1.Introduction

Attempts at ferroelectric memories never stop. In the past decades, many materials have been chosen to make ferroelectric memories, like Barium magnesium fluoride, bismuth titanate, and gallium arsenide. However, those traditional materials faced many problems. The main problem is the difficulty in processing. Many traditional ferroelectric materials are incompatible with Complementary metal-oxide-semiconductor (CMOS) technology. In some procedures, the high oxygen concentration can lead to the formation of complex oxides, which are not the target substance and resulting in the decline of reliability. The ferroelectric materials annealing in the hydrogen atmosphere will also experience degradation due to the combination of hydrogen ions with the apical oxygen ion in the oxid, which can prevent the Ti ion from switching. The high annealing temperature is also a problem with normal ferroelectric materials. Many traditional ferroelectric materials need a high annealing temperature(>900°C) to get the best performance. However, in such temperature, the structure of poly-silicon grain will be badly influenced.

Another serious problem is the poor future of normal ferroelectric materials. Traditional ferroelectric materials are gradually approaching their theoretical limit. To downsize the ferroelectric components without losing functions, the 3D structure is a replacement for the planar structure. However, in 3D structures, the PZT materials perform badly due to the difficulty in controlling the polarization of PZT films on the sides on small scale. Due to the small bandgap of current PZT materials, decreasing the size of ferroelectric components can lead to higher leak current and make the component less reliable. Furthermore, to commercialize the ferroelectric memories, the FeRAMs need to be highly integrated, but the traditional ferroelectric materials like perovskite oxides are difficult to etch and deposit a specific intense 3-D structure. To be specific, due to the large size and volatility of Pb materials, it is difficult to adopt chemical vapor deposition and atomic layer deposition in the production of ferroelectric components using normal ferroelectric materials.

The turning point came in 2011. A German research group reported that the film made by SiO2 doped hafnium oxide exhibits ferroelectricity when the doping density and the annealing temperature meet some proper conditions.[1] Normally, the ferroelectricity of material comes from its crystal structure. A centrosymmetric structure is considered not ferroelectric, and on the contrary, the non-centrosymmetric structure can show ferroelectricity and can be polarized in certain conditions. In those structures, the center of positive and negative charges do not coincide, thus the material shows spontaneous polarization. When an electric field is applied to the material, the electrical dipole moment can be reversed, and such property is called ferroelectricity.

There are many factors that can influence the remnant polarization of the HfO2 material with dopants, such as the doping density, the kind of dopants, the thickness of the ferroelectric material film, and the material of the electrode, and the annealing temperature.

2.Dopants

There are many dopants such as Si, Zr, Y, La, Gd, Al, and Sr that can lead to ferroelectricity in hafnium oxide[2] [3] [4] [5] [6] [7] [8] [9] [10]. Among those dopants, Si and Zr are more preferred and studied by researchers. That’s because Si doping is studied early and therefore has to be learned a lot. For Zr materials, its high dopping range and performance attracted many research groups to learn more.

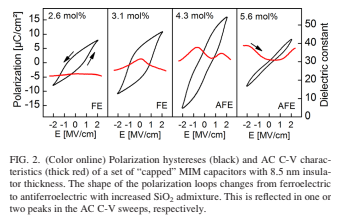

Si is the most common material in the semiconductor industry. The first research on hafnium oxide doping experiment and ferroelectricity chose Si as the dopant. In the research, the Si-doped HfO2 shows great ferroelectricity with remnant polarization between 10-15 μC/cm2, when the ferroelectric film was annealed at 500°C, with the thick of 5-10 nm, and with a doping concentration of 2.5–6 mol. % SiO2. According to the research data(Fig.1), the HSO layer shows increasing ferroelectricity as the concentration of dopants increases. After the concentration of dopants exceeds 4.3 mol. %, the SiO2 antiferroelectricity will gradually replace the ferroelectricity as the concentration continues to increase.[1] Since then, the HSO material has been studied wildly by researchers and put into applications in many aspects.

Figure 1.The remnant polarization of Hf1-xZrxO2 films with different dopants concentration[11].

Zr is another preferred element that is usually considered a dopant in the hafnium oxide. The compound is written as Hf1-xZrxO2 depending on the ratio of ZrO2 in it. Thanks to the massive application of ZrO2 in the MOSFET and DRAM manufacturing, it can be an ideal dopant material in the hafnium oxide.[12] The ferroelectricity of Hf1-xZrxO2 is highly affected by the concentration of ZrO2, in other words, the value of x in the compound. According to the experiment accomplished by Müller et al, when the value of x increases, the layer shows increasing ferroelectricity, and the polarization of the Hf1-xZrxO2 layer increases at the beginning and reaches its maximum roughly at x equal to 0.5, then the layer will gradually show its antiferroelectricity when x continues to increase[13].

Other dopants like Sr, Al, Y, etc. also induced ferroelectricity to hafnium oxide 插入文献. Those dopants produce polarizations between 15-20 μC/cm2 with a concentration from 5% to 10%. Some of those dopants also induced antiferroelectricity to the film, such as Al, and some of those dopants do not bring antiferroelectricity to the film, like Sr and Y[14]. Among those various dopant elements, some, like Si and Al, have a smaller atomic radius than Hf, thus they will stabilize the t-phase of HfO2; some like Y and Sr have a larger atomic radius than Hf, thus they will stabilize the c-phase of HfO2[15]. Zr is a little bit special because it has a similar atomic radius as Hf (155 nm).

Table 1. Ferroelectric characteristics of HfO2 with different dopants.

Dopants | Pr(μC/cm2) | Ec(MV/cm) | Endurance | Concentration(%) |

Si[2] | 12-24 | 1.0-2.5 | 106-108 | 4-6 |

Gd[3] | 12 | 1.75 | NA | 2 |

Zr[4] | 10-20 | 1.0-1.3 | >1010 | ~50 |

Al[5] | 7-21 | 3.6-4.4 | 104-107 | 6.5 |

Y[6] [7] | 10-24 | 1.2-3 | 105-108 | 5-5.2 |

Sr | 23 | 2.0 | >106 | 9.9 |

La[8] [9] | 17-25 | 1.0-3.0 | 109-1010 | 2.1-5 |

Ba [10] | 12 | 1.7 | NA | 7.5 |

Mg[10] | 3 | 1 | NA | 7.5 |

3.Thickness

The thickness of the film can effectively influence the polarization of the layer. Taking Hf1-xZrxO2 as an example, changing the thickness and stacking order of ZrO2 and HfO2 layers will result in significant differences in remnant polarization. When the thickness of the film increases, the interface confinement effect will be overcome by the bulk characteristics of the layer, and the remnant polarization will increase[16]. Increasing the thickness to 10 nm will result in a maximum polarization, and if we keep increasing the thickness to 25 nm, the polarization will decrease to 5 μC·cm-2, which is one-third of the maximum polarization at the thickness is 10 nm[17]. This phenomenon can be explained by the proportion of m-phase with the effect of average grain size. The thicker films will result in more m-phases and therefore weaker FE, especially when those films are manufactured with atomic layer deposition(ALD) [18] [19]. On the other side, thinner films will not always result in better performance. In normal conditions, the surface effect will significantly influence the formation of the t-phase if the thickness is less than a critical value.

Normally the surface boundary effect already occurred before the thickness decreased to 10 nm, so the films thinner than 10 nm won’t show better ferroelectricity. However, a research group developed ultra-thin Hf1-xZrxO2 films that show good ferroelectricity at 1nm. The Hf0.8Zr0.2O2 films are grown at the temperature of 250°C for 10 cycles and annealing at 500°C to produce a highly oriented noncentrosymmetric structure to keep the films have a steady FE[20].

4.Annealing and Electrodes

Normally, the material of electrodes and the annealing temperature both have significant impacts on the remnant polarization of the films. The mechanism of this effect can be explained by the different annealing temperatures and the different thermal expansion coefficients of different electrodes may result in different stress between films and electrodes. Those stress can change the crystal structure of the ferroelectric films, and when the value of the stress is in a proper interval, the crystal phases that lead to ferroelectricity will be formed, and then the films will show ferroelectricity.

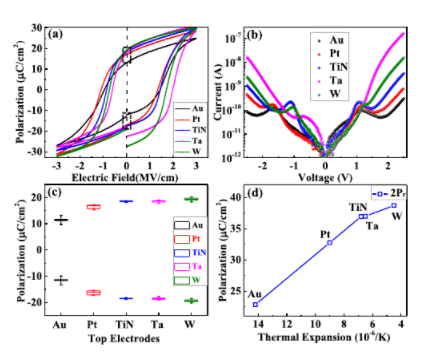

TiN is a common material to be used as electrode layers. Recent research shows that the Hf1-xZrxO2 films with TiN capping and annealed at the temperature of 400°C show great Pr, and this is because of a large amount of orthorhombic phase growth[11]. Capping electrode plays an important role in the formation of ferroelectricity of Hf1-xZrxO2 materials. But there is also research that shows that the TiN electrode can cause very few influences on the Hf1-xZrxO2 material and the remnant polarization is almost the same with and without a TiN cap. The group explained this phenomenon as the low annealing temperature of Hf1-xZrxO2 material and it does not induce a significant formation of m-phase[17]. Other materials can also be used as electrodes. Many other materials that can be used as an electrode for the annealing of normal semiconductor materials, like Pt and Au, usually have bad performance with Hf1-xZrxO2 films. For example, a research group uses Pt as the electrode and uses plasma atomic layer deposition without post-annealing to successfully get a thin ZrO2 film with ferroelectricity, and the remnant polarization is as high as 12 μC·cm-2[21]. However, the Pt electrode shows no advantages with Hf1-xZrxO2, compared with TiN.

Figure 2.The remnant polarization of Hf1-xZrxO2 films with different dopants[22].

The annealing temperature can also influence the ferroelectricity of the films significantly. To be more specific, the temperature can influence the structure of the crystal, so indifferent to annealing temperatures, the formation of the crystal phase can be different. Research shows that as the annealing temperature rise, the formation of the m-phase is increased. For example, the percentage of orthorhombic and tetragonal phases is 50% at the temperature of 500°C, and it will decrease close to 0 when the temperature raises to 1000°C[23].

The pressure during the annealing process also plays an important role in high polarization. Das etc. uses the material of 1:3 Hf: Zr ratio and utilizes the high-pressure post-metallization annealing method to get ferroelectric films with Pr of 29 µC·cm-2 which is much higher than such material of the same ratio under normal pressure, and even higher than normal 1:1 Hf: Zr material [24]. This phenomenon is caused by the formation of the o-phase at high pressure. Under normal pressure, the material tends to form more t-phase, but the raised pressure decreased the free energy of the o-phase, so the film will form more o-phase and show strong ferroelectricity. Hara etc. tried different pressure from 1 Pa to 1 atm, and find that the hafnium-zirconium dioxide films annealed in reduced pressure can introduce more stable orthorhombic phases and enhance the polarization. The best result appeared at the pressure of 100 Pa and start to decline over 1000 Pa, and the films crystallized at 100 Pa showed a good polarization of 20 µC·cm-2[25]. This phenomenon happens because of the lack of oxygen at low pressure and therefore makes the films form more orthorhombic phases.

5.Applications

The property of ferroelectric material makes it a good material in the application of non-volatile memories. There are two main applications of ferroelectric materials like hafnium oxide, one of them is the random access memory(RAM), and another is the field-effect transistor(FET).

As mentioned before, traditional eDRAMs are suffering from size limitations and SRAMs have high working power, and they are also volatile. Luo et al. successfully created a memory device with the HfZrO base that reached a size of 9 nm in width and 20 nm in length, and the device has a very good performance, including a switching speed of fewer than 20 ns, an operation voltage lower than 3 volts, and endurance over 1012 times[26].

Another main application is the field-effect transistor. Similarly, the traditional FETs are facing the challenge of size and performance. Traditional materials like the lead zirconate titanate(PZT) material usually have a size of 0.1 um to 1 um, and Shin et al. reported that the size of PZT FET can be thicker than 0.2 um [27]. However, Dünkel et al. have used the hafnium oxide material to make a fully functional FeFET with a size of 22 nm. According to their research, their fully depleted SOI technology is proven to be very successful, the endurance is at least 2×104 cycles, and can tolerate 300°C temperature for 1 hour [28].

6.Conclusion

In conclusion, important and recent development of material since 2011 have been reviewed in this article. Since Müller etc. found the important ferroelectricity in HfO2-based material, research about the FE property of HfO2-based material has been blooming. The non-centrosymmetric lattice structure formed during the manufacturing process contributes most to the ferroelectricity. There are many factors that can influence the remnant polarization, including dopants, film thickness, annealing pressure and temperature, and electrodes. For applications, FeFETs and FRAMs are the most-studied areas. FeFETs have advantages like low working power, non-volatile, and fast write/read speed. Although there are still problems with HfO2-based devices, like low endurance compared with SRAM and DRAM, there is still much to explore for HfO2-based materials, like high-density integration and low standby power. The huge potential of HfO2-based material will make great contributions to computers, electric cars, and other electric-relevant industries.

References

[1]. T. S. Böscke, J. Müller, D. Bräuhaus, U. Schröder, and U. Böttger, “Ferroelectricity in hafnium oxide thin films,” Applied Physics Letters, vol. 99, no. 10, pp. 102903, 2011.

[2]. X. Liu, D. Zhou, Y. Guan, S. Li, F. Cao, and X. Dong, “Endurance properties of silicon-doped hafnium oxide ferroelectric and antiferroelectric-like thin films: A comparative study and prediction,” Acta Materialia, vol. 154, pp. 190-198, 2018/08/01/, 2018.

[3]. U. Schroeder, S. Mueller, J. Mueller, E. Yurchuk, D. Martin, C. Adelmann, T. Schloesser, R. van Bentum, and T. Mikolajick, “Hafnium Oxide Based CMOS Compatible Ferroelectric Materials,” ECS Journal of Solid State Science and Technology, vol. 2, no. 4, pp. N69-N72, 2013.

[4]. S. J. Kim, J. Mohan, H. S. Kim, J. Lee, C. D. Young, L. Colombo, S. R. Summerfelt, T. San, and J. Kim, “Low-voltage operation and high endurance of 5-nm ferroelectric Hf0.5Zr0.5O2 capacitors,” Applied Physics Letters, vol. 113, no. 18, pp. 182903, 2018/10/29, 2018.

[5]. T.-J. Chang, C. Liu, C.-C. Fan, H.-H. Hsu, H.-H. Chen, W.-H. Chen, Y.-C. Fan, T.-M. Lee, C.-L. Lin, J. Ma, Z.-W. Zheng, C.-H. Cheng, S.-A. Wang, and C.-Y. Chang, “Investigation on polarization characteristics of ferroelectric memories with thermally stable hafnium aluminum oxides,” Vacuum, vol. 166, pp. 11-14, 2019/08/01/, 2019.

[6]. J. Müller, U. Schröder, T. S. Böscke, I. Müller, U. Böttger, L. Wilde, J. Sundqvist, M. Lemberger, P. Kücher, T. Mikolajick, and L. Frey, “Ferroelectricity in yttrium-doped hafnium oxide,” Journal of Applied Physics, vol. 110, no. 11, pp. 114113, 2011/12/01, 2011.

[7]. S. Starschich, S. Menzel, and U. Böttger, “Pulse wake-up and breakdown investigation of ferroelectric yttrium doped HfO2,” Journal of Applied Physics, vol. 121, no. 15, pp. 154102, 2017/04/21, 2017.

[8]. A. G. Chernikova, D. S. Kuzmichev, D. V. Negrov, M. G. Kozodaev, S. N. Polyakov, and A. M. Markeev, “Ferroelectric properties of full plasma-enhanced ALD TiN/La:HfO2/TiN stacks,” Applied Physics Letters, vol. 108, no. 24, pp. 242905, 2016/06/13, 2016.

[9]. T. Song, H. Tan, R. Bachelet, G. Saint-Girons, I. Fina, and F. Sánchez, “Impact of La Concentration on Ferroelectricity of La-Doped HfO2 Epitaxial Thin Films,” ACS Applied Electronic Materials, vol. 3, no. 11, pp. 4809-4816, 2021/11/23, 2021.

[10]. S. Starschich, and U. Boettger, “An extensive study of the influence of dopants on the ferroelectric properties of HfO2,” Journal of Materials Chemistry C, vol. 5, no. 2, pp. 333-338, 2017.

[11]. S. J. Kim, J. Mohan, S. R. Summerfelt, and J. Kim, “Ferroelectric Hf0.5Zr0.5O2 Thin Films: A Review of Recent Advances,” JOM, vol. 71, no. 1, pp. 246-255, 2019/01/01, 2019.

[12]. C. S. Hwang, Atomic Layer Deposition for Semiconductors, Newww York, 2014.

[13]. J. Müller, T. S. Böscke, U. Schröder, S. Mueller, D. Bräuhaus, U. Böttger, L. Frey, and T. Mikolajick, “Ferroelectricity in Simple Binary ZrO2 and HfO2,” Nano Letters, vol. 12, no. 8, pp. 4318-4323, 2012/08/08, 2012.

[14]. U. Schroeder, E. Yurchuk, J. Müller, D. Martin, T. Schenk, P. Polakowski, C. Adelmann, M. I. Popovici, S. V. Kalinin, and T. Mikolajick, “Impact of different dopants on the switching properties of ferroelectric hafniumoxide,” Japanese Journal of Applied Physics, vol. 53, no. 8S1, pp. 08LE02, 2014/07/10, 2014.

[15]. C.-K. Lee, E. Cho, H.-S. Lee, C. S. Hwang, and S. Han, “First-principles study on doping and phase stability of ${\text{HfO}}_{2}$,” Physical Review B, vol. 78, no. 1, pp. 012102, 07/03/, 2008.

[16]. Y. W. Lu, J. Shieh, and F. Y. Tsai, “Induction of ferroelectricity in nanoscale ZrO2/HfO2 bilayer thin films on Pt/Ti/SiO2/Si substrates,” Acta Materialia, vol. 115, pp. 68-75, 2016/08/15/, 2016.

[17]. M. Hyuk Park, H. Joon Kim, Y. Jin Kim, T. Moon, and C. Seong Hwang, “The effects of crystallographic orientation and strain of thin Hf0.5Zr0.5O2 film on its ferroelectricity,” Applied Physics Letters, vol. 104, no. 7, pp. 072901, 2014/02/17, 2014.

[18]. E. Yurchuk, J. Müller, S. Knebel, J. Sundqvist, A. P. Graham, T. Melde, U. Schröder, and T. Mikolajick, “Impact of layer thickness on the ferroelectric behaviour of silicon doped hafnium oxide thin films,” Thin Solid Films, vol. 533, pp. 88-92, 2013/04/30/, 2013.

[19]. M. Hyuk Park, H. Joon Kim, Y. Jin Kim, W. Lee, T. Moon, and C. Seong Hwang, “Evolution of phases and ferroelectric properties of thin Hf0.5Zr0.5O2 films according to the thickness and annealing temperature,” Applied Physics Letters, vol. 102, no. 24, pp. 242905, 2013/06/17, 2013.

[20]. S. S. Cheema, D. Kwon, N. Shanker, R. dos Reis, S.-L. Hsu, J. Xiao, H. Zhang, R. Wagner, A. Datar, M. R. McCarter, C. R. Serrao, A. K. Yadav, G. Karbasian, C.-H. Hsu, A. J. Tan, L.-C. Wang, V. Thakare, X. Zhang, A. Mehta, E. Karapetrova, R. V. Chopdekar, P. Shafer, E. Arenholz, C. Hu, R. Proksch, R. Ramesh, J. Ciston, and S. Salahuddin, “Enhanced ferroelectricity in ultrathin films grown directly on silicon,” Nature, vol. 580, no. 7804, pp. 478-482, 2020/04/01, 2020.

[21]. B.-T. Lin, Y.-W. Lu, J. Shieh, and M.-J. Chen, “Induction of ferroelectricity in nanoscale ZrO2 thin films on Pt electrode without post-annealing,” Journal of the European Ceramic Society, vol. 37, no. 3, pp. 1135-1139, 2017/03/01/, 2017.

[22]. R. Cao, Y. Wang, S. Zhao, Y. Yang, X. Zhao, W. Wang, X. Zhang, H. Lv, Q. Liu, and M. Liu, “Effects of Capping Electrode on Ferroelectric Properties of Hf0.5Zr0.5O2 Thin Films,” IEEE Electron Device Letters, vol. 39, no. 8, pp. 1207-1210, 2018.

[23]. H. A. Hsain, Y. Lee, G. Parsons, and J. L. Jones, “Compositional dependence of crystallization temperatures and phase evolution in hafnia-zirconia (HfxZr1−x)O2 thin films,” Applied Physics Letters, vol. 116, no. 19, pp. 192901, 2020/05/11, 2020.

[24]. D. Das, V. Gaddam, and S. Jeon, “Demonstration of High Ferroelectricity (Pr ~ 29 μ C/cm2) in Zr Rich HfxZr1-xO2 Films,” IEEE Electron Device Letters, vol. 41, no. 1, pp. 34-37, 2020. Y. Hara, Mohit, T. Murakami, S. Migita, H. Ota, Y. Morita, and E. Tokumitsu, “Impact of reduced pressure crystallization on ferroelectric properties in hafnium-zirconium dioxide films deposited by sputtering,” Japanese Journal of Applied Physics, vol. 60, no. SF, pp. SFFB05, 2021/07/23, 2021.

[25]. Q. Luo, T. Gong, Y. Cheng, Q. Zhang, H. Yu, J. Yu, H. Ma, X. Xu, K. Huang, X. Zhu, D. Dona, J. Yin, P. Yuan, L. Tai, J. Gao, J. Li, H. Yin, S. Long, Q. Liu, H. Lv, and M. Liu, "Hybrid 1T e-DRAM and e-NVM Realized in One 10 nm node Ferro FinFET device with Charge Trapping and Domain Switching Effects." pp. 2.6.1-2.6.4.

[26]. S. Shin, J.-M. Koo, S. Kim, B.-S. Seo, J.-H. Lee, H. Baik, Y. Park, H. Han, S. Baik, and J. K. Lee, “Fabrication of 3-Dimensional PbZr1−x Ti x O3 Nanoscale Thin Film Capacitors for High Density Ferroelectric Random Access Memory Devices,” Journal of Nanoscience and Nanotechnology, vol. 6, no. 11, pp. 3333-3337, //, 2006.

[27]. S. Dünkel, M. Trentzsch, R. Richter, P. Moll, C. Fuchs, O. Gehring, M. Majer, S. Wittek, B. Müller, T. Melde, H. Mulaosmanovic, S. Slesazeck, S. Müller, J. Ocker, M. Noack, D. A. Löhr, P. Polakowski, J. Müller, T. Mikolajick, J. Höntschel, B. Rice, J. Pellerin, and S. Beyer, "A FeFET based super-low-power ultra-fast embedded NVM technology for 22nm FDSOI and beyond." pp. 19.7.1-19.7.4.

Cite this article

You,H. (2023). Ferroelectric HfO2: A promising material for next-generation ferroelectric memory devices. Applied and Computational Engineering,7,1-7.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 3rd International Conference on Materials Chemistry and Environmental Engineering (CONF-MCEE 2023), Part II

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. T. S. Böscke, J. Müller, D. Bräuhaus, U. Schröder, and U. Böttger, “Ferroelectricity in hafnium oxide thin films,” Applied Physics Letters, vol. 99, no. 10, pp. 102903, 2011.

[2]. X. Liu, D. Zhou, Y. Guan, S. Li, F. Cao, and X. Dong, “Endurance properties of silicon-doped hafnium oxide ferroelectric and antiferroelectric-like thin films: A comparative study and prediction,” Acta Materialia, vol. 154, pp. 190-198, 2018/08/01/, 2018.

[3]. U. Schroeder, S. Mueller, J. Mueller, E. Yurchuk, D. Martin, C. Adelmann, T. Schloesser, R. van Bentum, and T. Mikolajick, “Hafnium Oxide Based CMOS Compatible Ferroelectric Materials,” ECS Journal of Solid State Science and Technology, vol. 2, no. 4, pp. N69-N72, 2013.

[4]. S. J. Kim, J. Mohan, H. S. Kim, J. Lee, C. D. Young, L. Colombo, S. R. Summerfelt, T. San, and J. Kim, “Low-voltage operation and high endurance of 5-nm ferroelectric Hf0.5Zr0.5O2 capacitors,” Applied Physics Letters, vol. 113, no. 18, pp. 182903, 2018/10/29, 2018.

[5]. T.-J. Chang, C. Liu, C.-C. Fan, H.-H. Hsu, H.-H. Chen, W.-H. Chen, Y.-C. Fan, T.-M. Lee, C.-L. Lin, J. Ma, Z.-W. Zheng, C.-H. Cheng, S.-A. Wang, and C.-Y. Chang, “Investigation on polarization characteristics of ferroelectric memories with thermally stable hafnium aluminum oxides,” Vacuum, vol. 166, pp. 11-14, 2019/08/01/, 2019.

[6]. J. Müller, U. Schröder, T. S. Böscke, I. Müller, U. Böttger, L. Wilde, J. Sundqvist, M. Lemberger, P. Kücher, T. Mikolajick, and L. Frey, “Ferroelectricity in yttrium-doped hafnium oxide,” Journal of Applied Physics, vol. 110, no. 11, pp. 114113, 2011/12/01, 2011.

[7]. S. Starschich, S. Menzel, and U. Böttger, “Pulse wake-up and breakdown investigation of ferroelectric yttrium doped HfO2,” Journal of Applied Physics, vol. 121, no. 15, pp. 154102, 2017/04/21, 2017.

[8]. A. G. Chernikova, D. S. Kuzmichev, D. V. Negrov, M. G. Kozodaev, S. N. Polyakov, and A. M. Markeev, “Ferroelectric properties of full plasma-enhanced ALD TiN/La:HfO2/TiN stacks,” Applied Physics Letters, vol. 108, no. 24, pp. 242905, 2016/06/13, 2016.

[9]. T. Song, H. Tan, R. Bachelet, G. Saint-Girons, I. Fina, and F. Sánchez, “Impact of La Concentration on Ferroelectricity of La-Doped HfO2 Epitaxial Thin Films,” ACS Applied Electronic Materials, vol. 3, no. 11, pp. 4809-4816, 2021/11/23, 2021.

[10]. S. Starschich, and U. Boettger, “An extensive study of the influence of dopants on the ferroelectric properties of HfO2,” Journal of Materials Chemistry C, vol. 5, no. 2, pp. 333-338, 2017.

[11]. S. J. Kim, J. Mohan, S. R. Summerfelt, and J. Kim, “Ferroelectric Hf0.5Zr0.5O2 Thin Films: A Review of Recent Advances,” JOM, vol. 71, no. 1, pp. 246-255, 2019/01/01, 2019.

[12]. C. S. Hwang, Atomic Layer Deposition for Semiconductors, Newww York, 2014.

[13]. J. Müller, T. S. Böscke, U. Schröder, S. Mueller, D. Bräuhaus, U. Böttger, L. Frey, and T. Mikolajick, “Ferroelectricity in Simple Binary ZrO2 and HfO2,” Nano Letters, vol. 12, no. 8, pp. 4318-4323, 2012/08/08, 2012.

[14]. U. Schroeder, E. Yurchuk, J. Müller, D. Martin, T. Schenk, P. Polakowski, C. Adelmann, M. I. Popovici, S. V. Kalinin, and T. Mikolajick, “Impact of different dopants on the switching properties of ferroelectric hafniumoxide,” Japanese Journal of Applied Physics, vol. 53, no. 8S1, pp. 08LE02, 2014/07/10, 2014.

[15]. C.-K. Lee, E. Cho, H.-S. Lee, C. S. Hwang, and S. Han, “First-principles study on doping and phase stability of ${\text{HfO}}_{2}$,” Physical Review B, vol. 78, no. 1, pp. 012102, 07/03/, 2008.

[16]. Y. W. Lu, J. Shieh, and F. Y. Tsai, “Induction of ferroelectricity in nanoscale ZrO2/HfO2 bilayer thin films on Pt/Ti/SiO2/Si substrates,” Acta Materialia, vol. 115, pp. 68-75, 2016/08/15/, 2016.

[17]. M. Hyuk Park, H. Joon Kim, Y. Jin Kim, T. Moon, and C. Seong Hwang, “The effects of crystallographic orientation and strain of thin Hf0.5Zr0.5O2 film on its ferroelectricity,” Applied Physics Letters, vol. 104, no. 7, pp. 072901, 2014/02/17, 2014.

[18]. E. Yurchuk, J. Müller, S. Knebel, J. Sundqvist, A. P. Graham, T. Melde, U. Schröder, and T. Mikolajick, “Impact of layer thickness on the ferroelectric behaviour of silicon doped hafnium oxide thin films,” Thin Solid Films, vol. 533, pp. 88-92, 2013/04/30/, 2013.

[19]. M. Hyuk Park, H. Joon Kim, Y. Jin Kim, W. Lee, T. Moon, and C. Seong Hwang, “Evolution of phases and ferroelectric properties of thin Hf0.5Zr0.5O2 films according to the thickness and annealing temperature,” Applied Physics Letters, vol. 102, no. 24, pp. 242905, 2013/06/17, 2013.

[20]. S. S. Cheema, D. Kwon, N. Shanker, R. dos Reis, S.-L. Hsu, J. Xiao, H. Zhang, R. Wagner, A. Datar, M. R. McCarter, C. R. Serrao, A. K. Yadav, G. Karbasian, C.-H. Hsu, A. J. Tan, L.-C. Wang, V. Thakare, X. Zhang, A. Mehta, E. Karapetrova, R. V. Chopdekar, P. Shafer, E. Arenholz, C. Hu, R. Proksch, R. Ramesh, J. Ciston, and S. Salahuddin, “Enhanced ferroelectricity in ultrathin films grown directly on silicon,” Nature, vol. 580, no. 7804, pp. 478-482, 2020/04/01, 2020.

[21]. B.-T. Lin, Y.-W. Lu, J. Shieh, and M.-J. Chen, “Induction of ferroelectricity in nanoscale ZrO2 thin films on Pt electrode without post-annealing,” Journal of the European Ceramic Society, vol. 37, no. 3, pp. 1135-1139, 2017/03/01/, 2017.

[22]. R. Cao, Y. Wang, S. Zhao, Y. Yang, X. Zhao, W. Wang, X. Zhang, H. Lv, Q. Liu, and M. Liu, “Effects of Capping Electrode on Ferroelectric Properties of Hf0.5Zr0.5O2 Thin Films,” IEEE Electron Device Letters, vol. 39, no. 8, pp. 1207-1210, 2018.

[23]. H. A. Hsain, Y. Lee, G. Parsons, and J. L. Jones, “Compositional dependence of crystallization temperatures and phase evolution in hafnia-zirconia (HfxZr1−x)O2 thin films,” Applied Physics Letters, vol. 116, no. 19, pp. 192901, 2020/05/11, 2020.

[24]. D. Das, V. Gaddam, and S. Jeon, “Demonstration of High Ferroelectricity (Pr ~ 29 μ C/cm2) in Zr Rich HfxZr1-xO2 Films,” IEEE Electron Device Letters, vol. 41, no. 1, pp. 34-37, 2020. Y. Hara, Mohit, T. Murakami, S. Migita, H. Ota, Y. Morita, and E. Tokumitsu, “Impact of reduced pressure crystallization on ferroelectric properties in hafnium-zirconium dioxide films deposited by sputtering,” Japanese Journal of Applied Physics, vol. 60, no. SF, pp. SFFB05, 2021/07/23, 2021.

[25]. Q. Luo, T. Gong, Y. Cheng, Q. Zhang, H. Yu, J. Yu, H. Ma, X. Xu, K. Huang, X. Zhu, D. Dona, J. Yin, P. Yuan, L. Tai, J. Gao, J. Li, H. Yin, S. Long, Q. Liu, H. Lv, and M. Liu, "Hybrid 1T e-DRAM and e-NVM Realized in One 10 nm node Ferro FinFET device with Charge Trapping and Domain Switching Effects." pp. 2.6.1-2.6.4.

[26]. S. Shin, J.-M. Koo, S. Kim, B.-S. Seo, J.-H. Lee, H. Baik, Y. Park, H. Han, S. Baik, and J. K. Lee, “Fabrication of 3-Dimensional PbZr1−x Ti x O3 Nanoscale Thin Film Capacitors for High Density Ferroelectric Random Access Memory Devices,” Journal of Nanoscience and Nanotechnology, vol. 6, no. 11, pp. 3333-3337, //, 2006.

[27]. S. Dünkel, M. Trentzsch, R. Richter, P. Moll, C. Fuchs, O. Gehring, M. Majer, S. Wittek, B. Müller, T. Melde, H. Mulaosmanovic, S. Slesazeck, S. Müller, J. Ocker, M. Noack, D. A. Löhr, P. Polakowski, J. Müller, T. Mikolajick, J. Höntschel, B. Rice, J. Pellerin, and S. Beyer, "A FeFET based super-low-power ultra-fast embedded NVM technology for 22nm FDSOI and beyond." pp. 19.7.1-19.7.4.