1. Introduction

Because of the development of science and technology, drone technology is becoming increasingly sophisticated. Nowadays, drones are widely used for a variety of purposes, including water quality monitoring, power grid inspection, weather monitoring, and aerial photography for entertainment etc. Compared to traditional manual methods, drones have clear advantages in the field of meteorological monitoring, including high flexibility, strong adaptation, low cost, and no casualties [1]. These advantages allow drones to complete a variety of tasks in harsh weather conditions. When it comes to the rainy and typhoon seasons in China’s coastal regions, poor weather and typhoons frequently cause significant losses to the property of local citizens. Some of the issues that humans have had with weather detection are being gradually resolved with the introduction of drones. However, due to strong winds and poor weather conditions in the local coastal areas, the problem of endurance is more prominent when drones are performing their tasks.

There are several difficulties for drones in strong winds: The first one is the reduced flight stability. Strong winds negatively affect the flight stability of a drone. It may result in large variations in the drone’s flight speed, making the flight path unstable and it may even cause the drone to lose control and crash; The second one is the increased energy consumption: In windy weather, drones require more energy to counter strong winds and stabilize. This results in faster battery drain and shorter endurance; The third one is difficulty in data collection. Strong winds may cause the drone to be disturbed while collecting data, affecting the accuracy and completeness of the data [2].

Objective: In response to the above difficulties, methods such as using light materials and design, further upgrading batteries and making optimal planning of the flight path should be used.

2. Solutions

2.1. Lightweight material and design

Since the mass of the drones are reduced, they experience reduced air resistance that allows them to fly through turbulent air more efficiently. This efficiency directly impacts their energy consumption, allowing for longer flight times and increased endurance. Furthermore, a lighter drone is more agile and responsive, making it better equipped to counteract the effects of wind gusts [3].

Former research paper “Weight reduction of a drone using generative design”, they aim to apply a generative algorithm and design to minimize the weight of UAVs’ frame so that the UAVs can carry batteries with greater capacity without being heavier. The term “Generative Design” refers to using algorithms to generate and explore multiple design iterations based on specific requirements and constraints. By inputting parameters such as material properties, load conditions, and desired performance goals, the software can generate optimized designs that minimize weight while ensuring structural integrity. However, in their design, there are geometries which cannot be produced even by 6-axis robotic arms. Additive manufacturing, also known as 3D printing, can solve this problem. It offers unprecedented design freedom and complexity, allowing the creation of intricate geometries, internal structures, and organic shapes that may be challenging or even impossible to achieve with traditional manufacturing methods. This enables designers to optimize parts for specific functions, reduce weight, and consolidate multiple components into a single, integrated design. The software for design they use is Fusion 360. Its generative design algorithm is a powerful tool that utilizes artificial intelligence and computational algorithms to automatically generate optimized designs based on user-defined goals and constraints. The algorithm goes through a series of iterations, exploring various design options and evaluating their performance against the specified criteria [4].

With the optimized design of the structure and the advanced manufacturing technology of 3D printing, if the materials can be explored further, the overall weight of the drone can be reduced even more effectively. In some former research, composite materials are introduced. Composites are materials composed of two or more constituents, typically a matrix or binder and a reinforcer, which exhibit diverse physical or chemical characteristics. When these substances are mixed, the just created composite exhibits unique characteristics that differ from its individual components. The load-bearing capability is primarily provided by the fibers, accounting for 70-90% of the load, while the matrix imparts rigidity and shape to the composite. The matrix also transfers the load to the fibers and serves as a barrier, preventing or slowing down crack propagation by isolating the fibers, enabling them to act individually.

Optimizing the shape of composite plies, alongside response surface optimization, can work out a lightweight construction without taking into account microstructural failure restrictions. Modern computer systems effectively carry out this operation and empowers engineers to simultaneously adjust multiple parameters to receive an optimal design. The intricate and unconventional design of the drone body offers numerous possibilities for weight reduction while retaining its structural integrity. The utilization of additive manufacturing techniques with advanced composite materials proves to be highly effective in reducing the weight of UAVs [5].

2.2. Battery technology advancements

In Oh, T. H.’s research paper “Conceptual design of small UAV long-duration voyage with PEMFC system”, the author mentioned that there’s a variety of power sources for small UAVs. The low gravimetric energy density of conventional batteries is well known, and the inefficiency and noise of internal combustion engines. Solar cells, on the other hand, heavily rely on weather conditions. However, fuel cells offer a promising alternative with their improved energy density, efficiency, and much less noise. Out of several different kinds of fuel cell types, PEMFCs stand out due to their satisfied energy density and swift start-up response, making them particularly suitable for small UAVs. [2, 5].

According to BCC Research analyst Donald Saxman, the essential components of PEMFC comprise the anode, cathode, membrane, and catalyst. A PEMFC directly produces electricity from a fuel source, like hydrogen, and an oxidant. Hydrogen is an ideal energy source owing to its thermodynamic properties. Fuel cells based on hydrogen feed operate on an electrochemical reaction between hydrogen and oxygen, which does not pollute the environment with hydrocarbons or particulates and has no sulfur or nitrogen oxides. As fuel cells do not burn the fuel to generate heat, they offer higher efficiency than typical power generation processes. Two catalytic electrodes are located distinct from one another in the fuel cell by an ion-conductive membrane that functions as the electrolyte. One electrode ionizes the hydrogen, and the oxygen ions and hydrogen ions migrate across the membrane to mix on the other electrode’s surface. Saxman highlights that PEMFCs are compact, have a long operating life, quick startup, low-temperature operation, and high energy density, making them an attractive power source for drones or fuel cell-powered vehicles. Intelligent Energy’s range extender provides extended hours of drone flight time compared to the typical maximum of 20 minutes. In addition, fuel cells greatly decrease the downtime necessary for recharging between flights, reducing it from one to two hours to an average of two minutes [6].

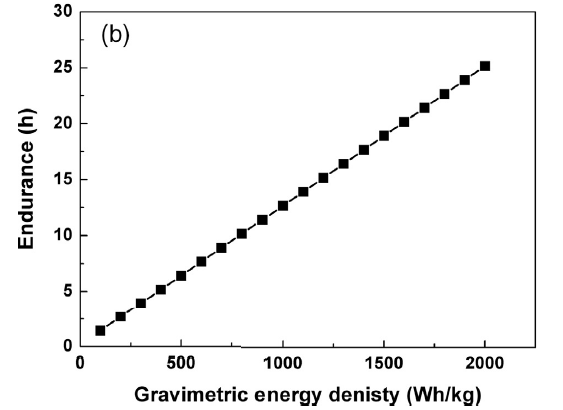

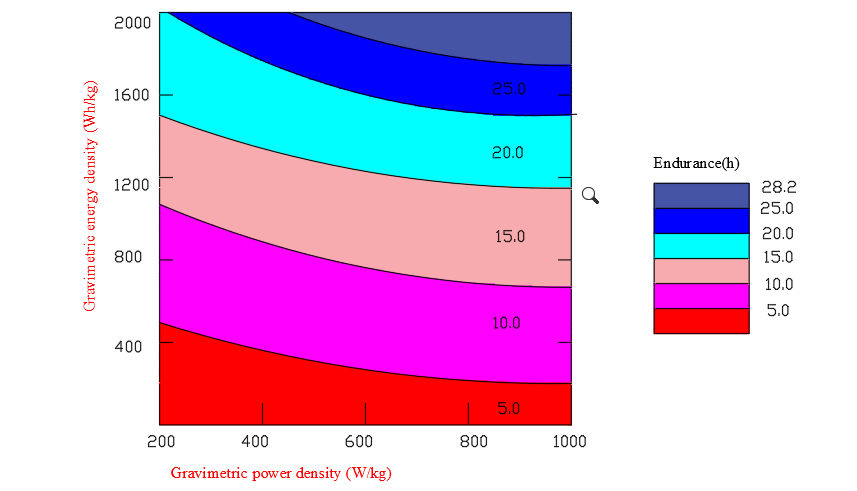

According to the paper, the performance of a small drone is heavily dependent on its densities of GPE of its PEMFC system, making them crucial factors. The fuel cell weight is subject to its GPD, while the gross system weight of storing the hydrogen is determined by its gravimetric energy density [7]. Figure 1 showed the effect of GPD and GED on range of the planned UAV. And, Figure 2 showed the range of the programmed UAV equipped with a system of PEMFC at different GPD and GED.

Figure 1. Effect of GPD and GED on range of the planned UAV: (a) Density of Gravimetric power and (b) Density of Gravimetric energy [8]

Figure 2. Range of the programmed UAV equipped with a system of PEMFC at different GPD and GED [9]

Based on the graphs, it is evident that the density of gravimetric energy of the system has a more significant impact on range compared to the fuel cell’s density of gravimetric power. By analyzing the endurance of UAVs with different power sources and varying combinations of GPD and GED, it becomes apparent that enhancing the density of gravimetric energy of the storage system for hydrogen can noticeably improve UAV range [10].

Other alternative battery technologies. Beyond traditional batteries, researchers have been investigating alternative energy storage options such as super-capacitors, hydrogen fuel cells, and solid-state batteries. Each of these technologies presents unique advantages and challenges, and their potential to offer longer flight times, improved performance in adverse weather, and reduced weight is of particular interest.

2.3. Coverage path planning

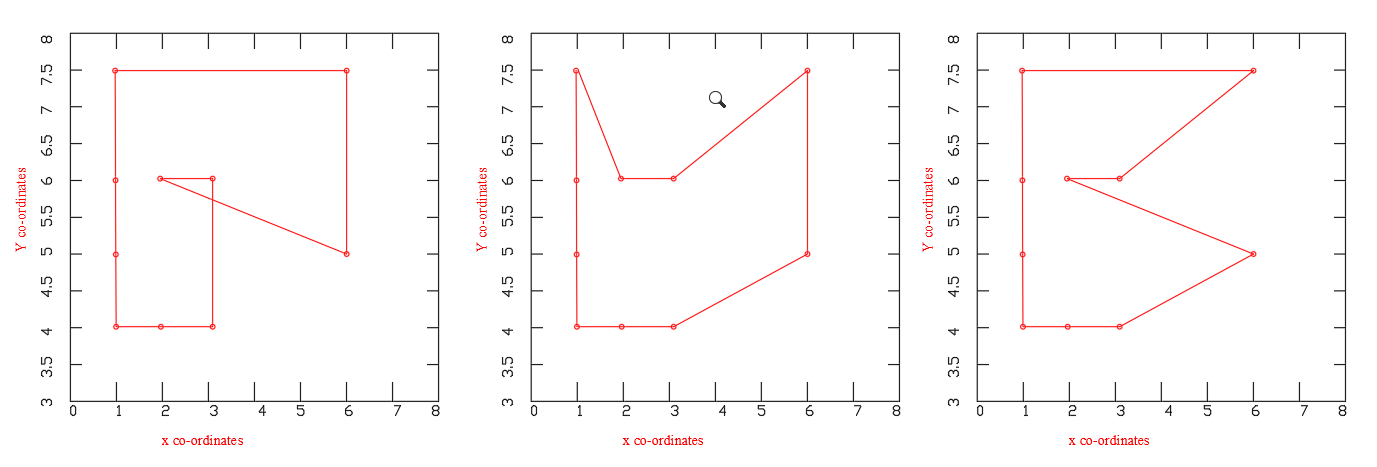

Flight planning for windy conditions. As this work mentioned before, windy days present unique challenges related to route optimization, altitude control, and obstacle avoidance. Therefore, flight planning must consider real-time wind data to calculate optimal flight paths, minimize energy consumption, and maintain stability. This work provided a drone path planning model taking account of the general energy consumed in accomplishing a job. The model of energy includes accelerating, decelerating, hovering and turning. The present study approached the problem of path planning for energy efficiency by formulating it as a variant of the classic traveling salesman problem. In this study, Programming through genetics was proposed to address the challenge of minimizing consumption of energy in drones by reducing the turns. The primary focus of this project was to minimize consumption of energy by decreasing the number of turns, as it was identified as a critical factor. To give a solution to the optimization problem, a genetic algorithm was proposed and implemented in MATLAB. The study demonstrated that the suggested algorithm is able to effectively reduce the energy consumed, particularly in areas with numerous waypoints [11]. Figure 3 showed the trajectory of a drone passing 10 waypoints in three different approaches. And, Table 1 and 2 showed the mean energy for genetic algorithm and greedy algorithmt, and their SD, respectively.

(a)GA with EO (b) GA with DO (c) Greedy algorithm with EO

Figure 3. The trajectory of a drone passing 10 waypoints was examined via three different approaches [11]

Table 1. The mean energy usage for 10 waypoints was computed for genetic algorithms and greedy algorithms

Algorithm | GA (EO) | GA (DO) | Greedy (EO) |

Energy consumed (KJ) | 1.877 | 2.201 | 2.076 |

Distance covered (m) | 19.123 | 15.739 | 20.984 |

Time consumed (sec) | 13 | 14 | 4 |

Table 2. The average energy usage of genetic algorithms, greedy algorithms, and their SD

No. of waypoints | GA(EO) | GA (DO) | Greedy (EO) | |||

Average | ±Std. deviation | Average | ±Std. deviation | Average | ± Standard deviation | |

10 | 1.877KJ | 0 | 2.20KJ | 0 | 2.076KJ | 0.199 |

25 | 26.304KJ | 2.65 | 28.826KJ | 8.972 | 57.727KJ | 16.483 |

50 | 58.740KJ | 7.91 | 67.336KJ | 16.508 | 160.218KJ | 80.534 |

100 | 826.790KJ | 44.80 | 1021.31KJ | 188.71 | 4362.8KJ | 1353.15 |

The results demonstrate that the GA proposed for the optimizing energy exhibits the lowest standard deviation and achieves minimal consumption of energy when compared to the GA utilizing DO and the greedy algorithm. Furthermore, compared to the greedy algorithm, the suggested GA with energy optimization can cut energy consumption by 2–5 times as the number of waypoints rises. The advantages of the suggested method are particularly notable in designing a larger network using coverage path planning when compared to the greedy algorithm [12].

3. Discussion

3.1. Synergies and trade-offs between different approaches’ combinations

3.1.1. Synergies. (a) Lightweight material design and battery technology advancements: Utilizing lightweight materials in drone construction reduces the overall weight, enhancing maneuverability and endurance, and it also helps in optimizing battery, as less power is required to lift and propel the drone. (b) Battery Technology Advancements and Flight Planning and path Optimization: Improved battery technology directly impacts flight planning and path optimization. With advancements in battery energy density, drones can carry more powerful batteries, resulting in longer flight endurance. This extended flight time allows for more flexibility in flight planning, enabling drones to cover larger distances or complete complex missions [13, 14]

3.1.2. Trade-offs and drawbacks. (a) Lightweight material design and battery technology Advancements: Advanced lightweight materials, carbon fiber material, for example, tend to be more expensive than traditional materials and these materials may be more susceptible to damage from crashes which requires careful handling and maintenance, or the endurance will get greatly decreased. Batteries with higher energy densities often have higher costs and may require additional safety measures. (b) Battery Technology Advancements and Flight Planning and path Optimization: flight planning and path optimization heavily rely on real-time data from sensors, such as GPS. These sensors greatly consume power, and it must be planned to sustain a balance between the power consumed by the sensors and the power available from the batteries. Efficient power management systems and algorithms are required to ensure that the sensors receive sufficient power while maximizing overall flight time.

4. Conclusion

Through a comparison of the three methods mentioned above, it can be observed that lightweight materials design, advanced batteries technology, and path planning all contribute to improving the endurance of unmanned aerial vehicles (UAVs) in strong wind conditions to some extent. However, each solution focuses on different aspects and yields varying benefits. Employing multiple solutions simultaneously can enhance the endurance of UAVs, but the weighting of different solutions should be determined based on specific application scenarios. This is because different scenarios have different concerns, such as endurance, payload capacity, maneuverability, communication capability, imaging capability, flight altitude, and controllability. With the continuous development of design and manufacturing capabilities, combined with advanced simulation technology, the future holds the potential for a more precise refinement of unmanned aerial vehicle (UAV) applications, thus providing the most effective solutions according to different usage scenarios. It is believed that with technological advancements, breakthroughs will be achieved in the field of UAV batteries. If it becomes possible to design advanced batteries with small volume yet high energy density, the endurance capability of UAVs will be significantly enhanced, enabling the development of a wider range of functionalities. This work possess a great enthusiasm for renewable energy and am wholeheartedly committed to the pursuit of developing a compact yet high-capacity energy storage solution.

References

[1]. Seregi, B. L., & Ficzere, P. (2021). Weight reduction of a drone using generative design. Hungarian Journal of Industrial Chemistry, 49(2), 19–22.

[2]. Oh, T. H. (2018). Conceptual design of small unmanned aerial vehicle with proton exchange membrane fuel cell system for long endurance mission. Energy Conversion and Management, 176, 349–356.

[3]. Stefanovic, M., & Yancey, R. (2010). Simulation driven weight optimization of a composite UAV spar using multiscale analysis.

[4]. Maričić, S., Haber, I. M., Veljovic, I., & Palunko, I. (2020). Implementation of optimal additive technologies design for unmanned aerial vehicle take-off weight increase. Eureka: Physics and Engineering, 6, 50–60.

[5]. Jain, N., Singh, R., & Karmakar, N. C. (2013). PEM Fuel cells: demand development and challenges. ResearchGate.

[6]. Anilkumar, G. M., Puneetha, N., Kumar, G. H., Palanisamy, K., & Gupta, A. (2020). Design and testing of proton exchange membrane fuel cell (PEMFC) power pack for platform vehicle. IOP Conference Series, 937, 012007.

[7]. Lee, C., Lee, S., & Chu, B. (2020). Extension of quadcopter flight range based on quadcopter transport system and autonomous ramp flight algorithm. IEEE Access, 8, 156422–156432.

[8]. Lussier, M. E., Detweiler, C., & Bradley, J. (2019). Extending Endurance of Multicopters: The Current State-of-the-Art. AIAA Scitech 2019.

[9]. Wang, J., Jia, R. Y., Liang, J., Chen, S., & Xu, Y. (2021). Evaluation of a small drone performance using fuel cell and battery; Constraint and mission analyzes. Energy Reports, 7, 9108–9121.

[10]. Sivakumar, M., & Tyj, N. M. (2021). A literature survey of unmanned aerial vehicle usage for civil applications. Journal of Aerospace Technology and Management, 13.

[11]. Dükkancı, O., Kara, B. Y., & Bektaş, T. (2021). Minimizing energy and cost in range-limited drone deliveries with speed optimization. Transportation Research Part C: Emerging Technologies, 125, 102985.

[12]. Ostojić, G., Stankovski, S., Tejić, B., Đukić, N., & Tegeltija, S. (2015). Design, control and application of quadcopter. International Journal of Industrial Engineering and Management, 6(1), 43–48.

[13]. Chu, T., Starek, M. J., Berryhill, J., Quiroga, C., & Pashaei, M. H. (2021). Simulation and characterization of wind impacts on SUAS flight performance for crash scene reconstruction. Drones, 5(3), 67.

[14]. Shivgan, R. and Dong, Z. Energy-Efficient Drone Coverage Path Planning using Genetic Algorithm, 2020 IEEE 21st International Conference on High Performance Switching and Routing (HPSR), Newark, NJ, USA, 2020, 1-6.

Cite this article

Gao,T. (2024). Improving the flight endurance of multi-rotor drones in windy days. Theoretical and Natural Science,30,86-92.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 3rd International Conference on Computing Innovation and Applied Physics

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Seregi, B. L., & Ficzere, P. (2021). Weight reduction of a drone using generative design. Hungarian Journal of Industrial Chemistry, 49(2), 19–22.

[2]. Oh, T. H. (2018). Conceptual design of small unmanned aerial vehicle with proton exchange membrane fuel cell system for long endurance mission. Energy Conversion and Management, 176, 349–356.

[3]. Stefanovic, M., & Yancey, R. (2010). Simulation driven weight optimization of a composite UAV spar using multiscale analysis.

[4]. Maričić, S., Haber, I. M., Veljovic, I., & Palunko, I. (2020). Implementation of optimal additive technologies design for unmanned aerial vehicle take-off weight increase. Eureka: Physics and Engineering, 6, 50–60.

[5]. Jain, N., Singh, R., & Karmakar, N. C. (2013). PEM Fuel cells: demand development and challenges. ResearchGate.

[6]. Anilkumar, G. M., Puneetha, N., Kumar, G. H., Palanisamy, K., & Gupta, A. (2020). Design and testing of proton exchange membrane fuel cell (PEMFC) power pack for platform vehicle. IOP Conference Series, 937, 012007.

[7]. Lee, C., Lee, S., & Chu, B. (2020). Extension of quadcopter flight range based on quadcopter transport system and autonomous ramp flight algorithm. IEEE Access, 8, 156422–156432.

[8]. Lussier, M. E., Detweiler, C., & Bradley, J. (2019). Extending Endurance of Multicopters: The Current State-of-the-Art. AIAA Scitech 2019.

[9]. Wang, J., Jia, R. Y., Liang, J., Chen, S., & Xu, Y. (2021). Evaluation of a small drone performance using fuel cell and battery; Constraint and mission analyzes. Energy Reports, 7, 9108–9121.

[10]. Sivakumar, M., & Tyj, N. M. (2021). A literature survey of unmanned aerial vehicle usage for civil applications. Journal of Aerospace Technology and Management, 13.

[11]. Dükkancı, O., Kara, B. Y., & Bektaş, T. (2021). Minimizing energy and cost in range-limited drone deliveries with speed optimization. Transportation Research Part C: Emerging Technologies, 125, 102985.

[12]. Ostojić, G., Stankovski, S., Tejić, B., Đukić, N., & Tegeltija, S. (2015). Design, control and application of quadcopter. International Journal of Industrial Engineering and Management, 6(1), 43–48.

[13]. Chu, T., Starek, M. J., Berryhill, J., Quiroga, C., & Pashaei, M. H. (2021). Simulation and characterization of wind impacts on SUAS flight performance for crash scene reconstruction. Drones, 5(3), 67.

[14]. Shivgan, R. and Dong, Z. Energy-Efficient Drone Coverage Path Planning using Genetic Algorithm, 2020 IEEE 21st International Conference on High Performance Switching and Routing (HPSR), Newark, NJ, USA, 2020, 1-6.