1. Introduction

In the era of rapid information development, supply chain management has become one of the key strategies for companies to enhance their competitiveness, especially for e-commerce enterprises [1]. With the increasing demand for orders, consumers' stringent standards for delivery, and the enormous operational costs, traditional supply chains can no longer meet today's market demands. Traditional supply chains suffer from low efficiency, insufficient operational agility, and high costs. Therefore, e-commerce companies are transitioning from traditional supply chain models to intelligent supply chain models to address market needs. Amazon, as a globally renowned e-commerce company, stands out in supply chain management. The company has employed numerous artificial intelligence technologies in its supply chain, such as demand forecasting, warehouse automation, intelligent algorithms, and drone delivery, all of which have improved operational efficiency and reduced supply chain costs [2].

This paper first introduces the background of Amazon e-commerce and the development process of supply chain, then analyzes how Amazon supply chain management uses AI and what contributions AI has made to supply chain, then conducts case analysis on AI, and finally discusses the challenges of intelligent supply chain management in Amazon and future development trends. This paper not only provides case studies on the integration of supply chains with AI but also offers important references for other e-commerce companies.

2. AI applications in Amazon’s supply chain management

Amazon has grown over the years into a global leader in commerce, expanding into cloud computing and artificial intelligence. The company has evolved from its early reliance on third-party delivery, through the development of Prime membership services and a global warehouse network, to the mature stage of automation technology and drone delivery, significantly enhancing operational efficiency[3].

2.1. Robotic learning algorithms and demand forecasting

Amazon’s robotics primarily rely on supervised learning, with some applications of reinforcement learning to optimize operations, while supervised learning applies XGBoost and LSTM for demand prediction [4-5].

First, the reinforcement learning system is composed of state space S, action space A, state transition function P, reward function R, and discount factor. Its goal is to learn an optimal strategy to achieve the maximum return. During the learning process, a precise model needs to be established. Amazon's robot reinforcement learning is typically applied to inventory management, logistics, and procurement. The shortest path in robot reinforcement learning saves time for each order, thereby improving the efficiency of Amazon's tens of thousands of daily orders. This not only reduces costs but also enhances customer satisfaction.

Secondly, supervised learning involves using known input data and corresponding expected output data, which are clearly defined and labeled, to train machine learning models. Algorithms in supervised learning include XGBoost, which combines regression analysis for precise prediction. LSTM is used to process time series data, learning sales trends. Typically, Amazon robots apply supervised learning to predict product sales, optimize inventory, manage sales activities, calculate the impact of different weather conditions on delivery times, forecast return rates, and predict market environments. For example, Amazon robots predict price movements and regularly update prices, maximizing their utilization. Secondly Amazon robots predict future sales based on the historical sales of each product, so that they can prepare accurate inventory in advance, so that inventory is optimized and storage costs are reduced. In addition Robots can predict delivery times for different weather conditions. This allows them to focus on deliveries during good weather and prepare adequately for deliveries in bad weather. They use different modes of transportation based on the weather, preparing goods in advance to save operational time costs. By predicting traffic flow and calculating traffic conditions on various roads at different times, they choose the shortest route for delivery [4].

2.2. Intelligent warehousing and automated delivery

In modern logistics management, the application of intelligent technology is particularly important.

Amazon has introduced Kiva robots, which can match the length, width, and height of goods to storage racks, maximizing storage space utilization while reducing human movement time and error rates. Moreover, AI algorithms enable the robots to calculate the shortest path for placing items, preventing collisions and saving time costs, thus enhancing logistics efficiency.

As technology continues to advance, drone delivery is gradually becoming a new trend. Amazon first launched an innovative last-mile drone delivery service in December 2022, utilizing artificial intelligence and remote control technologies to achieve drone delivery services. Artificial intelligence optimizes the delivery routes through machine learning, ensuring efficient delivery [6]. Computer vision and sensors enable drones to automatically avoid obstacles and accurately reach their destinations. The advantages of drone delivery include fast delivery speeds, reduced logistics costs, and the ability to ignore issues such as traffic and obstacles, while also being environmentally friendly and energy-saving.

In terms of autonomous delivery, the application of innovative technologies has made delivery services more efficient. Amazon began implementing autonomous delivery in 2020, using technologies such as autonomous driving algorithms, computer vision, navigation, and sensors to provide delivery services [7]. Autonomous driving algorithms accurately calculate delivery routes to ensure safety. Computer vision helps autonomous vehicles avoid obstacles and recognize traffic signals. Navigation and sensors enable autonomous vehicles to deliver safely and precisely to their destinations. This reduces carbon emissions, lowers delivery costs, and improves transportation efficiency.

3. Case studies of AI in Amazon’s supply chain

In today's rapidly evolving digital landscape, AI has become an essential technology for business success, and Amazon stands as a leader in leveraging its capabilities. The company has continuously pushed the boundaries of innovation, particularly in the realm of AI-driven solutions.

3.1. Machine learning in supply chain optimization

Amazon applies four key types of machine learning in its supply chain.

|

Learning types |

Definition |

Main Algorithms |

Applications |

|

|

1 |

Supervised Learning |

Training with labeled data to map inputs to outputs. |

Linear Regression, Decision Trees, XGBoost, LSTM |

Image classification, speech recognition, fraud detection, medical |

|

2 |

Unsupervised Learning |

Identifying patterns in unlabeled data. |

K-Means, PCA, Autoencoder, GANs |

Customer segmentation, anomaly detection |

|

3 |

Semi-Supervised Learning |

Combining small labeled datasets with large unlabeled data for improved accuracy. |

Semi-supervised support vector machine (S3VM), graph neural network (GNN), variational autoencoder (VAE) |

Medical imaging, fraud detection |

|

4 |

Reinforcement Learning |

Learning optimal policies by interacting with the environment. |

Q-Learning, deep Q network (DQN), Policy Gradient, Actor-Critic |

Robot control, AlphaGo, automation |

Table 1 shows the applications of machine learning across Amazon's supply chain.

In demand forecasting, supervised learning utilizes labeled data to build predictive models, enabling accurate forecasts. Techniques such as Long Short-Term Memory networks (LSTM), XGBoost, and ARIMA are employed to predict market demand, optimize inventory levels, and improve route planning. These advanced algorithms help Amazon enhance supply chain efficiency and responsiveness to market fluctuations.

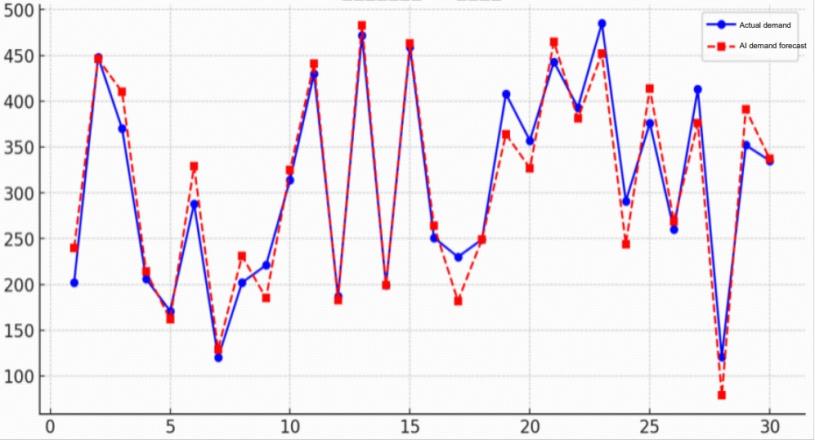

As can be seen from Figure 1, the difference between the demand forecast used by Amazon and the actual demand is not large, indicating that the accuracy of supervised learning is high.

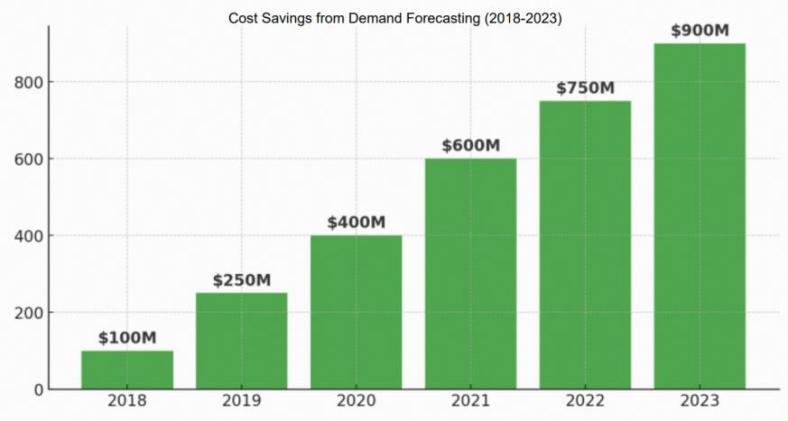

Figure 2 illustrates the cost savings Amazon has achieved through demand forecasting. As intelligent algorithms continue to evolve, predictions have become increasingly accurate, resulting in significant cost reductions. By precisely forecasting product demand for the upcoming week, Amazon minimizes excess inventory and prevents over-purchasing. Additionally, AI-driven demand prediction ensures sufficient stock of popular products, enhancing availability and improving overall customer satisfaction [8].

3.2. Automated warehouse management

The efficiency of Amazon's supply chain operations is largely driven by its automated warehouse management system. As early as 2012, Amazon invested $775 million to integrate robotic automation into its logistics network. Today, the company operates over 200,000 robots, forming an extensive and highly sophisticated supply chain ecosystem [2].

These automated robots perform a range of critical warehouse tasks. First, robots are programmed to calculate the shortest and most efficient routes for transporting goods within the warehouse. By minimizing travel distances, they significantly reduce processing time for each operation, leading to substantial time savings and increased operational efficiency. Second, equipped with computer vision technology, robots can scan and visually analyze inventory, allowing them to quickly locate specific items from large stacks of goods. They can also automatically recognize package sizes, ensuring efficient handling and placement. Additionally, robots are designed with obstacle detection capabilities—if a person or object is detected within a designated range, the robot will either stop or adjust its path, enhancing warehouse safety [10]. Third, by automating repetitive and labor-intensive tasks, robots effectively reduce dependence on manual labor, lowering labor costs and improving workplace safety. This allows employees to focus on higher-value tasks, minimizing human errors and optimizing overall productivity.

3.3. Smart logistics and delivery

Amazon's integration of artificial intelligence extends beyond demand forecasting and warehouse automation—it also plays a pivotal role in logistics and delivery. The company has leveraged cutting-edge technologies such as autonomous drones and self-driving delivery vehicles to enhance efficiency and redefine modern logistics.

Amazon's drone delivery system has revolutionized last-mile logistics by offering unparalleled advantages. It can bypass terrain obstacles, avoid traffic congestion and other potential barriers, making delivery routes more direct and efficient. Moreover, the flight capability of drones significantly reduces delivery time, especially for short-distance deliveries in cities and remote areas. Compared to human-operated delivery, drones provide a highly agile, fast, and automated solution, reducing the workload on delivery teams while enhancing customer satisfaction.

In addition to drones, Amazon's autonomous delivery vehicles represent another major advancement in smart logistics. These delivery vehicles optimize local distribution, equipped with computer vision, intelligent algorithms, and remote control technologies, ensuring safety and efficiency. Their advantages include recognizing environments and weather conditions, calculating optimal routes, and predicting traffic peaks to avoid deliveries during congested times. Due to the electric drive system used by the automated delivery vehicles, they are more environmentally friendly, reducing carbon emissions and meeting the requirements of sustainable development in today's society.

4. Challenges and future development of Amazon’s ai-driven supply chain

As computing power and artificial intelligence (AI) continue to advance at an unprecedented pace, alongside the growing demands of global consumers, Amazon’s supply chain must adapt swiftly to meet the evolving needs of the modern era. However, despite the remarkable advantages of AI-driven supply chain management (SCM) [11-12]. Several challenges persist, including technological hurdles, cost constraints, and security and regulatory concerns.

4.1. Current challenges

AI implementation in Amazon’s supply chain faces two major technological obstacles.

First, AI algorithms are complex. Global market data is vast and highly volatile, influenced by economic markets, policies, force majeure events, and competitive environments. Therefore, even with the most advanced algorithms, it is difficult to eliminate errors. Moreover, an increase in order volumes may lead to algorithm bottlenecks, causing delays when calculating optimal routes. Additionally, there are unstable factors with automated machines. Amazon's supply chain heavily relies on technologies such as automated robots and smart delivery systems. However, these technologies have inherent instability. During peak periods, as order volumes rise, automated delivery vehicles might experience delays, leading to traffic congestion. There is also a possibility of power outages during transit, and system errors in the automated delivery process could pose traffic safety risks. Furthermore, drones also present safety hazards and are affected by weather conditions.

Advanced AI solutions require significant financial investment in areas. Advanced technologies require a lot of costs, such as intelligent algorithms, automated robots, automated distribution, equipment maintenance, labor costs and so on. In addition, all intelligent devices need to be constantly optimized and updated. Since 2025, Amazon has invested $25 billion in artificial intelligence.

In terms of data challenges, the first is data inconsistency. Amazon’s supply chain spans multiple global regions, where different Enterprise Resource Planning (ERP) systems are in use. Discrepancies in data formats and structures create challenges in integrating and standardizing information, leading to inefficiencies in AI-driven predictions. Second, there are hidden dangers of data privacy. When Amazon's AI system collects market data and customer information, it may be attacked by hackers and steal information, resulting in the disclosure of customers' privacy and company secrets. This will threaten the security of customers' information and affect the competitiveness of enterprises.

4.2. Future development prospects

Amazon’s supply chain is increasingly reliant on AI-powered demand forecasting, robotic automation, warehouse management, and intelligent logistics. As AI technology advances, several key innovations are expected to further enhance efficiency, sustainability, and security.

In terms of green sustainable development, Amazon can be leveraged to calculate the shortest and most efficient delivery routes, reducing carbon emissions and improving environmental sustainability. AI-driven precision packaging can calculate the ideal package size, significantly reducing the use of plastic and non-recyclable materials

In terms of AI prediction, Amazon can optimize multivariate predictive models, such as extreme weather, emergencies, and real-time market data updates. Next, it can enhance intelligent algorithms and strengthen machine learning. These improvements can boost corporate competitiveness.

In supply chain integration and supervision, AI will play a central role in automating and integrating supply chain transactions, reducing reliance on intermediaries and streamlining operations. Second, end-to-end encryption protocols will be enforced to protect both internal enterprise data and customer information from cyber threats Third, AI-powered automated threat detection systems will enhance Amazon’s ability to identify, prevent, and neutralize hacking attempts and malware attacks.

5. Conclusion

This article takes the Amazon supply chain as an example to analyze the application of artificial intelligence in Amazon's supply chain and its contribution to Amazon enterprises. Through algorithmic learning, AI can predict customer consumption habits, market conditions, weather, and product availability, ensuring that companies have sufficient stock while reducing the pressure of inventory buildup. In terms of automated warehousing, advanced robotic technology is used to calculate the shortest path, measure cargo dimensions, and perform automatic scanning, all of which enhance supply chain efficiency and reduce operating costs. For intelligent delivery, automated and drone deliveries significantly improve operational efficiency, reduce carbon emissions, and also cut delivery costs. However, the Amazon supply chain faces challenges such as high costs, system stability issues, prediction errors, and information security. In the future, Amazon can optimize several of these challenges to enhance its competitiveness.

While this study provides valuable insights, it has certain limitations. The analysis is based on a relatively small datasets, which may impact the reliability and generalization of the conclusions. Future research should incorporate a larger sample size, covering multiple industries and geographical regions, to ensure greater accuracy and broader applicability of the findings.

Looking ahead, future supply chain research may integrate Multi-Agent Systems (MAS), where AI-driven agents collaborate dynamically across different supply chain nodes. This approach would enable efficient resource allocation and coordinated decision-making, further enhancing the adaptability and responsiveness of AI-powered supply chains.

References

[1]. Gartner. (2022). The Role of AI in Supply Chain Digital Transformation. Retrieved March 10, 2025, from https://www. gartner. com

[2]. Amazon Web Services. (2023). 2023 supply chain optimization & AI integration report. Retrieved March 10, 2025, from https://aws. amazon. com/whitepapers/2023-supply-chain-ai-report/

[3]. Financial Times. (2024, January 15). Amazon bets on AI to optimize supply chain efficiency. Financial Times. Retrieved March 10, 2025, from https://www. ft. com

[4]. Murphy, K. P. (2022). Probabilistic Machine Learning: An Introduction. MIT Press.

[5]. Hastie, T. , Tibshirani, R. , & Friedman, J. (2009). The Elements of Statistical Learning: Data Mining, Inference, and Prediction (2nd ed. ). Springer.

[6]. Business Insider. (2023, December 12). Amazon's AI-powered robotics could cut $10 billion in costs by 2030. Business Insider. Retrieved March 10, 2025, from https://www. businessinsider. com

[7]. MIT Technology Review. (2023, September 22). Amazon's AI supply chain strategy: Strengths and challenges. MIT Technology Review. Retrieved March 10, 2025, from https://www. technologyreview. com

[8]. Dehghan, A. , Cevik, M. , & Bodur, M. (2023). Dynamic AGV task allocation in intelligent warehouses. arXiv preprint arXiv:2312. 16026.

[9]. McKinsey & Company. (2023). AI in supply chain: The next big leap. Retrieved March 10, 2025, from https://www. mckinsey. com

[10]. World Economic Forum. (2023). How AI is revolutionizing supply chains. Retrieved March 10, 2025, from https://www. weforum. org

[11]. European Commission. (2023). AI and data regulations in supply chain management. Brussels: European Commission. Retrieved March 10, 2025, from https://ec. europa. eu

[12]. U. S. Federal Trade Commission. (2023). Data privacy and AI in logistics. Washington, D. C. : FTC. Retrieved March 10, 2025, from https://www. ftc. gov

Cite this article

Luo,T. (2025). The Application of Artificial Intelligence in Supply Chain Management: A Case Study of Amazon. Advances in Economics, Management and Political Sciences,195,192-198.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of ICMRED 2025 Symposium: Effective Communication as a Powerful Management Tool

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Gartner. (2022). The Role of AI in Supply Chain Digital Transformation. Retrieved March 10, 2025, from https://www. gartner. com

[2]. Amazon Web Services. (2023). 2023 supply chain optimization & AI integration report. Retrieved March 10, 2025, from https://aws. amazon. com/whitepapers/2023-supply-chain-ai-report/

[3]. Financial Times. (2024, January 15). Amazon bets on AI to optimize supply chain efficiency. Financial Times. Retrieved March 10, 2025, from https://www. ft. com

[4]. Murphy, K. P. (2022). Probabilistic Machine Learning: An Introduction. MIT Press.

[5]. Hastie, T. , Tibshirani, R. , & Friedman, J. (2009). The Elements of Statistical Learning: Data Mining, Inference, and Prediction (2nd ed. ). Springer.

[6]. Business Insider. (2023, December 12). Amazon's AI-powered robotics could cut $10 billion in costs by 2030. Business Insider. Retrieved March 10, 2025, from https://www. businessinsider. com

[7]. MIT Technology Review. (2023, September 22). Amazon's AI supply chain strategy: Strengths and challenges. MIT Technology Review. Retrieved March 10, 2025, from https://www. technologyreview. com

[8]. Dehghan, A. , Cevik, M. , & Bodur, M. (2023). Dynamic AGV task allocation in intelligent warehouses. arXiv preprint arXiv:2312. 16026.

[9]. McKinsey & Company. (2023). AI in supply chain: The next big leap. Retrieved March 10, 2025, from https://www. mckinsey. com

[10]. World Economic Forum. (2023). How AI is revolutionizing supply chains. Retrieved March 10, 2025, from https://www. weforum. org

[11]. European Commission. (2023). AI and data regulations in supply chain management. Brussels: European Commission. Retrieved March 10, 2025, from https://ec. europa. eu

[12]. U. S. Federal Trade Commission. (2023). Data privacy and AI in logistics. Washington, D. C. : FTC. Retrieved March 10, 2025, from https://www. ftc. gov