1. Introduction

The global supply chain is the result of enterprises seeking optimal resource allocation on a global scale [1]. In recent years, changes in the global political-economic environment, especially trade frictions, geopolitical tensions, public health emergencies, and frequent natural disasters, have presented significant challenges to the stability of the global supply chain [2]. Meanwhile, the rapid development of emerging technologies such as Digitalization and artificial intelligence (AI) has brought unprecedented opportunities for global supply chain management [3,4]. Applying these technologies can enhance the transparency and efficiency of the supply chain. Emerging markets and policies also provide new possibilities for the global supply chain. In this context, exploring the challenges and opportunities of global supply chain management is of significant importance for enterprises to formulate strategies that adapt to global changes.

This study aims to analyze the challenges and opportunities faced by global supply chain management. Specifically, this research aims to address the following questions:

1. What are the main challenges of global supply chain management?

2. How do emerging technologies and policies bring new opportunities to the global supply chain?

3. How can enterprises respond to these challenges and maximize global supply chain management opportunities?

This study provides a comprehensive analysis of the opportunities and challenges in global supply chain management, particularly focusing on recent research papers and reports. Reviewing existing literature, key global supply chain management factors are summarized and discussed.

2. Challenges in global supply chain management

In the global supply chain, geopolitical conflicts and sudden disasters may cause significant challenges [2]. Political factors such as policy shifts, trade protectionism, and warfare directly affect the sustainability and resilience of the global supply chain. They may lead to market uncertainties and operational risks for businesses. For instance, events like Brexit, the U.S.-China trade conflict, and the Russo-Ukrainian war have profoundly impacted the global supply chain [5,6] Furthermore, sudden disasters such as the COVID-19 pandemic and earthquakes also severely affect the global supply chain [7,8]. A thorough understanding of these challenges is crucial for maintaining the sustainability and resilience of the global supply chain.

2.1. Emergencies and disasters

2.1.1. COVID-19 pandemic

The COVID-19 pandemic profoundly disrupted global supply chains, exposing vulnerabilities and driving a critical reevaluation of resilience and flexibility in supply chain management. As the pandemic forced the abrupt closure of factories and transportation hubs, particularly in major manufacturing hubs like China, industries worldwide faced severe operational disruptions. This situation created significant demand-supply imbalances; for example, demand for medical supplies and home office equipment soared, while industries such as automotive and luxury goods experienced sharp declines. The pandemic underscored supply chains' need to be agile and capable of rapidly adjusting to market fluctuations and disruptions. Companies that had diversified their supplier base or invested in robust digital infrastructures were less affected, adapting more swiftly to these changes.

Moreover, the crisis accelerated the integration of digital technologies such as AI, machine learning, and IoT, which proved essential for predictive analytics and demand forecasting, enabling companies to anticipate disruptions and adjust inventories accordingly. Enhanced visibility and communication became pivotal, as firms with transparent supply chain operations could better track and manage disruptions, investing heavily in real-time data technologies to improve responsiveness to future emergencies. Overall, the COVID-19 pandemic has acted as a catalyst for rethinking strategies in global supply chain management, emphasizing the importance of resilience through diversification, technological advancement, and increased transparency to withstand future disruptions [9,10].

2.1.2. Natural disasters

In March 2011, Japan was struck by a devastating earthquake that reached 9 degrees on the Richter scale, followed by a massive tsunami and a severe nuclear crisis. These catastrophic events had profound impacts on both Japan and the global economy. Production was notably affected as facilities were damaged or shut down, severely disrupting the production links and leading to significant interruptions in the supply chain. Transportation and logistics also suffered considerable setbacks due to damage to roads, ports, and other critical infrastructure, which obstructed cargo transportation and caused delays in the delivery of goods. In response to these challenges, it became crucial to establish robust emergency response plans that included forming close partnerships with suppliers and timely adjustments to production and transportation strategies.

Furthermore, developing backup supply chains and maintaining additional inventory was essential to cope with potential disruptions in production or logistics and to ensure the continuous supply of goods. Enhancing cooperation and coordination between the government and enterprises was imperative to manage the crisis and mitigate its impacts effectively. These measures helped to stabilize the supply chain and promote sustainable development despite the severe disruptions caused by the crisis. Through such comprehensive countermeasures, it is possible to respond effectively to such crisis events and maintain the continuous operation and stability of the supply chain in challenging times.

2.2. Geopolitical issues

2.2.1. Brexit

Brexit's impact on the supply chain is unique. Brexit is a highly distinctive event, and its repercussions on the global economic landscape are exceptional. Its uniqueness stems from three aspects: the profound impact of the event itself, the exceedingly short response time granted to businesses, and the resultant uncertainty [11]. One of the effects of Brexit on manufacturing is the relocation of factories. Research indicates that many enterprises, post-Brexit, have had to adjust their site selection between the European mainland and the UK, shifting production centers from the UK to the European mainland and relocating distribution centers from the European mainland to the UK [12]. Many multinational corporations had pivotal segments of their supply chains established in the UK. Due to the uncertainty caused by Brexit, many of these entities experienced declines in stock prices, impacting their future investment decisions. Brexit exacerbated trade barriers between the UK and the European mainland and the shortage of low-skilled labor caused by immigration policies, both of which significantly affected the supply chains of manufacturing enterprises.

In conclusion, Brexit's negative impact on the supply chain stems from the uncertainty inherent in its policies. The main cause of Brexit's disruption to the supply chain is the event's unpredictability. Scholars propose that to better respond to such events, enterprises need to enhance information flow among entities within the supply chain and deepen their engagement with governments, thereby enhancing resilience in dealing with such contingencies.

2.2.2. Trade conflict

The Sino-US trade war poses a huge threat to supply chains and is a means of geopolitical struggle. It primarily affects the security and stability of global supply chains, a direct trade conflict for the imposition of tariffs. On August 18, 2017, the United States launched the "Section 301 investigation" against China in March 2018, imposing tariffs on Chinese imports and restricting Chinese enterprises' investment in the United States [13]. and in July the same year, imposing tariffs on China's manufacturing industry, which had a huge impact on the stability of the industrial and resulting in higher costs and also led to a large number of source-based relocations for supply chains both in China and the United States [6]. However, in response to the implementation of the negative list on May 19, 2022, the Canadian government banned Huawei and ZTE from participating in the construction of 5G networks in Canada on the grounds of national security, hindering the normal international service of the supply chain of Chinese multinational enterprises [6]. In addition to direct trade conflicts, indirect trade conflicts can also have a huge impact on supply chains, such as large regional agreements that exclude specific economies [14]. and these trade barriers create a closed and discriminatory supply chain [15].

2.2.3. Ukraine-Russan war

The Russo-Ukrainian war has caused significant disruption to the energy supply chain between Russia and Europe. Since the mid-to-late 20th century, Russia and Europe have formed an energy community in which Europe relies on Russia's abundant and cheap energy to meet the needs of various industries. At the same time, Russia is highly dependent on Europe's energy investment and technology. However, the beginning of the Russo-Ukrainian crisis led the EU to impose an energy ban on Russia, resulting in Europe losing a major cheap energy supplier while causing a significant shock to Russia's energy export market.

The "polarized division" caused by the Russia-Ukraine crisis in the international energy market has led to a severe polarization of oil and gas prices [16]. There is a significant difference between the energy prices of countries subject to sanctions and those not subject to sanctions. This phenomenon not only results in chaos in the international energy price mechanism but also encourages many high-risk enterprises in the market to engage in speculative behavior regarding energy prices.

The supply chain of oil and gas resources is extended by geopolitical conflicts, resulting in significant time and money required to transport massive oil and gas resources to complete transactions. Owing to the Russo-Ukrainian conflict and geopolitical issues, many energy resources cannot be transported via the shortest routes, leading to continuously increasing transportation costs for purchasing energy and posing a threat to the profitability of enterprises [12]. Some auto plants have shut down due to a lack of parts, and supply to Japan's steel industry has also been hit. At the same time, air transport across Ukraine has been affected by airspace closure due to the war.

2.2.4. Case: chip shortage

The chip industry is highly dependent on global supply chains. In recent years, events such as the 311 earthquake in Japan, the trade conflict between China and the United States, and the coronavirus outbreak have all caused chip shortages. Japan plays a pivotal and dominant role in the global Transport Equipment Industry (TEI), particularly as a major supplier of key components to car factories worldwide. Some of these components are so unique that no other company can match them in the foreseeable future. Therefore, the reduction in exports of essential parts for the Japanese automotive industry has led to a decline in global car production. For instance, Toyota, Honda, Opel, Nissan, and General Motors halted production immediately after the earthquake, resulting in a daily loss of $72 million [17]. Automotive production typically requires hundreds of chips. The production process for electronic components used in automotive chips involves multiple stages across different factories worldwide. Any issues within these links can result in production delays and delivery disruptions.

The coronavirus outbreak and infection control measures have significantly impacted the normal operations of global integrated circuit companies. This shortage originated in the automotive industry during the latter half of 2020 and gradually spread to other industries. During the COVID-19 pandemic, this multi-month production process increases vulnerability to uncontrollable factors amidst the ongoing impacts of the epidemic. Furthermore, chip supply within highly globalized automotive chip chains is also susceptible to economic conditions and geopolitical factors, including trade frictions. It should be noted that Automobile manufacturers only occupy 10% of the total semiconductor market, putting them at a disadvantage compared to other industries in ensuring chip supply. As a result, the automotive industry faced significant challenges in acquiring chips during the COVID-19 pandemic, leading to production interruptions and factory closures [18]. Due to the pandemic, remote work and online classes have gained popularity among students, increasing demand for electronic products such as computers, smartphones, and game consoles.

One method to enhance the semiconductor supply chain is to bring production back to the home country. Returning production to the home country can lead to improvements and demonstrate its benefits during supply shortages. Firstly, domestic manufacturing makes it easier to control various aspects of production, including quality and process management. Additionally, there are fewer government restrictions associated with domestic production. Moreover, local production contributes positively to surrounding communities. Lastly, reindustrializing production promotes sustainability by reducing transportation distances in the supply chain network [19].

3. Opportunities in global supply chain management

Despite facing numerous challenges, the global supply chain is encountering novel opportunities stemming from the evolution of emerging technologies, markets, and policies [1]. The rapid progression of digital technologies, encompassing automation, robotics, blockchain, 5G, Internet of Things (IoT), and artificial intelligence (AI), presents fresh avenues for supply chain innovation and efficiency enhancement. Applying these technologies augments supply chain transparency and responsiveness but also aids enterprises in better aligning with market dynamics and consumer demands [3]. Concurrently, emerging market policies such as China's Belt and Road Initiative offer nascent avenues for expanding and deepening global supply chains [20]. Emerging economies, including those in Africa, are actively integrating into global supply chains [21]. The emergence of these opportunities enables global supply chain management to navigate market fluctuations and demands with heightened flexibility, efficiency, and intelligence.

3.1. Emergent technologies

3.1.1. Artificial Intelligence (AI)

AI is revolutionizing global supply chain management by significantly enhancing operational efficiency and decision-making capabilities. AI accurately forecasts demand and inventory needs by enabling predictive analytics, minimizing waste, and reducing costs. It optimizes routing and logistics, dramatically improving delivery times and boosting customer satisfaction. Beyond enhancing operations, AI transforms supply chain transparency with machine learning models that provide real-time tracking from production to delivery, a vital feature for industries where provenance and quality are crucial. AI also excels in risk management by analyzing vast datasets to preemptively identify potential disruptions, such as shifts in supplier reliability or emerging geopolitical tensions, enabling proactive strategy adjustments. Through these diverse applications, AI not only streamlines current processes but also paves the way for redefining industry standards, solidifying its role as a strategic asset in global supply chain management.

3.1.2. Automation and robotics

The revolutionary impact of automation and robotics technology on the warehousing segment within the supply chain cannot be overstated. Technologies such as uncrewed vehicles and automated sorting brought about by automated robots have significantly enhanced the accuracy and efficiency of warehouse management [22]. Robots deployed in industrial production surpassed the 500,000 mark for two consecutive years, with an approximately 7% increase in 2023, reaching 590,000 units. Among these, China accounted for 290,300 units, representing over 58% of the total [23]. Automation robots are predominantly utilized in warehousing and logistics within the supply chain. Various types of robots assist factories in improving efficiency, cost savings, and quality in processes such as sorting, transportation, and packaging. Robots offer enhanced services for consumers, while for workers, they liberate them from mundane, repetitive tasks to engage in more complex, manual tasks [3]. According to the latest forecasts by IFR in 2024, the trends for automation robots in 2024 include AI and machine learning, cobots in applications, mobile manipulators, digital twins, and humanoids. These technologies simplify robot operations, aid workers in hazardous environments, facilitate precise operations, reduce labor, enable simulation and prediction, and better integrate into existing environments.

3.1.3. Blockchain

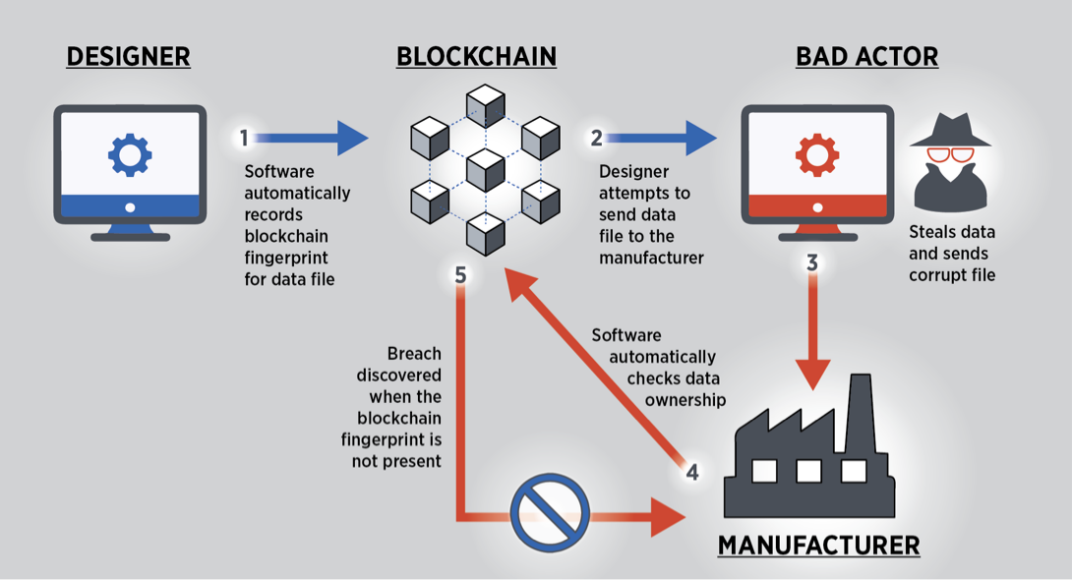

Blockchain technology has emerged as a transformative force in supply chain management, revolutionizing how businesses track and manage their products [24]. At its core, blockchain is a decentralized ledger system that ensures transaction transparency, security, and immutability. Its application in the supply chain brings unprecedented efficiency and trust [25].

In the supply chain, blockchain applies across various stages, from sourcing raw materials to delivering the final product to customers. By providing a secure and transparent record of every transaction, blockchain enhances traceability, allowing businesses to accurately track the journey of products from origin to destination [26].

Moreover, blockchain improves the efficiency of supply chain operations by automating processes such as contract execution, payment settlement, and inventory management. Blockchain-powered smart contracts enable self-executing agreements, reducing paperwork and streamlining transactions.

Additionally, blockchain mitigates risks associated with counterfeit products and fraudulent activities. With its immutable nature, blockchain ensures the authenticity and integrity of products, safeguarding consumers and businesses alike.

In conclusion, blockchain technology revolutionizes supply chain management by enhancing transparency, efficiency, and security. Its widespread adoption promises to reshape the future of global commerce, fostering trust and collaboration across supply chain networks.

3.1.4. 5G and IoT

5G technology offers ultra-low latency and gigabit-per-second data rates, enabling Supply Chain 4.0 to achieve timely information dissemination for informed decision-making and efficient order fulfillment.

Supply Chain 4.0 will affect all areas of supply chain management, mainly production planning, cargo transportation, performance management, order management, collaboration, supply chain strategy, and the other six aspects. Supply chain management applies the industry's innovative Internet of Things, advanced robotics, analytics, and big data to improve supply chain service capabilities and customer satisfaction comprehensively [28].

Moreover, integrating the Internet of Things (IoT) fosters collaboration among supply chain partners, suppliers, and customers, enhancing performance [29]. Leveraging the capabilities of 5G is expected to empower customers, suppliers, and internal logistics processes within organizations, thereby creating a competitive advantage comparable to industry peers.

To address various challenges in supply chain management, IoT introduces unprecedented levels of visibility, agility, and adaptability [30]. By incorporating IoT technologies into supply chain management practices, businesses can benefit from cost savings, improved inventory accuracy, and product tracking capabilities [31]. According to the Vice President and CTO at Telenor Research, deploying sensors on each item, real-time location details, and other attribute information from the 5G network revolutionizes consumer purchasing behavior [32].

Furthermore, Ubique Internet of Things (UCOT) enables real-time tracking and traceability throughout the supply chain while proposing blockchain technology for securely recording sensor information transmitted via 5G networks [33].

3.2. Emergent policies and markets

3.2.1. Belt and Road Initiative

The Belt and Road Initiative was proposed in September 2013. Its principle is to actively promote cooperation, promote win-win cooperation, and uphold the right approach to justice and shared interests. All countries are equal participants, contributors, and beneficiaries.

The reason why the Belt and Road has become a global supply chain is also related to its concept. Its opportunities lie in connecting trade interconnection, financial integration, and cultural exchanges, from which it can find its trade circulation, and so on.

The Belt and Road Initiative has provided a new solution for improving global governance and added vitality to economic globalization to promote common development and prosperity of the world. The Belt and Road Initiative focuses on the people, eliminating poverty, increasing employment, and improving people's livelihood. Many scholars believe that such a policy to win the hearts of the people, better benefit all the people [34].

This is an opportunity and high standards to promote cooperation in various fields and project construction, winning the trust of countries, which also makes the "Belt and Road" popular worldwide.

3.2.2. Africa economies

In accelerating the restructuring of global supply chains, African economies are expected to become an important manufacturing place and a key link in the global technology-intensive supply chain with their rich key resources and growing consumer markets [35]. 48.1% of the world's cobalt reserves and 47.6% of manganese reserves are in Africa. Africa also produces other important metals and minerals for the low-carbon transition: chromium, lithium, natural graphite, nickel, niobium, rare earth metals, silver, tellurium, and titanium. So, Africa can play the role of a raw material supplier in the global supply chain, reducing the cost of raw materials in the global supply chain.

However, backward productivity and added value have seriously hindered the pace of supply chain globalization in African economies [36]. Therefore, expanding the scale of Africa's infrastructure, improving productivity level and improving logistics performance have become the key to the next African development policy, which can strengthen Africa's position in the global supply chain. In addition, African economies should strengthen the management of existing supply chains to minimize the loopholes in their operations, thus further consolidating the global supply chain position. African economies are too single and very vulnerable to the impact of economic fluctuations. Therefore, strengthening the diversification of supply chains is the most important policy to avoid economic shocks and integrate into the global supply chain [36].

4. Conclusion

In this paper, we reviewed several typical opportunities and challenges faced by global supply chains and summarized some possible responses by enterprises. Generally, geopolitical conflicts and unforeseen events pose significant challenges to supply chains, while new technologies, policies, and markets present tremendous new opportunities for them.

For the global supply chain, opportunities and challenges often affect each other. New technologies may bring new problems, and new policies may require continuous improvement and a certain amount of time to demonstrate their advantages. For instance, although 5G technology is relatively advanced, the lack of application scenarios has not fully realized its advantages in the supply chain. Despite experiencing rapid development in recent years, Africa is still relatively underdeveloped at present. Thus, the development and application of new technologies in Africa will require some time to accumulate, and it will take some time for the benefits to the global supply chain to fully show. Similarly, the Belt and Road Initiative policy is still imperfect and requires improvement and adjustment to improve the global supply chain level.

At the same time, opportunities can also turn into challenges. For example, the pandemic has allowed some regions, such as Africa, to integrate into the global supply chain. Geopolitical conflicts also drive companies to accelerate the restructuring of their global supply chains to enhance their resilience.

Therefore, in the face of many new challenges and opportunities in the future, the development of the global supply chain is something to look forward to. Companies should prepare early for these new challenges and opportunities, improve their ability to adapt to uncertainty and enhance their supply chain, especially their global supply chain capabilities.

Acknowledgment

Xiaofei Liu, Xin Wang, Zixuan Wu, and Mingxuan Xie contributed equally to this work and should be considered co-first authors.

References

[1]. Research Institute of Global Value Chain (2020). The global supply chain revolution in the post-epidemic era—the road to transformation towards intelligence and resilience. University of International Business and Economics. https: //rigvc.uibe.edu.cn//docs/2020-09/c60a6d0693844bbc8f9cc30a7cf3f69f.pdf

[2]. Baldwin, R., & Freeman, R. (2022). Risks and Global Supply Chains: What We Know and What We Need to Know. Annual Review of Economics, 14(1), 153–180.

[3]. Attaran, M. (2020). Digital technology enablers and their implications for supply chain management. In Supply Chain Forum: An International Journal (Vol. 21, No. 3, pp. 158-172). Taylor and Francis Ltd.

[4]. Younis, H., & Wuni, I. Y. (2023). Application of industry 4.0 enablers in supply chain management: Scientometric analysis and critical review. In Heliyon (Vol. 9, Issue 11). Elsevier Ltd.

[5]. Jucyte, A., Kumar, V., & Ruan, X. (2021). Examining the Impact of Brexit on Supply Chain Risk Management: Evidence From the UK Manufacturing Sector. International Journal of Organizational Business Excellence, 4(1), 41-62.

[6]. Zhang, X., & Yang, Z. (2023). Geopolitical Conflict and Global Supply Chain Security and China’s Response Strategy. Asia-Pacific Economic Review, 2, 1–10.

[7]. Panwar, R., Pinkse, J., & de Marchi, V. (2022). The Future of Global Supply Chains in a Post-COVID-19 World. California Management Review, 64(2), 5–23.

[8]. Arto, I., Andreoni, V., & Rueda Cantuche, J. M. (2015). Global impacts of the automotive supply chain disruption following the Japanese earthquake of 2011. Economic Systems Research, 27(3), 306-323.

[9]. Ivanov, D., & Dolgui, A. (2020). "Viability of intertwined supply networks: Extending the supply chain resilience angles towards survivability. A position paper motivated by COVID-19 outbreak." International Journal of Production Research, 58(10), 2904-2915.

[10]. Chowdhury, P., Paul, S.K., Kaisar, S., & Moktadir, M.A. (2021). "COVID-19 pandemic related supply chain studies: A systematic review." Transportation Research Part E: Logistics and Transportation Review, 148, 102271.

[11]. Bednarski, L., Roscoe, S., Blome, C., & Schleper, M. C. (2023). Geopolitical disruptions in global supply chains: a state-of-the-art literature review. Production Planning and Control.

[12]. Moradlou, H., Reefke, H., Skipworth, H., & Roscoe, S. (2021). Geopolitical disruptions and the manufacturing location decision in multinational company supply chains: a Delphi study on Brexit. International Journal of Operations & Production Management, 41(2), 102-130.

[13]. Gao Debu, Liu Wenge, & Shao Yujia. (2018). The New pattern of World Economy and the Theory of Geopolitical Economy with Chinese Characteristics: An overview of the 4th Geopolitical Economy Forum. Journal of Economic Research, 53(10), 192-196.

[14]. Gulotty, R., & Li, X. (2020). Anticipating exclusion: Global supply chains and Chinese business responses to the Trans-Pacific Partnership. Business and Politics, 22(2), 253-278.

[15]. Wang, M. (2017). MEGA and Global Supply Chain: Change, Response and Reaction. Journal of World Economics, (6), 3-13.

[16]. Arvis, J. F., Rastogi, C., & Saslavsky, D. (2022). Effects of the war in Ukraine on Global Logistics and Connectivity.

[17]. Autonews, F. wire, 2011. Opel, Renault production hit by shortage of Japanese parts. http: //www.autonews.com/article/20110318/COPY01/303189860/opel-renaultproduction-hit-by-shortage-of-japanese-parts

[18]. Doerfler, Sue. (2021). “Global Chip Shortage Necessitates’ Fundamental Rethinking’.” Ismworld.

[19]. Casper, H., Rexford, A., Riegel, D., Robinson, A., Martin, E., & Awwad, M. (2021, August). The impact of the computer chip supply shortage. In Proceedings of the international conference on industrial engineering and operations management, Bangalore, India (pp. 236-245).

[20]. Thürer, M., Tomašević, I., Stevenson, M., Blome, C., Melnyk, S., Chan, H. K., & Huang, G. Q. (2020). A systematic review of China’s belt and road initiative: Implications for global supply chain management. International Journal of Production Research, 58(8), 2436-2453.

[21]. UNCTAD (2023). Economic Development in Africa Report 2023: The Potential of Africa to Capture Technology-Intensive Global Supply Chains (United Nations publication.). https: //unctad.org/system/files/official-document/aldcafrica2023_en.pdf

[22]. Rautela, P. S. Evaluation of Information Technology's Impact on Global Supply Chain and Logistics.

[23]. International Federation of Robotics. (2023). World Robotics 2023 report: Asia ahead of Europe and the Americas. Retrieved from https: //ifr.org/ifr-press-releases/news/world-robotics-2023-report-asia-ahead-of-europe-and-the-americas

[24]. Goyat, R., Kumar, G., Rai, M. K., & Saha, R. (2019). Implications of blockchain technology in supply chain management. Academia.

[25]. Gurtu, A., & Johny, J. (2019). The potential of blockchain technology in supply chain management: a literature review. International Journal of Physical Distribution & Logistics Management.

[26]. Petersen, O., & Jansson, F. (2017). Blockchain technology in supply chain traceability systems.

[27]. Veno, J. (2020). Blockchain Technology in The Food Industry. [online] Axxis Consulting. Available at: https: //axxis-consulting.com/blockchain-technology-in-the-food-industry/.

[28]. McKinsey. (2016). Supply Chain 4.0 – The Next-Generation Digital Supply Chain. Accessed March 30, 2019. https: //www.mckinsey.com/business-functions/operations/our-insights/supply-chain-40--the-next-generation-digital supply-chain.

[29]. De Vass, T., Shee, H., & Miah, S. J. (2018). The effect of “Internet of Things” on supply chain integration and performance: An organisational capability perspective. Australasian Journal of Information Systems, 22.

[30]. Ellis, S., Morris, H. D., & Santagate, J. (2015). IoT-enabled analytic applications revolutionize supply chain planning and execution. International Data Corporation (IDC) White Paper, 13.

[31]. Ben-Daya, M., Hassini, E., & Bahroun, Z. (2019). Internet of things and supply chain management: a literature review. International journal of production research, 57(15-16), 4719-4742.

[32]. Tøgard, A. (2017). The Impact of 5G: How Will 5G Affect Supply Chain & Logistics. Accessed March 23, 2019. https: //www.2wglobal.com/news-and-insights/articles/features/the-impact-of-5g/.

[33]. UCOT. (2018). Why Supply Chains Need 5G Technology – UCOT. https: //www.ucot.world/news/why-supply-chainsneed-5g-technology/.

[34]. People's Daily, (2024). High-quality Belt and Road cooperation has injected strong impetus into world modernization. http: //politics.people.com.cn/n1/2024/0430/c1001-40226868.html

[35]. Kapur, Yashoda. (2021). “Setting Up a Semiconductor Fabrication Plant in India: What Foreign Investors Should Know.” India Briefing News. www.india-briefing.com/news/setting-up-a-semiconductor-fabrication-plant-inindia-what-foreign-investors-should-know-22009.html/.

[36]. Leprince-Ringuet, Daphne. “The Impact of the Global Chip Shortage Continues to Ripple across the Tech Supply Chain.” ZDNet, ZDNet, 10 May 2021, www.zdnet.com/article/the-impact-of-the-global-chip-shortagecontinues-to-ripple-across-the-tech-supply-chain/.

Cite this article

Liu,X.;Wang,X.;Wu,Z.;Xie,M. (2025). Challenges and Opportunities in Global Supply Chain Management: A Literature Review. Advances in Economics, Management and Political Sciences,213,144-153.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 4th International Conference on Financial Technology and Business Analysis

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Research Institute of Global Value Chain (2020). The global supply chain revolution in the post-epidemic era—the road to transformation towards intelligence and resilience. University of International Business and Economics. https: //rigvc.uibe.edu.cn//docs/2020-09/c60a6d0693844bbc8f9cc30a7cf3f69f.pdf

[2]. Baldwin, R., & Freeman, R. (2022). Risks and Global Supply Chains: What We Know and What We Need to Know. Annual Review of Economics, 14(1), 153–180.

[3]. Attaran, M. (2020). Digital technology enablers and their implications for supply chain management. In Supply Chain Forum: An International Journal (Vol. 21, No. 3, pp. 158-172). Taylor and Francis Ltd.

[4]. Younis, H., & Wuni, I. Y. (2023). Application of industry 4.0 enablers in supply chain management: Scientometric analysis and critical review. In Heliyon (Vol. 9, Issue 11). Elsevier Ltd.

[5]. Jucyte, A., Kumar, V., & Ruan, X. (2021). Examining the Impact of Brexit on Supply Chain Risk Management: Evidence From the UK Manufacturing Sector. International Journal of Organizational Business Excellence, 4(1), 41-62.

[6]. Zhang, X., & Yang, Z. (2023). Geopolitical Conflict and Global Supply Chain Security and China’s Response Strategy. Asia-Pacific Economic Review, 2, 1–10.

[7]. Panwar, R., Pinkse, J., & de Marchi, V. (2022). The Future of Global Supply Chains in a Post-COVID-19 World. California Management Review, 64(2), 5–23.

[8]. Arto, I., Andreoni, V., & Rueda Cantuche, J. M. (2015). Global impacts of the automotive supply chain disruption following the Japanese earthquake of 2011. Economic Systems Research, 27(3), 306-323.

[9]. Ivanov, D., & Dolgui, A. (2020). "Viability of intertwined supply networks: Extending the supply chain resilience angles towards survivability. A position paper motivated by COVID-19 outbreak." International Journal of Production Research, 58(10), 2904-2915.

[10]. Chowdhury, P., Paul, S.K., Kaisar, S., & Moktadir, M.A. (2021). "COVID-19 pandemic related supply chain studies: A systematic review." Transportation Research Part E: Logistics and Transportation Review, 148, 102271.

[11]. Bednarski, L., Roscoe, S., Blome, C., & Schleper, M. C. (2023). Geopolitical disruptions in global supply chains: a state-of-the-art literature review. Production Planning and Control.

[12]. Moradlou, H., Reefke, H., Skipworth, H., & Roscoe, S. (2021). Geopolitical disruptions and the manufacturing location decision in multinational company supply chains: a Delphi study on Brexit. International Journal of Operations & Production Management, 41(2), 102-130.

[13]. Gao Debu, Liu Wenge, & Shao Yujia. (2018). The New pattern of World Economy and the Theory of Geopolitical Economy with Chinese Characteristics: An overview of the 4th Geopolitical Economy Forum. Journal of Economic Research, 53(10), 192-196.

[14]. Gulotty, R., & Li, X. (2020). Anticipating exclusion: Global supply chains and Chinese business responses to the Trans-Pacific Partnership. Business and Politics, 22(2), 253-278.

[15]. Wang, M. (2017). MEGA and Global Supply Chain: Change, Response and Reaction. Journal of World Economics, (6), 3-13.

[16]. Arvis, J. F., Rastogi, C., & Saslavsky, D. (2022). Effects of the war in Ukraine on Global Logistics and Connectivity.

[17]. Autonews, F. wire, 2011. Opel, Renault production hit by shortage of Japanese parts. http: //www.autonews.com/article/20110318/COPY01/303189860/opel-renaultproduction-hit-by-shortage-of-japanese-parts

[18]. Doerfler, Sue. (2021). “Global Chip Shortage Necessitates’ Fundamental Rethinking’.” Ismworld.

[19]. Casper, H., Rexford, A., Riegel, D., Robinson, A., Martin, E., & Awwad, M. (2021, August). The impact of the computer chip supply shortage. In Proceedings of the international conference on industrial engineering and operations management, Bangalore, India (pp. 236-245).

[20]. Thürer, M., Tomašević, I., Stevenson, M., Blome, C., Melnyk, S., Chan, H. K., & Huang, G. Q. (2020). A systematic review of China’s belt and road initiative: Implications for global supply chain management. International Journal of Production Research, 58(8), 2436-2453.

[21]. UNCTAD (2023). Economic Development in Africa Report 2023: The Potential of Africa to Capture Technology-Intensive Global Supply Chains (United Nations publication.). https: //unctad.org/system/files/official-document/aldcafrica2023_en.pdf

[22]. Rautela, P. S. Evaluation of Information Technology's Impact on Global Supply Chain and Logistics.

[23]. International Federation of Robotics. (2023). World Robotics 2023 report: Asia ahead of Europe and the Americas. Retrieved from https: //ifr.org/ifr-press-releases/news/world-robotics-2023-report-asia-ahead-of-europe-and-the-americas

[24]. Goyat, R., Kumar, G., Rai, M. K., & Saha, R. (2019). Implications of blockchain technology in supply chain management. Academia.

[25]. Gurtu, A., & Johny, J. (2019). The potential of blockchain technology in supply chain management: a literature review. International Journal of Physical Distribution & Logistics Management.

[26]. Petersen, O., & Jansson, F. (2017). Blockchain technology in supply chain traceability systems.

[27]. Veno, J. (2020). Blockchain Technology in The Food Industry. [online] Axxis Consulting. Available at: https: //axxis-consulting.com/blockchain-technology-in-the-food-industry/.

[28]. McKinsey. (2016). Supply Chain 4.0 – The Next-Generation Digital Supply Chain. Accessed March 30, 2019. https: //www.mckinsey.com/business-functions/operations/our-insights/supply-chain-40--the-next-generation-digital supply-chain.

[29]. De Vass, T., Shee, H., & Miah, S. J. (2018). The effect of “Internet of Things” on supply chain integration and performance: An organisational capability perspective. Australasian Journal of Information Systems, 22.

[30]. Ellis, S., Morris, H. D., & Santagate, J. (2015). IoT-enabled analytic applications revolutionize supply chain planning and execution. International Data Corporation (IDC) White Paper, 13.

[31]. Ben-Daya, M., Hassini, E., & Bahroun, Z. (2019). Internet of things and supply chain management: a literature review. International journal of production research, 57(15-16), 4719-4742.

[32]. Tøgard, A. (2017). The Impact of 5G: How Will 5G Affect Supply Chain & Logistics. Accessed March 23, 2019. https: //www.2wglobal.com/news-and-insights/articles/features/the-impact-of-5g/.

[33]. UCOT. (2018). Why Supply Chains Need 5G Technology – UCOT. https: //www.ucot.world/news/why-supply-chainsneed-5g-technology/.

[34]. People's Daily, (2024). High-quality Belt and Road cooperation has injected strong impetus into world modernization. http: //politics.people.com.cn/n1/2024/0430/c1001-40226868.html

[35]. Kapur, Yashoda. (2021). “Setting Up a Semiconductor Fabrication Plant in India: What Foreign Investors Should Know.” India Briefing News. www.india-briefing.com/news/setting-up-a-semiconductor-fabrication-plant-inindia-what-foreign-investors-should-know-22009.html/.

[36]. Leprince-Ringuet, Daphne. “The Impact of the Global Chip Shortage Continues to Ripple across the Tech Supply Chain.” ZDNet, ZDNet, 10 May 2021, www.zdnet.com/article/the-impact-of-the-global-chip-shortagecontinues-to-ripple-across-the-tech-supply-chain/.