1. Introduction

When the emergence of the steam engine symbolized the beginning of the first industrial revolution, it brought great changes to industrial production. With the use of electricity and internal combustion engines, the second industrial revolution also stepped on the historical stage, and then the third industrial revolution, represented by information technology, completely changed people's lives. Now, this study is facing the arrival of the fourth Industrial Revolution, the arrival of Industry 4.0 [1][2].

Industry 4.0 is a deeply integrated and interconnected network of people, machines, and systems. Due to the increasingly fierce business competition environment, Industry 4.0 or industrial Internet is actively applied in all walks of life, as well as intelligent manufacturing, Internet of things, supply chain, and other scenarios, and more and more enterprises are trying to use new technologies to improve production efficiency [3]. However, in China, Industry 4.0 is still a new thing that has not been actively implemented [4], which includes the research and application of SC systems. The traditional SC network adopts the supply model of linear structure, which will lead to instability in the inventory management process and the manufacturer's inventory [5]. According to the critical indicators of inventory level, inventory cost, and order fulfillment proposed by Ghadge, the traditional supply chain management will lead to the instability of inventory level and cost, which requires more information sharing to make inventory stable. For order fulfillment, the lack of communication and information sharing in traditional supply chain leads to a backlog of orders and the loss of customers. At the same time, the traditional supply chain is inflexible, and most companies are faced with significant challenges in SC, accompanied by the problem of difficult delivery of orders, and it is difficult for enterprises to quickly respond to SC from unexpected shocks such as COVID-19 [6].

According to the above theoretical research and the current development status of China's Industry 4.0, the current academic research lacks practical analysis of the supply chain of the industrial Internet industry and lacks good models to analyze the supply chain of China's industrial Internet enterprises and platforms. This study will focus on the above issues, enrich the theoretical research content in the field of Industry 4.0 supply chain, and promote the development of industrial Internet platforms and industry.

Therefore, this paper studies whether the current environment of China's industrial Internet industry can implement Industry 4.0 in SC, and uses SC inventory and process planning suitable for Industry 4.0.

2. Literature review

For Industry 4.0, since Kagermann et al. [7] created the concept, with the study of related technologies and different application scenarios, Lee et al. [8] in their paper explored the implementation of information physical systems (CPS), which provide a framework for the connection between physical devices and networks. In addition to CPS, Monostori [9] has developed another system called the Information Physical Production System (CPPS), which can track the specific process of the manufacturing system. With the in-depth exploration of researchers in this field, Industry 4.0 has gradually been applied in many enterprises, and the research in this aspect is mainly based on cases. MajeedheRupasinghe [10] proposed that ERP systems can have a significant impact on warehousing and warehousing operations in inventory management, aiming at enterprise research in the shoe industry. This is a significant application of Industry 4.0 technology in common supply chain management. Meanwhile, research by Strange and Zucchella [11] suggests that the most significant applications of Industry 4.0 will occur in the areas of industrial manufacturing and management, logistics, and business process management.

In China, driven by national policies, enterprise competition, and new technologies, Industry 4.0 has emerged, which affects the digital transformation of enterprises. After the Chinese government issued several guidelines, Internet background enterprises Ali, Tencent, and so on began to form a preliminary industrial Internet system on the cloud platform[4]. The existing policy documents have less definition of the connotation of the industrial Internet, so intelligent manufacturing and industrial Internet are the names of Industry 4.0 in China. To promote the development of intelligent manufacturing, the Chinese government has introduced more standard system guidelines, tried to build an industrial Internet architecture, and applied related technologies of the industrial Internet around the supply chain, management system, and production system. In contrast, compared with the development and exploration of the global industry 4.0 field, China's industrial Internet has more excellent policy support. The research on this aspect of intelligent manufacturing mode is mainly based on cases. Because of the enterprise cases of industrial Internet platforms, Lv et al. [12] proposed that the legal norms of industrial Internet intelligent manufacturing should be improved, and the relevant standards were not established at the technical level. In the field of industrial Internet supply chain management, policy assistance is also needed to enable leading enterprises and SMEs to build a good ecology and better supply chain management processes.

Based on the summary and analysis of domestic and foreign research literature, it is evident that the current global research on Industry 4.0 primarily focuses on developing models suitable for different application scenarios. Researchers are also exploring the application of these models in digital factories and supply chain fields, leading to significant research outcomes. In China, the exploration and research in the industrial Internet field are mainly driven by government policies. Large leading enterprises are primarily focused on the practical application of intelligent manufacturing and production systems. Overall, the application of Industry 4.0 in the supply chain field has become pivotal.

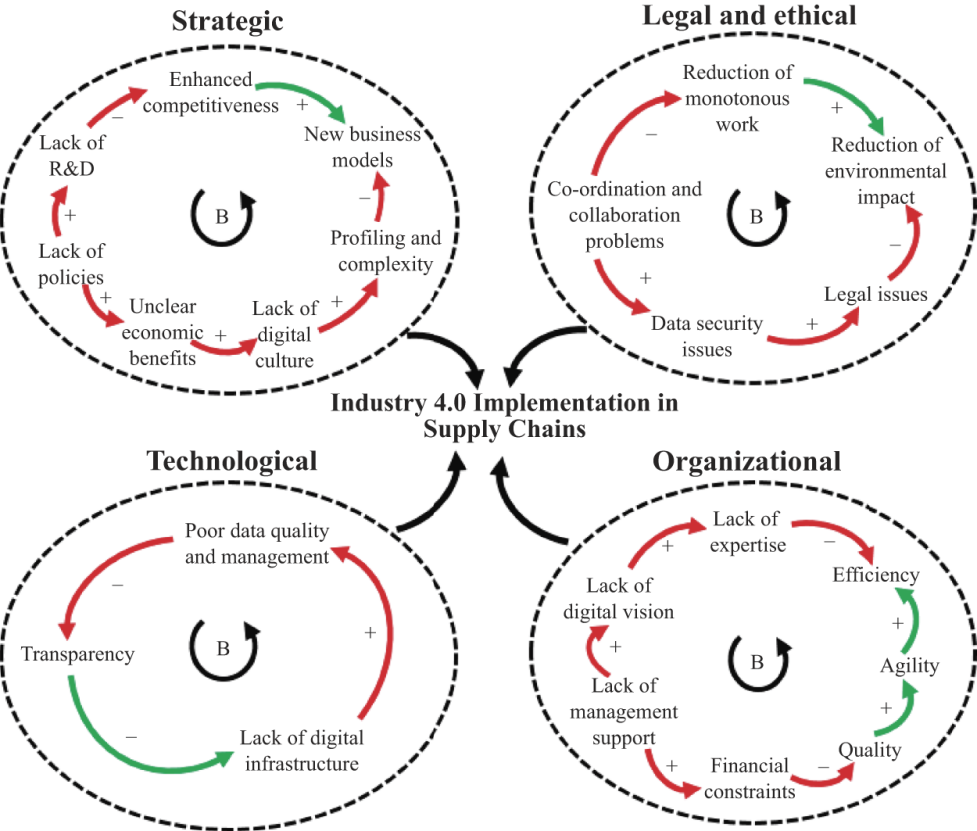

Analyzing the four factors of strategy, law and ethics, technology, and organization in China's industrial Internet industry, it is possible to assess the implementation of Industry 4.0 in different enterprise supply chains. This assessment can pave the way for digital transformation from traditional supply chains to more advanced and efficient Industry 4.0-enabled supply chains.

3. Research method

After establishing the research objectives, this study consulted the relevant materials of the supply chain in Industry 4.0 through libraries, archives and other channels to collect a large amount of information. It was found that the SD model designed by Abhijeet et al[5]. could well analyze the influence of different driving factors and obstacles in Industry 4.0. In this paper, the above model is combined with the status quo of China's industrial Internet industry to analyze whether the new industry 4.0 SC can be applied.

Through a comprehensive literature review, learn about the best models on a global scale and the corresponding analysis of the four factors that influence the implementation of Industry 4.0 in SC: strategy, law and ethics, technology and organization. At the strategic level, China's industrial Internet industry benefits from strong government support and continuous policy promotion, fostering a favorable environment for its development. This support ensures that enterprises are well-informed about the economic benefits of Industry 4.0, prompting them to invest significantly in research and development. As a result, the implementation of Industry 4.0 is made less complex due to the clarity and stability of the policy environment. This strategic alignment between government policy and industrial development underscores China's commitment to advancing its industrial Internet industry and embracing the principles of Industry 4.0.

In terms of law and ethics, there is a lot of cooperation and coordination among various enterprises in the industrial Internet industry. This collaboration is driven by the realization that most enterprises with a single background cannot meet all the functional requirements of the industrial Internet platform. Such cooperation not only enhances the overall functionality of the platform but also has a positive impact on data security and data ownership. Additionally, this collaboration reduces monotonous and repetitive work, as well as potential legal problems that may arise from the lack of cooperation. This trend underscores the industry's commitment to ensuring that legal and ethical considerations are paramount in the development and deployment of industrial Internet technologies.

At the technical level, many well-established enterprises are recognizing the imperative for digital transformation. This transformation involves the integration of digital technology into all areas of a business, fundamentally changing how businesses operate and deliver value to customers. However, a significant obstacle to this transformation is the lack of robust digital infrastructure. This infrastructure includes not only hardware and software but also the necessary data management processes and capabilities. Many enterprises are struggling to keep pace with the rapid advancements in digital technology, leading to an increasing demand for skilled professionals who can navigate this complex landscape. Additionally, the integration of digital technology requires significant investments in upgrading existing infrastructure and acquiring new technologies. This process can be costly and time-consuming, complicating the digital transformation journey.

Finally, on the organizational side, business management needs the best in the industry to explore the platform governance approach and the need for a digital vision, which leads to the inefficient adoption of Industry 4.0. Achieving successful digital transformation requires more than just implementing new technologies; it requires a fundamental shift in organizational mindset and culture. Business leaders must be willing to embrace change and foster a culture of innovation within their organizations. This includes investing in employee training and development to ensure that staff have the necessary skills to succeed in a digital environment.

In the course of comprehensive analysis, this study found that China's industrial Internet industry does face challenges in terms of technology and organization. On the technology side, digital transformation requires significant investment and technology updates, and some organizations may lack the resources and experience to meet these challenges. In addition, organizational difficulties also include cultural changes and management system adjustments within the company, which require long-term investment of time and resources.

However, despite these challenges, this study also sees positive factors in China's industrial Internet sector. The government's support and promotion at the policy level provide a solid foundation for the development of the industry. In addition, more and more enterprises are realizing the urgency of digital transformation and are beginning to invest more in exploring more efficient digital solutions.

Therefore, although the road ahead may be tortuous, on the whole, China's industrial Internet industry is developing in a positive direction. By overcoming technical and organizational difficulties, applying Industry 4.0 concepts to supply chain processes will bring more efficient, flexible and competitive operating models to enterprises, and help China's industrial Internet industry move towards a more prosperous future (see figure 1).

Figure 1: Brief introduction (Abhijeet et al.[5])

4. Result

The results of this comprehensive study indicate that the environment of China's industrial Internet industry has been analyzed meticulously, focusing on four key aspects: strategy, law and ethics, technology, and organization. Despite the presence of challenges at the organizational and technical levels, the overall assessment suggests that China's industrial Internet environment is robust and progressing positively. This bodes well for the effective integration of Industry 4.0 principles into the supply chain. In light of these findings, this study recommends that the industrial Internet industry in China adopt a new supply chain (SC) model. This model should integrate elements from both the traditional SC model and the SC model that emerge after the application of Industry 4.0 technologies. This integration will not only address current challenges but also ensure a seamless transition towards a more advanced and efficient supply chain ecosystem.

The emerging supply chain (SC) model represents a significant advancement, as it integrates cloud computing and Radio-Frequency Identification (RFID) technology into the traditional model. This integration offers substantial benefits by enhancing the dynamics of the supply chain through the utilization of Industry 4.0 principles. Specifically, cloud computing plays a pivotal role in various stages of the supply chain, including raw material storage, manufacturer storage, distributor storage, and more. It enables the real-time assessment of supply chain operations by providing access to critical data such as inventory levels and order fulfillment status. This integration not only improves the efficiency and transparency of the supply chain but also facilitates better decision-making and resource allocation.

The study highlights a thorough analysis of China's industrial Internet industry, focusing on strategy, law, technology, and organization. Despite challenges, the industry shows robustness and positive progress, indicating readiness for Industry 4.0 integration. The recommendation is to adopt a new supply chain model that combines traditional and Industry 4.0 elements. This model, integrating cloud computing and RFID, enhances supply chain dynamics, enabling real-time assessment and improving efficiency and decision-making.

5. Discussion

As to whether China's current industrial Internet industry has sufficient environmental conditions to implement the new SC system, this study analyze the environment of China's industrial Internet industry from the perspectives of strategy, law and ethics, technology, and organization. According to this study that China's current industrial Internet industry has some shortcomings at the technical and organizational levels, but overall, the industry has a suitable environment in which to implement new and innovative SC systems. This means that although the Industry 4.0 market is not preferred by Chinese enterprises, due to the government's financial support and policy support, and the mutual help and support between enterprises in the industrial Internet field, the industry environment is relatively excellent.

There are several limitations to consider in this study. Firstly, the selection of industrial Internet enterprises in China predominantly focuses on those with an Internet background, rather than encompassing industrial Internet platforms with backgrounds in ICT, data processing, and other related fields. This may limit the generalizability of the findings to a broader range of industrial Internet entities. Secondly, while the SD model designed by Abhijeet et al. provides a valuable framework, its applicability to the analysis of Industry 4.0 industries in all regions may be limited. Finally, the study lacks detailed technical and organizational data support, which could provide more comprehensive insights into the implementation and impact of Industry 4.0 in the industrial Internet sector.

Based on the comprehensive study conducted on China's industrial Internet industry and its readiness for integrating Industry 4.0 principles into the supply chain, several key recommendations emerge for future research and industry practice.

Firstly, the study underscores the importance of adopting a new supply chain model that blends traditional practices with emerging Industry 4.0 technologies. This model, as proposed, should integrate cloud computing and Radio-Frequency Identification (RFID) technology into the traditional supply chain model. Such integration enhances supply chain dynamics, enabling real-time assessment, and improving efficiency and decision-making.

Moreover, future research should focus on developing detailed integration models tailored to the specific challenges and opportunities faced by industrial Internet enterprises in China. These models should consider the unique characteristics of the Chinese market and regulatory environment to ensure their practical relevance and effectiveness.

Additionally, there is a need for in-depth case studies to examine the practical implementation of the proposed supply chain model. These case studies can provide valuable insights into the challenges and benefits of adopting Industry 4.0 technologies in the supply chain, helping to inform future industry practices.

Furthermore, researchers should consider expanding the analysis to include a broader range of industrial Internet enterprises, including those with backgrounds in ICT, data processing, and related fields. This broader perspective can help validate the findings and assess the generalizability of the proposed supply chain model.

Lastly, future research should investigate the technical and organizational challenges faced by industrial Internet enterprises in China in more detail. This includes examining issues such as digital infrastructure, data management processes, and organizational culture to identify specific areas where support and intervention are needed.

In conclusion, further research in these areas can contribute significantly to a better understanding of the opportunities and challenges of integrating Industry 4.0 principles into the supply chain in China. It can also help guide the development of strategies and policies to support this transition, ultimately driving the industrial Internet industry towards a more prosperous future.

6. Conclusion

China's industrial Internet industry is on the verge of a significant transformation as it embraces the principles of Industry 4.0. This revolution is characterized by a blend of traditional practices and cutting-edge technologies, promising enhanced operational efficiency and competitiveness. Despite facing challenges, such as technological and organizational obstacles, the industry's overall environment fosters innovation and growth. The integration of Industry 4.0 principles into China's industrial Internet sector is a complex process that requires collaboration, innovation, and strategic foresight.

The proposed supply chain model, combining traditional practices with emerging technologies, offers a pathway to improved efficiency and competitiveness. This model harmoniously integrates cloud computing and Radio-Frequency Identification (RFID) technology, enhancing supply chain dynamics, real-time assessment, efficiency, and decision-making. Future research should focus on developing detailed integration models tailored to the unique challenges and opportunities in China's industrial Internet landscape. By addressing these challenges and leveraging the potential of emerging technologies, China's industrial Internet industry can realize its full potential and lead the way in the Fourth Industrial Revolution. Despite the challenges, the industry is poised for a positive transformation, driven by a supportive policy environment and collaboration among enterprises. This transformation will not only enhance China's industrial Internet industry but also redefine global industrial production.

In conclusion, China's industrial Internet industry is at a critical juncture, poised for significant growth and innovation. By confronting challenges head-on and embracing emerging technologies, the industry can lead the Fourth Industrial Revolution and set new standards for industrial excellence on a global scale. The integration of Industry 4.0 principles into China's industrial Internet sector is a challenging but rewarding endeavor that promises to reshape the future of industrial production.

References

[1]. Dalenogare, L.S., Benitez, G.B., Ayala, N.F. and Frank, A.G. (2018), “The expected contribution of Industry 4.0 technologies for industrial performance”, International Journal of Production Economics, Vol. 204, pp. 383-394.

[2]. Frank, A.G., Dalenogare, L.S. and Ayala, N.F. (2019), “Industry 4.0 technologies: implementation patterns in manufacturing companies”, International Journal of Production Economics, Vol. 210, pp. 15-26.

[3]. Muhuri, P. K., Shukla, A. K. and Abraham, A. (2019) “Industry 4.0: A bibliometric analysis and detailed overview,” Engineering applications of artificial intelligence, 78, pp. 218–235. doi: 10.1016/j.engappai.2018.11.007.

[4]. Li X H. "Comparison of Global Industrial Internet Development." Gansu Social Sciences.06(2020):187-196. doi: 10.15891/j.cnki.cn62-1093/c.2020.06.027.

[5]. Ghadge, A. et al. (2020) “The impact of Industry 4.0 implementation on supply chains,” Journal of manufacturing technology management, 31(4), pp. 669–686. doi: 10.1108/jmtm-10-2019-0368.

[6]. Spieske, A. and Birkel, H. (2021) “Improving supply chain resilience through industry 4.0: A systematic literature review under the impressions of the COVID-19 pandemic,” Computers & industrial engineering, 158(107452), p. 107452. doi: 10.1016/j.cie.2021.107452.

[7]. Kagermann et al. (2011) Kagermann, H., W. Lukas and W. Wahlster, 2011: Industrie 4.0: Mit dem Internet der Dinge auf dem Weg zur 4. industriellen Revolution. VDI nachrichten, 13.

[8]. Lee, J., Bagheri, B. and Kao, H.-A. (2015) “A Cyber-Physical Systems architecture for Industry 4.0-based manufacturing systems,” Manufacturing letters, 3, pp. 18–23. doi: 10.1016/j.mfglet.2014.12.001.

[9]. Monostori, L., 2014. Cyber-physical production systems: Roots, expectations and R & D challenges. Proc. CIRP 17, 9–13.

[10]. Majeed, A. A., & Rupasinghe, T. D. (2017). Internet of things (IoT) embedded future supply chains for industry 4.0: An assessment from an ERP-based fashion apparel and footwear industry. International Journal of Supply Chain Management, 6(1), 25–40. Retrieved from https://core.ac.uk/download/pdf/230745642.pdf

[11]. Strange, R., & Zucchella, A. (2017). Industry 4.0, global value chains and international business. Multinational Business Review, 25(3), 174–184. doi:10.1108/mbr-05-2017-0028

[12]. Lv Wenjing, Chen Jin,and Liu Jin." Intelligent manufacturing model and enterprise platform construction of Industrial Internet: Based on the case study of Haier Group." China Soft Science.07(2019):1-13.

Cite this article

Liu,T. (2024). Toward Industry 4.0: A Study of China's Industrial Internet Industry and Its Readiness for Supply Chain Transformation. Advances in Economics, Management and Political Sciences,87,248-254.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2nd International Conference on Management Research and Economic Development

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Dalenogare, L.S., Benitez, G.B., Ayala, N.F. and Frank, A.G. (2018), “The expected contribution of Industry 4.0 technologies for industrial performance”, International Journal of Production Economics, Vol. 204, pp. 383-394.

[2]. Frank, A.G., Dalenogare, L.S. and Ayala, N.F. (2019), “Industry 4.0 technologies: implementation patterns in manufacturing companies”, International Journal of Production Economics, Vol. 210, pp. 15-26.

[3]. Muhuri, P. K., Shukla, A. K. and Abraham, A. (2019) “Industry 4.0: A bibliometric analysis and detailed overview,” Engineering applications of artificial intelligence, 78, pp. 218–235. doi: 10.1016/j.engappai.2018.11.007.

[4]. Li X H. "Comparison of Global Industrial Internet Development." Gansu Social Sciences.06(2020):187-196. doi: 10.15891/j.cnki.cn62-1093/c.2020.06.027.

[5]. Ghadge, A. et al. (2020) “The impact of Industry 4.0 implementation on supply chains,” Journal of manufacturing technology management, 31(4), pp. 669–686. doi: 10.1108/jmtm-10-2019-0368.

[6]. Spieske, A. and Birkel, H. (2021) “Improving supply chain resilience through industry 4.0: A systematic literature review under the impressions of the COVID-19 pandemic,” Computers & industrial engineering, 158(107452), p. 107452. doi: 10.1016/j.cie.2021.107452.

[7]. Kagermann et al. (2011) Kagermann, H., W. Lukas and W. Wahlster, 2011: Industrie 4.0: Mit dem Internet der Dinge auf dem Weg zur 4. industriellen Revolution. VDI nachrichten, 13.

[8]. Lee, J., Bagheri, B. and Kao, H.-A. (2015) “A Cyber-Physical Systems architecture for Industry 4.0-based manufacturing systems,” Manufacturing letters, 3, pp. 18–23. doi: 10.1016/j.mfglet.2014.12.001.

[9]. Monostori, L., 2014. Cyber-physical production systems: Roots, expectations and R & D challenges. Proc. CIRP 17, 9–13.

[10]. Majeed, A. A., & Rupasinghe, T. D. (2017). Internet of things (IoT) embedded future supply chains for industry 4.0: An assessment from an ERP-based fashion apparel and footwear industry. International Journal of Supply Chain Management, 6(1), 25–40. Retrieved from https://core.ac.uk/download/pdf/230745642.pdf

[11]. Strange, R., & Zucchella, A. (2017). Industry 4.0, global value chains and international business. Multinational Business Review, 25(3), 174–184. doi:10.1108/mbr-05-2017-0028

[12]. Lv Wenjing, Chen Jin,and Liu Jin." Intelligent manufacturing model and enterprise platform construction of Industrial Internet: Based on the case study of Haier Group." China Soft Science.07(2019):1-13.