1. Introduction

1.1. Description of structure optimization

Structural optimization is a method to improve the safety, weights but also economic of a mechanical structure. It can optimize structures through their size, shape and topology. The aim for the optimization is to make the structure become lighter but also with enough strength under some limitations, like in order to fit for the conditions of working, the machine should have a particular size and volume. Structural optimization is starting from the field of aerospace due to that such field always need lighter weights but still should remain a high strength under the limitations. However, with the development of technology, optimization has been applied in lots of fields, like car production and architecture.

1.2. Description of optimization methods and some literature reviews

It can use size optimization method to improve, which is through some mathematical modelling and calculations but also analyze through the field of force to imitate what will happen after we have change into the new size. Therefore, after the processes and experiments, we can get an optimum size under the condition. For example, Wang et al. proposed a gradual optimization method in "Truss structure shape and size combination optimization [1]’’, which separated the design variables to optimize the shape and size of the truss structure by using the progressive node movement method and the full stress method, respectively. Through cyclic iteration, the interaction relationship between the shape and size variables is coupled to obtain the minimum weight of the structure.

It also can through shape and structure to improve the performance of the machine but also use the materials economically. Structure shape optimization is distinguished from the object, mainly including the truss frame type of rod system structure and the continuum structure of block, plate and shell. Liu et al. established an engineering method to optimize structure shape in "Research [2] based on Kriging proxy model". This method uses the test design method to select the position variable sample point, and optimizes the size of the corresponding structure of each sample point, and then establishes the Kriging agent model according to the sample point and size optimization results, and then uses the genetic algorithm to find the optimal position variable solution, and then get the optimal structure solution. Sun et al. proposed a two-stage algorithm for the shape optimization of discrete section variable space truss in the "The shape optimization of discrete variable truss design [3]". The example shows that this method is simple, smooth convergence, and the optimization effect is good.

For topology, Structural topology and layout optimization are high-level parts of the optimization field and are recognized as one of the most challenging research topics. Since Bendsoe and Kikuchi proposed the basic theory of structure topology optimization design based on homogenization method in 1988, the research of structure topology design has been extensive in recent decades, and has become a hot spot in the field of international engineering structure and product innovation design. At present, there are three main kinds of topology optimization methods: (a) homogenization method; (b). relative density method; (c). evolutionary structure optimization method [4].

For building materials, we can use different materials to improve the performance but also the weights. For example, the aerospace ship in NASA after starting uses the carbon fibers which is becoming lighter for a large range the before. In many other fields, structural design optimization also plays a very important role [5-7]. Nowadays, the algorithms of structural design optimization are also emerging in endlessly [8-10]. This paper focuses on the optimization design of the most common manipulator structure in the field of mechanical engineering. The influence of structural optimization method on weight reduction and strength is analyzed and studied by using a variety of software and algorithms.

2. Description of calculation case: an optimization case of a mechanical beam structure

There is a mechanical beam structure in the factory, which is used to hang the objects with high weight. The beam originally has a length, width, and height of 0.5 m, 60 mm, and 100 mm, respectively, and is made of steel. The left side of the beam is fixed to the wall. Things always hang on the beam with one tone around and they will be hung on the right side of the beam. However, people find that beam design in this way is not the optimum way. The weight is too high but also using too much material in the beam making is not quite economic. Therefore, we design the beam again and use the computer software ‘Solidworks’ to model the new beam.

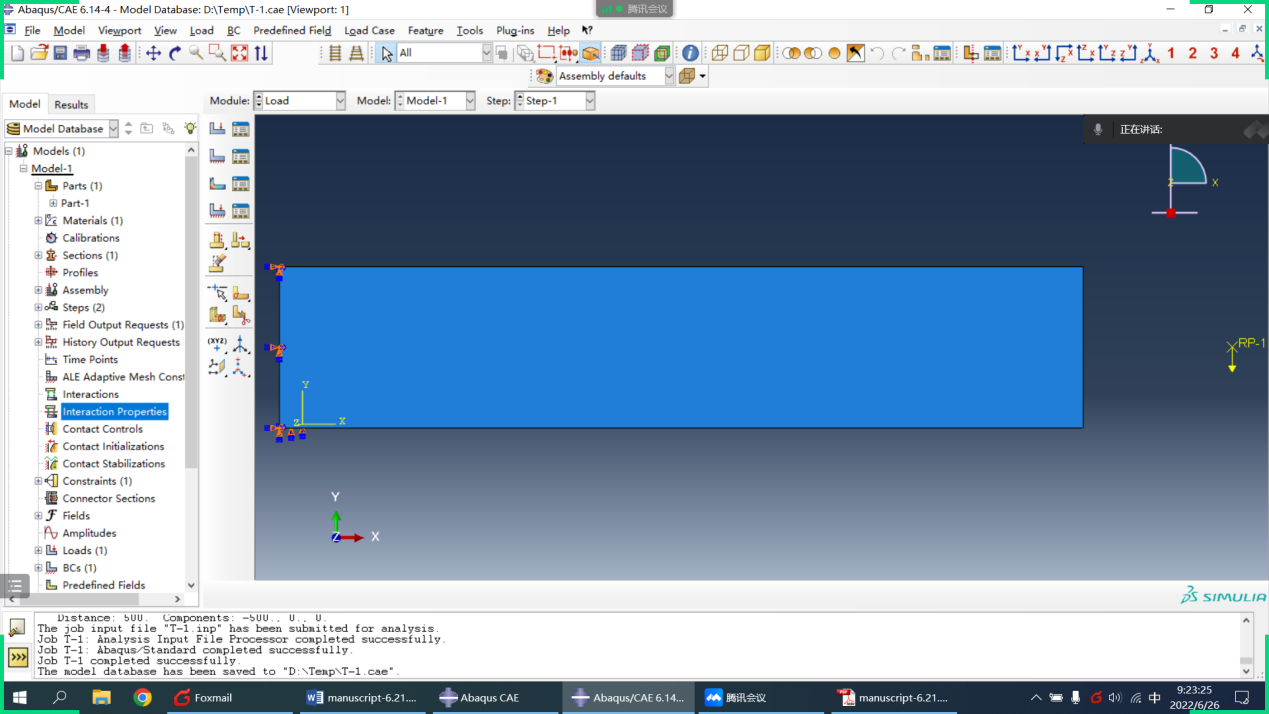

This time, we find that due to the moment is equal to force times the perpendicular distance from the pivot. Therefore, because the object of hanging in right side and also there’s a long distance between the pivot and fore. So that a large moment will act on the left side. We want to make a new beam with a lighter weight but still, have enough strength. We remodel the beam in the Solidworks. The second generation of beam has same size in left. Due to there’s less moment acting on with moving to the right, therefore we cut down some materials in proportion to the distance from the pivot. The new pivot has the same length and width but becomes thinner with the distance between the pivot and force. In the end of right size, there are only about 40 mm in height. But in this generation, we don’t have lots of precise calculations, so we cannot sure whether it is the optimum pattern. So we started to use the computer software ABAQUS to have some optimization calculations. In this time, we get lots of data about force and moment et al. that act on each part of the beam. Therefore, the topology is also used in the modeling of beam. We change the shape and size again but also cut down some parts with little force and moment acted on. Also, we find that aluminum alloy is lighter but has a high strength. As a result, we change to new material. After the whole process of optimization, the beam becomes much lighter than before but still have high strength. Through the explanation above, the original beam is shown in fig1. Designed in ABAQUS software. Left side is fixed and hangs the object with 10000N in the right side.

Figure 1. 1st version of design of the mechanical beam.

3. Results and discussion

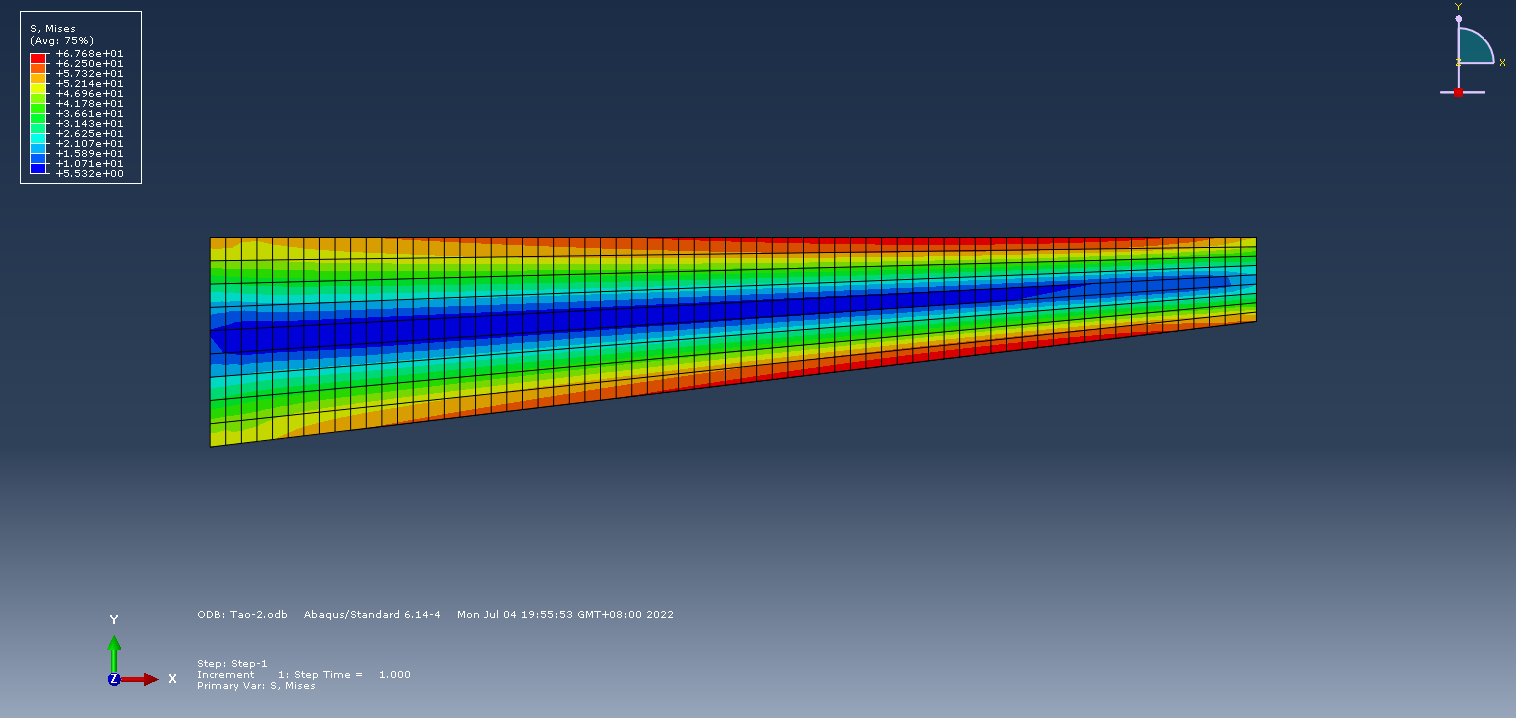

Figure 2. Bearing ability analysis of Design 1.

In this work, ABAQUS and SolidWorks softwares are used to analyze and simulate the bearing performance of the initial design of the structure of the beam. When the initial structure carries a load of 1 ton on the right side, the stress distribution is shown in Fig. 2. Under the first condition, the maximum stress in the mechanical structure is 65 MPa and the maximum end displacement is 0.69 mm. The yield stress of the steel is 300 MPa. It can be seen from the above that the mechanical structure is safe and even have the surplus in safety. At this time, the total weight of the beam is 23 kg, which can be further optimized.

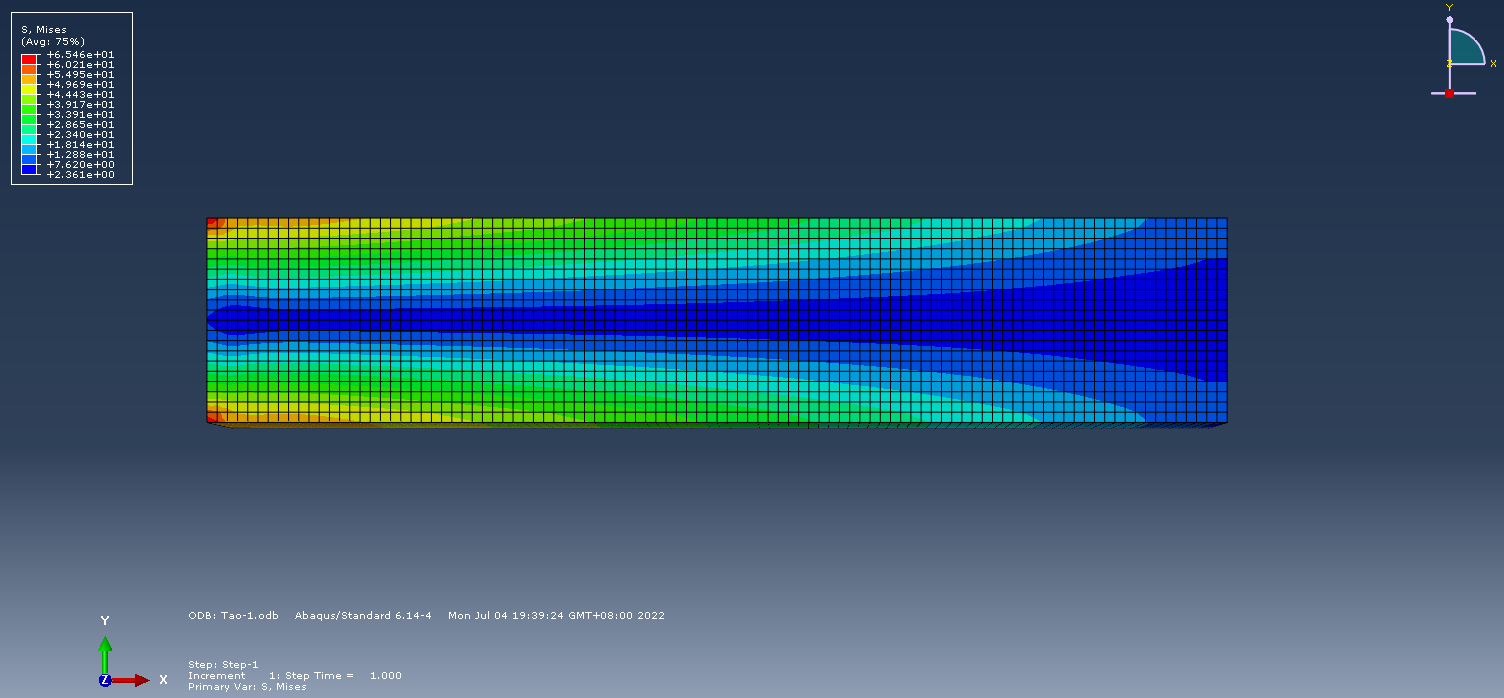

The following is the calculation and analysis after the size optimization design, as shown in Fig. 3. When the height of the right end face is reduced to 40 mm, the analysis of the bearing capacity is shown in the following figure. At this time, the maximum stress in the mechanical structure is 67 MPa and the maximum deformation is 1.59 mm. There is no sharply increase comparing with the initial design, but the deformation increases more. Considering that the length of the whole beam is 500 mm, the deformation of design 2 is still at a small value. However, at this time, the beam mass is reduced to about 16 kg, a decrease of about 30%, and the optimization effect is significant.

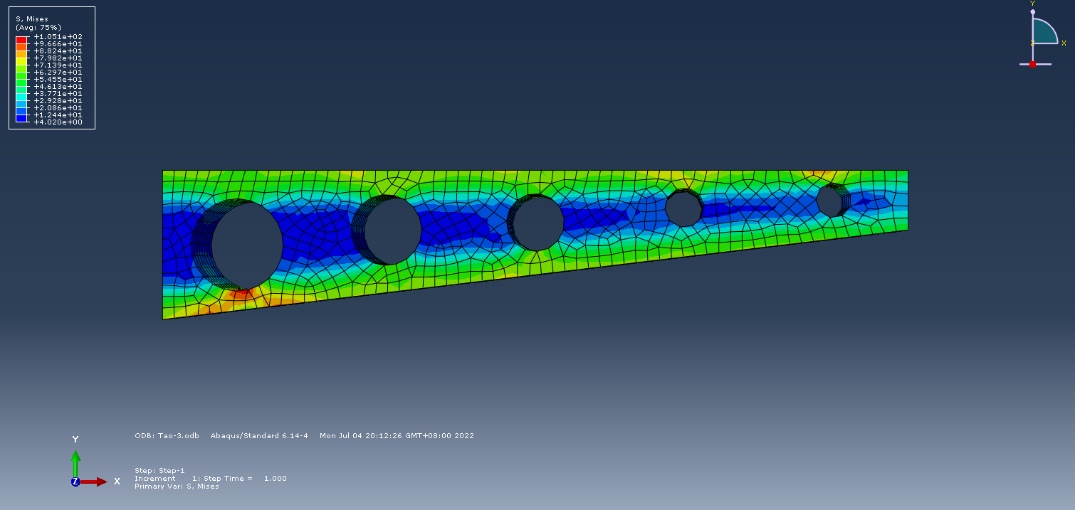

Next, the model is further optimized. By observing Fig. 2 and Fig. 3, we can find that in the first and second designs, in the imitation diagram of bearing capacity, the middle part of the mechanical beam is blue, indicating that there is waste of materials in the middle part. Therefore, in the third optimization design, the intermediate materials are removed and a series of circular holes are opened in the middle of the beam to reduce the weight of the beam as a whole and carry out topology optimization. At the sametime, because the steel material is too heavy, set the material property to aluminum alloy and observe the change. It is calculated that the maximum stress in the beam at this time is 105 MPa, which is less than 200 MPa (stress that aluminum alloy can usually bear). At this time, the maximum deformation of the beam increases greatly, reaching 5 mm, but the value is still quite small comparing to the full beam length. In the field of non-precision instrument application, it can be considered to meet the requirements. It is worth noting that the weight of the mechanical beam at this time is only 4.5 kg, which is significantly reduced by 80.4% compared with 23 kg in design 1, and the optimization effect is remarkable.

Figure 3. Bearing ability analysis of Design 2.

Figure 4. Bearing ability analysis of Design 3.

4. Conclusions

This paper summarizes the concept of structural design optimization and introduces the commonly used structural optimization algorithms. Taking the cantilever beam of robot mechanical structure as an example, this paper uses the methods of size optimization and structure optimization, and adopts ABAQUS and SolidWorks softwares to design and optimize the structure of robot cantilever beam. After the final optimization design, under the condition of ensuring the strength safety of the beam, the total weight is reduced by 80% compared with the original design, and the optimization effect is remarkable.

References

[1]. Wang D, Zhang W, Jiang J. Combined shape and sizing optimization in truss design. Chinese Journal of Applied Mechanics. 2002, 19(3): 72-76

[2]. Liu K, Yao W, Mu X. Effect of strain softening on delamination tip-field in composite laminate. Chinese Journal of Computational Mechanics. 2006, 23(3): 344-347

[3]. Ye Y. Summary of research on optimization design method of truss structure. Engineering Science. 2014, 14: 204-204

[4]. Zhao L, Guo P, Sun H, et al. Development actuality and prospect on research of structural topology optimization. Journal of Liaoning Institute of Technology. 2004, 24(1): 46-49

[5]. Vachal P, Jacobsen EN. Structure-based analysis and optimization of a highly enantioselective catalyst for the strecker reaction. Journal of the American Chemical Society, 2002, 124(34): 10012-10014

[6]. Reich C, Gibbon P, Uschmann II, et al. Yield optimization and time structure of femtosecond laser plasma kalpha sources. Physical Review Letters, 2000, 84(21): 4846

[7]. Kajiwara K, et al. Approach for simultaneous optimization of a structure and control system. AIAA Journal, 1994

[8]. Kottcke M, Heinz K. A new approach to automated structure optimization in LEED intensity analysis. Surface Science, 1997, 376(1-3):352-366

[9]. Huber T, Torda AE, Gunsteren WV. Structure optimization combining soft-core interaction functions, the diffusion equation method, and molecular dynamics. Journal of Physical Chemistry A, 1997, 101(33): 5926-5930

[10]. Andreani R, JM Martínez, L Martínez, et al. Continuous optimization methods for structure alignments. Mathematical Programming, 2008, 112(1): 93-124

Cite this article

Tao,Z. (2023). Stress Analysis and Size Optimization of Suspension Beam Structure of Robot Manipulator. Theoretical and Natural Science,2,92-96.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the International Conference on Computing Innovation and Applied Physics (CONF-CIAP 2022)

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Wang D, Zhang W, Jiang J. Combined shape and sizing optimization in truss design. Chinese Journal of Applied Mechanics. 2002, 19(3): 72-76

[2]. Liu K, Yao W, Mu X. Effect of strain softening on delamination tip-field in composite laminate. Chinese Journal of Computational Mechanics. 2006, 23(3): 344-347

[3]. Ye Y. Summary of research on optimization design method of truss structure. Engineering Science. 2014, 14: 204-204

[4]. Zhao L, Guo P, Sun H, et al. Development actuality and prospect on research of structural topology optimization. Journal of Liaoning Institute of Technology. 2004, 24(1): 46-49

[5]. Vachal P, Jacobsen EN. Structure-based analysis and optimization of a highly enantioselective catalyst for the strecker reaction. Journal of the American Chemical Society, 2002, 124(34): 10012-10014

[6]. Reich C, Gibbon P, Uschmann II, et al. Yield optimization and time structure of femtosecond laser plasma kalpha sources. Physical Review Letters, 2000, 84(21): 4846

[7]. Kajiwara K, et al. Approach for simultaneous optimization of a structure and control system. AIAA Journal, 1994

[8]. Kottcke M, Heinz K. A new approach to automated structure optimization in LEED intensity analysis. Surface Science, 1997, 376(1-3):352-366

[9]. Huber T, Torda AE, Gunsteren WV. Structure optimization combining soft-core interaction functions, the diffusion equation method, and molecular dynamics. Journal of Physical Chemistry A, 1997, 101(33): 5926-5930

[10]. Andreani R, JM Martínez, L Martínez, et al. Continuous optimization methods for structure alignments. Mathematical Programming, 2008, 112(1): 93-124