1.Introduction

The prefabricated concrete structure constitutes a pivotal component of residential industrialization, offering superior resource utilization compared to the cast-in-place concrete construction method. This alternative approach not only shortens the construction period but also yields greater economic benefits by reducing material and energy consumption. Consequently, it possesses significant developmental potential in China as well as globally[1].

The design and construction process of prefabricated concrete buildings typically involves the utilization of precast columns, beams, floors, stairs, and external wall panels. In practice, the most commonly employed approach is to assemble these one-dimensional components into a frame structure system with rigid joint connections. The performance of this system is essentially equivalent to that of cast-in-place structures in terms of seismic resistance, design methodology, and applicable height[2]. Prefabricated buildings originated in Europe and have been widely adopted globally, particularly for post-war reconstruction and residential construction projects[3].

The development of prefabricated buildings is no longer solely focused on quality and cost performance, but rather places greater emphasis on cost reduction, environmental impact mitigation, and the advancement of resource-recycling buildings. To promote the sustainable growth of prefabricated concrete buildings, it is imperative to shift from a singular pursuit of energy efficiency and environmental friendliness towards a more intricate design approach that caters to individual needs[4]. Furthermore, there should be an enhanced focus on establishing comprehensive standards for prefabricated building construction. Additionally, the application value of Building Information Modeling(BIM) and Artificial intelligence(AI) technology holds significant potential in optimizing the entire life cycle of prefabricated buildings[5].

This paper provides an objective analysis of the advantages and disadvantages of prefabricated concrete in practical applications, as well as its potential areas for improvement, through a comprehensive case study and extensive literature review. Additionally, it presents a concise overview of the domestic and international development of this technology. In summary, prefabricated concrete buildings have a strong position in the construction sector and offer promising growth opportunities through technological advancements and standardized systems to meet modern architectural design requirements.

2.Prefabricated concrete building development overview

Prefabricated concrete buildings have the characteristics of high factory pre-system, controllable prefabrication environment, significantly reduced construction period and high technical installation level requirements, which can effectively improve the construction efficiency and quality, make the building design more effectively adapt to the actual needs, and be less affected by the construction environment. But at the same time, there are high costs and high precision requirements of technical problems[6-7].

2.1.Advantages of Prefabricated Concrete Buildings

2.1.1.Standards for quality of structural components

The quality of precast concrete structures is ensured by precast concrete plants through the formulation of precise production specifications.

Prefabricated concrete structures offer improved efficiency, and enhanced project quality, and address limitations of on-site casting through factory production. This method allows for precise control over manufacturing processes, minimizes potential issues, eliminates weather-related constraints, enables parallel workflows, reduces labor requirements, and shortens project timelines [7].

2.1.2.Short construction period and high efficiency

The drawbacks of cast-in-place structures are addressed through factory processing and on-site assembly, leading to enhanced production efficiency and engineering quality. Additionally, this construction method significantly reduces the construction cycle, minimizes expenditure costs, and improves overall construction quality and efficiency.

Since the building parts can be maintained in the factory, the degree of seasonal impact is small, and normal construction can be carried out throughout the year, thus ensuring the safety and reliability of the construction process[8].

2.1.3.Minimal impact on the environment

Prefabricated concrete buildings can effectively improve the building quality, extend the life of residential buildings, and realize energy saving and material saving in the whole life cycle of residential buildings[7].

Additionally, this approach to construction not only focuses on sustainability but also prioritizes the efficient use of resources. By incorporating eco-friendly materials and energy-saving technologies, it minimizes waste production and reduces carbon emissions. Moreover, this sustainable construction method promotes a healthier living environment by utilizing natural ventilation systems and maximizing natural light penetration. It also considers the long-term impact on the surrounding ecosystem by implementing measures to protect biodiversity and preserve green spaces.

Overall, this approach offers a holistic solution that balances environmental responsibility with practical benefits such as cost savings and improved quality of life for residents.

2.2.The development status at home and abroad

In recent years, precast concrete structure as an efficient construction technology has attracted wide attention and research in the country. Internationally, developed regions such as Europe and the United States have been exploring these systems since the 17th century, aiming to improve construction efficiency, reduce costs, and reduce environmental impact[9]. In Europe and other countries, there is a greater emphasis on environmental protection and energy efficiency[10].

The development of prefabricated concrete buildings in Germany has a rich historical background and extensive technical expertise. Germany boasts a comprehensive and well-established standard specification system for prefabricated buildings, which sets forth stringent technical performance requirements encompassing structural safety, fire resistance, environmental sustainability, and non-toxicity[11]. These standards not only ensure the quality and safety of prefabricated buildings but also foster continuous technological innovation and advancement.

Japan and South Korea have learned from the experience of Europe and the United States, combined with their own actual conditions and needs in the prefabricated structure, volume of seismic resistance and isolation design has made breakthrough progress[12].

In China, research has focused on combining traditional construction methods with modern technologies to achieve standardized design of precast concrete structures and promote the development of modular industrial production[7]. Due to construction site and environmental constraints, prefabricated buildings are very common in Hong Kong and Taiwan, and most high-rise residential buildings use stacked floors, prefabricated stairs and prefabricated exterior walls [10,12].

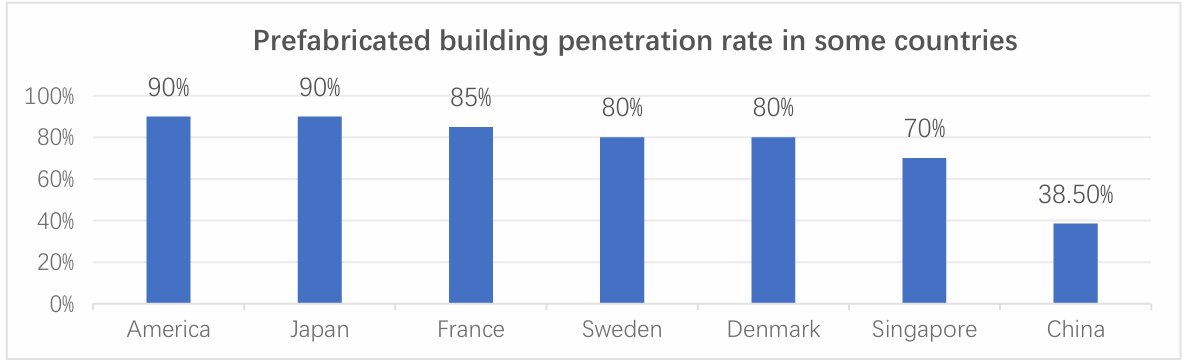

The penetration rate of prefabricated buildings in some countries is shown in Figure 1:

Figure 1: Prefabricated building penetration rate in some countries(Prospective Industry Research Institute)

2.3.Common problems in prefabricated concrete buildings

Although prefabricated concrete construction has broad development prospects in the world, it still faces some challenges, including cost control, technical difficulties, and a lack of professionals. Solving these problems requires the joint efforts of the government, enterprises and research institutions[13].

Firstly, in the actual construction of prefabricated concrete structures, there often exist disparities between the idealized assumptions made during the design phase and the realities encountered during construction. Designers operate under ideal conditions when formulating their plans, often overlooking various intricate circumstances that may arise on-site, such as technological limitations, environmental constraints, and material performance discrepancies. Consequently, this frequently gives rise to a discrepancy between design intent and actual implementation[10].

Secondly, prefabricated components rely on factory production; however, due to the extensive scale of production, lengthy assembly lines, and intricate interconnections among various stages, factories often encounter challenges in maintaining consistently high standards of quality control throughout each stage[14]. Consequently, this frequently results in performance variations across different batches of components. Additionally, during transportation and storage processes, prefabricated components are susceptible to environmental factors that can significantly impact their performance.

The presence of numerous construction links in prefabricated concrete structures indicates a strong level of professionalism. However, due to the lack of specialized skills and inadequate training, construction personnel often struggle to effectively address technical issues during construction operations, thereby increasing safety risks in the process.

Although prefabricated concrete structures can reduce certain environmental impacts in the production and construction process compared to traditional construction methods, waste disposal and energy consumption in the production process of prefabricated components may have negative impacts on the environment and need to be properly dealt with[14].

3.Improvement and optimization of prefabricated concrete construction technology

How to ensure the sustainable development of prefabricated concrete buildings can be done by taking the following measures:

3.1.Construction component production stage

Enhance the research and development initiatives for prefabricated concrete structures, focusing on improving structural integrity through innovative curing techniques or the utilization of high-performance materials[14]. Additionally, refine the production operational procedures and standardization system for prefabricated components by implementing a hybrid inspection approach that integrates both human expertise and machine assistance to significantly elevate the quality assurance rate of prefabricated components prior to their departure from the manufacturing facility.

Additionally, another avenue worth exploring is the utilization of high-performance materials in prefabricated concrete structures. This involves investigating advanced materials such as fiber-reinforced polymers (FRPs), ultra-high-performance concrete (UHPC), or self-healing materials that possess superior mechanical properties compared to traditional construction materials. Incorporating these high-performance materials into prefabrication processes can lead to stronger and more resilient structures capable of withstanding extreme loads or environmental conditions.

3.2.Construction and installation stage

The transportation of prefabricated components necessitates the implementation of protective measures. Depending on the factory's location, a judicious selection between maritime and terrestrial transport should be made to minimize component damage during transit.

Furthermore, employing Building Information Modeling (BIM) technology facilitates the creation of parametric models, enabling on-site simulations and virtual analyses that significantly enhance design efficiency while reducing error rates[15]. The use of Building Information Modeling (BIM) software can facilitate efficient design coordination between architects, engineers, and manufacturers while ensuring accurate fabrication specifications are met.

The design and construction of prefabricated structures represent a highly integrated engineering endeavor; thus, it is imperative to strengthen the professional training of operational personnel to elevate construction technology standards[12].

Moreover, collaboration among academia, industry professionals, and government agencies should be encouraged to foster a multidisciplinary approach towards advancing prefabricated concrete technology.

4.Conclusion

This paper presents an objective analysis of the advantages and disadvantages of prefabricated concrete buildings, followed by proposed strategies to enhance the prefabricated building system in light of various factors that impact its development. Prefabricated concrete building is a major change in the history of construction technology, and its promotion and development is the inevitable trend of the future development of the construction industry, which brings the opportunity for innovation and development for the construction industry.

Drawing on successful experiences from countries worldwide, such as policy support and BIM technology integration, this study aims to improve construction efficiency while ensuring quality and safety standards are met, ultimately promoting sustainable development within the construction industry. The paper exhibits certain limitations in terms of the diversity of case analysis and data, and falls short in providing a comprehensive discussion of its economic value and significance.

As related technologies continue to progress and innovate, it is expected that prefabricated concrete buildings will play an increasingly important role in shaping the future of construction. It is expected that in the future, the global innovation in prefabricated concrete technology and construction methods will continue.

References

[1]. KUANG Zhiping, FANG Xu, LI Jianbao. Development of housing industry in China[J]. Structural Engineers,2013,29 (3): 164-169.

[2]. Hou Jianguo. Design and Construction Technology Analysis of prefabricated concrete Structure for building [J]. China Real Estate Industry,2019(7):100-101. (in Chinese) DOI: 10.3969/j.issn.1002-8536.2019.07.076.

[3]. Clyde Zhengdao Li, Vivian WY. Tam, Mingcong Hu, Yijun Zhou, Lean construction management: A catalyst for evaluating and enhancing prefabricated building project performance in China, Journal of Building Engineering, Volume 94, 2024, 109930, ISSN 2352-7102, https://doi.org/10.1016/j.jobe.2024.109930.

[4]. Liu Ge, misia. Precast concrete building development and research status [J]. Architectural technology, 2020 ploidy (5) : 542-545. The DOI: 10.3969 / j.i SSN. 1000-4726.2020.05.008.

[5]. XieBo. Talk about prefabricated concrete structure design [J]. Construction of Shanxi Province, 2018, 44 (13): 57102. DOI: 10.3969 / j.i SSN. 1009-6825.2018.13.031.

[6]. Wang Xuejun. Research on Prefabricated Concrete Structure Construction Technology in Residential Building Engineering[J]. Residence Industry, 2024(5):14-16. DOI: 10.3969/j.issn.2095-4085.2024.05.006.

[7]. Qin Geng. Advantages and Applications of Prefabricated Concrete Structural Technology[J]. Building Materials and Decoration, 2018(19):25. DOI: 10.3969/j.issn.1673-0038.2018.19.018.

[8]. Zhao Qingyang, Liu Chang, Tian Lizhu, et al. Characteristics and Development of Prefabricated Buildings[J]. Concrete World, 2022(4):27-30. DOI: 10.3969/j.issn.1674-7011.2022.04.008.

[9]. Han Yun. Prefabricated construction development present situation at home and abroad research [J]. Journal of building materials and decoration, 2017 (45): 35. DOI: 10.3969 / j.i SSN. 1673-0038.2017.45.029.

[10]. Wang X J. (2024). Research on construction technology of prefabricated concrete structures in building engineering. Residential Industry (05), 14-16.

[11]. Lu Qiu. German prefabricated building standard specification and technical system [J]. Housing Industry,2017(6):19-26.

[12]. Qi Baobao, Zhang Yang. Research on Development Bottleneck and Countermeasures of prefabricated buildings [J]. Journal of Shenyang Jianzhu University (Social Science Edition),2015,17(02):156-159.

[13]. Cheng Shuanglin. Research on Key Technologies of Prefabricated Concrete Building Structure Construction[J]. Construction Engineering Technology and Design, 2023, 11(21): 4-6.

[14]. Wu Kun. (2024). Application of BIM technology in prefabricated concrete structure design. Building Materials Development Orientation,22(10),58-61.

[15]. Wang Hailong. Analysis of Common Quality Problems in Prefabricated Concrete Structures[J]. Railway Construction Technology, 2024(6):99-102,121. DOI: 10.3969/j.issn.1009-4539.2024.06.024.

Cite this article

Lan,S. (2025). The Discourse and Investigation Regarding the Advancement of Prefabricated Concrete Building Technology. Theoretical and Natural Science,79,139-144.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 4th International Conference on Computing Innovation and Applied Physics

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. KUANG Zhiping, FANG Xu, LI Jianbao. Development of housing industry in China[J]. Structural Engineers,2013,29 (3): 164-169.

[2]. Hou Jianguo. Design and Construction Technology Analysis of prefabricated concrete Structure for building [J]. China Real Estate Industry,2019(7):100-101. (in Chinese) DOI: 10.3969/j.issn.1002-8536.2019.07.076.

[3]. Clyde Zhengdao Li, Vivian WY. Tam, Mingcong Hu, Yijun Zhou, Lean construction management: A catalyst for evaluating and enhancing prefabricated building project performance in China, Journal of Building Engineering, Volume 94, 2024, 109930, ISSN 2352-7102, https://doi.org/10.1016/j.jobe.2024.109930.

[4]. Liu Ge, misia. Precast concrete building development and research status [J]. Architectural technology, 2020 ploidy (5) : 542-545. The DOI: 10.3969 / j.i SSN. 1000-4726.2020.05.008.

[5]. XieBo. Talk about prefabricated concrete structure design [J]. Construction of Shanxi Province, 2018, 44 (13): 57102. DOI: 10.3969 / j.i SSN. 1009-6825.2018.13.031.

[6]. Wang Xuejun. Research on Prefabricated Concrete Structure Construction Technology in Residential Building Engineering[J]. Residence Industry, 2024(5):14-16. DOI: 10.3969/j.issn.2095-4085.2024.05.006.

[7]. Qin Geng. Advantages and Applications of Prefabricated Concrete Structural Technology[J]. Building Materials and Decoration, 2018(19):25. DOI: 10.3969/j.issn.1673-0038.2018.19.018.

[8]. Zhao Qingyang, Liu Chang, Tian Lizhu, et al. Characteristics and Development of Prefabricated Buildings[J]. Concrete World, 2022(4):27-30. DOI: 10.3969/j.issn.1674-7011.2022.04.008.

[9]. Han Yun. Prefabricated construction development present situation at home and abroad research [J]. Journal of building materials and decoration, 2017 (45): 35. DOI: 10.3969 / j.i SSN. 1673-0038.2017.45.029.

[10]. Wang X J. (2024). Research on construction technology of prefabricated concrete structures in building engineering. Residential Industry (05), 14-16.

[11]. Lu Qiu. German prefabricated building standard specification and technical system [J]. Housing Industry,2017(6):19-26.

[12]. Qi Baobao, Zhang Yang. Research on Development Bottleneck and Countermeasures of prefabricated buildings [J]. Journal of Shenyang Jianzhu University (Social Science Edition),2015,17(02):156-159.

[13]. Cheng Shuanglin. Research on Key Technologies of Prefabricated Concrete Building Structure Construction[J]. Construction Engineering Technology and Design, 2023, 11(21): 4-6.

[14]. Wu Kun. (2024). Application of BIM technology in prefabricated concrete structure design. Building Materials Development Orientation,22(10),58-61.

[15]. Wang Hailong. Analysis of Common Quality Problems in Prefabricated Concrete Structures[J]. Railway Construction Technology, 2024(6):99-102,121. DOI: 10.3969/j.issn.1009-4539.2024.06.024.