduce the risk of inventory shortages and excess. In addition, in terms of logistics, blockchain technology has helped us achieve real-time tracking of goods, reducing logistics delays. | 8 | Optimize inventory management |

Firstly, the immutability of blockchain ensures the authenticity and reliability of data. Secondly, the decentralized nature of blockchain enables all parties involved to access and verify data, increasing the transparency of the supply chain. For example, our supply chain partners can view the source and quality testing results of each batch of raw materials through the blockchain platform to ensure product quality and compliance. | 2 | Ensure product quality |

Yes, after implementing blockchain technology, our supply chain management has significantly improved in terms of transparency and traceability. Now, we can monitor every link in the supply chain in real time, from raw material procurement to product delivery, and all data can be traced. | 6 | Realize real-time supervision |

For example, when a supplier is unable to deliver on time, the blockchain platform will immediately issue an alarm to notify relevant departments to take emergency measures. | 2 | Ensuring transaction security |

Smart contracts can automatically execute preset inventory replenishment and logistics scheduling rules, reducing human intervention and errors. For example, when inventory levels drop to a critical point, smart contracts can automatically place orders with suppliers to ensure timely replenishment of inventory | 1 | Automatically generate orders |

At present, our company has launched pilot projects for blockchain technology in some key supply chain links, mainly focusing on raw material procurement and product traceability. By applying blockchain technology, we can ensure that the source and flow of each batch of raw materials and products are clear and traceable. | 12 | Improve transaction traceability |

Supply chain resilience refers to the ability of the supply chain to respond and recover in the face of unexpected events or disturbances. It includes the ability to respond quickly, restore normal operations, and prevent similar incidents in the future. In our company, the importance of supply chain resilience is reflected in ensuring production continuity, reducing risks, and improving customer satisfaction. | 1 | Increase customer stickiness |

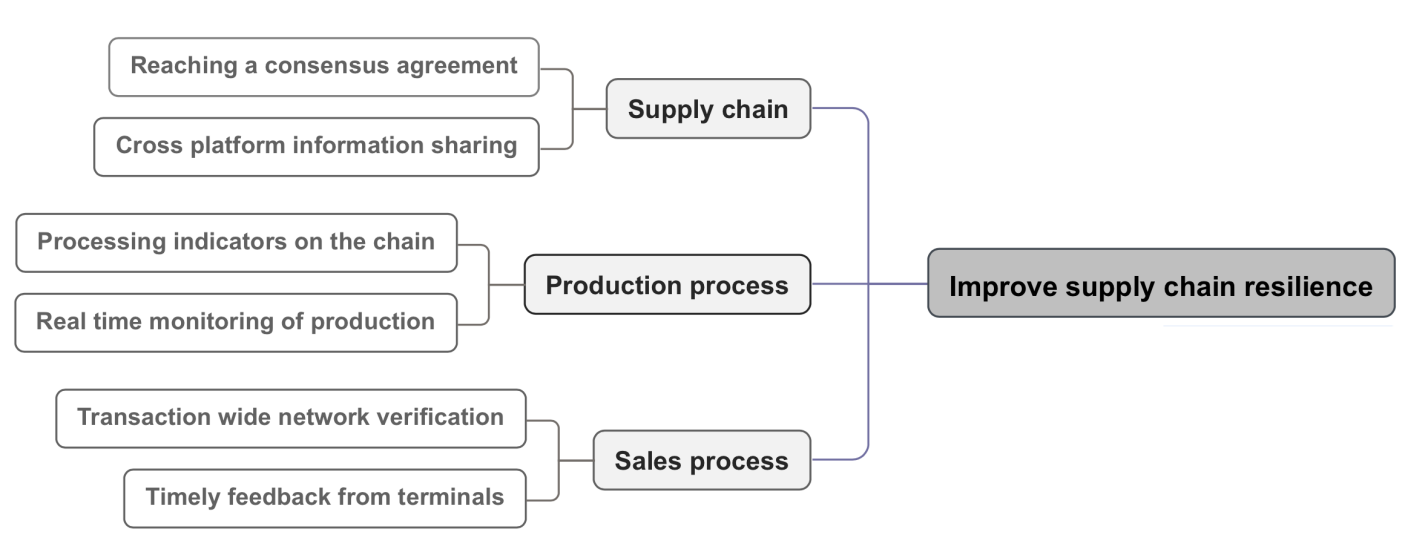

4.2. Spindle encoding

After sorting out the six initial categories, it was found that the corresponding supply chain links were related. Among them, reaching consensus agreements and cross-platform information sharing mostly affect the supply chain link; processing indicators on the chain and real-time production monitoring mostly affect the production link of the supply chain; and transaction network-wide verification and timely feedback from terminals mostly affect the sales link of the supply chain. There are also deep-level relationships between the initial categories. Therefore, this paper further summarizes the six initial categories that affect different supply chain links into three main categories when dealing with the initial categories, and finally obtains the main axis coding as shown in Table 2.

Table 2: Spindle Encoding

Initial category | Frequency | Conceptualization | Frequency |

Reaching a consensus agreement | 24 | Regular risk assessment | 6 |

Building a supply system | 4 | ||

Establishing trust mechanisms | 1 | ||

Design emergency plans | 7 | ||

Improve collaboration performance | 6 | ||

Cross platform information sharing | 30 | Ensure data security | 12 |

Information sharing mechanism | 5 | ||

Increase transaction transparency | 13 | ||

Processing indicators on the chain | 12 | Enhance collaboration skills | 4 |

Optimize inventory management | 8 | ||

Real time monitoring of production | 8 | Ensure product quality | 2 |

Realize real-time supervision | 6 | ||

Transaction wide network verification | 3 | Ensuring transaction security | 2 |

Automatically generate orders | 1 | ||

Timely feedback from terminals | 13 | Improve transaction traceability | 12 |

Increase customer stickiness | 1 |

4.3. Selective Encoding

In the selective coding stage, this research integrated the above themes to form three core categories for improving supply chain resilience: supply link, production link, and sales link. The results are shown in Table 3.

Table 3: Selective Encoding

Core categories | Initial category |

Supply chain | Reaching a consensus agreement |

Cross platform information sharing | |

Production process | Processing indicators on the chain |

Real time monitoring of production | |

Sales process | Transaction wide network verification |

Timely feedback from terminals |

The theoretical model structure obtained by the final analysis is shown in Figure 1.

Figure 1: A theoretical model of blockchain for improving supply chain resilience

5. Discussion

5.1. Interpretation of results

The results of the grounded theory coding analysis of this study show that through the application of blockchain technology, enterprises can improve the transparency, data security, emergency response capabilities, collaboration capabilities and efficiency of supply chain management, thereby improving the overall supply chain resilience. The following is an explanation of the main results:

(1) Data transparency and traceability: Blockchain technology ensures the transparency and traceability of supply chain data through its immutability and decentralization. Enterprises can monitor and manage every link in the supply chain in real time, improving the reliability and collaborative efficiency of the supply chain.

(2) Risk management and emergency response: Smart contracts can automatically execute emergency plans, ensuring that the supply chain responds quickly and resumes normal operations when emergencies occur, maintaining stability and continuity. Through regular risk assessment and emergency plan design, companies can better cope with uncertainties and emergencies in the supply chain.

(3) Inventory management and logistics efficiency: Blockchain technology optimizes inventory management through real-time data sharing and smart contracts, reduces the risk of inventory shortages and excesses, improves logistics efficiency, and ensures timely delivery of products. Through the application of blockchain technology, companies can achieve precise control of inventory levels and optimization of logistics scheduling.

(4) Supply chain collaboration and trust mechanism: The blockchain platform enables multi-party information sharing, which enhances the collaboration and trust of all parties in the supply chain. Regular training and seminars increase the understanding and trust of supply chain partners in blockchain technology, ensuring the stability and efficient operation of the supply chain.

5.2. Practical applications and theoretical contributions

The application of blockchain technology in the manufacturing supply chain not only improves the resilience of the supply chain, but also provides enterprises with more powerful data management and risk control capabilities. Our research supports the potential value of blockchain technology in supply chain management through qualitative analysis, and provides theoretical support and practical guidance for enterprises on how to effectively apply blockchain technology in actual operations.

5.3. Study limitations and recommendations

Although this study reveals many advantages of blockchain technology in improving supply chain resilience, there are still some limitations. First, the data in this study mainly come from specific industries and enterprises and may not be widely applicable. Second, blockchain technology still faces problems of technical integration and system compatibility in practical applications, which requires further research and exploration.

Future research can consider more types of industry and enterprise applications to further verify and expand our research results. At the same time, as blockchain technology develops and matures, studying its specific effects and challenges in different application scenarios will provide more comprehensive guidance and support for enterprise supply chain management.

6. Conclusion

This research aimed to identify the potential of blockchain technology to improve the resilience of manufacturing supply chains. Based on the qualitative analysis of supply chain performance after blockchain implementation, it can be concluded that blockchain technology helps manufacturing companies in data transparency and traceability, risk management and emergency response, inventory management and logistics efficiency, and supply chain collaboration capabilities, thereby improving the overall supply chain resilience of the company.

The results show that when blockchain is used to improve data transparency, inventory management and logistics efficiency, the supply chain is more resilient to disruptions and operational inefficiencies.

While the focus on interviews in the manufacturing sector limits the generalizability of the results, this approach provides new insights into the application of blockchain technology in supply chain management. Based on these conclusions, practitioners should consider the transformative opportunities that blockchain technology offers to enhance manufacturing supply chain resilience. By improving transparency, security, collaboration, and risk management, blockchain can help manufacturing companies better respond to disruptions and maintain operational continuity.

References

[1]. Ivanov, D., & Das, A. (2020). Coronavirus (COVID-19/SARS-CoV-2) and supply chain resilience: A research note. International Journal of Integrated Supply Management, 13(1), 90-102.

[2]. Christopher, M., & Peck, H. (2004). Building the resilient supply chain. International Journal of Logistics Management, 15(2), 1-14.

[3]. Ponis, S. T., & Koronis, E. (2012). Supply chain resilience: Definition of concept and its formative elements. Journal of Applied Business Research, 28(5), 921-930.

[4]. Yang, X. (2021). Research on strategies to enhance supply chain resilience through blockchain technology. New Economy, (12), 59-63. doi:CNKI:SUN:XJJB.0.2021-12-014

[5]. Christopher, M., & Peck, H. (2004). Building the resilient supply chain. The International Journal of Logistics Management, 15(2), 1-14.

[6]. Wang, H., Tan, J., & Wang, T. (2018). Research on the relationship between supply chain resilience and supply chain competitiveness: Based on the perspective of dynamic capability. Management Review, 30(11), 223-233. doi:10.14120/j.cnki.cn11-5057/f.2018.11.021.

[7]. Modgil, S., et al. (2021). Artificial intelligence for supply chain resilience: learning from Covid-19. The International Journal of Logistics Management, 33(4), 1246-1268.

[8]. Wang, W., et al. (2021). Impact of demand forecast information sharing on the decision of a green supply chain with government subsidy. Annals of Operations Research, 329(1-2), 953-978.

[9]. Vann Yaroson, E., et al. (2023). The role of power-based behaviours on pharmaceutical supply chain resilience. Supply Chain Management: An International Journal, 28(4), 738-759.

[10]. Zighan, S., et al. (2023). Knowledge management for supply chain resilience in pharmaceutical industry: evidence from the Middle East region. The International Journal of Logistics Management.

[11]. Tian, F. (2016). An agri-food supply chain traceability system for China based on RFID & blockchain technology. In 13th International Conference on Service Systems and Service Management (ICSSSM) (pp. 1-6). IEEE. doi:10.1109/ICSSSM.2016.7538424

[12]. Swan, M. (2015). Blockchain: Blueprint for a New Economy. O'Reilly Media, Inc.

[13]. Kouhizadeh, M., & Sarkis, J. (2018). Blockchain practices, potentials, and perspectives in greening supply chains. In 25th International Conference on Production Research Manufacturing Innovation: Cyber Physical Manufacturing (pp. 1-8). doi:10.3390/proceedings2131051

[14]. Saberi, S., Kouhizadeh, M., Sarkis, J., & Shen, L. (2019). Blockchain technology and its relationships to sustainable supply chain management. In International Conference on Production Research (pp. 1-10). doi:10.1016/j.ijpe.2018.12.002

[15]. Chen, X., & Zhou, Y. (2022). Qualitative research on the knowledge sharing model among open-source software project members based on grounded theory. Journal of Management, 19(6), 901-909.

Cite this article

Zhou,Y. (2024). Blockchain Technology Improves the Resilience of Manufacturing Supply Chain — An Exploration Based on Grounded Theory. Advances in Economics, Management and Political Sciences,128,91-102.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 3rd International Conference on Financial Technology and Business Analysis

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Ivanov, D., & Das, A. (2020). Coronavirus (COVID-19/SARS-CoV-2) and supply chain resilience: A research note. International Journal of Integrated Supply Management, 13(1), 90-102.

[2]. Christopher, M., & Peck, H. (2004). Building the resilient supply chain. International Journal of Logistics Management, 15(2), 1-14.

[3]. Ponis, S. T., & Koronis, E. (2012). Supply chain resilience: Definition of concept and its formative elements. Journal of Applied Business Research, 28(5), 921-930.

[4]. Yang, X. (2021). Research on strategies to enhance supply chain resilience through blockchain technology. New Economy, (12), 59-63. doi:CNKI:SUN:XJJB.0.2021-12-014

[5]. Christopher, M., & Peck, H. (2004). Building the resilient supply chain. The International Journal of Logistics Management, 15(2), 1-14.

[6]. Wang, H., Tan, J., & Wang, T. (2018). Research on the relationship between supply chain resilience and supply chain competitiveness: Based on the perspective of dynamic capability. Management Review, 30(11), 223-233. doi:10.14120/j.cnki.cn11-5057/f.2018.11.021.

[7]. Modgil, S., et al. (2021). Artificial intelligence for supply chain resilience: learning from Covid-19. The International Journal of Logistics Management, 33(4), 1246-1268.

[8]. Wang, W., et al. (2021). Impact of demand forecast information sharing on the decision of a green supply chain with government subsidy. Annals of Operations Research, 329(1-2), 953-978.

[9]. Vann Yaroson, E., et al. (2023). The role of power-based behaviours on pharmaceutical supply chain resilience. Supply Chain Management: An International Journal, 28(4), 738-759.

[10]. Zighan, S., et al. (2023). Knowledge management for supply chain resilience in pharmaceutical industry: evidence from the Middle East region. The International Journal of Logistics Management.

[11]. Tian, F. (2016). An agri-food supply chain traceability system for China based on RFID & blockchain technology. In 13th International Conference on Service Systems and Service Management (ICSSSM) (pp. 1-6). IEEE. doi:10.1109/ICSSSM.2016.7538424

[12]. Swan, M. (2015). Blockchain: Blueprint for a New Economy. O'Reilly Media, Inc.

[13]. Kouhizadeh, M., & Sarkis, J. (2018). Blockchain practices, potentials, and perspectives in greening supply chains. In 25th International Conference on Production Research Manufacturing Innovation: Cyber Physical Manufacturing (pp. 1-8). doi:10.3390/proceedings2131051

[14]. Saberi, S., Kouhizadeh, M., Sarkis, J., & Shen, L. (2019). Blockchain technology and its relationships to sustainable supply chain management. In International Conference on Production Research (pp. 1-10). doi:10.1016/j.ijpe.2018.12.002

[15]. Chen, X., & Zhou, Y. (2022). Qualitative research on the knowledge sharing model among open-source software project members based on grounded theory. Journal of Management, 19(6), 901-909.