1.Introduction

One of the first companies in the specialized wax sector, Heilongjiang Z Company, is a bright example of supply chain management innovation. Initially established as a modest family workshop in 2000, it has evolved into a state-of-the-art manufacturing hub. Z Company, which specializes in creating specialized waxes for use in food packaging, cosmetics, and industrial applications, has established a significant market share in China, especially in the Northeast region. Z Company has amassed a sizable clientele because to its commitment to providing high-quality, timely service. It is well-known for its agility and deep understanding of regional demands.But like any successful business, it had enormous supply chain management difficulties, including inconsistent raw material sources, slow production rates, poor quality control, and slow market reaction. Z Company implemented Six Sigma, a data-centric methodology intended to improve business processes and reduce defects, in order to overcome these obstacles. The company's journey toward Six Sigma began with a comprehensive audit of its manufacturing processes, along with the establishment of important quality objectives and performance benchmarks to identify areas in need of development. Z Company greatly increased the efficiency of its supply chain by strengthening its relationships with suppliers, increasing turnover through the modernization of inventory systems, and using lean manufacturing methods. The implementation of the Six Sigma project has produced impressive outcomes, including reduced lead times for raw material deliveries, reduced production downtime, and increased customer order fulfillment rates. This case study demonstrates how Six Sigma strengthened Z Company's market flexibility and overall competitiveness in addition to improving the quality and productivity of the company's specialized wax products. The Six Sigma initiative at Z Company has demonstrated its effectiveness in the specialty wax industry by lowering costs and increasing operational efficiency. Its path offers a guide for other industry participants who want to adopt data-driven tactics to attain operational excellence. In the realm of modern business, the Six Sigma management approach has an unshakeable reputation due to its exceptional abilities in process optimization and quality improvement. Since Motorola first launched Six Sigma in 1986, it has developed into a vital strategic initiative for companies all around the world striving for operational excellence. Six Sigma's focus on reducing defects in products and services has increased customer satisfaction and significantly decreased operational costs for businesses. At present, six Sigma management method has evolved into a process and product quality improvement method based on statistical technology, and into the concept of fine management. Six sigma the basic connotation of management is to improve customer satisfaction and reduce the cost of resources, emphasize from the perspective of the whole organization management, not just emphasize the quality of a single product service or process, emphasize the organization to stand on the customer position consider quality problems, using scientific methods, in the field of all the pursuit of "no defects" quality, in order to greatly reduce the cost, improve competitiveness. That is to say, the current six Sigma is not only a data on the product situation or production process, but also a management system to achieve the best state to improve the organizational performance, which is a goal to achieve nearly complete continuously[1].Over time, this method has evolved into a set of managerial strategies and scientific tools, In addition to technical and technological support, a successful Six Sigma deployment includes adjustments to company culture and organizational structure to ensure that innovation and continuous improvement become the enterprise's guiding principles.

2.Theoretical basis

A case study entails the detailed and intensive analysis of a single case—a single organization, a single location or a single event[2].The specialty wax market is expanding quickly, which is consistent with the growing size of the worldwide market, which is expected to reach $2.703 billion in 2022 and Asia emerging as a key participant. Notwithstanding this positive trend, the industry's supply chain faces substantial obstacles. These include the unpredictable nature of the supply of raw materials, the manufacturing efficiency gap, the strict quality control standards, and the pressing need to respond quickly to the market. These difficulties are made much more difficult by the fluctuating prices of raw materials and the possibility of supply chain interruptions, which are made worse by stricter environmental laws that raise operating expenses and add layers of complexity. Under these conditions, the Six Sigma technique shows itself as a strong approach for the sector, providing a solution to improve quality and process optimization. Using Heilongjiang Z Company as an example, its supply chain management procedures show how Six Sigma is used in the specialized wax industry. The company's development from a modest family firm at the beginning in 2000 to a contemporary manufacturing organization reflects the drive for efficiency and sophistication in the sector as a whole. The success of Heilongjiang Z Company may be ascribed to its strategic concentration on the domestic market, with a specific focus on building a strong clientele in the northeastern area. Six Sigma's client-centric attitude and agility are demonstrated by its market positioning strategy, which is based on tailored solutions and prompt customer reaction. To study variability, Six Sigma utilizes a problem-solving methodology to define, measure, analyze, improve and control processes and implement cost-effective solutions leading to significant financial savings[3].The DMAIC framework—Define, Measure, Analyze, Improve, and Control—provides a methodical way to find and remove waste and faults in processes, and it is the cornerstone of the Six Sigma implementation. This methodical approach not only improves the caliber of goods and services but also increases customer pleasure, lowers expenses, and simplifies processes. Companies may monitor existing performance levels, analyze data to find areas for improvement, and apply solutions that increase process efficiency by carefully outlining project goals and client demands. The last control stage makes sure that these gains are maintained, which fosters a continuous improvement culture that is essential to the Six Sigma philosophy. But there are several obstacles in the way of implementing Six Sigma. It necessitates a large initial investment in new technology and tools for data collecting and analysis, as well as a major commitment to staff involvement and training. Another obstacle is the reluctance of firms to modify their cultural norms, as Six Sigma calls for a customer-centric and continuous improvement mentality. The long-term advantages of Six Sigma outweigh these challenges. Six Sigma is about overall business strategy, culture and change, and the small companies embarking on Six Sigma initiative need to build all of this into a sound corporate strategy plan[4]. Companies such as Heilongjiang Z Company should expect notable improvements in quality, cost-effectiveness, and customer happiness if they successfully overcome these obstacles. The strategic use of Six Sigma methods will be essential to negotiating the challenges of supply chain management and gaining a competitive edge in the global marketplace as the specialty wax sector grows.

Located in China's northeast, Heilongjiang Z Company has come a long way since its humble beginnings in 2000. From humble beginnings as a small family-run workshop, it has grown into an advanced manufacturer with state-of-the-art production equipment, meeting the needs of diverse industries such as food packaging, cosmetics, and industrial manufacturing. By utilizing its adaptability and in-depth market knowledge to cater to the specific requirements of its clientele, this local business has cemented its position in the specialized wax industry.

The company's main products are a range of specialized waxes that are made to satisfy the exacting specifications of certain industrial uses, such rubber protection wax and emulsified explosive wax. These goods' unique chemical makeup and performance traits serve as a monument to Z Company's dedication to excellence. Z Company has developed a strong clientele by concentrating entirely on the home market, especially in the Northeast's industrial core. The market strategy of the organization is based on offering customized solutions and promptly responding to the changing needs of its customers. Like many of its peers, Z Company has been relentlessly pursuing business excellence and has resorted to Six Sigma, a management approach that minimizes variability and faults in order to increase process efficiency. In respect to the Six Sigma implementation in service processes, the idea of using the tool in service processes such as transportation and distribution. He also indicated that reducing the lead time and providing faster delivery as two customer value goals are considered when selecting a Six Sigma project[5].This iterative procedure aims to consistently raise the bar for both product and service quality, exceeding clients' expectations in the process. The first step in the process is identifying the goals of a Six Sigma project, which entails a thorough analysis of client needs. The measurement phase then comes next, in which opportunities for improvement are identified by gathering and analyzing data to evaluate present performance. The next step of the analytical process is a detailed investigation to identify the underlying causes of problems, which leads to the creation of workable remedies. These solutions are put into practice during the improvement phase, and their long-term maintenance is ensured during the final control phase. Every everybody in the company, from the executive suite to the shop floor, must be committed to and involved in Six Sigma for it to become successfully embedded. The integration of Six Sigma ideas into daily operations is ensured by this comprehensive approach. In addition, a thorough training program is necessary to provide staff members with the abilities and information needed to implement Six Sigma projects. Six Sigma has shown to be a useful tool in supply chain management, helping businesses to improve the overall responsiveness and efficiency of the chain by streamlining cash flow, information movement, and logistics. It gives businesses the ability to manage inventory more skillfully, lowering expenses while lowering the dangers of overstock and stock outs. Furthermore, Six Sigma may help improve the procedures for choosing and assessing suppliers, which can result in higher-quality and more effective procurement. The real challenge of Six Sigma methodology is not in making improvements to the process but in providing as ustained improvement to the optimization[6]. The road to implementing Six Sigma is not without its challenges, though. Organizational culture-based reluctance to change, the difficulties of promoting cross-departmental collaboration, and the complexity of data gathering and analysis are issues that businesses frequently face. A solid foundation of management practices, a strong commitment to a culture of continuous improvement, and a well-defined project execution plan are necessary to overcome these obstacles. To sum up, Six Sigma offers companies a thorough foundation for continuous process improvement and quality development. Businesses like Z Company may increase customer satisfaction and strengthen their competitive edge by pursuing improvement efforts that not only satisfy but also excite their consumers with unwavering adherence to the DMAIC cycle. The long-term benefits of Six Sigma are evident, even though the path may be difficult at first. It provides a viable route to greatness in a cutthroat industry.

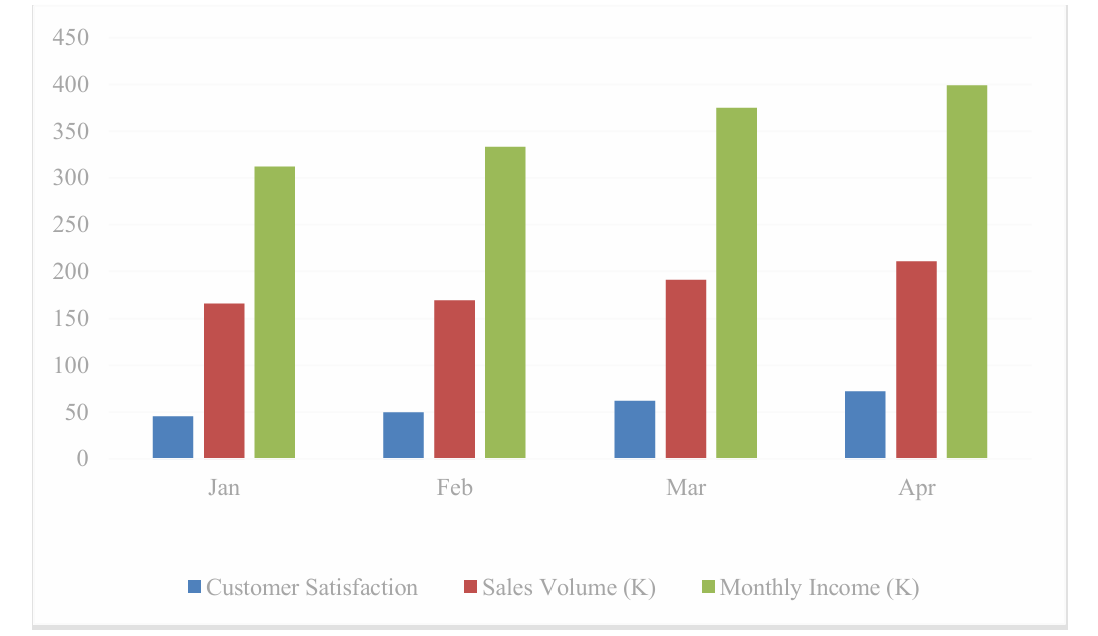

Figure 1: Hei Longjiang Z Company's data changes in the four months following the implementation of Six Sigma management.

independent variables andfactors were collected using survey data, and improvement actions determined on thebasis of the analysis of these data[7].There has been a discernible and encouraging trend in the data since Heilongjiang Z Company implemented Six Sigma management. Figure 1 displays a steady increase in customer satisfaction and most likely has a column for each of the months January through April. A line graph that begins at a lower value in January and grows slowly through April may be used to illustrate this.

2.1.Customer Satisfaction

Several Six Sigma initiatives may be credited for the increasing trend in customer satisfaction. For example, the business may have used voice of the customer (VOC) analysis to pinpoint major pain spots in the customer experience and then focused on improving these areas. This might be anything from shortening wait times to raising the caliber of products and services after the sale. Customers are therefore more satisfied with every engagement, which raises customer satisfaction scores.

2.2.Sales Volume

Sales volume has been greatly but indirectly affected by the rise in customer satisfaction. Customers are more likely to continue doing business with Z Company and to make larger purchases as they grow more happy. The sales volume data, which indicates a month-over-month increase, reflects this. It's possible that the Six Sigma initiatives also concentrated on enhancing the general effectiveness of the sales channels, cutting down on errors in the order fulfillment process, and optimizing the sales process.

2.3.Monthly Income

It seems sense to observe a growth in monthly income in tandem with the increase in sales volume. The combination of increased sales and enhanced pricing power that comes with a greater brand recognition has helped the company's revenue. It's possible that the Six Sigma initiatives also focused on waste minimization and cost reduction, which would have improved profitability and the bottom line.

2.4.The Cycle of Improvement

Continuous improvement is now a cycle at Z Company thanks to the Six Sigma management approach. Loyalty grows along with consumer pleasure, encouraging repeat business and favorable word-of-mouth recommendations. As a result, the company's monthly revenue and sales volume increase, freeing up more funds for quality improvement projects. The cycle is then continued by this investment, increasing consumer pleasure even further. Heilongjiang Z Company's Six Sigma management implementation has demonstrated a definite upward trend throughout the first four months. The corporation started improving the quality of its products and services in January by launching projects based on client input. By February, this had resulted in a little increase in customer satisfaction and a small increase in sales volume. A more evident effect was observed when the Six Sigma efforts were improved throughout March. Sales volume increased dramatically and customer satisfaction increased even more, leading to the first apparent increase in monthly income. The effective adoption of Six Sigma principles was demonstrated by the cumulative impacts of the practice, which became completely evident by April. Sales volume and monthly revenue both saw significant increases, while customer satisfaction peaked for the time.

3.Benefits and challenges of the Six Sigma approach

Unquestionably, Six Sigma offers several benefits, including improved customer satisfaction, financial savings, streamlined corporate processes, and higher-quality goods and services. Adopting Six Sigma gives businesses a competitive edge in a highly competitive market by helping them understand customers' wants more precisely, reduce waste, and boost efficiency. First off, Six Sigma greatly raises the caliber of goods and services. By using the DMAIC method (Define, Measure, Analyze, Improve, and Control), businesses may find and remove the main reasons behind defects, which lowers mistakes and variability and results in more dependable and consistent goods. Businesses may outperform their rivals in terms of goods and services, drawing in more clients and taking up more market share, by always improving and pursuing excellence. But there are difficulties with putting Six Sigma into practice as well[8].This improvement in quality immediately increases client happiness and trust, which helps build brand loyalty.

Second, Six Sigma optimizes operations to cut waste and expenses. Through Six Sigma efforts, businesses may find and remove non-value-adding operations, streamline processes, and cut down on pointless procedures and delays. This reduces production costs and speeds up a product's time to market, allowing companies to react to changes in the market faster. Establish a multi-level incentive system, formulate and implement a personalized incentive plan. State-owned enterprises can understand, through big data analysis and other methods, their employees' personal characteristics, work performance and career development needs, and formulate different levels of incentive measures and personalized incentive plans[9].

Additionally, Six Sigma increases a business's ability to compete in the market. First of all, it necessitates a high degree of training and staff involvement. Employees must implement Six Sigma's tools and ideas in their everyday work in addition to understanding them. Training staff members is necessary, especially for those assuming the responsibilities of Six Sigma Black and Green Belts, and this takes time and money. Second, there may be a significant upfront cost associated with Six Sigma. Companies may need to spend money on new tools and technology in addition to training expenses in order to facilitate data collecting and analysis. An additional difficulty is cultural reluctance to change. Companies using Six Sigma must change their basic beliefs to emphasize customer satisfaction and continual improvement. Employee resistance may arise when long-standing work routines and culture are changed. Finally, strong organizational commitment and leadership support are necessary for the effective implementation of Six Sigma. Six Sigma projects may find it difficult to get started and remain ongoing without the top management's unambiguous support and resource allocation. Notwithstanding these difficulties, Six Sigma offers organizations an effective instrument for achieving operational excellence and continuous improvement. In terms of quality, cost, and customer happiness, businesses should anticipate major long-term gains from effectively implementing Six Sigma after overcoming these obstacles. In conclusion, it is clear from this report's exploration of the challenges and application of Six Sigma in the specialty wax industry—which uses Heilongjiang Z Company as a case study—that Six Sigma, as a management philosophy aimed at near perfection, has improved not only the quality of goods and services but also the efficiency of business operations, cut expenses, and raised customer satisfaction by implementing the DMAIC framework. Heilongjiang Z Company has achieved continual process improvement and a notable improvement in quality by effectively addressing difficulties including inconsistent raw material supply, low production efficiency, and sluggish market reaction. But putting Six Sigma into practice is not without its difficulties. It encounters opposition to cultural change, necessitates a large initial investment in new tools and technology, and involves intensive staff involvement and training. Furthermore, Six Sigma efforts could find it difficult to get traction and sustain themselves without explicit top-level management endorsement and resource commitment. However, Six Sigma gives companies an effective instrument for attaining operational excellence and continuous improvement. Companies that successfully navigate these obstacles and use Six Sigma should expect significant long-term gains in cost, quality, and customer satisfaction. As a key component of enterprise operation, the efficiency and transparency of supply chain management are particularly important to enterprise success. With the continuous progress of information technology, the supply chain management field has experienced a profound digital revolution [10].In the end, this study finds that the Six Sigma approach may significantly increase supply chain management effectiveness in the specialty wax market and offers recommendations for improvement tactics for other businesses operating in the same industry.

4.Conclusion

This study report examines the problems and use of Six Sigma methodologies in the specialty wax industry. Heilongjiang Z Company is used as an example to examine how this management strategy can assist businesses in improving supply chain quality management. In addition to increasing the quality of goods and services through the use of the DMAIC framework, Six Sigma, as a nearly perfect management philosophy, also optimizes the business's operational processes, lowers costs, and boosts customer happiness. Heilongjiang Z Company has effectively addressed issues related to uneven raw material supply, inefficient production, and sluggish market reaction by implementing the Six Sigma methodology. This has resulted in ongoing process enhancement and notable quality improvement.But putting Six Sigma into practice is not without its difficulties. It confronts opposition to cultural change, necessitates a significant initial investment in new tools and technology, and demands a high level of staff participation and training. Furthermore, it might be challenging to launch and maintain Six Sigma programs without explicit top-level support and resource commitment. However, Six Sigma gives companies an effective instrument for achieving operational excellence and continuous improvement. In terms of quality, cost, and customer happiness, firms should anticipate substantial long-term gains from effectively implementing Six Sigma after overcoming these obstacles. In the conclusion, the study finds that the Six Sigma methodology may successfully raise supply chain management effectiveness in the specialized wax sector and offers suggestions for improvement tactics to other businesses operating in the same sector.

References

[1]. Li Ruohan & Zhou Hongwen. (2024). The Application of Six Sigma Theory in the Quality Management of Pile Foundation Construction. tile(06),103-105.doi:10.16001/j.cnki.1001-6945.2024.06.021.

[2]. E. V. Gijo,Johny Scaria & Jiju Antony.(2011).Application of six sigma methodology to reduce defects of a grinding process.Quality and Reliability Engineering International(8),1221-1234.

[3]. Murmura Federica,Bravi Laura,Musso Fabio & Mosciszko Aleksandra.(2021).Lean Six Sigma for the improvement of company processes: the Schnell S.p.A. case study.The TQM Journal(7),351-376.

[4]. Jiju Antony.(2008).Can Six Sigma be effectively implemented in SMEs?.International Journal of Productivity and Performance Management(5),420-423.

[5]. Nabhani, Farhad & Shokri, Alireza.(2009).Reducing the delivery lead time in a food distribution SME through the implementation of six sigma methodology.Journal of Manufacturing Technology Management(7),957-974.

[6]. LI Li.(2016).Implementing Six Sigma Techniques in Accounting Information Quality Management for China's Securities Companies.(eds.)Proceedings of the 1st International Seminar on Education, Innovation and Economic Management (SEIEM 2016)(pp.103-108).School of Business Beijing Language and Culture University;

[7]. Alessandro Laureani & Jiju Antony.(2010).Reducing employees' turnover in transactional services: a Lean Six Sigma case study.International Journal of Productivity and Performance Management(7),688-700.

[8]. XIAO Geng & ZHANG Yansheng.(2015).China's Evolving Growth Model: The Foshan Story.(eds.)Beijing Forum (2015) Civilized Harmony and Common Prosperity — Different paths and common responsibilities: Collection of special papers and abstracts on International Economic Cooperation and Development and Belt and Road Initiative under the New Normal(pp.495-761).The University of Hong Kong LAW Cheung-kwok & Dominic MEAGHER;

[9]. Zeng Shaojiao. (2024). Exploration on the current situation and path of performance management of state-owned enterprises in the digital era. Investment and entrepreneurship(17),113-115.

[10]. Yu Zhongfa. (2024). Academic history combing and research trends of supply chain digitalization from a global perspective. supply chain management(09),58-70.doi:10.19868/j.cnki.gylgl.2024.09.005. 2

Cite this article

Zong,Z. (2024). Application and Challenges of Six Sigma in SCM: A Case Study of Heilongjiang Z Company. Advances in Economics, Management and Political Sciences,141,170-176.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of ICFTBA 2024 Workshop: Finance's Role in the Just Transition

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Li Ruohan & Zhou Hongwen. (2024). The Application of Six Sigma Theory in the Quality Management of Pile Foundation Construction. tile(06),103-105.doi:10.16001/j.cnki.1001-6945.2024.06.021.

[2]. E. V. Gijo,Johny Scaria & Jiju Antony.(2011).Application of six sigma methodology to reduce defects of a grinding process.Quality and Reliability Engineering International(8),1221-1234.

[3]. Murmura Federica,Bravi Laura,Musso Fabio & Mosciszko Aleksandra.(2021).Lean Six Sigma for the improvement of company processes: the Schnell S.p.A. case study.The TQM Journal(7),351-376.

[4]. Jiju Antony.(2008).Can Six Sigma be effectively implemented in SMEs?.International Journal of Productivity and Performance Management(5),420-423.

[5]. Nabhani, Farhad & Shokri, Alireza.(2009).Reducing the delivery lead time in a food distribution SME through the implementation of six sigma methodology.Journal of Manufacturing Technology Management(7),957-974.

[6]. LI Li.(2016).Implementing Six Sigma Techniques in Accounting Information Quality Management for China's Securities Companies.(eds.)Proceedings of the 1st International Seminar on Education, Innovation and Economic Management (SEIEM 2016)(pp.103-108).School of Business Beijing Language and Culture University;

[7]. Alessandro Laureani & Jiju Antony.(2010).Reducing employees' turnover in transactional services: a Lean Six Sigma case study.International Journal of Productivity and Performance Management(7),688-700.

[8]. XIAO Geng & ZHANG Yansheng.(2015).China's Evolving Growth Model: The Foshan Story.(eds.)Beijing Forum (2015) Civilized Harmony and Common Prosperity — Different paths and common responsibilities: Collection of special papers and abstracts on International Economic Cooperation and Development and Belt and Road Initiative under the New Normal(pp.495-761).The University of Hong Kong LAW Cheung-kwok & Dominic MEAGHER;

[9]. Zeng Shaojiao. (2024). Exploration on the current situation and path of performance management of state-owned enterprises in the digital era. Investment and entrepreneurship(17),113-115.

[10]. Yu Zhongfa. (2024). Academic history combing and research trends of supply chain digitalization from a global perspective. supply chain management(09),58-70.doi:10.19868/j.cnki.gylgl.2024.09.005. 2