1. Introdution

Cold chain logistics, as an emerging industry, is an essential part of the national economic system and has thrived under the high regard of the government and concerned industrial organizations. Global trade has led to a rise in the sophistication of the transnational transportation system. Therefore, there is a greater need to organize refrigerated as well as frozen products, particularly in the field of food and pharmaceuticals. The analysis of food cold chain transportation is the main topic of this essay. By 2050, the world's population is expected to have increased by roughly 2.3 billion people, which would result in a dramatic rise in food requirement according to the Food and Agriculture Organization of the United Nations [1]. Cold chain logistics has become a vital and necessary component in order to meet this expanding need and guarantee the quality and safety of food and agricultural products throughout the manufacturing, transportation, storage, and distribution processes. As consumers pay more and more attention to food quality and food safety issues, and as external tourists continue to explore the specialty foods of destinations, the needs of regional fresh farm goods and local specialties for cold chain logistics are also rapidly on the rise. There has been a growing interest in CCL as it can successfully decrease the likelihood of food spoilage and decay, ensuring consumers receive safe and fresh goods. Therefore, the challenge of maintaining the high quality and freshness of foods during long-distance transportation has become a central element of the supply chain for the delivery in cold products. By combining domestic and international cases of food cold chain transportation, this paper compares and analyzes the routing and freshness preservation technologies of different geographic regions in cross-region cold chain logistics, aiming to explore the optimizable links. A variety of creative solutions to the present demands of the supply chain sector are also intended to be shown in this study. The objective is to improve the feasibility and universality of cold chain delivery of agricultural products and specialized foods.

2. Analysis of the current situation of cold chain logistics

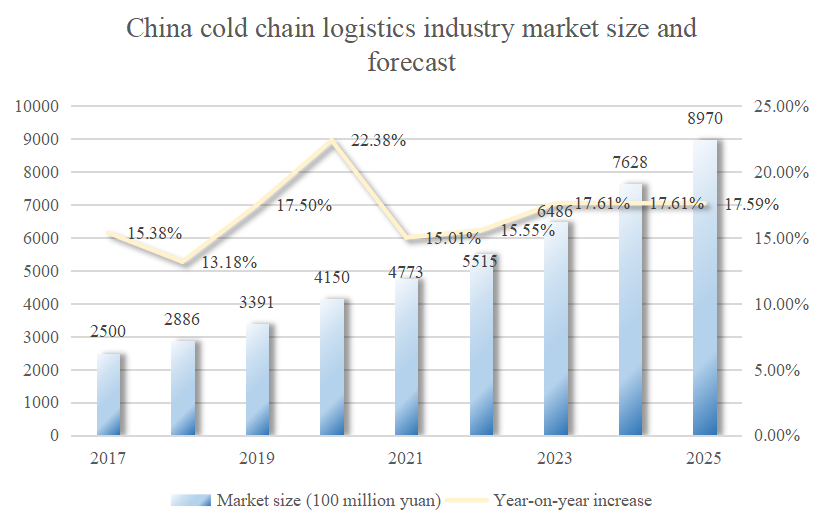

With the rapid development of the cold chain market and the continuous growth of China's economy, cold chain logistics in China is being upgraded across the board, and the level of technology and infrastructure is constantly being upgraded and improved. Some studies have shown that thousands of food products are shipped daily from manufacturing plants, and there is a close link between poor temperature control and high loss rates of product. Thermal temperature as an influence on the relationship between the rate of food loss and shelf life. Every food has a maximum temperature at which it should be stored; storing it over or under the limit will affect both mass and security. An too high temperature can encourage the growth of food germs, which can result in foodborne illnesses or food poisoning. When temperatures are critically low, fresh products may suffer from hypothermia, especially fresh perishable commodities, which need to be stocked at consistently low temperatures to prolong their life span [1]. According to data that is available to the public from the China Business Industry Research Institute (CBIRI) and the Cold Chain Committee of the CFLP, the market size of China's cold chain logistics industry reached RMB 339.1 billion at the end of 2019, representing a growth rate of 17.50% year over year. The cold chain logistics industry in China is expanding quickly and has a lot of room to grow. It is projected that by 2025, the size of China's cold chain logistics market might surpass RMB 897 billion due to this continuous growth pattern [2] (Figure below).

Figure 1: The worldwide market and prediction for the cold chain logistics sector in China

3. Problems in the development process

As the markets for fresh agricultural products and specialty foods in different regions continue to develop, there is an increasing requirement for external cold chain transportation of organic food product. The needs in CCL in China for fresh agricultural products is particularly huge. However, due to the decentralized nature of farming output and the comparatively tiny scale of enterprises, cold chain logistics in China for raw agri-food products at the provincial stage faces a number of obstacles. Among them, the lack of uniform industry standards, high operating costs, differences in technological capabilities, and insufficient cold chain infrastructure are major challenges. These difficulties directly affect the long-term development and market-oriented operation of fresh produce cold chain logistics [3]. In addition, the problem of insufficient transportation timeliness is particularly prominent, resulting in difficulties in guaranteeing food freshness, which is closely related to the shortest path principle followed in cold chain transportation. Given that third-party cold chain logistics companies are developing slowly, cold chain logistics for agricultural products and specialized foods is not as marketable. This limits the potential for integrated services that include distribution, warehousing, and transportation. The quality and prompt delivery of fresh agricultural products while in transit, as well as the information synergy between the supply chain's upstream and downstream sectors, are all adversely affected by this circumstance [4]. Therefore, for these core problems and challenges in cold chain logistics, this thesis will deeply analyze the causes and propose corresponding optimization strategies to promote the efficient development of cold chain logistics industry.

4. Analysis of problems that arise in cold chain logistics transportation in some regions

4.1. Analysis of Cold Chain Transportation Issues

Transportation in the cold chain is a highly facility-dependent industry that includes activities such as frozen food manufacturing, stocking, and distributing, and plays a vital part in maintaining the quality of perishable goods, especially in the food industry [5]. Due to the temperature and time sensitivity of many types of food products, this industry not only requires a large capital investment to build the infrastructure in the early stages, but also a large amount of resources to maintain and manage the technology in the later stages. However, this has resulted in the centralization of cold supply chain infrastructure in coastal areas and developed first-tier cities [1]. In contrast, the middle and western regions are facing the dilemma of lack of critical supply of cold chain resources, even though they are responsible for most of the national wholesale trade of organic farm products [6]. Meanwhile, many mountainous areas produce a variety of specialty farm products all year round, relying on their unique geological environment and natural resources. These agricultural products not only meet the dietary needs of mountain residents, but also gradually become an important local economic industry. However, due to the remote location of these mountainous areas, the transportation is not fluent, and it is difficult to cover the cold chain logistics, which leads to the restriction of the sales channels of the special agricultural products, thus restricting the development of the special food economy in mountainous areas to a large extent. How to overcome this barriers by optimizing the cold chain logistics system has become a key issue to promote the economic growth of these regions. The increasing focus of experts in this field on improving the cold chain logistics for fresh agricultural products has resulted in the identification of three main research directions: (i) improving the cold chain logistics' efficiency, encompassing elements like the cooling speed, consistency and equilibrium, and wrapping style; (ii) guaranteeing the cold chain's integrity by means of precise control measures like continuous surveillance and the lifespan forecast; and (iii) promoting ecological and sustainable development within the cold chain by minimizing consumption of energy, costs, and adverse effects on the environment[7].

In view of present situation of cold chain logistics in China, especially deficiency in mountainous and remote areas, we can utilize e-commerce platform to strengthen brand building so as to enhance market recognition and attached worth of an item. Meanwhile, improving the capability of cold storage trucks is also a crucial point to ensure transport. First of all, the refrigerated truck not only needs to adopt a high-powered engine to cope with the complex terrain and climatic conditions in mountainous areas, but also should connect the temperature control system of the truck container with mobile devices or Apps to achieve real-time temperature monitoring and remote adjustment. During the transportation of farm produce, temperature control is a core factor that affects the shelflife of the product. For this reason, we propose in this paper to construct a time-window based delivery path model for frigid chain distribution to cope with the dual challenges of transportation timeliness and temperature control [8]. By using an improved genetic algorithm for model solving, the temperature and routes are flexibly adjusted according to the specific needs of different agricultural products, thus shortens turnaround, ensureng the food quality is pure and fresh as it can be. At a Technology Application Level (TAL), Boxmart Fresh Life uses information technology such as RFID radio frequency identification, GIS geographic information system and back-temperature sensors in the transportation process. The combination of these technologies allows real-time tracking of cargo location, temperature changes, and cargo status, thus dramatically improving the visibility and accuracy of cold chain transportation. On this basis, we will further explore how to realize a better and more comprehensive cold chain logistics system through the integration of these information technologies.

Concurrently, the future of cold chain logistics will be defined by an improved overall service level propelled by these innovations, given the current market's breakthroughs in Internet of Things, Cloud Computing, and Big Data technologies. For example, analysis based on big data can predict the best transportation time and path to optimize the distribution efficiency; cloud computing platform can centralize the management of many types of data during the cold chain process to achieve rapid response. This also provides the main research direction and innovation path for the transformation of cold chain logistics in China to digitalization and technology, and promotes the industry to take a new step forward in preserving agricultural products' quality, improving delivery efficiency and reducing operating costs.

4.2. Analysis on the problem of specialty food

The core of specialty food lies in its unique regionality and flavor, which is an important reason why it is sought after by tourists and consumers. However, some specialty foods have been refined in taste when they are sold across regions, resulting in the loss of their original features. Taking the malatang of Tianshui, Gansu as an example, for those who have left their hometowns in Gansu, they often say that it is difficult to find the same flavor as that of their hometowns in foreign places. To make authentic Tianshui malatang, there are two essential key ingredients: potato flour and chili pepper from the local. However, many outside traders choose to use domestic chili peppers and other alternative ingredients in order to satisfy local market demand or for cost considerations, which ultimately changes the original flavor and characteristics. This kind of phenomenon reflects that in the process of cross-regional dissemination of specialty foods, how to balance the regionality and market adaptability of the products has become an important challenge.

To solve the problem of specialty foods losing their original flavor in cross-regional transportation, local governments can consider establishing regional production bases, centrally integrating the unique recipes used by local merchants, and forming standardized production lines. After production is completed, cold chain transportation technology is used to lock in freshness and ensure that specialty foods are quickly delivered to consumers across the country. In addition, in order to deal with the many products on the market that lack authentic flavor under the banner of “specialty food,” local residents can be invited to participate in food tastings and use this as a way to promote local “orthodox” flavor products. At the same time, with the local well-known e-commerce anchor cooperation, through the form of live with goods to enhance brand awareness and market influence.

4.3. Analysis of food quality problems

At present, in the course of cold chain express of grains, vegetables, fruits and other crops, although the transportation tools and paths have been enhanced, the phenomenon of normal-temperature transportation and “chain breakage” is still common throughout the transfer from the point of origin to the point of sale, resulting in a significant loss of fresh agricultural products. This is because, throughout the supply chain, physical, chemical, and biological elements frequently affect fresh food, which can reduce shelf life and result in product loss. Maintaining proper cold storage of food products in the supply chain is known to be key to preventing quality degradation and extending shelf life. Consequently, cold chain management is becoming more and more important, and one of the core tasks in ensuring food quality is the distribution program. In addition to the extra investment of temperature-controlled vehicles to ensure the transportation temperature, the strict control of temperature and time needs to be intensified [9].

To resolve this problem, in order to strive for policy support, in addition to strengthening communication with the higher agricultural departments and financial departments on a long-term basis, e.g., CIMC takes the cold chain base as the core and relies on the county-level cold chain distribution centers, and lays out mobile cold storage and pre-cooling tanks in the fields of the production areas, so as to realize the whole cold chain transportation of fruits, vegetables, seafood and other products[10]. A TSP model and a cold chain logistics path optimization model with a low-carbon concept can also be applied and MATLAB can be used for solving the problem in order to find out the most suitable locations for establishing warehouses nationwide, so as to achieve the optimization of the layout of the transfer station with the shortest path, the lowest cost as well as the least amount of time from the place of production to the consumer, and to maximize the use of the existing infrastructure to achieve the high efficiency of the end distribution. In the transit station, this study combines the case of Boxmart Fresh Life's DC temperature-controlled processing and testing center, and suggests adding a food quality testing link in the warehouse, so that the food products transported over can be uniformly inspected in terms of packaging, temperature, and quality, in order to ensure the safety and quality of the food products.

5. Conclusion

The current state of China's cold chain transportation system is far from ideal, making it difficult to completely guarantee food quality when moving specialty foods and agricultural products between regions. In this particular setting, the challenges related to cold chain logistics remain substantial. In order to counteract this problem and meet the growing demand in the field of transportation of specialty foods and agricultural products, it is recommended that production places strengthen regional branding with the help of Internet e-commerce platforms, and upgrade and optimize transportation means. At the same time, local governments can take the lead in setting up regional factories, gather recipes from local merchants, carry out standardized assembly line production, and ensure the flavor and quality of products through unified production processes and efficient cold chain transportation. In addition, it is recommended to take the cold chain base as the core and the county-level cold chain distribution center as the support, and lay out the mobile refrigeration equipment in the production area to realize the whole cold chain collection and transportation of the products, so as to guarantee the preservation of freshness in the transportation process. At the same time, the transportation model and solution method applicable to the transportation process are applied to enhance the efficiency. Furthermore, this system can be improved for use in the food industry as well; it offers useful information and references for cold chain transportation of pharmaceuticals. Since pharmaceuticals are highly susceptible to temperature changes, the food cold chain logistics industry's successful tactics can be applied to improve pharmaceutical cold chain transportation.

Nonetheless, cold chain transportation is currently still limited by technological applications and government policies, and some of the options may encounter difficulties in practical application. Future research should expand the scope of the data sample to cover cold chain transportation issues in more regions, promote technological innovation, and ensure that costs remain manageable while technology is upgraded. This study expects that through these measures, a smarter and intensive cold chain delivery model can be achieved in the future, so that local specialty foods and agricultural products can be delivered to consumers in a way that is more efficient and orderly while maintaining their original flavors and food safety. Building on this success, public health programs can benefit greatly from the additional integration and improvement of cold chain transportation networks for both food and pharmaceuticals. Through continuous enhancement of cold chain logistics' effectiveness and dependability, we can better satisfy consumer expectations and eventually ensure a safe and healthy supply of food and medications.

Authors Contribution

All the authors contributed equally and their names were listed in alphabetical order.

References

[1]. Li, M., Xie, B., Li, Y., Cao, P., Leng, G., & Li, C. (2024). Emerging phase change cold storage technology for fresh products cold chain logistics. Journal of Energy Storage, 88, 111531. https://doi.org/10.1016/j.est.2024.111531

[2]. Anon. (2021). The Current Situation, Challenges, and Policy Suggestions for the Development of Cold Chain Logistics in China. Baidu. https://baijiahao.baidu.com/s?id=1702258102154155683&wfr=spider&for=pc

[3]. Fan, X., Zhang, Y., Xue, J., & Cao, Y. (2024). Exploring the path to the sustainable development of cold chain logistics for fresh agricultural products in China. Environmental Impact Assessment Review, 108, Article 107610. https://doi.org/10.1016/j.eiar.2024.107610

[4]. Li, Y., Chen, H., Zhang, L., Chen, L., & Zhang, D. (2024). Research and analysis of the current situation of cold chain logistics in Hubei Province. Refrigeration and Air Conditioning, 1-6.

[5]. Chen, G., Mohamed Ismail, M. W., & Fang, L. (2024). Coordinated replenishment policies for a single-supplier multi-retailer cold chain for fresh produce. Journal of Modelling in Management. https://doi.org/10.1108/JM2-12-2024-XXXX

[6]. Peng, H. (2021). Exploring the general ideas and experiences of the economic development of characteristic foods in mountainous areas. Food Research and Development, 42(08), 241.

[7]. Han, J.-W., Zuo, M., Zhu, W.-Y., Zuo, J.-H., Lü, E.-L., & Yang, X.-T. (2021). A comprehensive review of cold chain logistics for fresh agricultural products: Current status, challenges, and future trends. Trends in Food Science & Technology, 109, 536-551. https://doi.org/10.1016/j.tifs.2021.01.066

[8]. Li, J. (2024). Optimization method for cold chain distribution routes of fresh agricultural products considering time windows. China Shipping Weekly, (33), 75-77.

[9]. Hsiao, Y.-H., Chen, M.-C., & Chin, C.-L. (2017). Distribution planning for perishable foods in cold chains with quality concerns: Formulation and solution procedure. Trends in Food Science & Technology, 61, 80-93. https://doi.org/10.1016/j.tifs.2016.11.016

[10]. Chen, J. (2023, October 25). Xinjiang cold chain logistics secures the "freshest one kilometer." China Water Transport News, (007). https://doi.org/10.28142/n.cnki.ncsyb.2023.0014

Cite this article

Guan,K.;Lin,W.;Zhou,X. (2024). A Case Study on How to Improve Cold Chain Logistics for Specialty Food and Agricultural Products. Advances in Economics, Management and Political Sciences,143,136-141.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of ICFTBA 2024 Workshop: Finance's Role in the Just Transition

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Li, M., Xie, B., Li, Y., Cao, P., Leng, G., & Li, C. (2024). Emerging phase change cold storage technology for fresh products cold chain logistics. Journal of Energy Storage, 88, 111531. https://doi.org/10.1016/j.est.2024.111531

[2]. Anon. (2021). The Current Situation, Challenges, and Policy Suggestions for the Development of Cold Chain Logistics in China. Baidu. https://baijiahao.baidu.com/s?id=1702258102154155683&wfr=spider&for=pc

[3]. Fan, X., Zhang, Y., Xue, J., & Cao, Y. (2024). Exploring the path to the sustainable development of cold chain logistics for fresh agricultural products in China. Environmental Impact Assessment Review, 108, Article 107610. https://doi.org/10.1016/j.eiar.2024.107610

[4]. Li, Y., Chen, H., Zhang, L., Chen, L., & Zhang, D. (2024). Research and analysis of the current situation of cold chain logistics in Hubei Province. Refrigeration and Air Conditioning, 1-6.

[5]. Chen, G., Mohamed Ismail, M. W., & Fang, L. (2024). Coordinated replenishment policies for a single-supplier multi-retailer cold chain for fresh produce. Journal of Modelling in Management. https://doi.org/10.1108/JM2-12-2024-XXXX

[6]. Peng, H. (2021). Exploring the general ideas and experiences of the economic development of characteristic foods in mountainous areas. Food Research and Development, 42(08), 241.

[7]. Han, J.-W., Zuo, M., Zhu, W.-Y., Zuo, J.-H., Lü, E.-L., & Yang, X.-T. (2021). A comprehensive review of cold chain logistics for fresh agricultural products: Current status, challenges, and future trends. Trends in Food Science & Technology, 109, 536-551. https://doi.org/10.1016/j.tifs.2021.01.066

[8]. Li, J. (2024). Optimization method for cold chain distribution routes of fresh agricultural products considering time windows. China Shipping Weekly, (33), 75-77.

[9]. Hsiao, Y.-H., Chen, M.-C., & Chin, C.-L. (2017). Distribution planning for perishable foods in cold chains with quality concerns: Formulation and solution procedure. Trends in Food Science & Technology, 61, 80-93. https://doi.org/10.1016/j.tifs.2016.11.016

[10]. Chen, J. (2023, October 25). Xinjiang cold chain logistics secures the "freshest one kilometer." China Water Transport News, (007). https://doi.org/10.28142/n.cnki.ncsyb.2023.0014