1. Introduction

In the contemporary global economy, efficient logistics and supply chain management are critical for the competitiveness and sustainability of businesses. Effective logistics optimization ensures timely delivery of goods, reduces operational costs, and enhances customer satisfaction. As global trade volume grows, optimizing logistics operations has become increasingly important to manage the complex network of suppliers, manufacturers, and distributors. Also, logistics optimization is vital in mitigating environmental impacts by minimizing fuel consumption and reducing greenhouse gas emissions.

Despite advancements in logistics technology, the industry faces significant challenges in reducing fuel consumption and improving operational efficiency. Rising fuel prices and stringent environmental regulations compel logistics companies to find innovative solutions to cut costs and emissions. Traditional logistics operations often involve inefficiencies such as empty backhauls, sub-optimal routing, and poor load management. Addressing these challenges requires integrating advanced technologies and methodologies to streamline operations and maximize resource utilization.

Truck platooning and clustering are two innovative techniques gaining traction in logistics optimization. Truck platooning involves linking multiple trucks in a convoy, controlled by advanced driver-assistance systems and vehicle-to-vehicle (V2V) communication. This technique allows trucks to maintain close distances, reducing aerodynamic drag and improving fuel efficiency. Platooning enhances road safety and traffic flow by synchronizing vehicle movements [1, 2]. To ensure the truck platoon technique can maximize its performance, Zhou et al. developed a route planning approach based on a clustering algorithm [3]. Clustering refers to grouping delivery points based on geographic proximity and demand patterns. By employing clustering algorithms, logistics planners can identify optimal clusters for the truck fleet to operate, thus reducing overall distances and improving load consolidation and delivery times [4, 5].

This paper aims to provide a comprehensive overview of the integration of truck platooning and clustering algorithms in logistics path planning. It examines these areas' theoretical foundations, practical applications, and technological advancements. This review highlights key research findings, methodologies, and future directions by synthesizing existing literature and identifying research gaps. It offers insights into how these combined approaches can significantly enhance logistics efficiency and sustainability, discussing potential benefits, challenges, and future research and application direction for logistics companies considering these innovations.

2. Background of Truck Platooning

2.1. Definition and Concept

Truck platooning is a technology-driven approach where multiple trucks travel in a convoy or platoon, closely following each other at a consistent speed. In this system, the lead truck is controlled by a human driver, while the following trucks are connected via V2V communication systems, allowing them to mirror the lead truck’s movements with minimal delay. This step reduces the aerodynamic drag for the following trucks, resulting in improved fuel efficiency and reduced emissions [1, 6].

The primary benefits of truck platooning include:

(1) Fuel Efficiency: By reducing aerodynamic drag, platooning can significantly lower fuel consumption for the trucks in the convoy. Studies indicate fuel savings ranging from 5% to 15% [2, 6, 7].

(2) Reduced Emissions: Lower fuel consumption directly translates to reduced greenhouse gas emissions, contributing to environmental sustainability [1, 8].

(3) Safety Improvements: Platooning enhances road safety by reducing human error. The V2V communication systems enable precise and coordinated braking and acceleration, reducing the likelihood of accidents [2, 9].

2.2. Technological Requirements

Implementing truck platooning requires several key technologies:

(1) V2V Communication Systems allow the trucks in a platoon to exchange information in real time. Dedicated short-range communications (DSRC) or cellular networks transmit data about speed, braking, and acceleration, ensuring synchronized movements across the platoon [1, 10].

(2) Adaptive Cruise Control (ACC) and Cooperative Adaptive Cruise Control (CACC) are essential for maintaining safe and consistent distances between trucks in a platoon. ACC uses sensors and radar to monitor the distance to the vehicle ahead and adjust speed accordingly. CACC builds on ACC by incorporating V2V communication, enabling more precise control and coordination within the platoon [2, 9].

2.3. Current Research and Applications

Numerous case studies and pilot projects have demonstrated the feasibility and benefits of truck platooning. For example, the European Truck Platooning Challenge involved multiple truck manufacturers and logistics companies testing platooning technology across Europe. These trials highlighted significant fuel savings, reduced emissions, and positive safety outcomes [1, 6].

Recent research has provided valuable insights into the operational benefits and challenges of truck platooning. For instance, Alam et al. and Lammert et al. found that platooning can lead to considerable fuel savings and emission reductions. However, they also noted challenges, such as the need for robust V2V communication systems and regulatory frameworks to support widespread adoption [1, 2, 8].

3. Clustering Algorithms in Logistics

3.1. Introduction to Clustering Techniques

Clustering is a statistical data analysis method used to group similar data points. In logistics, clustering algorithms such as K-means, DBSCAN, and hierarchical clustering are pivotal for optimizing delivery routes and schedules.

The commonly used clustering algorithms include:

(1) K-means Clustering: K-means minimises the variance within clusters because it is known for its efficiency with large datasets. It is especially useful for its speed in segmenting large data sets into distinct, non-overlapping groups [11].

(2) DBSCAN: It identifies outliers and handles arbitrarily shaped clusters. It focuses on regions of high density, allowing it to discover clusters of varying shapes and sizes, which is particularly useful in geographical clustering [12].

(3) Hierarchical Clustering: It builds a dendrogram representing data arrangements in a hierarchical tree. This method is advantageous for detailed data analysis and finding precise relationships between data points, often used in scientific research to build taxonomies and classify species [13].

3.2. Applications in Logistics

Effective clustering directly contributes to optimizing logistics by enabling more precise grouping of delivery points, reducing travel distances and improving delivery services' efficiency. By applying clustering techniques, logistics operations can significantly decrease the number of miles driven, thereby reducing fuel costs and improving overall operational efficiency. Studies such as those by Ghaffari-Nasab et al. and Xie et al. have shown that clustering can substantially improve route planning and resource allocation in logistics settings, leading to more streamlined operations [4, 5].

3.3. Challenges and Limitations

While clustering provides numerous benefits, it also presents challenges, particularly in logistics applications. Logistics companies frequently handle vast amounts of data that clustering algorithms must process efficiently. Managing and analysing this data in real-time is crucial for the timely and effective delivery of services. Besides, as logistics networks expand, the scalability of clustering algorithms becomes critical. These algorithms must be able to perform under increasing data loads without a degradation in performance or speed.

4. Integration of Truck Platooning and Clustering for Route Planning

4.1. Conceptual Framework

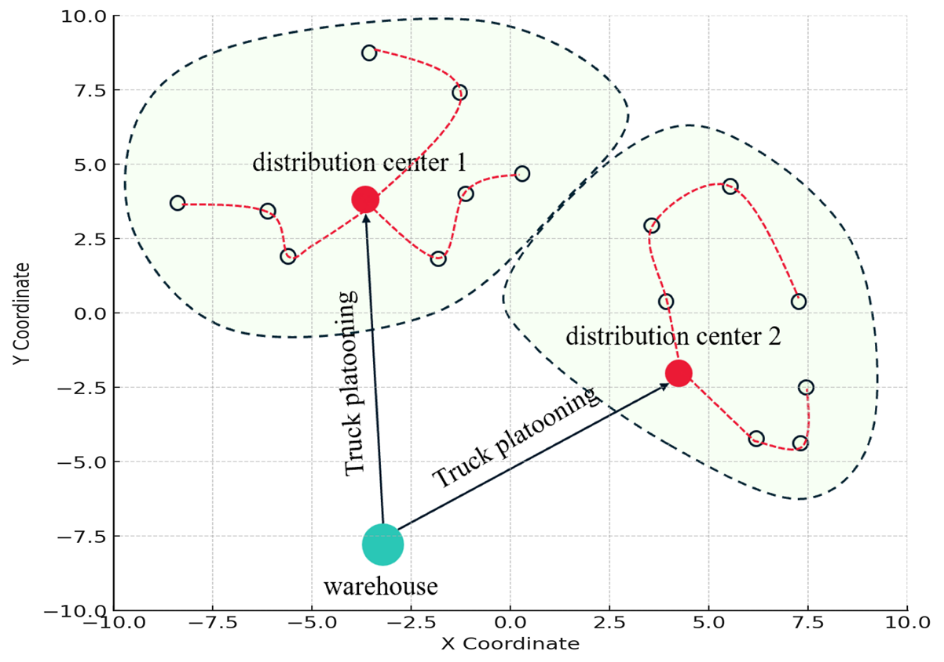

Combining clustering algorithms with truck platooning offers a significant advancement in logistics planning. The grouping of delivery points through clustering provides the distribution centers for trucks to use truck platooning better. Logistics operations can substantially improve fuel efficiency, emission reductions, and cost savings. The concepts are common across studies. For an operational route planning problem within a supply chain network that transports goods from factories to customers, the input data typically include the location coordinates of factories and customers, a road network model, and supply and demand information. To maximize the utility of the truck platooning technique, one integrates a clustering model to determine set points that extend the distance the truck fleet can cover throughout the journey. This path-planning method first partitions the customer coordinates and identifies the distribution center using a clustering algorithm. Subsequently, it employs the common shortest path model to plan the routes for the truck fleet and each truck or sub-fleet post-distribution separately.

Figure 1 shows the supply chain network under this route planning approach, including the factory, distribution centers, and customers, and the partitioning of customer regions.

Figure 1: The supply chain network under this route planning approach (Original Figure)

4.2. Methodologies

Recent studies have explored various methodologies to combine these techniques, demonstrating their potential in enhancing logistics operations. Chen et al. developed a multi-agent system where trucks dynamically form platoons based on real-time traffic and delivery requirements. Their approach employs machine learning algorithms to optimize platoon configurations and routes. The system can dynamically adjust the platoon formation and routing by integrating real-time data to respond to current traffic conditions and delivery demands. This methodology enhances logistics operations' efficiency and minimizes fuel consumption and emissions by maintaining optimal platoon configurations. The use of machine learning algorithms in this context highlights the potential for advanced technologies to improve the management of truck platoons in real-time significantly, making logistics operations more adaptive and efficient [14].

Building on this, Zhou et al. combined hierarchical clustering and path-planning algorithms to manage logistics from multiple distribution centers. Their study demonstrated how clustering can optimize the grouping of delivery points, while platooning can enhance delivery efficiency and reduce costs. By applying hierarchical clustering, Zhou et al. created optimal clusters of delivery points, which were then used to plan efficient delivery routes. The integration of platooning into these routes allowed truck platoons to form together, reducing aerodynamic drag and fuel consumption. This approach effectively synchronized clustered delivery routes with platooning, achieving significant improvements in logistics performance. The study provides a comprehensive framework for integrating clustering and platooning to optimize delivery operations from multiple distribution centers [3].

Ghaffari-Nasab et al. focused on an integrated approach for vehicle routing problems with time windows. They initially employed clustering algorithms to group delivery points and optimization algorithms to manage truck platoons. This study addressed the complexities of urban delivery by optimizing the routing and scheduling of truck platoons within specific time windows. By clustering delivery points based on proximity and time constraints, the methodology ensured that deliveries were grouped efficiently. The optimization algorithms then managed the formation and routing of truck platoons, leading to significant improvements in urban delivery efficiency. This approach reduced travel time and operational costs and minimized the environmental impact by optimizing fuel usage. The methodologies developed by Ghaffari-Nasab et al. are highly adaptable and can be extended to broader logistics contexts, demonstrating the versatility of integrating clustering and platooning in vehicle routing problems [4].

Hao et al. further investigated the integration of truck platooning within capacitated vehicle routing problems. This study provided valuable insights into truck fleets' dynamic scheduling and optimization. By incorporating clustering techniques to group delivery points and platooning strategies to manage the movement of truck fleets, the study highlighted the benefits of synchronizing these techniques. Based on current traffic conditions and delivery requirements, Hao et al. used dynamic scheduling algorithms to adjust truck routes and platoon formations in real-time. This methodology not only improved logistics operations' efficiency but also enhanced truck fleets' flexibility and responsiveness. The study represents a significant advancement in understanding the complexities of combining clustering and platooning in practical applications, providing a robust framework for optimizing logistics operations under varying conditions [15].

4.3. Case Studies and Results

Successful implementations of these integrated approaches have shown remarkable improvements in logistics operations. For instance, a European logistics provider utilized DBSCAN for regional clustering and genetic algorithms for route optimization, achieving a 12% annual reduction in fuel usage. Similarly, a North American transport company employed hierarchical clustering combined with a rule-based platooning strategy, resulting in a 15% reduction in delivery times and a 10% decrease in fuel consumption. These case studies illustrate the practical benefits of integrating clustering and platooning, including:

(1) Fuel Savings: Reports indicate fuel savings ranging from 10% to 20% due to more efficient route planning and reduced aerodynamic drag.

(2) Emissions Reduction: Significant reductions in CO2 emissions, typically around 15%, have been observed.

(3) Cost Efficiency: Operational costs have been reduced by up to 18% through better vehicle utilization and optimized routing.

The collective findings from these studies underscore the theoretical and practical benefits of combining truck platooning with clustering algorithms, paving the way for future advancements in logistics optimization.

5. Path Planning Algorithms in Integrated Systems

5.1. Overview of Path Planning Algorithms

Path planning is crucial in logistics to determine the most efficient routes for delivery vehicles. Classical algorithms such as Dijkstra, A*, and Bellman-Ford are widely used for their reliability in finding shortest paths in static networks, with Dijkstra’s algorithm being particularly effective for weighted graphs. However, for dynamic and real-time applications, A* provides improvements by using heuristics, while Bellman-Ford handles graphs with negative weights, though it is less efficient for purely positive weights.

Metaheuristic algorithms like Genetic Algorithm (GA), Ant Colony Optimization (ACO), and Particle Swarm Optimization (PSO) have gained prominence for their ability to handle complex, large-scale logistics problems. GA mimics natural selection processes, making it robust for solving the vehicle routing problem (VRP) with various constraints. Excel finds optimal paths by simulating pheromone trails, particularly useful in logistics optimization. PSO, modeled after the social behavior of birds, is noted for its simplicity and quick convergence, making it suitable for dynamic path planning.

5.2. Specific Applications in Truck Platooning and Clustering

Studies integrating path planning algorithms with truck platooning and clustering have demonstrated significant enhancements in logistics efficiency: Boysen et al. integrated clustering with ACO to optimize truck platooning in urban logistics, achieving substantial fuel savings and reduced operational costs. Their work emphasized the synergy between clustering delivery points and optimizing paths using ACO, resulting in efficient urban logistics operations [16].

Alam et al. combined real-time data clustering with genetic algorithms to optimize platoon formations and routes for heavy-duty vehicles. This integration led to notable improvements in fuel efficiency and emission reductions, showcasing the potential of real-time data integration with genetic optimization techniques [1]. Eren and Kilic applied PSO to dynamic vehicle routing, incorporating real-time traffic data and clustering to form efficient truck platoons. Their approach resulted in reduced travel times and costs, highlighting the effectiveness of PSO in adaptive logistics scenarios.

5.3. Comparative Analysis

Path planning algorithms differ in their efficiency, computational complexity, and scalability. Classical algorithms like Dijkstra and A* are efficient for static problems but can become computationally intensive in large-scale dynamic scenarios.

Metaheuristics such as GA, ACO, and PSO, though generally slower per iteration, offer faster convergence to optimal solutions in complex, real-world logistics environments. Metaheuristic algorithms also scale better with problem size due to their iterative nature and adaptability, making them more suitable for dynamic and large-scale logistics operations.

6. Challenges and Future Trends

6.1. Implementation Challenges

Despite these advancements, several implementation challenges remain. Technical challenges in V2V communication and synchronization are critical for effective platooning. Reliable V2V communication ensures that trucks in a platoon can maintain optimal spacing and coordination, essential for safety and efficiency. However, achieving this in diverse real-world environments with varying traffic conditions and infrastructure capabilities is complex [1].

Legal and regulatory issues also pose significant hurdles. Different regions have varying regulations regarding autonomous driving and platooning, which can complicate the deployment of these technologies on a global scale. Ensuring that these regulations keep pace with technological advancements is essential for the widespread adoption of platooning [6].

Operational challenges include coordinating clustered delivery points and dynamic re-routing based on real-time traffic data. Effective clustering can optimize delivery points, but real-time disruptions such as traffic jams or accidents require adaptive re-routing strategies. Studies like those by Eren and Kilic have shown the potential of using PSO for dynamic vehicle routing, but further refinement is needed to handle real-time data effectively.

6.2. Future Directions and Research Opportunities

The future of integrated truck platooning and clustering is promising, driven by AI and machine learning advancements. These technologies can enhance clustering and path planning by predicting traffic patterns, optimizing real-time routes, and improving decision-making processes [14].

Developing more robust and adaptive algorithms, capable of learning from new data and adjusting to changing conditions is crucial for the next generation of logistics solutions.

Emerging trends in autonomous driving technology will also impact platooning. Fully autonomous trucks can enhance the efficiency and safety of platoons by reducing human error and optimizing driving patterns. Integration with other logistics innovations, such as electric vehicles and drones, could improve sustainability and operational efficiency.

Several research gaps must be addressed to realize the full potential of integrated truck platooning and clustering. One area needing further investigation is the development of algorithms that can handle the scalability and complexity of real-world logistics networks. While metaheuristic algorithms like GA and ACO have shown promise, their application in large-scale, dynamic environments requires further exploration [16].

More research is needed to address the legal and regulatory challenges associated with autonomous platooning. Establishing international standards and guidelines will be critical for the global deployment of these technologies [6]. Finally, integrating emerging technologies, such as AI, machine learning, and autonomous driving, with traditional logistics practices presents opportunities and challenges that require comprehensive study [14].

The implications of integrating truck platooning and clustering for the logistics industry are profound. These technologies can significantly enhance logistics efficiency, reduce operational costs, and improve sustainability. By optimizing routes and reducing fuel consumption, they contribute to lower emissions and a smaller carbon footprint, aligning with global sustainability goals.

In conclusion, integrating truck platooning and clustering algorithms represents a transformative approach to logistics optimization. The advancements and methodologies discussed in this review highlight these technologies' potential benefits and challenges. Continued research and innovation in this field are essential to overcome existing challenges and fully realize the benefits of these integrated systems. Encouraging interdisciplinary collaboration and leveraging emerging technologies will be key to driving future advancements and achieving sustainable logistics solutions.

7. Conclusions

Integrating truck platooning and clustering algorithms represents a transformative approach to logistics optimization. This paper has highlighted significant advancements by various studies, demonstrating how these methodologies can enhance supply chain efficiency, reduce operational costs, and improve sustainability.

The logic behind combining these techniques lies in the ability of clustering algorithms to divide a specific area into zones, each with a distribution center. This setup extends the distance truck fleets can travel together in platoon formation, thus maximizing the environmental and operational benefits. By maintaining optimal platoon configurations over longer distances, logistics operations can significantly reduce fuel consumption and emissions, alongside improved delivery efficiency.

Despite these advancements, several implementation challenges remain, including technical issues in V2V communication, legal and regulatory hurdles, and operational complexities in dynamic re-routing and real-time traffic data handling. However, emerging AI, machine learning, and autonomous driving technology trends offer promising solutions to these challenges.

Future research should focus on developing more robust and adaptive algorithms, addressing legal and regulatory issues, and integrating new technologies with traditional logistics practices. The logistics industry can significantly improve efficiency and sustainability by encouraging interdisciplinary collaboration and leveraging technological advancements.

The review concludes that continued research and innovation are essential to overcome existing challenges and fully realize the benefits of integrating truck platooning and clustering algorithms in logistics operations. This approach can revolutionize logistics planning, contributing to more efficient, cost-effective, and environmentally friendly supply chain networks.

References

[1]. Alam, A., Besselink, B., Turri, V., M ̊artensson, J. and Johansson, K. H. (2015) Heavy-Duty Vehicle Platooning for Sustainable Freight Transportation: A Cooperative Method to Enhance Safety and Efficiency. IEEE Control Systems Magazine, 35 (6), 34-56.

[2]. Lammert, M. P., Duran, A., Diez, J., Burton, K. and Nicholson, A. (2014) Effect of Platooning on Fuel Consumption of Class 8 Vehicles Over a Range of Speeds, Following Distances, and Mass. SAE International Journal of Commercial Vehicles, 7 (2), 626-639.

[3]. Zhou, Z., Chen, J., Wang, L. and Yu, B. (2021) Clustering and Platooning in Freight Transportation: A Case Study. IEEE Transactions on Vehicular Technology, 70 (8), 7645-7656.

[4]. Ghaffari-Nasab, N., Torabi, S. A. and Dullaert, W. (2020) An integrated approach for sustainable supply chain planning in chemical industries. Transportation Research Part B: Methodological, 130, 202-220.

[5]. Xie, C., Feng, T. and Zhou, X. (2016) Clustering Algorithms for Transportation Systems Analysis: A Review. Transportation Research Part B: Methodological, 89, 84-105.

[6]. Tsugawa, S., Jeschke, S. and Shladover, S. E. (2016) A Review of Truck Platooning Projects for Energy Savings. IEEE Transactions on Intelligent Vehicles, 1 (1), 68-77.

[7]. Brown, A. and Gonder, J. (2013) Analyzing the Impact of Truck Platooning on Energy Savings and Traffic Flow. Transportation Research Record: Journal of the Transportation Research Board, 2396 (1), 11-18.

[8]. Larson, J., Liang, K. Y. and Johansson, K. H. (2015) A Distributed Framework for Coordinated Heavy-Duty Vehicle Platooning. IEEE Transactions on Intelligent Transportation Systems, 16 (1), 419-429.

[9]. Nowakowski, C., Shladover, S. E., Lu, X.-Y., Ferlis, R. A. and Spring, J. (2015) Cooperative Adaptive Cruise Control: Driver Acceptance of Following Gap Settings Less Than One Second. IEEE Transactions on Intelligent Transportation Systems, 16 (4), 1903-1912.

[10]. Van Arem, B., van Driel, C. J. G. and Visser, R. (2006) The Impact of Cooperative Adaptive Cruise Control on Traffic-Flow Characteristics. IEEE Transactions on Intelligent Transportation Systems, 7 (4), 429-436.

[11]. Arthur, D. and Vassilvitskii, S. (2007) k-means++: The Advantages of Careful Seeding. Proceedings of the Eighteenth Annual ACM-SIAM Symposium on Discrete Algorithms, 1027-1035.

[12]. Ester, M., Kriegel, H. P., Sander, J. and Xu, X. (1996) A Density-Based Algorithm for Discovering Clusters in Large Spatial Databases with Noise. Proceedings of the Second International Conference on Knowledge Discovery and Data Mining (KDD-96), 226-231.

[13]. Murtagh, F. and Contreras, P. (2012) Algorithms for hierarchical clustering: an overview, II. Wiley Interdisciplinary Reviews: Data Mining and Knowledge Discovery, 2(1), 86-97.

[14]. Chen, J., Zhou, Z., Duan, Y. and Yu, B. (2022) Research on Reinforcement-Learning-Based Truck Platooning Control Strategies in Highway On-Ramp Regions. World Electric Vehicle Journal, 14 (10), 273.

[15]. Hao, Y., et al. (2024) Planning of Truck Platooning for Road-Network Capacitated Vehicle Routing Problem. arXiv, 2404.13512.

[16]. Boysen, N., Briskorn, D. and Emde, S. (2018) Truck Platooning in Mixed Autonomy: An Operational Analysis. Transportation Research Part B: Methodological, 117, 447-461.

Cite this article

Huang,H. (2024). Route Planning of Freight Transport and Logistics Considering Truck Platooning. Advances in Economics, Management and Political Sciences,123,63-71.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of ICEMGD 2024 Workshop: Policies to Enhance Sustainable Development through the Green Economy

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Alam, A., Besselink, B., Turri, V., M ̊artensson, J. and Johansson, K. H. (2015) Heavy-Duty Vehicle Platooning for Sustainable Freight Transportation: A Cooperative Method to Enhance Safety and Efficiency. IEEE Control Systems Magazine, 35 (6), 34-56.

[2]. Lammert, M. P., Duran, A., Diez, J., Burton, K. and Nicholson, A. (2014) Effect of Platooning on Fuel Consumption of Class 8 Vehicles Over a Range of Speeds, Following Distances, and Mass. SAE International Journal of Commercial Vehicles, 7 (2), 626-639.

[3]. Zhou, Z., Chen, J., Wang, L. and Yu, B. (2021) Clustering and Platooning in Freight Transportation: A Case Study. IEEE Transactions on Vehicular Technology, 70 (8), 7645-7656.

[4]. Ghaffari-Nasab, N., Torabi, S. A. and Dullaert, W. (2020) An integrated approach for sustainable supply chain planning in chemical industries. Transportation Research Part B: Methodological, 130, 202-220.

[5]. Xie, C., Feng, T. and Zhou, X. (2016) Clustering Algorithms for Transportation Systems Analysis: A Review. Transportation Research Part B: Methodological, 89, 84-105.

[6]. Tsugawa, S., Jeschke, S. and Shladover, S. E. (2016) A Review of Truck Platooning Projects for Energy Savings. IEEE Transactions on Intelligent Vehicles, 1 (1), 68-77.

[7]. Brown, A. and Gonder, J. (2013) Analyzing the Impact of Truck Platooning on Energy Savings and Traffic Flow. Transportation Research Record: Journal of the Transportation Research Board, 2396 (1), 11-18.

[8]. Larson, J., Liang, K. Y. and Johansson, K. H. (2015) A Distributed Framework for Coordinated Heavy-Duty Vehicle Platooning. IEEE Transactions on Intelligent Transportation Systems, 16 (1), 419-429.

[9]. Nowakowski, C., Shladover, S. E., Lu, X.-Y., Ferlis, R. A. and Spring, J. (2015) Cooperative Adaptive Cruise Control: Driver Acceptance of Following Gap Settings Less Than One Second. IEEE Transactions on Intelligent Transportation Systems, 16 (4), 1903-1912.

[10]. Van Arem, B., van Driel, C. J. G. and Visser, R. (2006) The Impact of Cooperative Adaptive Cruise Control on Traffic-Flow Characteristics. IEEE Transactions on Intelligent Transportation Systems, 7 (4), 429-436.

[11]. Arthur, D. and Vassilvitskii, S. (2007) k-means++: The Advantages of Careful Seeding. Proceedings of the Eighteenth Annual ACM-SIAM Symposium on Discrete Algorithms, 1027-1035.

[12]. Ester, M., Kriegel, H. P., Sander, J. and Xu, X. (1996) A Density-Based Algorithm for Discovering Clusters in Large Spatial Databases with Noise. Proceedings of the Second International Conference on Knowledge Discovery and Data Mining (KDD-96), 226-231.

[13]. Murtagh, F. and Contreras, P. (2012) Algorithms for hierarchical clustering: an overview, II. Wiley Interdisciplinary Reviews: Data Mining and Knowledge Discovery, 2(1), 86-97.

[14]. Chen, J., Zhou, Z., Duan, Y. and Yu, B. (2022) Research on Reinforcement-Learning-Based Truck Platooning Control Strategies in Highway On-Ramp Regions. World Electric Vehicle Journal, 14 (10), 273.

[15]. Hao, Y., et al. (2024) Planning of Truck Platooning for Road-Network Capacitated Vehicle Routing Problem. arXiv, 2404.13512.

[16]. Boysen, N., Briskorn, D. and Emde, S. (2018) Truck Platooning in Mixed Autonomy: An Operational Analysis. Transportation Research Part B: Methodological, 117, 447-461.