1. Introduction

Brain–computer interfaces—which allow direct communication between the brain and external computers—have potential applications in neuroscience, medicine and virtual reality. Brain-computer interface (BCI) can realize the exchange of information between the brain and the external devices, for the diagnosis and treatment of diseases associated with brain provides a new solution. One of the key factors determining the performance of neural interfaces is the electrode material used to establish electrical communication with neural tissues, which needs to meet comprehensive requirements. Neural electrodes play a crucial role in transmitting electronic, optical, and chemical signals between brain tissue and external electronic devices, affecting the performance and lifetime of BCI. For example, electrodes are used to stimulate hypothalamus continued to study mechanism of deep depression [1] or implant photoelectric sensors around eyes in order to realize the visual recovery [2]. Researchers have devoted to enhance its function in the brain. Electrodes and electronic devices have firstly been made of rigid metals and silicon which are implanted into brain to detect signals and stimulate nerves. However, there are obvious differences in mechanical properties between traditional electronic devices based on metals, ceramics, and plastics and human soft tissues, he structure and properties of these rigid bioelectronic devices result in a mismatch between tissue-electrode interfaces in terms of mechanics, biosignal transmission, and biocompatibility, making them limited in adapting to the dynamic and complex neural activities of the brain, and even potentially leading to serious complications such as tissue damage, and device failure. Therefore, the development of new materials with similar mechanical properties and high biocompatibility to human tissues has become an important research direction in this field. Scientists have begun to develop soft bioelectronic devices, which are constructed of flexible and conductive materials that can better adapt to neural activities of the brain and provide higher detection accuracy and therapeutic effects. Soft biological electronic equipment and materials can be made by changing their structure or essence soft electronic materials to become soft, and to make it compatible with mechanical software organization meanwhile. By using these strategies the flexibility of bioelectronic devices can be maximized. The mainstream of the strategy is to mix the flexible polymer and electronic materials synthesis, get both mechanical strength, electrical conductivity and biocompatibility of the composite biological electronics.

The current biological research has made some progress in the field of electronic materials, but lack of the corresponding analysis and summary. Hence, this review summarizes recent advances in designs for soft bioelectronic devices focusing on monitoring and modulating the brain to explore future potentials for BCIs. Firstly, this paper will highlight the importance of flexible bioelectronic materials and then continue with superiority of flexible bioelectronic materials. Then this work focuses on characteristics of various bioelectronics and evaluate their performances according to biocompatibility, mechanical properties, electrical conductivity and integration and systematization. Finally, concluding remarks are provided with highlighting current limitations and perspectives for future research.

2. Necessity and strengths

Soft implantable bioelectronic devices can be considered as a powerful and innovative supplement to traditional rigid material of electronic devices. With the characteristics of extensibility, biocompatibility and electrical conductivity, it can effectively construct interactive electron-biological interfaces with various real or artificial tissues and organs, and continue to carry out stable health monitoring and therapeutic intervention [3]. Thus it can be applied to monitor neural stimulation and treat disorders, including Alzheimer’s disease, Parkinson’s disease, physiological dysfunctions, and muscular disabilities. By implanting electrodes between target neurons, specific neurons, pathways, or networks can be activated or inhibited, thereby modulating the brain. However, high requirements are put forward for material properties.

The neuromodulation effect of traditional electrodes is affected by multiple factors such as mechanical mismatch, neuroinflammation, deformation of nerve segments, and electrode corrosion. And soft bioelectronics with bioactive polymers can overcome the challenges brought about by the traditional electrodes. Firstly, bioactive polymers have strong flexibility and good softness, which can not only perfectly fit the irregular brain surface, but also prolong the effective time of signal acquisition. Secondly, it has good biological activity, good compatibility, and strong anti-inflammatory response, which can improve the working efficiency of nerve electrodes. At the same time, it is easy to process and customize, which facilitates the development of neural interfaces with different types and structural designs [4]. They are thought to contribute to great intervention with enhancing cognition and recovering muscle activities. To sum up the emergence of soft bioelectronics in nerve disease treatment has brought great prospect to clinical transformation in brain function.

3. Manufacturing technology

From a structural design perspective, conventional fabrication methods rely on nanofabrication methods such as lithography, electron beam evaporation, and increasing the conductive, dielectric, and semiconducting properties of flexible substrates. These traditional approaches are difficult to achieve monomer integration of different functional components and cannot overcome the limitations of planar device geometries, which are often incompatible with biological systems. As an alternative to traditional nano-manufacturing methods, the recent emergence of printing and 3D printing technology and its advantages of low cost, rapid prototyping and customization can achieve non-planar device integration and material buckling [5]. At the same time, laser processing technology has been widely used in soft electronic products to achieve surface texture processing and customized material properties, and to achieve accurate detection of the dynamic environment of the brain. In addition, to overcome the limitation of mechanical mismatch between electronic devices and biological interfaces, electronic devices are adhered to elastic polymers such as hydrogels to form thin conductive nanocomposites. The biocompatibility and flexibility of this material make it suitable for use in implantable devices. Another motivation for this study was to develop a method for conducting hydrogel preparation with precise patterns at the micrometer scale using lithography, precision chemical design, and microfluidic techniques [6]. This is of great technical value for the fabrication of complex bioelectronic devices and sensor networks, such as high-density microelectrode arrays that can provide targeted therapy for different neurological diseases such as Huntington's disease, or with exoskeleton signaling pathways to control their movement.

4. Material property

For implantable electronic materials, long-term functional stability is the most important goal of research, which involves a variety of factors, including mechanical properties, biocompatibility, conductivity, and system integration. Traditional rigid material on the structural characteristics and tissue interface has a huge difference, signal transmission is poor, easy to cause rejection. Compared with the traditional rigid electrode, soft biological electronic because of its excellent mechanical compliance of biological tissue with good biocompatibility and conductivity, thus increase the stability.

Soft bioelectronic materials have excellent biocompatibility while ensuring mechanical properties, minimizing mechanical damage to surrounding tissues after implantation, and reducing the risk of immune response. Superior biocompatibility ensures that the materials do not elicit inflammatory reactions in the tissue, allowing for long-term stable residence within the biological environment. High electrical conductivity guarantees effective transmission of electronic signals, a critical factor for monitoring and stimulating neural signals. System integration capabilities ensure that multiple electronic components can work in concert, forming intricate circuit systems to meet diverse bioelectronic application requirements.

4.1. Mechanical properties

Due to their complex structure and application scenarios, it is particularly important to evaluate the mechanical properties of soft electronic materials, including bending properties, tensile properties, and fatigue resistance. However, the Young's modulus of electronic materials is generally much higher than that of soft tissue biological tissues, so crack propagation at the interface is more likely to occur under tensile conditions, leading to mismatch in interfacial mechanical properties.

At present, the mainstream research and development strategy is to adhere electronic devices to soft materials, which can effectively reduce crack propagation and improve the tensile properties of functional layers. The conjugated polymers have good optoelectronic properties and are easy to process to form stretchable flexible conductive materials. A dual network structure with excellent mechanical properties was obtained by the combination of bonded polymers with semiconductors. Compared with conventional rigid electrodes, soft bioelectronic devices have increased stability due to their good mechanical compliance with biological brain tissue. For example, the electron duration has a small Young's modulus of ∼ 1 MPa comparable to the natural duration. The mesh electronic component has a bending stiffness similar to that of neural tissue (10-2-10-1 nN/m), while the conventional electrode material has a higher bending stiffness (103-105 nN/m[7]). At present, such materials have achieved good carrier mobility matching with polysilicon, so they can better match the biological tissue environment and construct good electrobiological interfaces. At the same time, their high conductivity makes them more promising in the manufacture of implantable bioelectronic products, such as neural probes that can monitor electrical signals in the brain, flexible electronic devices for long-term chronic electrical stimulation and monitoring.

4.2. Biocompatibility

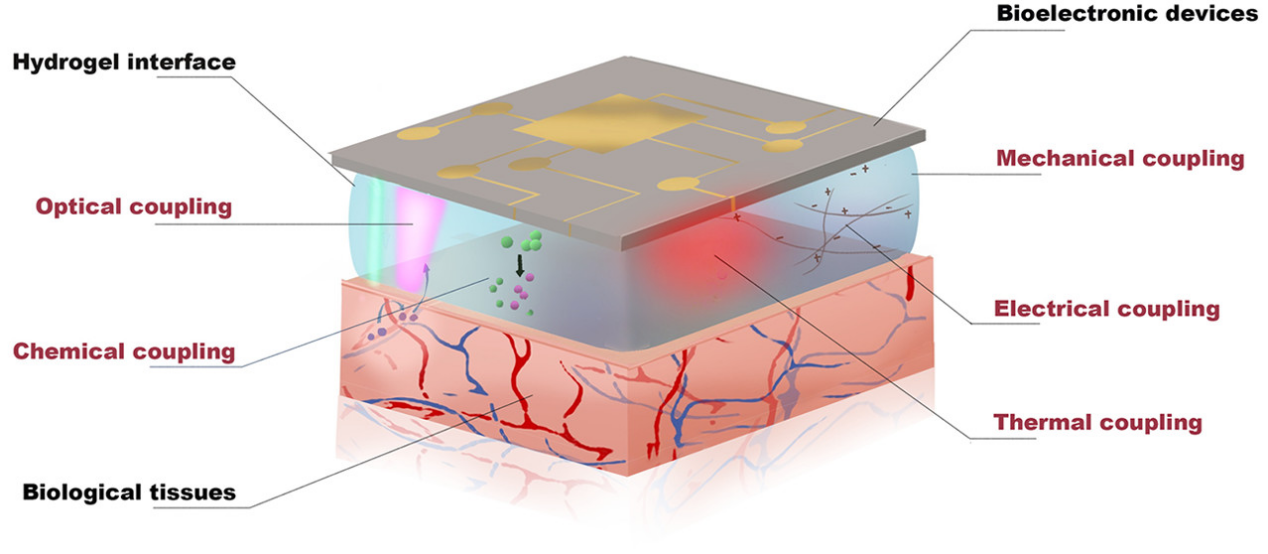

Traditional electronic devices are often based on rigid materials, and the mechanical mismatch between rigid components and human soft tissues can lead to tissue damage, while the resulting inflammatory response and fibrosis accumulation can easily reduce material performance [8]. The physical isolation of the device from the surrounding biological tissue also affected the proper function of the material. To address these challenges, hydrophilic, soft biodegradable materials with low Young's modulus can provide new solutions for collecting accurate biological information and maintaining a stable working environment by integrating components such as sensing units, power supplies, and communication systems into biological systems (Figure 1). In addition, biodegradable or naturally derived materials, combined with conductive polymers and graphene materials, have been used to create reusable environmentally friendly electronic materials. In addition, the integration of different types of electrodes into electronic systems allows for real-time interaction with the complex physiological environment to restore vision, enhance memory, control muscles, and other functions.

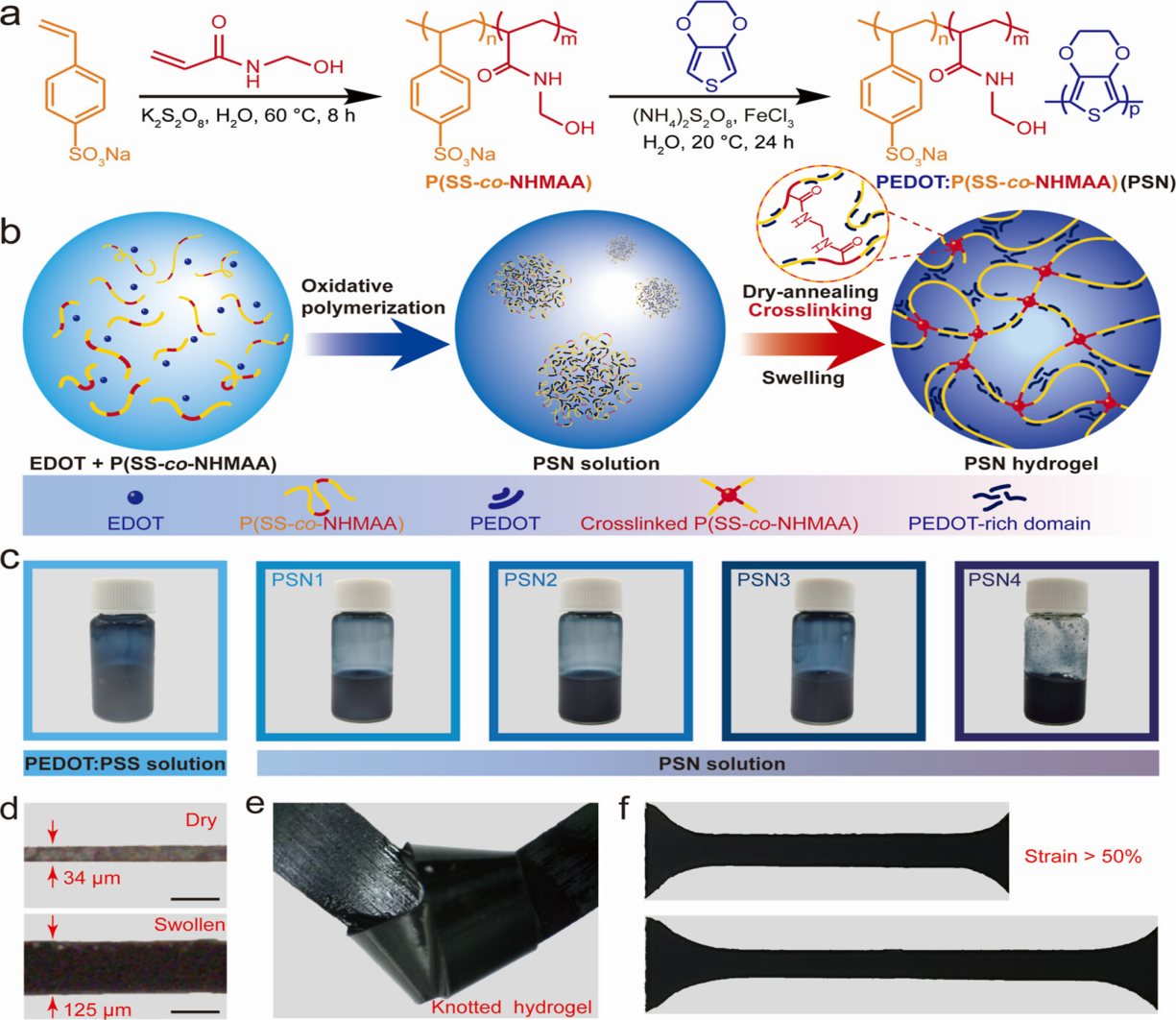

Under this background, hydrogels have become a popular direction for fabricating bioelectronic devices due to their excellent biocompatibility. Hydrogels are made of a variety of natural polymers or synthetic polymers, which have a high similarity to the environment of biological tissues and good hydropathy, and thus great biocompatibility. Then ionic conduction can be achieved by further dissolving electrolyte molecules such as lithium chloride, sodium chloride, potassium chloride into the hydrogel [9]. In this way, the hydrogel has good biocompatibility and conductivity, and becomes an ideal bioelectronic material. However, such materials have very low ionic conductivity and cannot function properly in vivo. To this end, hydrogels are used as substrates and incorporated with conductive materials such as carbon nanotubes and graphene to form gel networks with both electrical conductivity and flexibility (Figure 2). Experiments show that the composite can exhibit high electrical conductivity and mechanical properties up to about 50 S/m, and stretsibility up to about 600% [10].

Figure 1. Structure graphing of the hydrogel network [8]

Figure 2. Schematic of the design and preparation of the PSN hydrogel, (a) Synthesis route of aqueous solution of PSN. (b) Preparation of cross-linked PSN hydrogel. (c) Photographs of PEDOT:PSS and different PSN aqueous dispersions. (d) volume change from dry film to hydrogel. (e,f) Photographs of PSN hydrogels under various mechanical deformations such as knotting and stretching [10].

4.3. Electrical conductivity

Bioelectronic materials need to transmit electrical signals with adjacent biological tissues to achieve nerve stimulation, so higher requirements are put forward for the conductivity of materials. The use of hydrogels as substrates provides better electrical conductivity compared to conventional chemical materials. Introduction of electronic or ion-conducting elements into the hydrogel network produces the desired level of conductivity to ensure proper material functionality. The ions in the ion-conductive hydrogel matrix have good electrical conductivity and can be used as an ideal conduction medium inside the living organism. However, if the ion concentration in the hydrogel matrix is too high, it may lead to an imbalance in the in vivo environment, while the mechanical stability of the hydrogel also needs to be considered. To this end, hydrogel matrix-dependent micro/nanocomposites have been used for modification. For example, a polyacrylamyl-alginate gel embedded in a silver sheet can achieve a conductivity of >35000 S/m while maintaining the mechanical properties and conductivity of the tissue. At the same time, conductive polymers such as polystyrene sulfonate (PEDOT: PSS) can significantly improve the conductivity of the hydrogel matrix. PEDOT: PSS hydrogel electrode (thickness 100 μm) had a conductivity of 47.4 S/cm and a Young's modulus of 30 kPa. Compared with the control plastic sleeve electrode, PEDOT: PSS hydrogel electrode showed mild nerve tissue damage and inflammation after continuous electrical stimulation to the mouse nerve [11]. In conclusion, hydrogel networks provide a promising strategy by significantly improving conductivity while maintaining a good electrobiological adhesion interface.

4.4. Stability

Long-term stability prolongs the service life of the device, which is particularly important for the treatment of brain diseases that require chronic electrical regulation, such as the application of neuroprostheses. In a recent study, an implantable probe can modulate parameters in real time, allowing deep brain stimulation while maintaining long-term stability and adjusting parameters in real time. The nerve stimulation probe consists of multiple thin layers with both functional and mechanical properties to minimize tissue damage [12]. The current and voltage output from the stimulator remained constant over a wide load range, indicating that the soft probe was able to provide stable stimulation over a wide frequency range. The stability and lifetime of the device were investigated through acceleration tests of packaging the device in PBS solution. Among the materials now under investigation, conductive hydrogels have similar mechanical properties and high electrical conductivity to human tissues, thus being widely used to fabricate electrodes that can interface and work with biological tissues for long periods of time.

However, despite the decent mechanical properties and electrical conductivity of conductive hydrogels, there are still problems of durability and reliability in humid environments. For example, conductive hydrogels filled with polyphenyl sulfonate (PEDOT: PSS) have been extensively studied due to their high electrical conductivity and flexibility. However, electronic devices using such hydrogels are limited by short-term operation in a humid environment, which is easy to fall off once the water of the contact interface penetrates, eventually leading to device failure [13]. Conductive hydrogels made of purely conductive polymers exhibit high mechanical stability and electrical conductivity under wet conditions, but the problem of detachment from the substrate remains unresolved. Therefore, a method to prepare hydrogels that can stably adhere to the substrate is needed to meet the requirements of stable operation of electronic devices for a long time in humid physiological environment.

In view of the shortcomings of conventional conductive hydrogels in wet stability and interfacial adhesion, laser-induced phase separation technology is proposed to improve the performance of conductive polymer hydrogels. By laser processing, the structure of hydrogels can be precisely controlled at the microscopic scale and their electrical and mechanical properties can be optimized. The formation of a strong mechanical interlocking structure between the conductive hydrogel and the polymer substrate was successfully achieved by the laser-induced metho. This structure improved wet adhesion strength of the materials and mechanical stability, and make it more suitable for long-term implantation or continuous contact with the application of the organism. For example, by studying the PEDOT: PSS and optical properties of basal to optimize laser parameters: 532 nm visible laser beam to the PEDOT: PSS positive, can pass through a transparent polymer base, and then with the PEDOT: PSS contact interface part of absorb light heat, producing the strong bonding interface [13]. Subsequently, wet adhesion tests showed that the material had excellent wet conductivity (101 S/cm), excellent wet adhesion (57 kPa) and high pattern resolution (5 μm). Wet stability characterization results showed that even in the wet state, Hydrogels under 100% strain can be firmly attached to the basal and relative resistance change is very small (10%), showed its good stability. These improvements not only enhance the adaptability and stability of conductive hydrogels in complex biological environments, but also provide support for the development of a new generation of bioelectronic devices that can communicate electrical signals with the brain more effectively for long-term and more precise monitoring and treatment.

5. Conclusion

This review highlights recent advances in flexible electronic materials as implantable brain computer interfaces. The content includes the introduction of the advantages of new bioelectronic materials, preparation strategies, and the research status of bioelectronic devices from the perspectives of mechanical properties, biocompatibility, conductivity, and long-term stability. As a cutting-edge research direction, functional hydrogels have both mechanical and electrical properties and biosafety, which will provide opportunities for new bioelectronic technologies to be applied to the treatment of neurological diseases and the enhancement of cognitive ability.

Recent studies have demonstrated that bioelectronic materials can enable efficient signal transmission through biological tissue interfaces, which can raise the possibility of bidirectional adaptive signal operation and dynamic adaptation to chemical or physical changes in biology and bioelectronics. On the basis of current researches, future adaptive biological tissue interfaces may automatically adjust their conductivity based on different peaks of neural activity, and thus adjust the current density provided by electronic components such as sensors to optimize BCI functionality. Such intelligent and adaptive bioelectronic materials may establish a temporal and spatial correspondence between electronics and biology. In addition, advances in technologies such as laser printing and microfluidic manipulation have made it possible to construct complex 3D structural systems. Through guided or deterministic assembly methods, the level of interaction between IC components and biological tissues can be further improved beyond the traditional interface. The wide diversity of bioelectronic materials.

References

[1]. Scangos K.W., Khambhati A.N., et al. Closed-loop neuromodulation in an individual with treatment-resistant depression, 2021, Nat Med. Oct 1 ;27(10):1696-1700.

[2]. Ruyi Y., Peng Z., et al. Assessment of visual function in blind mice and monkeys with subretinally implanted nanowire arrays as artificial photoreceptors.2023 , Nat Biomed Eng. Nov 23; 2157-846X

[3]. Woongchan L., Huiwon Y., et al. Nanoscale Materials and Deformable Device Designs for Bioinspired and Biointegrated Electronics. 2021, Accts Mater Res. 266-281.

[4]. Junge L., Wei Y., et al. Sensing Performance Enhancement Based on High-Frequency Polarization of Materials. 2024, Accts Mater Res. 544-559.

[5]. Yuyao L., Geng Y., et al. Stretchable graphene–hydrogel interfaces for wearable and implantable bioelectronics. 2023, Nat Electron. 51-65

[6]. Chenlong W., Yajuan S., et al. Advances in Electrospun Nanofibers: Versatile Materials and Diverse Biomedical Applications. 2024, Accts Mater Res. 07,15

[7]. Park S., Yuk H., et al. Adaptive and multifunctional hydrogel hybrid probes for long-term sensing and modulation of neural activity.2021, Nat Commun. 12 (1).

[8]. Yang Q., Hu Z., Rogers J.A. Functional Hydrogel Interface Materials for Advanced Bioelectronic Devices. 2021, Accts Mater Res., 2. 11, 1010–1023

[9]. Canhui Y., Zhigang S. Hydrogel ionotronics.2018, Nat Rev Mater. 3 (6), 125-142

[10]. Jiawen Y., Fajuan T., et al. Design of Highly Conductive, Intrinsically Stretchable, and 3D Printable PEDOT:PSS Hydrogels via PSS-Chain Engineering for Bioelectronics. 2023, Chem Mater. July 25,

[11]. Yuxin L., Jia L., Chen, et al. Soft and elastic hydrogel-based microelectronics for localized low-voltage neuromodulation. 2019, Nat Biomed Eng. 3 (1)

[12]. Sung-Hyuk S., Sang Ihn H., et al. Soft bioelectronics for the management of cardiovascular diseases. 29 September 2023.

[13]. Daeyeon W., HyeongJun K., et al. Laser-induced wet stability and adhesion of pure conducting polymer hydrogels. 02 May 2024, 475–486

Cite this article

Tang,M. (2024). Soft bioelectronic materials for brain computer interface. Theoretical and Natural Science,62,197-203.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 4th International Conference on Biological Engineering and Medical Science

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Scangos K.W., Khambhati A.N., et al. Closed-loop neuromodulation in an individual with treatment-resistant depression, 2021, Nat Med. Oct 1 ;27(10):1696-1700.

[2]. Ruyi Y., Peng Z., et al. Assessment of visual function in blind mice and monkeys with subretinally implanted nanowire arrays as artificial photoreceptors.2023 , Nat Biomed Eng. Nov 23; 2157-846X

[3]. Woongchan L., Huiwon Y., et al. Nanoscale Materials and Deformable Device Designs for Bioinspired and Biointegrated Electronics. 2021, Accts Mater Res. 266-281.

[4]. Junge L., Wei Y., et al. Sensing Performance Enhancement Based on High-Frequency Polarization of Materials. 2024, Accts Mater Res. 544-559.

[5]. Yuyao L., Geng Y., et al. Stretchable graphene–hydrogel interfaces for wearable and implantable bioelectronics. 2023, Nat Electron. 51-65

[6]. Chenlong W., Yajuan S., et al. Advances in Electrospun Nanofibers: Versatile Materials and Diverse Biomedical Applications. 2024, Accts Mater Res. 07,15

[7]. Park S., Yuk H., et al. Adaptive and multifunctional hydrogel hybrid probes for long-term sensing and modulation of neural activity.2021, Nat Commun. 12 (1).

[8]. Yang Q., Hu Z., Rogers J.A. Functional Hydrogel Interface Materials for Advanced Bioelectronic Devices. 2021, Accts Mater Res., 2. 11, 1010–1023

[9]. Canhui Y., Zhigang S. Hydrogel ionotronics.2018, Nat Rev Mater. 3 (6), 125-142

[10]. Jiawen Y., Fajuan T., et al. Design of Highly Conductive, Intrinsically Stretchable, and 3D Printable PEDOT:PSS Hydrogels via PSS-Chain Engineering for Bioelectronics. 2023, Chem Mater. July 25,

[11]. Yuxin L., Jia L., Chen, et al. Soft and elastic hydrogel-based microelectronics for localized low-voltage neuromodulation. 2019, Nat Biomed Eng. 3 (1)

[12]. Sung-Hyuk S., Sang Ihn H., et al. Soft bioelectronics for the management of cardiovascular diseases. 29 September 2023.

[13]. Daeyeon W., HyeongJun K., et al. Laser-induced wet stability and adhesion of pure conducting polymer hydrogels. 02 May 2024, 475–486