1. Introduction

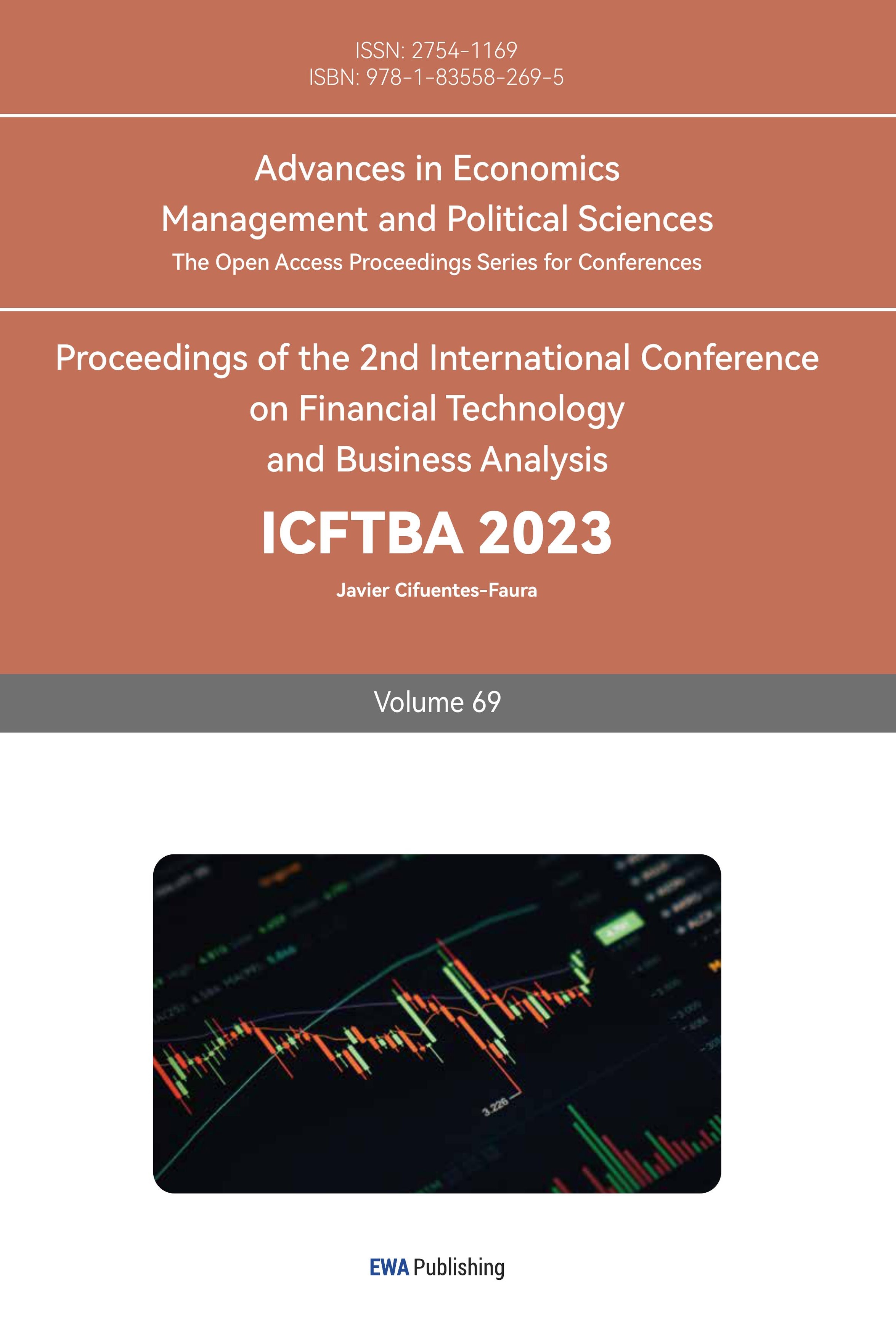

In recent years, Walmart(China) has partnered with the China Chain Franchise Association (CCFA), PricewaterhouseCoopers (PwC), Inner Mongolia Kerchin Co. Ltd. and VeChain to create a traceability platform on top of the VeChain’s blockchain.

The platform uses blockchain technology to create a 'source-to-shelf' model that tracks food as it moves through the supply chain. Walmart begins tracking 23 product lines last year, including 50 per cent of fresh meat sales, 40 per cent of packaged vegetables and 12.5 per cent of seafood.

From a technology perspective, VeChain's blockchain technology will allow Walmart to seamlessly deploying its trackable strategy and allow for the use of this distributed technology at scale. By simply scanning a product, customers will be able to access a vast amount of niche data related to their product, including their source, logistics processes, product inspection reports and other data points of interest. Here is an innovative blockchain-based model for food supply chain collaboration.

Figure 1: Diagram of VeChain’s blockchain

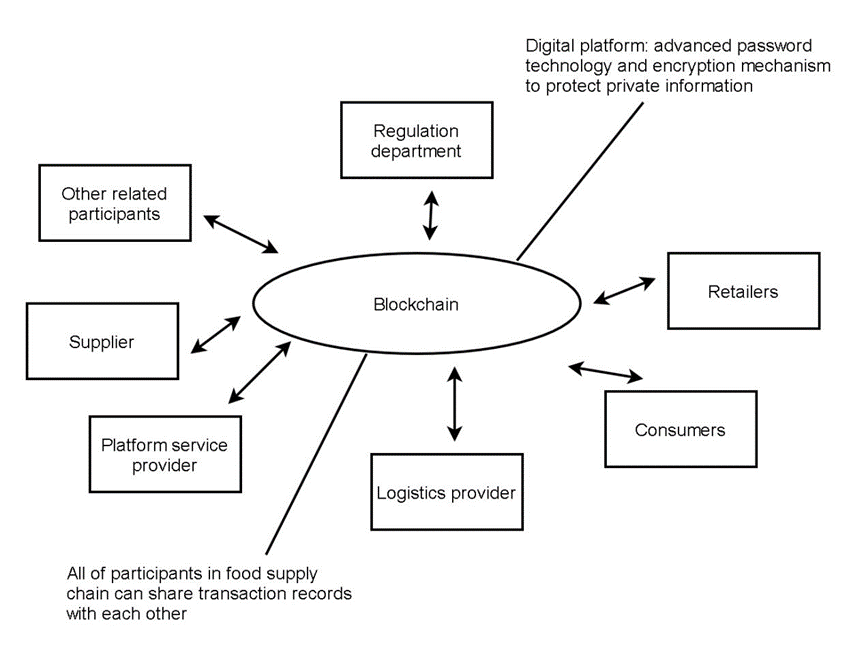

As for the reason why supply chain system is suitable for applying the blockchain technology, the “Blockchain Fit Assessment Framework” can be used for analyzing the detailed fitting conditions.

Figure 2: Blockchain Fit Assessment Framework

Generally, this assessment framework can be divided into seven aspects. The image above is about the “Blockchain Fit Assessment Framework”. The detailed assessment of why supply chain system is applicable for using the blockchain technology is shown below.

Assessment of blockchain application:

1.Intermediary: The food supply chain is enormous, encompassing farmers, producers and processors, retailers, transporters, salespeople, and consumers, as well as a diverse variety of additional participants and a vast geographical distribution range. This is the best example of decentralization. Each participant can share its own data and information to the entire supply chain and it will provide convenience to all the participants in the supply chain network to access accurate and on-time information of the product.

2.Transparency: It is the purpose of traceability. Each node in the supply chain should have observable and unmodifiable data to enable speedy tracking and identification of accountable parties. Besides, some issues may be perceived earlier because everyone will know the data from beginning.

3.Golden source: Supply chain data updates should be consistent; conflicting data is likely to result in traceability delays and mistakes, resulting in increased losses.

4.Trust: Each node in the supply chain has unique needs for product quality, transportation, and delivery. Once formed, it cannot be altered, and smart contracts circumvent this issue by simply encoding it in code.

5.Authentication: No one can avoid accountability because of the digital signature.

6.Manual processing: As previously stated, the high volume of the supply chain increases the likelihood of human mistake during the process.

7.Time sensitivity: Time is money for this industry. Because each time a supply chain issue arises, it is not a little issue; it has a ripple effect across the sector.

Thus, according to the seven aspects of blockchain application assessment, the supply chain system in the food market can fit the blockchain technology well.

Therefore, applying blockchain technology to food supply chain can confronts significant and complicated hurdles in food safety and other areas. Since a full food supply chain often entails hundreds of operational processes and hundreds of geographic locations and inspections worldwide. In this way, supply chain system based on blockchain technology increases supply chain efficiency and transparency. Prior to the advent of blockchain technology, there were no applicable technological methods for addressing food safety concerns such as vegetables and meat, and the industry was also in a state of weakness. If there are improved traceability measures in place to identify the source of the problem food in the first place, i.e.: to identify it as a specific farm or breeding farm. Then only a smaller amount of the problem food needs to be discarded, which will help to alleviate society's panic and it will also help to protect many innocent manufacturers and related parties in the industry chain from harm.

Another significant issue is that manufacturing and sales data are tampered. Food manufacturing and distribution businesses also play a critical part in the food supply chain. However, the buying time of food production businesses from the source of food raw materials and the purchasing time of food sales enterprises from food manufacturers both play a significant role in determining food safety. It is critical to keep accurate records of food components and completed food products. When time is manipulated, it has an effect on the food's shelf life. Consumers are prone to purchase substandard food over their expiration date without realizing it and it can endanger their health.

With the application of blockchain in Walmart, every authorized food safety officer has the ability to view the records that have been saved on the blockchain. It would significantly reduce the time required for document search since the papers cannot be tampered with and can be accessible by all participants in the network. It will also effectively eliminate integrity concerns such as illegal manipulation of information. If a mistake is discovered prior to implementing the blockchain, food safety managers must manually verify each document to determine the breadth of the issue, which is not only time-consuming and labor-intensive, but it is also necessarily affected by human factors. Following the use of blockchain technology, the data stored in the blockchain can be tracked back to its source, allowing for more accurate management of the shelf life of each product once it is produced. Since the system based on blockchain may reduce food waste and increase the transparency of supply chain management, which results in an overall improvement in the efficiency and level of supply chain management.

2. The Usage of Blockchain Technology Bringing Traceability to Supply Chain in Wal-Mart

2.1. Background of Customer’s Concerns about Foods Origins and Enterprises Reactions

Nowadays, it is very common to see foods safety incidents happen in the world, which makes people pay more attention to foods safety in their daily life. There is no doubt that people will not buy those problematic foods in the market, and they will have a bad impression on those problematic foods production enterprise. In this way, customers care about the source of foods and they hope there is a method that can trace relate foods production information since it is closely related to their diet safety [1]. Today, more and more food supply chains in an enterprise need to corporate with other enterprises which may be located in other countries. Thus, it is important to provide a safe and reliable supply system for the procurement enterprise and create a close cooperation between customers, producing enterprises, and governments [2].

2.2. Applying Blockchain Traceability on Supply Chain

When it comes to the traceability, it is generally about the ability to trace all processes from procurement of raw materials to production, consumption and disposal to clarify "when and where the product was produced by whom". Thus, more specifically, traceability represents the ability of accessing to records or information in supply chain, such as raw material, producing places, time, production method and so on [3]. As for the time range of applying the traceability in supply chain, it should be applied from the start of production point to the ending production point, which exists throughout the entire process. If an enterprise wants to trace and collect timely information of productions, for example, they can apply QR code, NFC, Wireless Sensor Network (WSN) and so on in their productions. But only applying these IoT devices still cannot ensure if data of productions have never been modified or manipulated because this operation depends on a centralized platform [4]. In this way, blockchain is an immutable, distributed, transparent, secure and auditable ledger [5] . Under the application of blockchain technology, the trust mechanisms for information transparency and security can be achieved. Thereby making the exchange of information be available in the traceable supply chain.

When it comes to this traceable supply chain, Wal-Mart has begun to try this model in its business. For instance, in Wal-Mart, on its pork supply chain database, the implementation of digital management is emphasized in the whole process in order to significantly increase the efficiency in the overall production process. Hence, all basic farm information such as manufacturing batch numbers, factory and processing information, expiry dates, storage temperatures, and shipping and distribution information can be maintained.

2.3. The Requirements’ Analysis of Traceable Supply Chain System Based on Blockchain Technology

Based on previous requirements’ analysis of traceable supply chain system, the demands can be classified into eight types, and they are shown below [6].

Table 1: Analysis of traceable supply chain system

Demands of Building a Traceable Blockchain Supply Chain System | ||

Needs of Supply Chain System | Types | |

1 | IoT-based data acquisition and transmission | Technical |

2 | Data security | Technical |

Table 1: (continued) | ||

3 | Information transparency | Technical |

4 | Data sharing | Technical |

5 | Transactions speed | Performance |

6 | Adaptability | Performance |

7 | System reliability, stability and scalability | Performance |

8 | Deployment | Performance |

With a constant growth of agriculture food, more and more computing capacity is needed in order to support the whole supply chain [7] . As for other food products which have comparatively short shelf life, they also need this computing capacity for the reason that it is crucial for selling them under a reasonable edible time period. Since, it is more significant for supply chain system possess the ability such as storage capacity, scalability, stability, and processing capability. Moreover, the low power consumption, high speed and safety performance is also important for the whole production supply chain based on using blockchain technology [6].

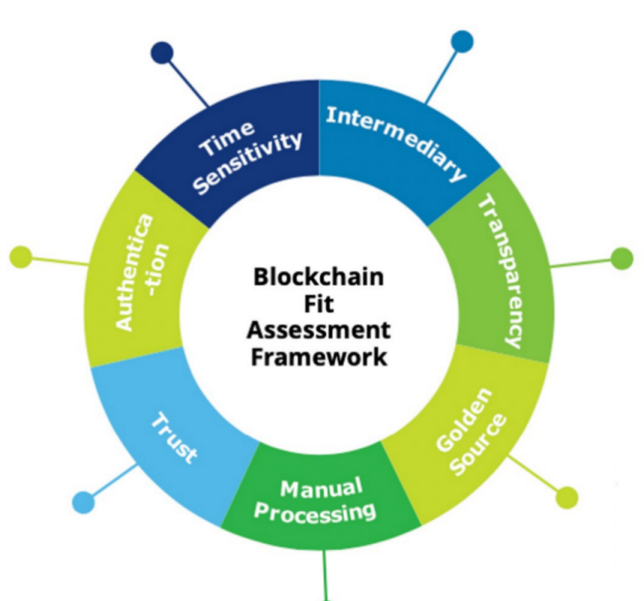

2.4. The Mechanism of Traceable Blockchain Supply Chain System

As for the system, during the process of food manufacturing, processing, storing or transportation, all of this information can be gotten by IoT devices and then be sent to the platform. In the end of the supply chain, a QR code can be generated, which can support customers to get foods ‘information [8].

According to the Traceability Information Generation Flow graph shown , we can see that the IoT can record all of data and information that comes from the supply chain process, which includes production, storage, carriage, market information and so on. This IoT platform links to the traceability system based on blockchain and Internet of Things. And then, the QR code is generated by the traceability system and it includes all of needed information. Since, once it is palced on each product in the market, it makes product’s traceability easier.

Figure 3: Traceability Information Generation Flow

2.5. The Procedure for Creating a Blockchain-Based Pork Product Supply Chain in Wal-Mart

The first stage is completed by the pig processing plant, which places the processed pork product into a packing box and applies a particular label to it. As part of this procedure, the staff generates a new QR code and uploads all relevant product description data to the blockchain using this QR code, guaranteeing that any authorized user may acquire the chain information in order to verify the operating process. The operational information of a certain node.

When completing the second step, the employee who is responsible for delivering the pork to the Wal-Mart distribution center creates a transportation record, enters the license plate number of the transportation vehicle, scans the pallet to be loaded, and then waits for the system to display the location to which the batch of pork will be delivered. In order to do so, each authorized user must first identify the distribution center and purchase order, and then upload images of these documents to the blockchain, which will create an unalterable data file for each authorized user to log in and read at the same time, without the need for human intervention.

3. Proposed Solution

With the rapid development of the e-commerce industry, the growth and scale of e-commerce business has led to the development of the supply chain. At present, information asymmetry between the intermediate participants, manufacturers and consumers does exist. End customers are in an unequal position of accessing the products information, including the production details information, transportation and quality controls. This leads to the trust problem between the end customers and the manufacturers.

In addition, the current supply chain system relies on a central database, which can be easily tampered with by companies or individuals in the initialization, transportation, wholesale, and other aspects.

Since the rapid growth of cross-border e-commerce transactions, product branding for both domestic and foreign manufacturers become critical to the success of international business. Cross-border products traceability requirement has emerged. It is still difficult to strictly supervise the source channels of goods in the cross-border e-commerce sector as it involves multiple links such as product production, sales, cross-border transportation, customs clearance and domestic distribution. Improving the information construction of cross-border logistics, gradually realizing the whole process of logistics information tracking, and ensuring that the whole process of logistics can be recorded. Real and reliable information is the key issue that cross-border e-commerce needs to be solved urgently.

3.1. Product anti-counterfeiting and tracking issues in the Supply Chain

In the production process of product, through the application of IoT technology, the information of product can be traced. In this way, information about the product can be obtained. For example, the information about the production environment, time and process of the product is then uploaded to the database.

When the product leaves the warehouse, the product information, packaging information and production information are uploaded to the supply chain. When the logistician receives the product information, it scans the logo and uploads the logistician's own information to the supply chain. The product is then shipped ready for transport. When the product arrives at its destination, it needs to be traded with the retailer, who has to make a deal before it can be stocked. The retailer verifies the product information in turn before stocking it and uploads the retailer's information to the supply chain. Consumers can scan the traceability code on the box to find out all the information about the product and purchase and consume it with confidence.

The RFID and blockchain-based product anti-counterfeiting traceability system model combines RFID anti-counterfeiting mechanisms with decentralized blockchain technology to meet the above requirements.

RFID technology is used to establish a logistics information chain for each product from the manufacturer to the end consumer, and blockchain technology is used to maintain the information chain and manage the transfer of ownership of the product, thereby ensuring the trustworthiness of the product's origin.

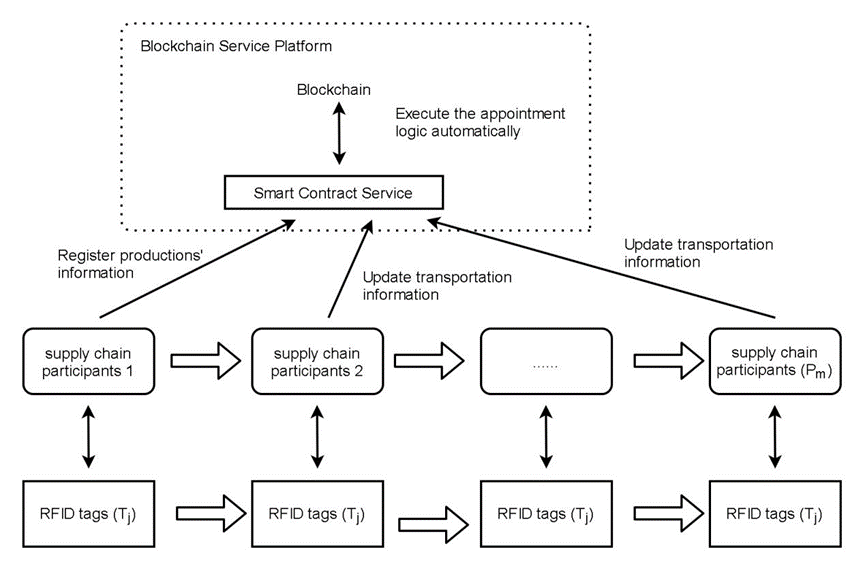

The model of product anti-counterfeiting and traceability system based on RFID and blockchain is shown in Figure.

Figure 4: The model of product anti-counterfeiting and traceability system based on RFID and blockchain

The supply chain contains m participants Pi (1<i<m) and n product tags Tj (1<j<n). The system model consists of three components: RFID tags, supply chain participants and a blockchain service platform. Each product will be shipped from the manufacturer to the end consumer through the remaining intermediate supply chain participants.

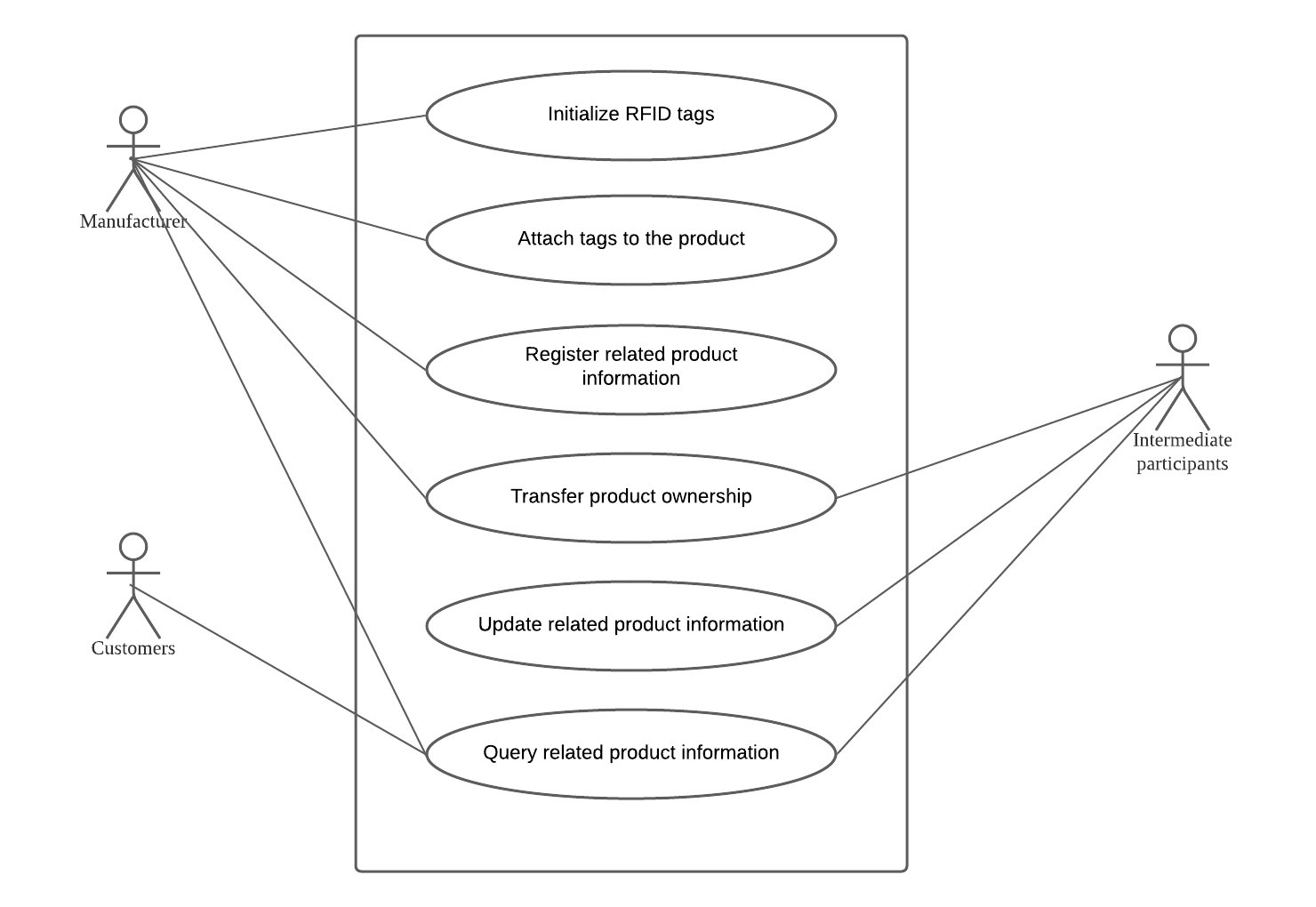

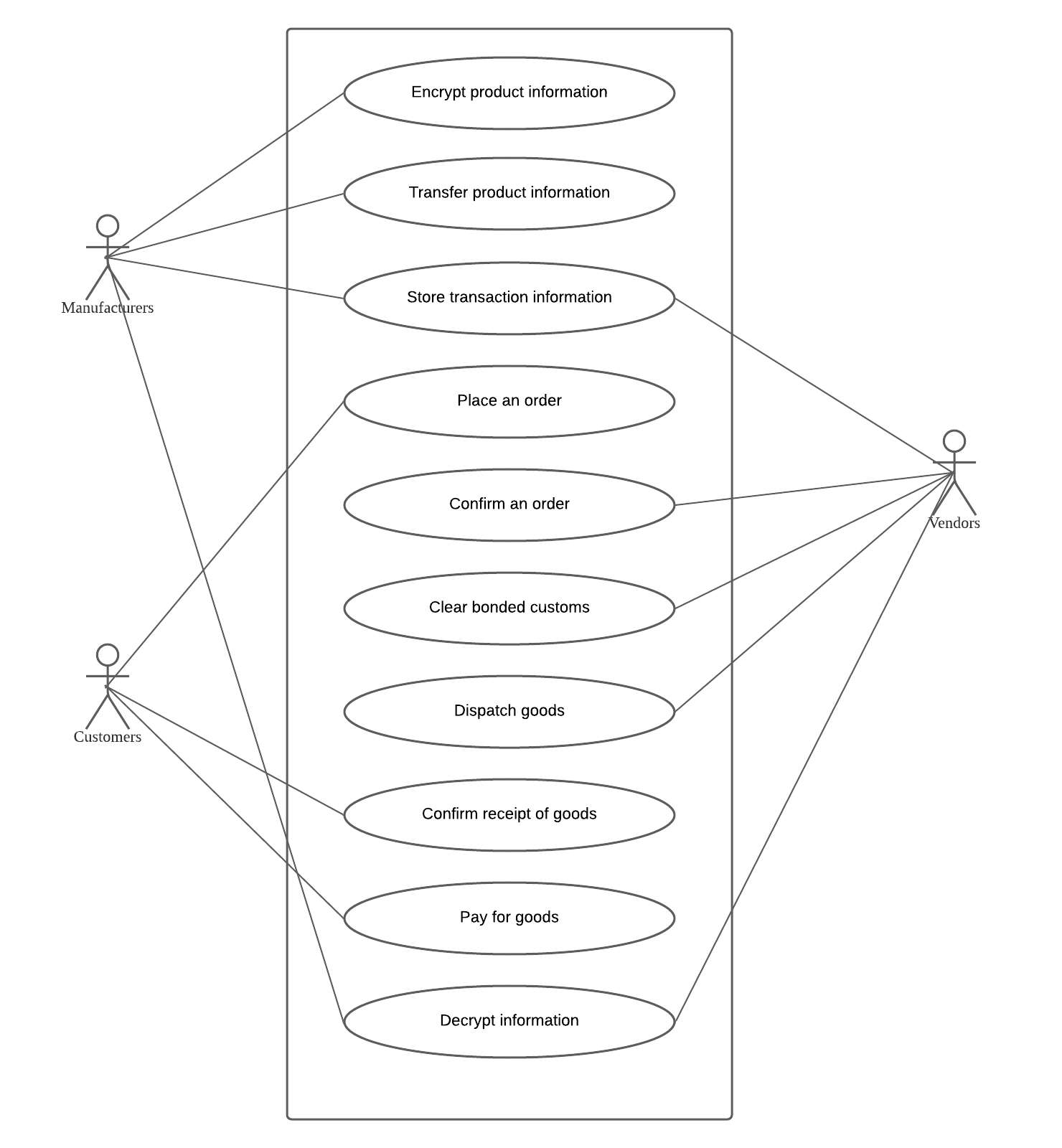

UML use case diagram of the system is shown in Figure.

Figure 5: UML use caase diagram 1-(manufaactures,customers and participants)

As the initial owner of the product, the manufacturers will be responsible for the initialization of the RFID tag to uniquely identify the product attached to the tag. At the same time, manufacturer should register production’s information. Each supply chain participant should transfer product ownership to next participant. When an RFID tag flows through intermediate participants, that participant submits the relevant information obtained from the tag to the blockchain service platform to update and maintain the information chain of the product. In the RFID and blockchain-based supply chain product anti-counterfeit traceability system, each supply chain participant can initiate anti-counterfeit traceability query requests, and the system performs business logic verification and anti-counterfeit detection based on the product logistics records and relevant anti-counterfeit data provided by the blockchain service platform to determine the authenticity of the products.

3.2. Cross-border e-commerce and products traceability issues in the supply chain

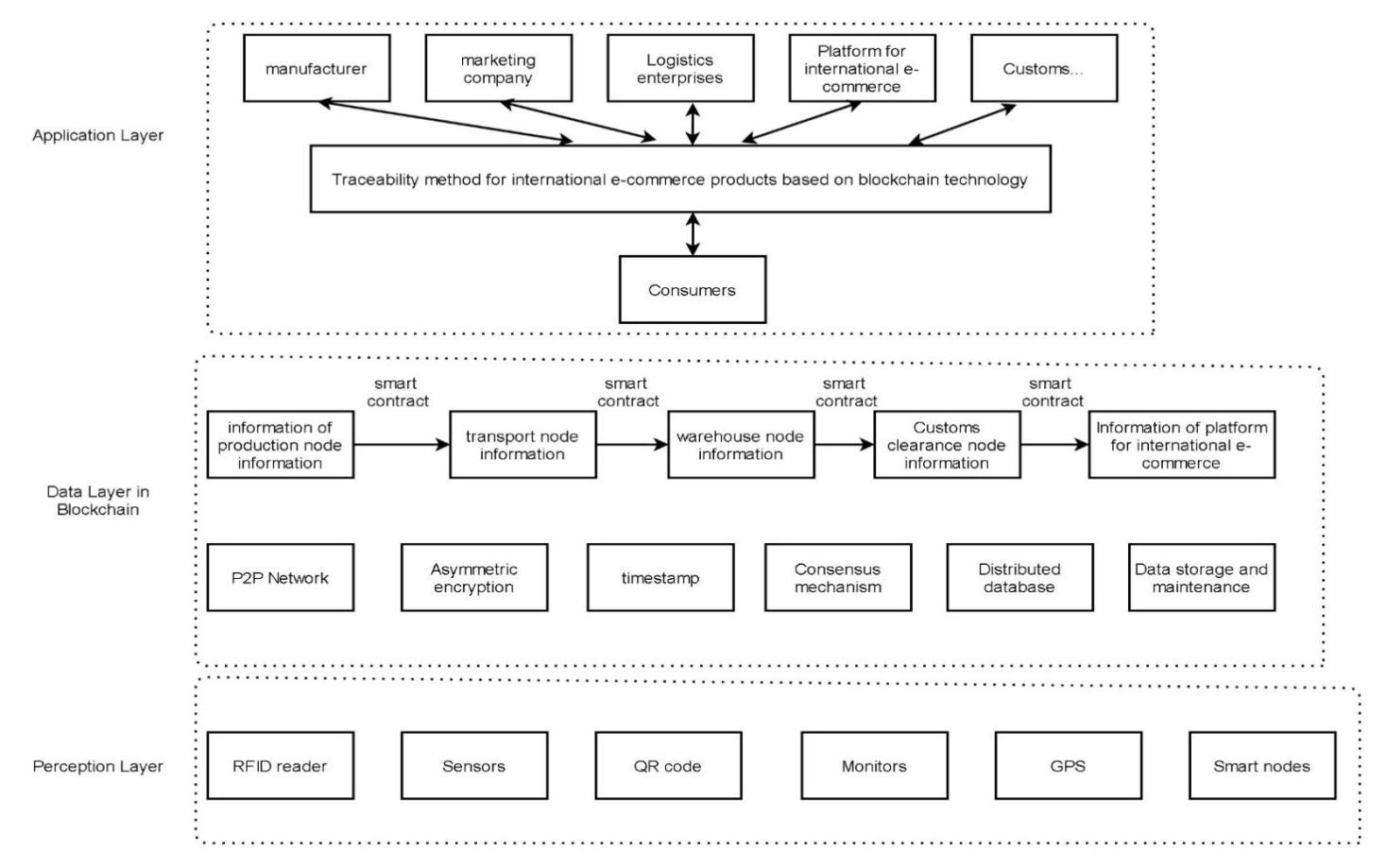

The main application of blockchain technology in the traceability of cross-border products is reflected in the assurance of information authenticity. The authenticity of source information can play a role in ensuring that products can be traced and investigated for errors, avoiding problems such as the sale of counterfeit and substandard products by e-commerce companies. The authenticity of the source information is used to guarantee the authenticity of cross-border products. To achieve these goals, a powerful database is needed to store and process information in order to provide data support for the traceability of cross-border products. The real-time information and traceability functions of blockchain can strengthen the creation of a traceability system for cross-border products, as shown in the figure below.

Figure 6: Blockchain real-time traceability system model

By combining the Internet of Things with blockchain technology, products are effectively identified and a range of data can be accessed, including the source of raw materials, date of production, date of sale, mode of transport, time of customs declaration, time of customs clearance, etc. By unifying the basic data of all parties involved in cross-border e-commerce, such as manufacturers, sales enterprises, e-commerce platforms and customs, into one database, the information block allows the information of each node to be traced and linked together to form a complete data chain. The establishment of the basic database not only provides perfect information services, but also the data network can achieve effective traceability of cross-border products and timely enquiry to understand the whole process. It effectively strengthens the quality control capability of cross-border products and contributes to the orderly development of cross-border e-commerce.

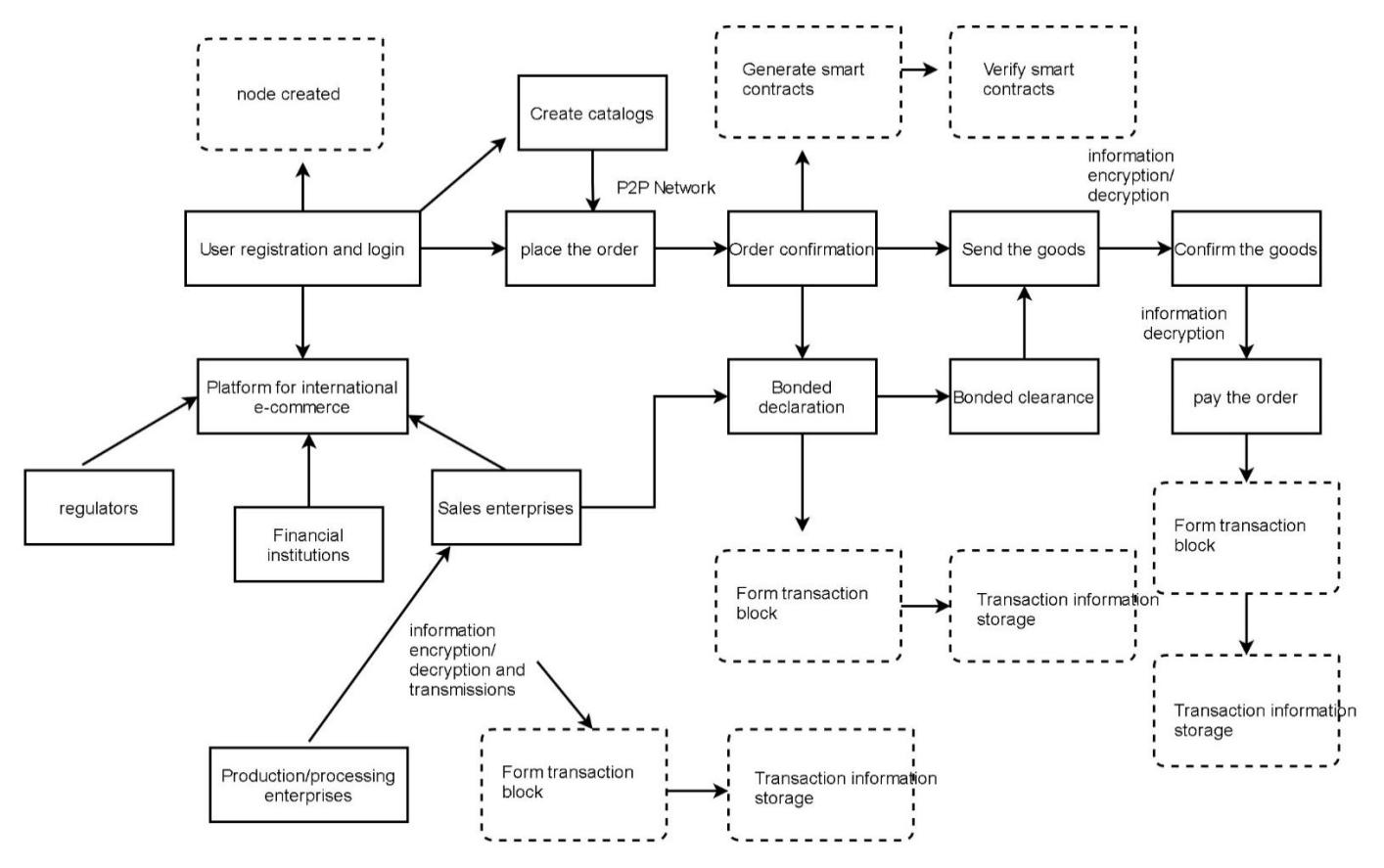

The cross-border logistics system based on blockchain technology makes full use of the distributed bookkeeping and timestamp features of blockchain to ensure that the logistics information is recorded throughout the process and is authentic and reliable, as shown in the diagram below.

Figure 7: Blockchain cross-border logistics system model

UML use case diagram of the system is shown in Figure.

Figure 8: UML use case diagram 2 - of the system

4. Conclusion

Blockchain technology promotes the development of cross-border logistics in the following two main aspects: 1. Real-time query of logistics process. Using the characteristics of blockchain such as non-tamper ability and high trust, specific access rights are given to each block, and information is effectively shared on the blockchain, enabling real-time tracking of the logistics status of cross-border products. If the distribution status is found to be not in line with the order requirements, it can be directly communicated with the international logistics company to achieve prior control. And the basic data combined with big data algorithm can optimize the logistics route and improve the efficiency of distribution. 2. Improve the efficiency of customs clearance. Using blockchain technology for ledger information sharing, it can be submitted in advance for audit in the customs system, and according to the preset customs clearance standards, the automatic analysis and operation will give the audit result quickly.

References

[1]. D. Asioli, A. Boecker, M. Canavari. On the linkages between traceability levels and expected and actual traceability costs and benefits in the Italian fishery supply chain. Food Control, 46 (2014), pp. 10-17.

[2]. World Health Organization. Food safety. Retrieved from: https://www.who.int/news-room/fact-sheets/detail/food-safety (2019).

[3]. M.M. Aung, Y.S. Chang. Traceability in a food supply chain: Safety and quality perspectives. Food Control, 39 (2014), pp. 172-184, 10.1016/j.foodcont.2013.11.007

[4]. A. Imeri, D. Khadraoui. The security and traceability of shared information in the process of transportation of dangerous goods. 2018 9th IFIP International Conference on New Technologies, Mobility and Security (NTMS) (2018).

[5]. S.F. Wamba, J.R.K. Kamdjoug, R. Epie Bawack, J.G. Keogh. Bitcoin, blockchain and fintech: A systematic review and case studies in the supply chain. Production Planning and Control, 31 (2–3) (2020), pp. 115-142.

[6]. H.Feng, X.Wang, Y.Duan, J.Zhang, X.Zhang. Applying blockchain technology to improve agri-food traceability: A review of development methods, benefits and challenges. Journal of Cleaner Production, Volume 260 (2020), pp.7

[7]. T.M. Fernández-Caramés, P. Fraga-Lamas. A review on the use of blockchain for the internet of things. IEEE Access, 6 (2018), pp. 32979-33001.

[8]. Lu.Yi, Li.Peng, Xu.He. A Food anti-counterfeiting traceability system based on Blockchain and Internet of Things. Procedia Computer Science, 199 (2022), pp.629–636.

Cite this article

Yan,X. (2024). Blockchain Technology in Supply Chain-Taking Wal-Mart as an Example. Advances in Economics, Management and Political Sciences,69,134-145.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2nd International Conference on Financial Technology and Business Analysis

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. D. Asioli, A. Boecker, M. Canavari. On the linkages between traceability levels and expected and actual traceability costs and benefits in the Italian fishery supply chain. Food Control, 46 (2014), pp. 10-17.

[2]. World Health Organization. Food safety. Retrieved from: https://www.who.int/news-room/fact-sheets/detail/food-safety (2019).

[3]. M.M. Aung, Y.S. Chang. Traceability in a food supply chain: Safety and quality perspectives. Food Control, 39 (2014), pp. 172-184, 10.1016/j.foodcont.2013.11.007

[4]. A. Imeri, D. Khadraoui. The security and traceability of shared information in the process of transportation of dangerous goods. 2018 9th IFIP International Conference on New Technologies, Mobility and Security (NTMS) (2018).

[5]. S.F. Wamba, J.R.K. Kamdjoug, R. Epie Bawack, J.G. Keogh. Bitcoin, blockchain and fintech: A systematic review and case studies in the supply chain. Production Planning and Control, 31 (2–3) (2020), pp. 115-142.

[6]. H.Feng, X.Wang, Y.Duan, J.Zhang, X.Zhang. Applying blockchain technology to improve agri-food traceability: A review of development methods, benefits and challenges. Journal of Cleaner Production, Volume 260 (2020), pp.7

[7]. T.M. Fernández-Caramés, P. Fraga-Lamas. A review on the use of blockchain for the internet of things. IEEE Access, 6 (2018), pp. 32979-33001.

[8]. Lu.Yi, Li.Peng, Xu.He. A Food anti-counterfeiting traceability system based on Blockchain and Internet of Things. Procedia Computer Science, 199 (2022), pp.629–636.