1. Introduction

According to Grand View Research, the global logistics market scale is expected to grow at a rate of 7.2% year by year from 2024 to 2030, and the vast majority of market shares is in North America and the Asia Pacific region, which are the most densely populated regions [1]. This rapid growth poses significant operational challenges for the logistics industry, often compounded by outdated infrastructure that limits efficiency.

A key tool driving the transformation of the logistics industry is the Logistics Information System (LIS), which enhances operational efficiency by streamlining data management and decision-making processes. To address inefficiencies, companies, and institutions are increasingly adopting LIS to optimize processes. These systems, whether digital or paper-based, enable data aggregation, analysis, and visualization, empowering users to make informed decisions and manage supply chains more effectively [2]. The emergence of Industry 4.0 marks a transformative shift in the way that manufacturing, improvement, and distribution processes are conducted. The implementation of the LIS plays a key role in reshaping the way data is processed in the logistics industry. Also, new technologies such as artificial intelligence (AI) have great potential in changing supply chain management. It enables enterprises to more accurately predict demand, optimize transportation routes, and then enhance resource use and reduce costs to improve efficiency [3].

At present, the combination of new technology and LIS is still in the initial stage of technology integration. Many applications are highly similar to other industries without considering the particularity of the logistics industry. This paper will focus on the LIS's performance, introduce several well-integrated mainstream directions, including improving user service, improving internal communication efficiency, logistics process synchronization, etc., and discuss the LIS's future challenges and research directions.

2. Logistics Information System

2.1. Definition of Logistics Information System (LIS)

A logistics information system (LIS), also known as a logistics management information system, is designed to facilitate the coordination of logistics activities, material flow, and inventory replenishment [4]. These systems can be customized to various settings according to their configuration. For instance, LIS can optimize the process by tracking inventory movement and location, making it particularly suitable for warehousing and transportation management. In addition, LIS can be categorized based on its specific functions, such as supply chain and logistics management, distribution and material movement, production logistics and management, and reverse logistics and product return.

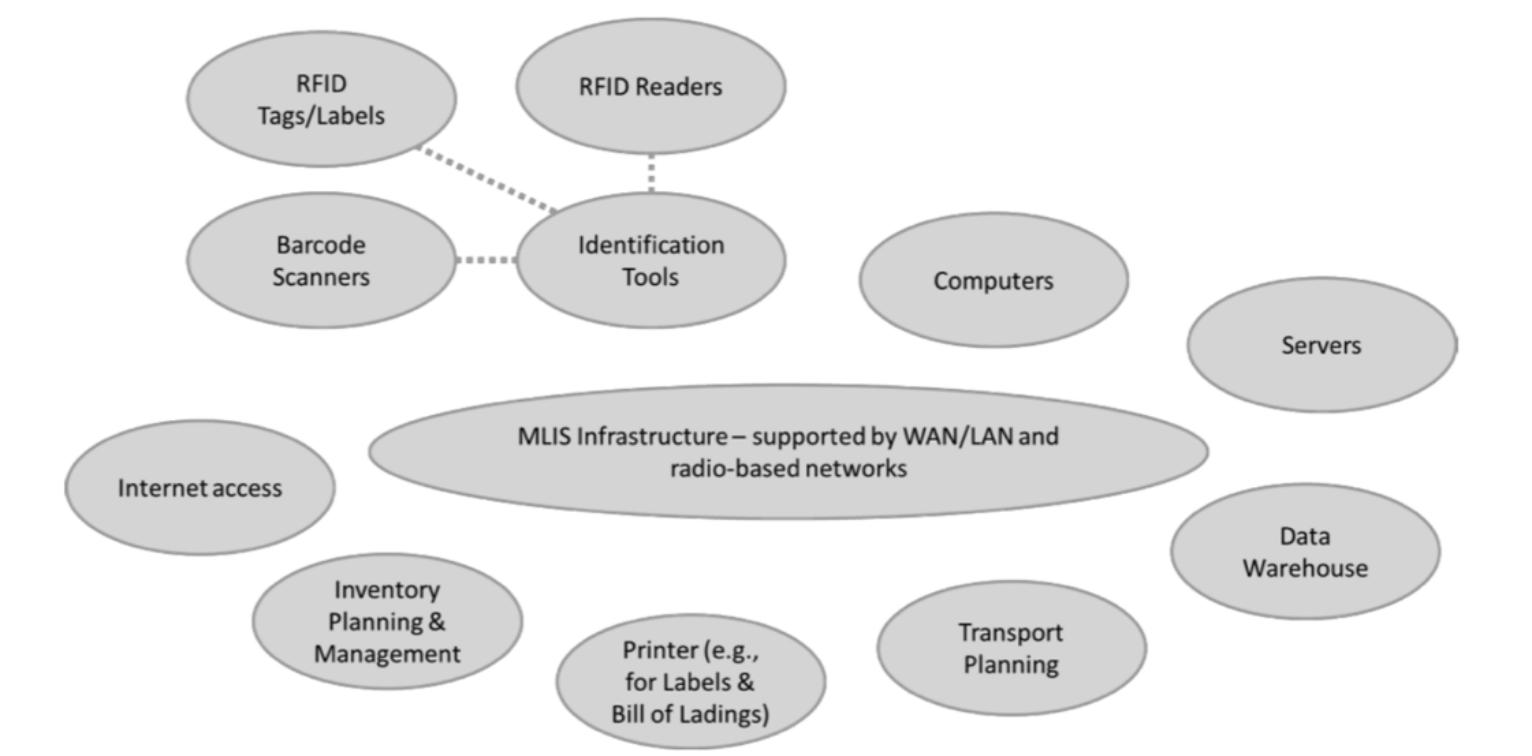

Generally, a LIS is mainly used as a transaction system to capture and record all data, information changes, and material movements in the system. Its core responsibility lies in collecting critical information, such as personnel flow, material locations, equipment status, and financial transactions. Although basic technologies such as bar code and RFID (Radio Frequency Identification) are essential, it can also incorporate advanced components such as enterprise resource planning (ERP) software, warehouse management systems, quality management systems, inter-company data exchange, and transportation management systems. Figure 1 illustrates the core components of an LIS, showcasing its integration with various subsystems to provide a holistic logistics management framework. By using transaction data and optimization tools within the LIS, logistics managers can make data-driven decisions to enhance operational efficiency in transportation, material handling, and inventory control.

Figure 1: Logistics information system components [4]

2.2. Importance of LIS to the Logistics Industry

The scope and role of logistics have changed significantly in recent years, from focusing on the limited support function of transportation and storage to the core element of enterprise strategy. This change is largely driven by the exponential increase in data volume, which has greatly affected the significance and practice of logistics management [5]. As companies move from national to multinational operations, the logistics landscape has become increasingly complex, with longer channels and more participants.

Information flow has become central to achieving logistics efficiency, operating alongside the physical flow of goods. Modern logistics processes demand faster and smarter data handling, making the application of information systems (IS) in logistics essential [5]. According to Facchini, LIS encompasses the coordination and management of diverse activities, including scheduling, inventory replenishment, and flow planning [6]. LIS has an important impact on the strategic direction of logistics management. These systems provide enterprises with timely and actionable information to support planning and execution.

In comparing more than 30 factories in different industries in northern Thailand, Raming Wong found that using LIS for logistics intervention can save 25% of the transportation cost, 55% of the storage cost, and 20% of the management cost on average while improving the planning ability [7]. In terms of customers, using LIS or a similar ERP system can significantly improve customer satisfaction by more than 80% [8]. Further studies corroborate that an enterprise’s ability to optimize logistics costs and service levels is directly linked to its LIS implementation [9]. Given these advantages, the adoption of LIS has become a prerequisite for enterprises to seek to improve the efficiency and accuracy of their logistics process and minimize the total lead time from suppliers to consumers.

3. Analysis of LIS Performance

3.1. Enhancements Brought by LIS

3.1.1. Improving communication efficiency within the organization.

Effective information exchange is an important part of the logistics management process, which can ensure the seamless and timely transfer of tasks [10]. Achieving this requires the integration of critical components, such as integrated dashboards, unified data sources, powerful planning modules, and comprehensive tracking and tracing functions.

The establishment of a LIS has promoted the development of an intelligent network, integrating physical and virtual infrastructure with real-time communication exchange, thus significantly enhancing the communication between shippers and carriers [7]. Optimized communication modes include reduced reliance on mail management, the use of an integrated system, a package tracking function, and multi-platform support. Empirical data collected from customers who have implemented LIS communication solutions show that organizational productivity has increased by about 25% on average [11].

3.1.2. Synchronizing the logistics processes.

The integration of cloud systems is completely changing the operation of almost all industries, especially when combined with LIS [12]. LIS provides a comprehensive dashboard for process visualization, data analysis, and integration from various sources, and an interface tailored to specific business needs. This facilitates access to real-time pricing, inventory data, and other key logistics information anytime, anywhere. Cloud integration supports the synchronization of all components from multiple suppliers and provides direct integration and visualization of execution layer activities.

3.1.3. Improvement in customer service and satisfaction.

Improvements in delivery, constraint management, and tracking are key drivers for improving logistics performance. Trust, which is built through consistent service delivery, is essential for maintaining customer loyalty and reinforcing LIS’s perceived value [13,14]. Professional and continuous system updates further ensure the reliability of the service, while user-centered design prioritizes convenience, visual clarity, and effective layout. This eliminates the complex procedures and waiting time related to the traditional process, and greatly improves the user experience. This, in turn, enables logistics companies to achieve cost efficiency while maintaining a high level of customer service and ultimately improving customer satisfaction [15,16].

3.2. Potential Adverse Impacts of the LIS

3.2.1. Technology investment pressure

Efficient LIS systems require substantial investments in IoT devices, sensors, and supporting infrastructure. The popularity of IoT equipment has increased technology investment, which may bring pressure to small and medium-sized enterprises with limited funds and affect their competitiveness [17]. To solve this problem, the government and financial institutions should provide financial support and tax incentives, and technology suppliers can provide customized solutions according to the size of enterprises to avoid over-investment.

3.2.2. The impact of customer experience caused by high-tech dependence

LIS’s high-tech dependence improves efficiency and transparency, but it also brings the risk that equipment failure may affect the logistics chain. System failures in components like sensors, barcode scanners, GPS, or cloud platforms can disrupt logistics operations, causing delays in logistics chains and information synchronization [18]. Therefore, risk management, backup system, and redundancy design are the key to ensuring the continuous operation of LIS, while maintaining smooth communication channels with customers to avoid misunderstanding caused by information asymmetry.

3.3. Case Studies on the Application of LIS

3.3.1. CONPAS helps improve operational efficiency at the Port of Yokohama

Due to larger container ships, the number of containers handled by the Yokohama port increased significantly, accelerating the land-side congestion and challenging the container terminal’s operational efficiency. In response, Japan’s Ministry of Land, Infrastructure, Transport, and Tourism has implemented a new port LIS called CONPAS (Container Fast Pass), which combined multiple technologies including 5G, cloud computing, multi-platform systems, and IoT. In the trial run, about 14% of incoming trailers were booked through CONPAS LIS, and the total waiting time was reduced by 10%, successfully establishing mutual understanding among all parties [19,20].

3.3.2. Senseaware enhances customer service quality at FedEx

FedEx has significantly improved the quality of customer service by implementing its intelligent LIS Senseaware. This system allows customers to monitor package location, temperature, humidity, and other metrics in real-time, reducing uncertainty and increasing transparency. In addition, FedEx also provides customers with an abnormal reminder function through this system. For example, when the package is delayed or the index exceeds the standard, the system will automatically send an alarm to notify customers in time. Through these technological innovations, FedEx has not only improved customer trust and satisfaction but also reduced customer complaints through a more efficient delivery process [21].

4. Challenges and Recommendations

4.1. Data Security

4.1.1. Challenges

The integration of 5G technologies into logistics, particularly in transportation and storage, has significantly advanced industry capabilities. However, the reliance on complex networks has also increased vulnerability to data breaches. Logistics companies entrust a large amount of information to operators or other stakeholders, which will soon become the target of some malicious people [22]. Once the data security is destroyed, it will significantly impact the relevant business of logistics enterprises. This section highlights three primary challenges to data security: network configuration, internal threats, and IoT devices.

Even a correctly configured network is not immune to vulnerabilities. As Ivankova notes, the Internet is a dynamic and evolving entity [23]. Therefore, the configuration can be changed to adapt to the evolving Internet. It is also difficult to monitor who is doing what on the whole Internet. Therefore, Enache pointed out that "zero trust" has always been the first choice for ISPs (Internet service providers) [24]. However, the neglected point is that the threat may also come from internal employees or supply chain contractors, which is difficult to find. Another huge threat to data security is the variety of IOT devices. Ivankova said that the increasing number of IOT devices makes it more difficult to prevent malicious organizations from attacking the security environment [23].

4.1.2. Recommendations

Multi-signature is an advanced technology widely used in cryptocurrencies such as Bitcoin and Dogecoin. It uses a hash function to encrypt information and obtain a corresponding hash value. Once the encrypted information changes, the hash value will change to prevent the information from being changed.

As a responsibility, data security is not just a problem for logistics companies, it also belongs to third-party suppliers, partners, and other participants in the supply chain. Third-party suppliers need to work with the same level of data security as deployed, they must be responsible for the data they process [25]. It is wise to hire professional partners who can ensure the safety of the logistics industry and cooperate with professional technology companies for advanced tools to protect logistics [25].

4.2. Change Management

4.2.1. Challenges

Although the early LIS was a simple system to help users obtain standard reports, its ability to support decision-making was poor [26]. At present, LIS is an integrated system that integrates humans, machines, and software. Depending on a company’s operational needs, LIS may include subsystems for inventory management, procurement, production, packaging, warehousing, and distribution [27]. The organization and implementation of LIS not only requires the purchase and installation of software but also the appropriate management of different LIS systems to make them run synchronously. However, user resistance and insufficient training remain major challenges for logistics organizations. Lilja also pointed out that many employees lack the knowledge to adapt to the changing business environment and market demand [28]. While employees may excel in their specialized areas, integrating different LIS departments can be a daunting task, resulting in inefficiencies and higher costs when aligning disparate systems.

4.2.2. Recommendations

To overcome these challenges, senior logistics managers must align strategic objectives across departments and invest in continuous education and skill development. Managers should also invite employees from other partner companies with common goals to provide more effective services to customers and improve customer satisfaction. The feasible enterprise solution is a learning management system with strong adaptability. The company can provide various learning resources and tools to help employees prepare for new projects and systems for the first time [29]. In addition, the organization should seek advice on how to synchronize different LIS systems and delete redundant departments for efficient work and user convenience.

5. Conclusion

Managing data and using information have become crucial roles in the logistics industry under digitization. The enterprise architecture of the logistics industry includes the management of information as the operational planning layer. However, data security and change management are the challenges of the deployment of LIS. It is recommended that a cipher security strategy, such as multi-signature, testing team, and regular assessment, is necessary to address the concern of data security. With the emergence of new logistics technologies such as drones, driverless, dynamic route planning, and so on, the LIS also needs to reserve the possibility of upgrading for the emergence of new technologies, while considering the reliability and learning cost of new technologies. Meanwhile, a top-to-bottom strategy among internal logistics companies, a customized e-learning system, and an effective synchronizing system could solve the challenge of change management.

References

[1]. Grand View Research. (2023). Logistics Market Size, Share & Trends Analysis Report By Service, By Category (Conventional Logistics, E-Commerce Logistics), By Model, By Type, By Operation, By Mode of Transport, By End Use, By Region, And Segment Forecasts, 2024 - 2030. GVR-4-68040-323-8. Available from: https://www.grandviewresearch.com/industry-analysis/logistics-market-report

[2]. United Nations ESCAP. (2016). Standard Model of Logistics Information Systems. Moscow: Third session of the Ministerial Conference on Transport. Available from: https://www.unescap.org/sites/default/d8files/knowledge-products/Model%20Logistics%20Information%20Systems.pdf

[3]. Chen W, Men Y, Fuster N, Osorio C, Juan AA. (2024). Artificial Intelligence in Logistics Optimization with Sustainable Criteria: A Review. Sustainability. 16(21):9145.

[4]. Wood LC, Reiners T, Pahl J. (2014). Manufacturing and logistics information systems. In: Advances in information quality and management [Internet]. 2014 p. 5136–44. Available from: https://doi.org/10.4018/978-1-4666-5888-2.ch507

[5]. Ngai EWT, Lai KH, Cheng TCE. (2007). Logistics information systems: The Hong Kong experience. International Journal of Production Economics [Internet]. 2007 Jul 25;113(1):223–34. Available from: https://doi.org/10.1016/j.ijpe.2007.05.018

[6]. Facchini F, Oleśków-Szłapka J, Ranieri L, Urbinati A.(2019). A Maturity Model for Logistics 4.0: An Empirical analysis and a Roadmap for future research. Sustainability [Internet]. 2019 Dec 20;12(1):86. Available from: https://doi.org/10.3390/su12010086

[7]. Sakgasem Ramingwong, Apichat Sopadang, Korrakot Yaibuathet Tippayawong, Jutamat Jintana. (2024). Factory Logistics Improvement: A Case Study Analysis of Companies in Northern Thailand, 2022–2024. Logistics. 2024 Sep 9 ;8(3):88–8. Available from: https://doi.org/10.3390/logistics8030088

[8]. Li Q, Wu G. (2021). ERP System in the Logistics Information Management System of Supply Chain Enterprises. Tsai SB, editor. Mobile Information Systems. 2021 Oct 13;2021:1–11.

[9]. Bardi EJ, Raghunathan TS, Bagchi PK. (1994). LOGISTICS INFORMATION SYSTEMS: THE STRATEGIC ROLE OF TOP MANAGEMENT /. Journal of Business Logistics [Internet]. Available from: https://trid.trb.org/view.aspx?id=546679

[10]. BlueGrace. (2019). How to Build an Effective Logistics Communication Process. Available from: https://mybluegrace.com/blog/how-to-build-an-effective-logistics-communication-process/

[11]. Motorola. (2022). Take Your Communications Further. Motorola Solutions Team Communications for Transportation & Logistics. Team communications for manufacturing. Available from: https://www.motorolasolutions.com/content/dam/msi/docs/en-xu/manufacturing/team-communications/meet-or-beat-your-deadlines-with-team-communications-infographic-en.pdf

[12]. Chen J, Wu H, Zhou X, Wu M, Zhao C, Xu S. (2021). Optimization of Internet of Things E-Commerce Logistics Cloud service platform based on mobile communication. Complexity. 2021 :1–11.

[13]. SAP. (2022). The Intelligent Enterprise Whitepaper for the Cargo Industry. SAP Industries White Paper, Travel and Transportation - Cargo. Available from: https://www.sap.com/documents/2016/08/a4b8625f-827c-0010-82c7-eda71af511fa.html

[14]. Purdescu C. A, Moise A. V, Stanculeanu F. (2009). Improving Customer Service Using Logistics Information Systems. International Conference on Management and Industrial Engineering. p. 92.

[15]. Cortes JAZ, Serna MDA, Gomez RA. (2013). INFORMATION SYSTEMS APPLIED TO TRANSPORT IMPROVEMENT. DYNA [Internet]. 2013 Jul 1;80(180):77–86. Available from: https://dialnet.unirioja.es/descarga/articulo/7697257.pdf

[16]. Arshinina P, Kiseleva A. (2020). Evaluation of the Effectiveness of the Logistics System. Proceedings of the International Conference on Economics, Management and Technologies. ICEMT.

[17]. Radicic D, Petković S. (2023). Impact of digitalization on technological innovations in small and medium-sized enterprises (SMEs). Technological Forecasting and Social Change. 191(122474):122474.

[18]. Hensley RL, Utley JS. (2019). Assessing the Cumulative Effect of Service Errors on Customer Perceptions. Journal of Service Science and Management. 12(04):521–30.

[19]. Ministry of Land, Infrastructure, Transport and Tourism. Cyber Port integrated portal. Available from: https://www.cyber-port.mlit.go.jp/ja/

[20]. World Ports Sustainability Program. (2017). Port of Yokohama – Container Fast Pass (CONPAS). Available from: https://sustainableworldports.org/project/port-of-yokohama-container-fast-pass-conpas/

[21]. FedEx. (2020). FedEx to Transform Package Tracking with SenseAware ID, the Latest Innovation in FedEx Sensor Technology [Internet]. FedEx Newsroom. FedEx Newsroom. Available from: https://newsroom.fedex.com/newsroom/united-states-english/senseaware-id

[22]. CartonCloud. (2021). Data Security And Why It Matters In The Logistics Industry. Available from: https://www.cartoncloud.com/blog/data-security-and-why-it-matters-in-the-logistics-industry

[23]. Ivankova GV, Mochalina EP, Goncharova NL. (2020). Internet of Things (IoT) in logistics. IOP Conference Series Materials Science and Engineering [Internet]. 940(1):012033.

[24]. Enache GI. (2023). Logistics security in the era of big data, cloud computing and IoT. Proceedings of the . International Conference on Business Excellence [Internet]. 17(1):188–99.

[25]. Tata. (2022). Data Security Best Practices for the Logistics Sector [Internet]. Tata Tele Business Services. Tata Tele Business Services Ltd.; Available from: https://www.tatatelebusiness.com/articles/4-data-security-best-practices-for-the-logistics-sector

[26]. Gao L, Qi E. (2007). Study on Cooperative Logistics Information System According to Supply Chain Management. IEEE International Conference on Automation and Logistics. 2007. pp. 2576-2579, doi: 10.1109/ICAL.4339014.

[27]. Hart M, Lukoszová X, Taraba P. (2013). Methodics of production layout design and its importance to logistics management. Research in Logistics & Production [Internet]. 2013 Sep 30;3(3):225–38.

[28]. Lijia T. (2021). Change management in digitalization of project logistics and implementation of a new logistics management system. Lut University. Available from: https://lutpub.lut.fi/handle/10024/162295

[29]. Cameron BH. (2008). Enterprise systems education. Proceedings of the 2008 ACM SIGMIS CPR conference on Computer personnel doctoral consortium and research.

Cite this article

Gong,C. (2025). Advancing Operational Efficiency in the Logistics Industry: The Role of Logistics Information Systems (LIS). Advances in Economics, Management and Political Sciences,167,34-40.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 4th International Conference on Business and Policy Studies

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Grand View Research. (2023). Logistics Market Size, Share & Trends Analysis Report By Service, By Category (Conventional Logistics, E-Commerce Logistics), By Model, By Type, By Operation, By Mode of Transport, By End Use, By Region, And Segment Forecasts, 2024 - 2030. GVR-4-68040-323-8. Available from: https://www.grandviewresearch.com/industry-analysis/logistics-market-report

[2]. United Nations ESCAP. (2016). Standard Model of Logistics Information Systems. Moscow: Third session of the Ministerial Conference on Transport. Available from: https://www.unescap.org/sites/default/d8files/knowledge-products/Model%20Logistics%20Information%20Systems.pdf

[3]. Chen W, Men Y, Fuster N, Osorio C, Juan AA. (2024). Artificial Intelligence in Logistics Optimization with Sustainable Criteria: A Review. Sustainability. 16(21):9145.

[4]. Wood LC, Reiners T, Pahl J. (2014). Manufacturing and logistics information systems. In: Advances in information quality and management [Internet]. 2014 p. 5136–44. Available from: https://doi.org/10.4018/978-1-4666-5888-2.ch507

[5]. Ngai EWT, Lai KH, Cheng TCE. (2007). Logistics information systems: The Hong Kong experience. International Journal of Production Economics [Internet]. 2007 Jul 25;113(1):223–34. Available from: https://doi.org/10.1016/j.ijpe.2007.05.018

[6]. Facchini F, Oleśków-Szłapka J, Ranieri L, Urbinati A.(2019). A Maturity Model for Logistics 4.0: An Empirical analysis and a Roadmap for future research. Sustainability [Internet]. 2019 Dec 20;12(1):86. Available from: https://doi.org/10.3390/su12010086

[7]. Sakgasem Ramingwong, Apichat Sopadang, Korrakot Yaibuathet Tippayawong, Jutamat Jintana. (2024). Factory Logistics Improvement: A Case Study Analysis of Companies in Northern Thailand, 2022–2024. Logistics. 2024 Sep 9 ;8(3):88–8. Available from: https://doi.org/10.3390/logistics8030088

[8]. Li Q, Wu G. (2021). ERP System in the Logistics Information Management System of Supply Chain Enterprises. Tsai SB, editor. Mobile Information Systems. 2021 Oct 13;2021:1–11.

[9]. Bardi EJ, Raghunathan TS, Bagchi PK. (1994). LOGISTICS INFORMATION SYSTEMS: THE STRATEGIC ROLE OF TOP MANAGEMENT /. Journal of Business Logistics [Internet]. Available from: https://trid.trb.org/view.aspx?id=546679

[10]. BlueGrace. (2019). How to Build an Effective Logistics Communication Process. Available from: https://mybluegrace.com/blog/how-to-build-an-effective-logistics-communication-process/

[11]. Motorola. (2022). Take Your Communications Further. Motorola Solutions Team Communications for Transportation & Logistics. Team communications for manufacturing. Available from: https://www.motorolasolutions.com/content/dam/msi/docs/en-xu/manufacturing/team-communications/meet-or-beat-your-deadlines-with-team-communications-infographic-en.pdf

[12]. Chen J, Wu H, Zhou X, Wu M, Zhao C, Xu S. (2021). Optimization of Internet of Things E-Commerce Logistics Cloud service platform based on mobile communication. Complexity. 2021 :1–11.

[13]. SAP. (2022). The Intelligent Enterprise Whitepaper for the Cargo Industry. SAP Industries White Paper, Travel and Transportation - Cargo. Available from: https://www.sap.com/documents/2016/08/a4b8625f-827c-0010-82c7-eda71af511fa.html

[14]. Purdescu C. A, Moise A. V, Stanculeanu F. (2009). Improving Customer Service Using Logistics Information Systems. International Conference on Management and Industrial Engineering. p. 92.

[15]. Cortes JAZ, Serna MDA, Gomez RA. (2013). INFORMATION SYSTEMS APPLIED TO TRANSPORT IMPROVEMENT. DYNA [Internet]. 2013 Jul 1;80(180):77–86. Available from: https://dialnet.unirioja.es/descarga/articulo/7697257.pdf

[16]. Arshinina P, Kiseleva A. (2020). Evaluation of the Effectiveness of the Logistics System. Proceedings of the International Conference on Economics, Management and Technologies. ICEMT.

[17]. Radicic D, Petković S. (2023). Impact of digitalization on technological innovations in small and medium-sized enterprises (SMEs). Technological Forecasting and Social Change. 191(122474):122474.

[18]. Hensley RL, Utley JS. (2019). Assessing the Cumulative Effect of Service Errors on Customer Perceptions. Journal of Service Science and Management. 12(04):521–30.

[19]. Ministry of Land, Infrastructure, Transport and Tourism. Cyber Port integrated portal. Available from: https://www.cyber-port.mlit.go.jp/ja/

[20]. World Ports Sustainability Program. (2017). Port of Yokohama – Container Fast Pass (CONPAS). Available from: https://sustainableworldports.org/project/port-of-yokohama-container-fast-pass-conpas/

[21]. FedEx. (2020). FedEx to Transform Package Tracking with SenseAware ID, the Latest Innovation in FedEx Sensor Technology [Internet]. FedEx Newsroom. FedEx Newsroom. Available from: https://newsroom.fedex.com/newsroom/united-states-english/senseaware-id

[22]. CartonCloud. (2021). Data Security And Why It Matters In The Logistics Industry. Available from: https://www.cartoncloud.com/blog/data-security-and-why-it-matters-in-the-logistics-industry

[23]. Ivankova GV, Mochalina EP, Goncharova NL. (2020). Internet of Things (IoT) in logistics. IOP Conference Series Materials Science and Engineering [Internet]. 940(1):012033.

[24]. Enache GI. (2023). Logistics security in the era of big data, cloud computing and IoT. Proceedings of the . International Conference on Business Excellence [Internet]. 17(1):188–99.

[25]. Tata. (2022). Data Security Best Practices for the Logistics Sector [Internet]. Tata Tele Business Services. Tata Tele Business Services Ltd.; Available from: https://www.tatatelebusiness.com/articles/4-data-security-best-practices-for-the-logistics-sector

[26]. Gao L, Qi E. (2007). Study on Cooperative Logistics Information System According to Supply Chain Management. IEEE International Conference on Automation and Logistics. 2007. pp. 2576-2579, doi: 10.1109/ICAL.4339014.

[27]. Hart M, Lukoszová X, Taraba P. (2013). Methodics of production layout design and its importance to logistics management. Research in Logistics & Production [Internet]. 2013 Sep 30;3(3):225–38.

[28]. Lijia T. (2021). Change management in digitalization of project logistics and implementation of a new logistics management system. Lut University. Available from: https://lutpub.lut.fi/handle/10024/162295

[29]. Cameron BH. (2008). Enterprise systems education. Proceedings of the 2008 ACM SIGMIS CPR conference on Computer personnel doctoral consortium and research.