1. Introduction

The waist is a crucial support area of the human body, bearing enormous pressure during daily activities such as standing, walking, and lifting heavy objects. Long-term high-intensity loads can easily lead to fatigue and injury of the waist muscles and bones. In industries such as industrial production and logistics, workers are required to perform bending and lifting actions for extended periods, which exert particularly great pressure on the waist. Occupational diseases such as lumbar disc herniation and lumbar muscle strain are common. For instance, China, India, and the United States significantly influence the quality of workers' lives and companies' productivity. The proportion of workers experiencing lumbar issues in the logistics, construction, and medical rehabilitation industries stands at 84%, 75%, and 67%, respectively [1,2]. This issue has escalated into a societal concern.

2. Literature review

2.1. Research status

To tackle this, numerous solutions have been proposed, with lumbar exoskeleton research standing out as particularly noteworthy. Data indicates that wearing an Assistive Lumbar Exoskeleton (ALE) can decrease lumbar spine muscle activity by up to 30%. The H-WEXv1 model uses a single actuator to aid in lifting heavy objects, effectively decreasing major muscle activities related to lumbar motion by 10% to 30%. In contrast, the H-WEXv2 (weighing 5.5 kg) employs a Series Elastic Actuator (SEA)-driven wire rope transmission system for enhanced performance. Meanwhile, the Robo-Mate (weighing 11.604 kg) offers lumbar support via elastic actuators, featuring a unique design that guarantees extensive freedom of movement without impeding daily activities. On the other hand, SIAT-WEXv1 utilizes two brushless motors equipped with harmonic drive gears as its power source and integrates a clutch mechanism for energy-efficient operation. Currently available exoskeletons often suffer from bulkiness, inconvenience in wearing, limited adaptability, ineffective assistance, and high costs [3-7].

2.2. Project goal

This paper endeavors to design a lightweight and user-friendly exoskeleton device, addressing these shortcomings, objectives of this project are as follows:

• Design and develop an ergonomic exoskeleton wearable power device based on the human body structure,

• Use electromyography (EMG), motion capture (IMU) technology and torque sensors to collect posture data, test joint torque and monitor waist muscle activity.

• Evaluate and analyze the application of exoskeleton devices with the help of multi-dimensional data collection.

3. Methodology

3.1. Introduction to mechanical principles

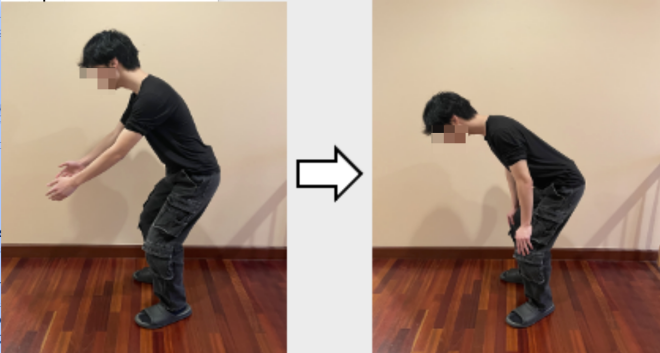

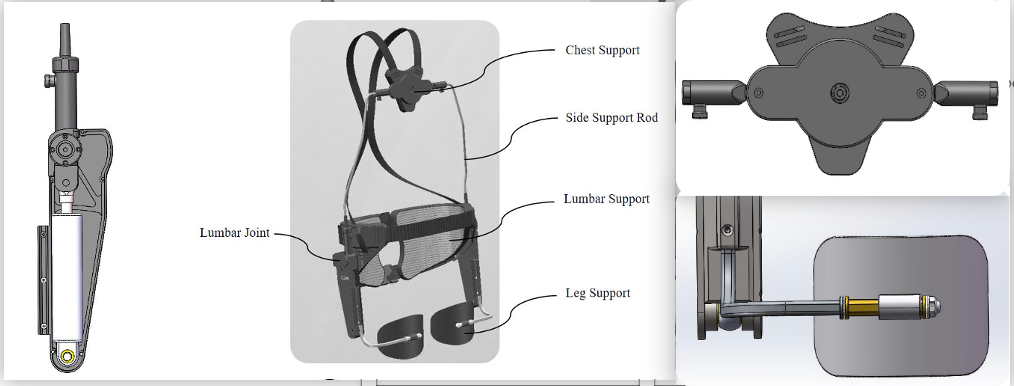

As shown in Figure 1(a), working in a forward bending position causes great pressure on the back. The exoskeleton supports the body weight and relies on the body's own knee bending force to transfer the force to the thigh, while the hands can move freely, and the pressure on the back is reduced.

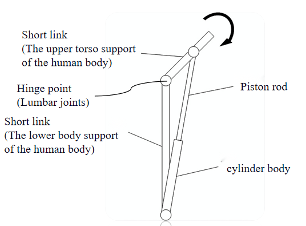

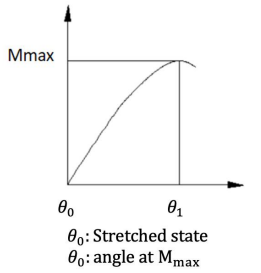

Drawing inspiration from this simple daily phenomenon, the waist joint of the exoskeleton is designed using a crank slider mechanism as shown in Figure 1(b). The gas spring connecting rod waist joint converts the linear motion of the cylinder into the rotational motion of the joint.

Figure 1. Structural analysis and design

3.2. Needs analysis

After analysis, the exoskeleton needs to have the following functions.When wearing it, the shoulder straps and waist belt can be adjusted to a comfortable tightness according to different body types. After putting it on, one can walk with a normal stride, and the waist can also twist normally without restriction.In the default mode, the exoskeleton lumbar does not provide support torque when the human body is upright, but begins to provide support when the body bends forward.

When the human body needs to walk for an extended period, the release buttons on both sides can be pressed to relieve the joint torque, allowing the person to walk with large strides quickly. When needing to squat down to pick up items from the ground, the release buttons can also be pressed to squat freely, and the device will automatically return to standing mode once the person stands up.

3.3. Medical research

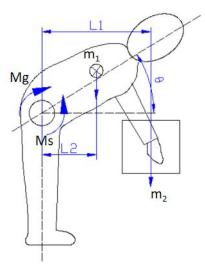

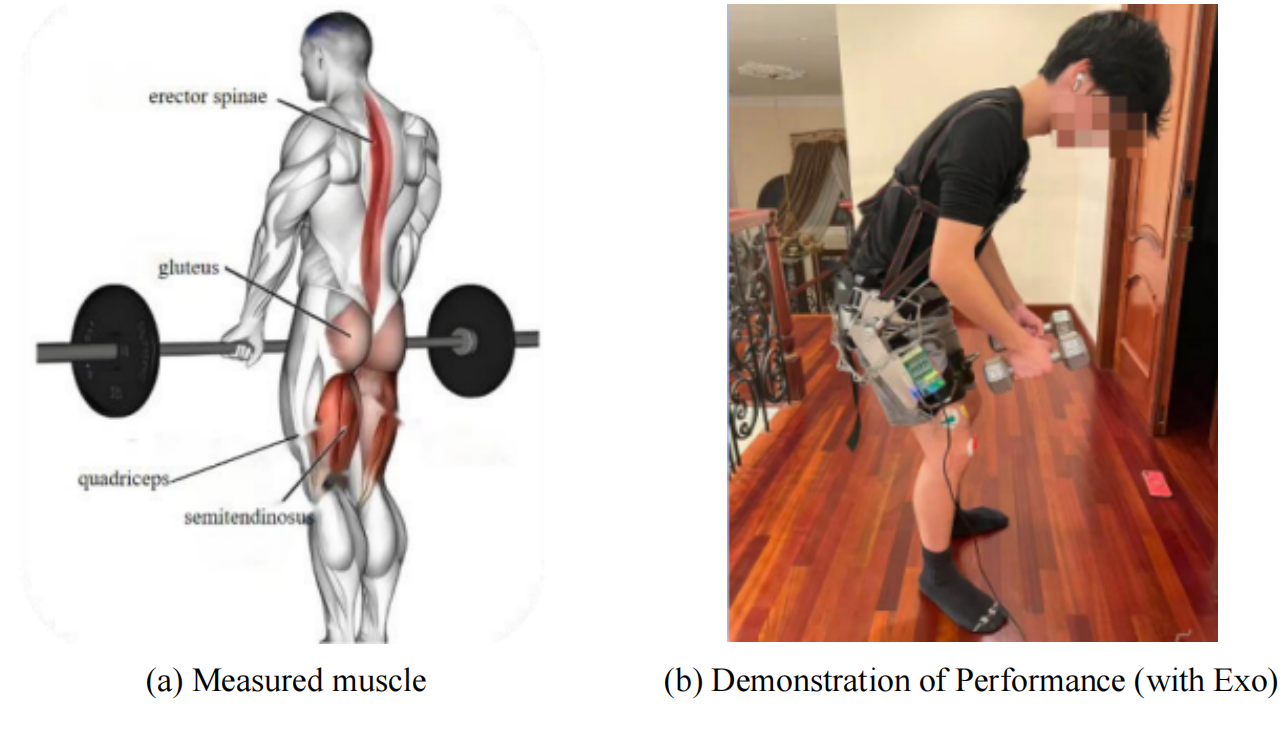

Gain insight into the structure and function of the lumbar spine bones, muscles, ligaments, and other tissues, and how they work together to support the various movements of the human lumbar spine. As shown in the figure 2, during forward bending, these four muscles of the body - erector spinae, gluteus maximus, semitendinosus, and quadriceps femoris - are significantly affected.

Electromyography (EMG) is the preferred method for assessing exoskeletons in research. Recently, several studies have measured the activation of specific muscles in participants performing repetitive weightlifting tasks [8,9]. Antwi-Afari et al. [10] distinguished the collected signals based on whether the weights were being lifted or loaded, and through data analysis, they compared the average activation values across different weights, finding a significant reduction in activation when the device was in use. Additionally, other studies have conducted EMG measurements in real-world working environments and calculated the differences [11,12]. These studies also observed significant variations, including decreased activity in the target muscles and increased activity in others. Although the movements in real-world scenarios are authentic, comparisons between different conditions may lack stringent control. In some cases, muscle activity measurements are taken to input data into EMG-driven spine models [13,14], facilitating further calculations such as joint tension estimates. This article utilizes motion capture (IMU) technology, torque sensors, and EMG sensors to collect posture data, test joint torque, and monitor lumbar muscle activity [15-18].

Figure 2. Forces acting on human movement

3.4. Mechanical design

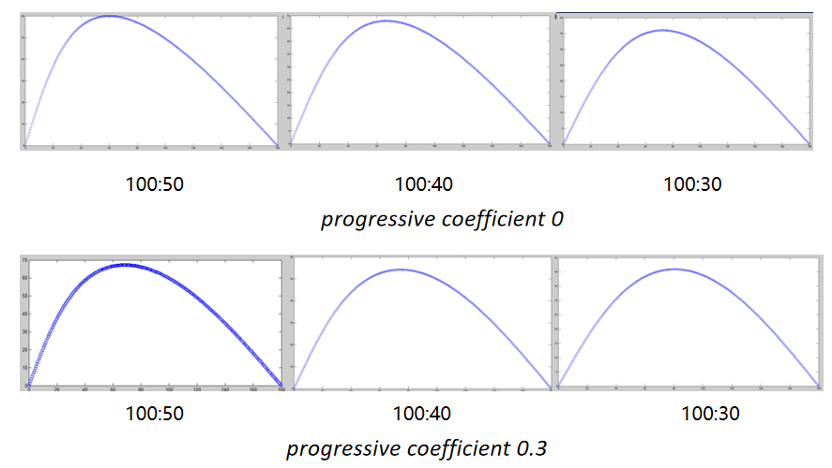

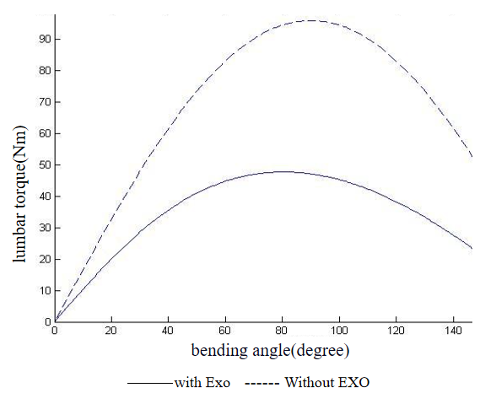

The mechanical design was created using SolidWorks to develop a 3D model of the exoskeleton, which features: a chest support for enhanced comfort and flexibility; a linkage slider mechanism that transforms rotational motion into linear motion to provide support during forward bending; adjustable straps to ensure a customized fit for various body types. The mechanical parts were primarily manufactured through CNC machining and 3D printing, and were ultimately assembled into a complete exoskeleton.A ball-joint back (or chest) support that can reduce leg constraints during walking and ensure even distribution of force on the back or chest contact surface.A leg support with left-right following capability has been designed to increase the lateral swing range of the thigh.As shown in Figure 3, By appropriately selecting the ratio of rod lengths and the progressive coefficient of the gas spring, a torque output that closely approximates a sine curve can be achieved. Additionally, the peak torque is approximately proportional to the length, as shown in Figure 4.

4. Testing and result

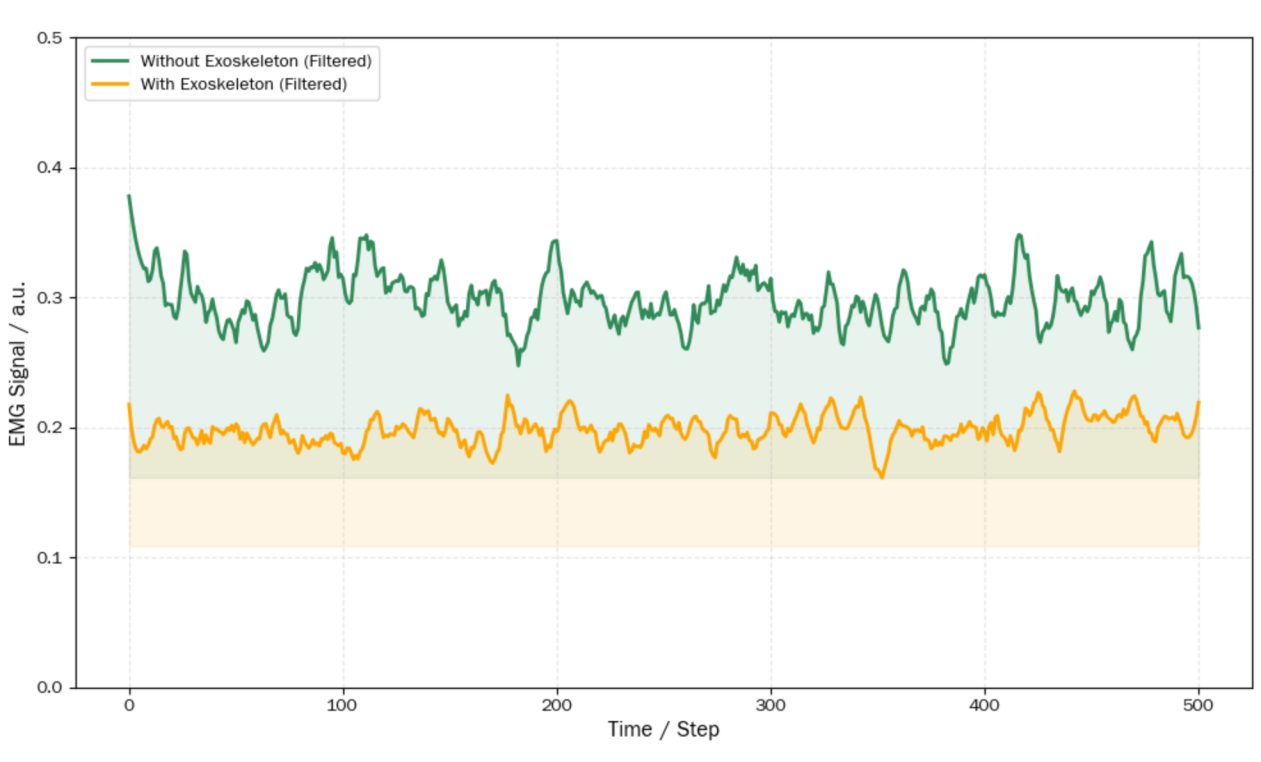

As shown in the figure 5, electromyography (EMG) sensors are mainly used to detect and quantify electrical signals generated by muscle activity, while inertial measurement units (IMUs) can measure angular changes. Combining EMG with IMU can test EMG signals at different angles; integrating torque sensors with IMU can measure torque at different angles.

Three participants were invited to participate in the exoskeleton test. Before each trial, the straps and mechanical devices were adjusted and the EMG/IMU connection was verified. Participants lifted 5 kg and 10 kg barbells, alternating between wearing and not wearing the exoskeleton, and rested for 15 minutes between each task to minimize fatigue. Lumbar joint torque was measured using a torque sensor or a tensiometer.

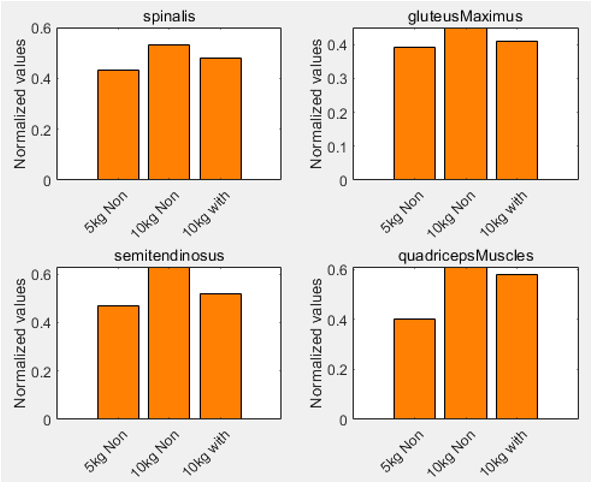

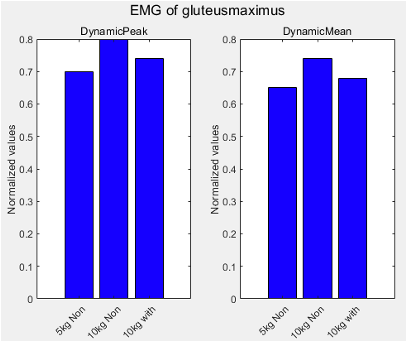

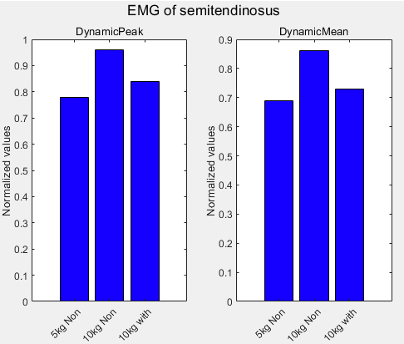

The muscle parts measured included the erector spinae, gluteus maximus, semitendinosus, and quadriceps femoris. Electrodes were attached to the four muscles to measure the EMG values. The EMG values of the muscles were measured under static and dynamic conditions, with and without the exoskeleton, and with loads of 5kg and 10kg, respectively, as shown in the figure 6.

The Root Mean Square (RMS) is the square root of the average power of a signal, reflecting the energy level of the signal. Therefore, RMS can be used as an indicator of muscle activation level.The calculation method for RMS is as follows.

|

Task phase |

Load weight |

Wearing condition |

Spinalis |

Gluteus maximus |

Semitendinosus |

Quadriceps muscles |

|

|

Static |

Mean EMG |

5kg |

Non-wearing |

0.42 |

0.39 |

0.47 |

0.40 |

|

10kg |

Non-wearing |

0.54 |

0.45 |

0.63 |

0.61 |

||

|

10kg |

Wearing |

0.49 |

0.41 |

0.53 |

0.58 |

||

|

Dynamic |

Peak EMG |

5kg |

Non-wearing |

0.78 |

0.70 |

0.78 |

0.66 |

|

10kg |

Non-wearing |

0.90 |

0.80 |

0.96 |

0.75 |

||

|

10kg |

Wearing |

0.82 |

0.74 |

0.84 |

0.72 |

||

|

Mean EMG |

5kg |

Non-wearing |

0.70 |

0.65 |

0.69 |

0.63 |

|

|

10kg |

Non-wearing |

0.84 |

0.74 |

0.86 |

0.72 |

||

|

10kg |

Wearing |

0.74 |

0.68 |

0.74 |

0.64 |

||

Figure 7. Torque at different angles and EMG values from different muscles

Figure 8. EMG values from dynamic testing of different muscles

From the experimental results shown in Table1,Figure 7 and Figure 8, it can be seen that the waist exoskeleton can provide about 30Nm of assistance, which meets the design goals. Electromyography (EMG) analysis showed a reduction in muscle activity, most notably in the erector spinae (11.6%) and semitendinosus (14.2%), followed by the gluteus medius (8.4%) and quadriceps femoris (6.2%). The lower EMG signal when wearing the exoskeleton confirms the reduction in muscle activation and fatigue. The dynamic peak EMG value is higher than the average due to the heavy load during the peak of the movement.

5. Conclusion

The main innovation of this study is the development of an exoskeleton waist protector based on myoelectric sensors, specifically for people with pain caused by waist diseases.

Motion capture (IMU) technology, torque sensors, and electromyography (EMG) sensors were used to collect posture data, test joint torque, and monitor lumbar muscle activity. Experimental data after actual testing showed that the exoskeleton can provide up to 32 Newton meters of assistance, significantly reducing the activity of the muscles: erector spinae (11.6%), gluteus maximus (8.4%), semitendinosus (14.2%) and quadriceps femoris (6.2%). These data show that muscle fatigue has been reduced, thus confirming that the exoskeleton has a significant effect in reducing the burden on the body.

In the future, the design can be further optimized in many aspects, such as making the waist joint exoskeleton design lighter. Adding entertainment functions to work and play. Implementing data transmission functions to record exoskeleton data in real time, facilitating adjustments and better adapting to each person. Equipped with motors and using artificial intelligence technology to make it more intelligent and form an intelligent ecosystem.

References

[1]. Ji, Xinyu, et al. "SIAT‐WEXv2: A Wearable Exoskeleton for Reducing Lumbar Load during Lifting Tasks." Complexity 2020.1 (2020): 8849427.

[2]. Arık, Ece. Investigation of the Effect of Spine Health Training and Lumbal Region Support on Back Pain and Discomfort in City Bus Drivers. MS thesis. 2024.

[3]. Zhang, Y.; Ke, J.; Wu, X.; Luo, X. A Biomechanical Waist Comfort Model for Manual Material Lifting. Int. J. Environ. Res. Public Health 2020, 17, 5948. https: //doi.org/10.3390/ijerph17165948

[4]. de Looze, M. P., Bosch, T., Krause, F., Stadler, K. S., & O’Sullivan, L. W. (2015). Exoskeletons for industrial application and their potential effects on physical work load. Ergonomics, 59(5), 671–681. https: //doi.org/10.1080/00140139.2015.1081988

[5]. L. Grazi, B. Chen, F. Lanotte, N. Vitiello and S. Crea, "Towards methodology and metrics for assessing lumbar exoskeletons in industrial applications, " 2019 II Workshop on Metrology for Industry 4.0 and IoT (MetroInd4.0& IoT), Naples, Italy, 2019, pp. 400-404, doi: 10.1109/METROI4.2019.8792877. keywords: {Exoskeletons; Electromyography; Task analysis; Muscles; Kinematics; Physiology; Exoskeletons; benchmarking; industry 4.0; metrics},

[6]. TANG Xinyao, LIU Xiaoyi, WANG Xupeng, HAO Yuyang, ZHANG Xinyi. Research Status and Key Technology Analysis of Wearable Lumbar Spine Exoskeleton [J]. INFORMATION AND CONTROL, 2025, 54(2): 161-183. CSTR: 32166.14.xk.2024.2422

[7]. Qu Y, Wang X, Tang X, Liu X, Hao Y, Zhang X, Liu H, Cheng X. A Review of Wearable Back-Support Exoskeletons for Preventing Work-Related Musculoskeletal Disorders. Biomimetics (Basel). 2025 May 20; 10(5): 337. doi: 10.3390/biomimetics10050337. PMID: 40422167; PMCID: PMC12108747.

[8]. Koopman, A.S.; Kingma, I.; Faber, G.S.; de Looze, M.P.; van Dieën, J.H. Effects of a passive exoskeleton on the mechanical loading of the low back in static holding tasks. J. Biomech. 2019, 83, 97–103.

[9]. Bosch, T.; van Eck, J.; Knitel, K.; de Looze, M. The effects of a passive exoskeleton on muscle activity, discomfort and endurance time in forward bending work. Appl. Ergon. 2016, 54, 212–217.

[10]. Antwi-Afari, M.F.; Li, H.; Anwer, S.; Li, D.; Yu, Y.; Mi, H.Y.; Wuni, I.Y. Assessment of a passive exoskeleton system on spinal biomechanics and subjective responses during manual repetitive handling tasks among construction workers. Safety Sci. 2021, 142, 105382.

[11]. Ochia, Ruth S., and Peter R. Cavanagh. "Reliability of surface EMG measurements over 12 hours." Journal of electromyography and Kinesiology 17.3 (2007): 365-371.

[12]. Cole, D. C., et al. "Multivariate, longitudinal analysis of the impact of changes in office work environments on surface electromyography measures." International archives of occupational and environmental health 85 (2012): 493-503.

[13]. Brouwer, Niels P., et al. "Can intermittent changes in trunk extensor muscle length delay muscle fatigue development?." Journal of Biomechanics 162 (2024): 111881.

[14]. NIU Miaohe, LEI Fei. Motion intention recognition algorithms for lower limb exoskeleton [J]. CAAI Transactions on Intelligent Systems, 2025, 20(2): 407-415. doi: 10.11992/tis.202403025

[15]. Lugrís, Urbano, et al. "Human motion capture, reconstruction, and musculoskeletal analysis in real time." Multibody System Dynamics 60.1 (2024): 3-25.

[16]. Taborri, Juri, et al. "Sport biomechanics applications using inertial, force, and EMG sensors: A literature overview." Applied bionics and biomechanics 2020.1 (2020): 2041549.

[17]. Shi, Yongjun, et al. "Human joint torque estimation based on mechanomyography for upper extremity exosuit." Electronics 11.9 (2022): 1335.

[18]. Zhou, Dong, et al. "A real-time posture assessment system based on motion capture data for manual maintenance and assembly processes." The International Journal of Advanced Manufacturing Technology 131.3 (2024): 1397-1411.

Cite this article

Hsu,R. (2025). Design and Evaluation of a Lightweight Lumbar Exoskeleton for Reducing Lumbar Load. Theoretical and Natural Science,139,81-89.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of ICBioMed 2025 Symposium: AI for Healthcare: Advanced Medical Data Analytics and Smart Rehabilitation

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Ji, Xinyu, et al. "SIAT‐WEXv2: A Wearable Exoskeleton for Reducing Lumbar Load during Lifting Tasks." Complexity 2020.1 (2020): 8849427.

[2]. Arık, Ece. Investigation of the Effect of Spine Health Training and Lumbal Region Support on Back Pain and Discomfort in City Bus Drivers. MS thesis. 2024.

[3]. Zhang, Y.; Ke, J.; Wu, X.; Luo, X. A Biomechanical Waist Comfort Model for Manual Material Lifting. Int. J. Environ. Res. Public Health 2020, 17, 5948. https: //doi.org/10.3390/ijerph17165948

[4]. de Looze, M. P., Bosch, T., Krause, F., Stadler, K. S., & O’Sullivan, L. W. (2015). Exoskeletons for industrial application and their potential effects on physical work load. Ergonomics, 59(5), 671–681. https: //doi.org/10.1080/00140139.2015.1081988

[5]. L. Grazi, B. Chen, F. Lanotte, N. Vitiello and S. Crea, "Towards methodology and metrics for assessing lumbar exoskeletons in industrial applications, " 2019 II Workshop on Metrology for Industry 4.0 and IoT (MetroInd4.0& IoT), Naples, Italy, 2019, pp. 400-404, doi: 10.1109/METROI4.2019.8792877. keywords: {Exoskeletons; Electromyography; Task analysis; Muscles; Kinematics; Physiology; Exoskeletons; benchmarking; industry 4.0; metrics},

[6]. TANG Xinyao, LIU Xiaoyi, WANG Xupeng, HAO Yuyang, ZHANG Xinyi. Research Status and Key Technology Analysis of Wearable Lumbar Spine Exoskeleton [J]. INFORMATION AND CONTROL, 2025, 54(2): 161-183. CSTR: 32166.14.xk.2024.2422

[7]. Qu Y, Wang X, Tang X, Liu X, Hao Y, Zhang X, Liu H, Cheng X. A Review of Wearable Back-Support Exoskeletons for Preventing Work-Related Musculoskeletal Disorders. Biomimetics (Basel). 2025 May 20; 10(5): 337. doi: 10.3390/biomimetics10050337. PMID: 40422167; PMCID: PMC12108747.

[8]. Koopman, A.S.; Kingma, I.; Faber, G.S.; de Looze, M.P.; van Dieën, J.H. Effects of a passive exoskeleton on the mechanical loading of the low back in static holding tasks. J. Biomech. 2019, 83, 97–103.

[9]. Bosch, T.; van Eck, J.; Knitel, K.; de Looze, M. The effects of a passive exoskeleton on muscle activity, discomfort and endurance time in forward bending work. Appl. Ergon. 2016, 54, 212–217.

[10]. Antwi-Afari, M.F.; Li, H.; Anwer, S.; Li, D.; Yu, Y.; Mi, H.Y.; Wuni, I.Y. Assessment of a passive exoskeleton system on spinal biomechanics and subjective responses during manual repetitive handling tasks among construction workers. Safety Sci. 2021, 142, 105382.

[11]. Ochia, Ruth S., and Peter R. Cavanagh. "Reliability of surface EMG measurements over 12 hours." Journal of electromyography and Kinesiology 17.3 (2007): 365-371.

[12]. Cole, D. C., et al. "Multivariate, longitudinal analysis of the impact of changes in office work environments on surface electromyography measures." International archives of occupational and environmental health 85 (2012): 493-503.

[13]. Brouwer, Niels P., et al. "Can intermittent changes in trunk extensor muscle length delay muscle fatigue development?." Journal of Biomechanics 162 (2024): 111881.

[14]. NIU Miaohe, LEI Fei. Motion intention recognition algorithms for lower limb exoskeleton [J]. CAAI Transactions on Intelligent Systems, 2025, 20(2): 407-415. doi: 10.11992/tis.202403025

[15]. Lugrís, Urbano, et al. "Human motion capture, reconstruction, and musculoskeletal analysis in real time." Multibody System Dynamics 60.1 (2024): 3-25.

[16]. Taborri, Juri, et al. "Sport biomechanics applications using inertial, force, and EMG sensors: A literature overview." Applied bionics and biomechanics 2020.1 (2020): 2041549.

[17]. Shi, Yongjun, et al. "Human joint torque estimation based on mechanomyography for upper extremity exosuit." Electronics 11.9 (2022): 1335.

[18]. Zhou, Dong, et al. "A real-time posture assessment system based on motion capture data for manual maintenance and assembly processes." The International Journal of Advanced Manufacturing Technology 131.3 (2024): 1397-1411.